Fuel cell sealing material and preparation method thereof

A technology for sealing materials and fuel cells, which is applied in the direction of sealing materials, battery pack parts, battery boxes/coatings, etc., can solve the problems of unsatisfactory sealing effect, high cost, complicated operation, etc., and achieve the advantages of external sealing, The effect of improving production efficiency and increasing viscous force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

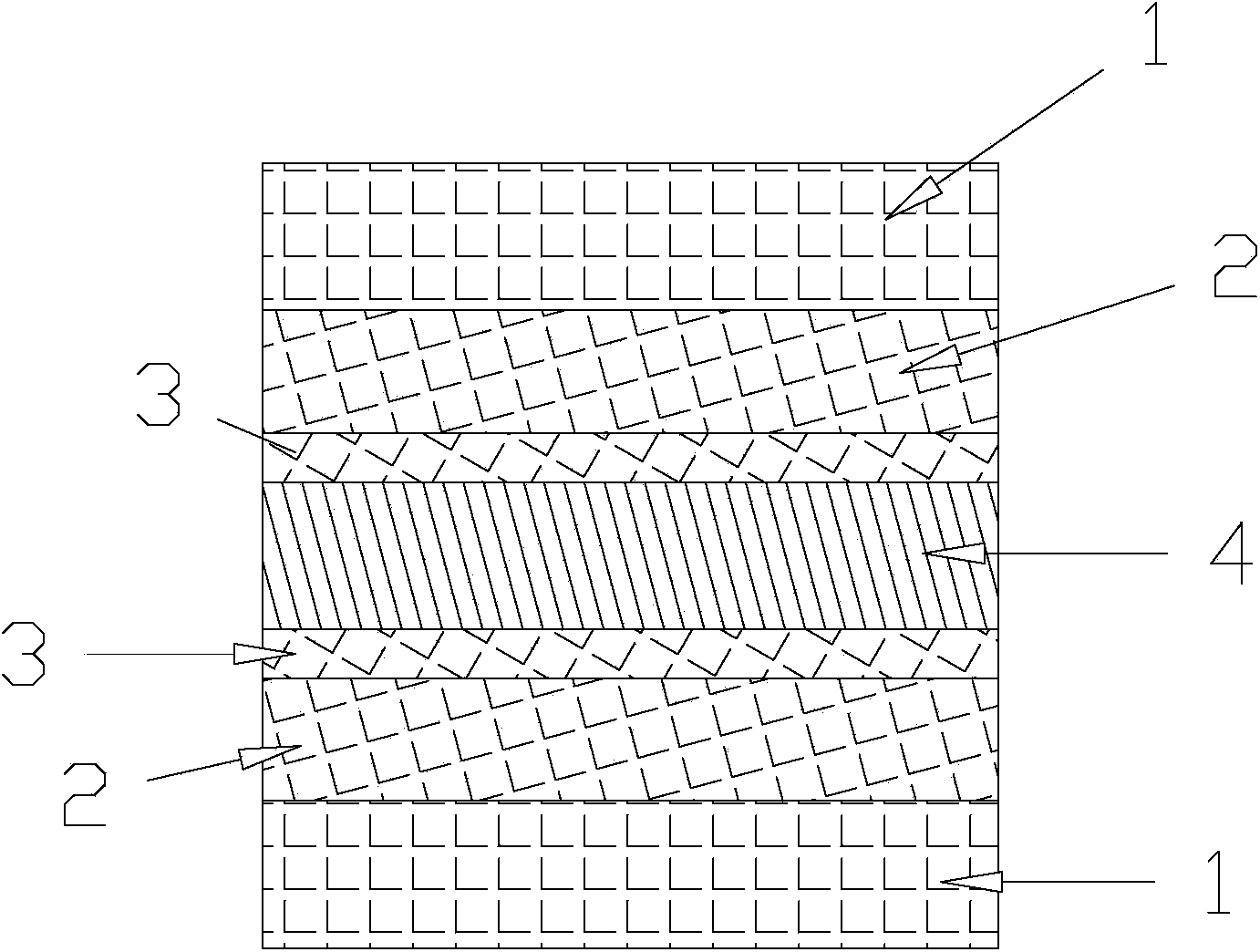

[0024] A fuel cell sealing material such as figure 1 As shown, it includes a release film layer 4 and an adhesive layer 3 , a base film 2 and an elastic sealant layer 1 that are arranged symmetrically on both sides of the release film layer 4 in sequence. It is prepared by the following method:

[0025] (A) At 25°C, one side of the base film 2 is coated with an adhesive layer 3, and the other side is coated with an elastic sealant layer 1, and the three layers of materials form an integral sealing layer structure, which is sticky. The viscosity of the mixture is around 5000cP;

[0026] (B) After the adhesive adhesive layer 3 in the sealing layer structure is cured, control the hardness at about 40 Shore hardness, then compound the two layers of sealing layer structure symmetrically, and pass a layer between the two adhesive adhesive layers 3 The delamination type film layer 4 is isolated to obtain the fuel cell sealing material.

[0027] Wherein, the material of the above-m...

Embodiment 2~8

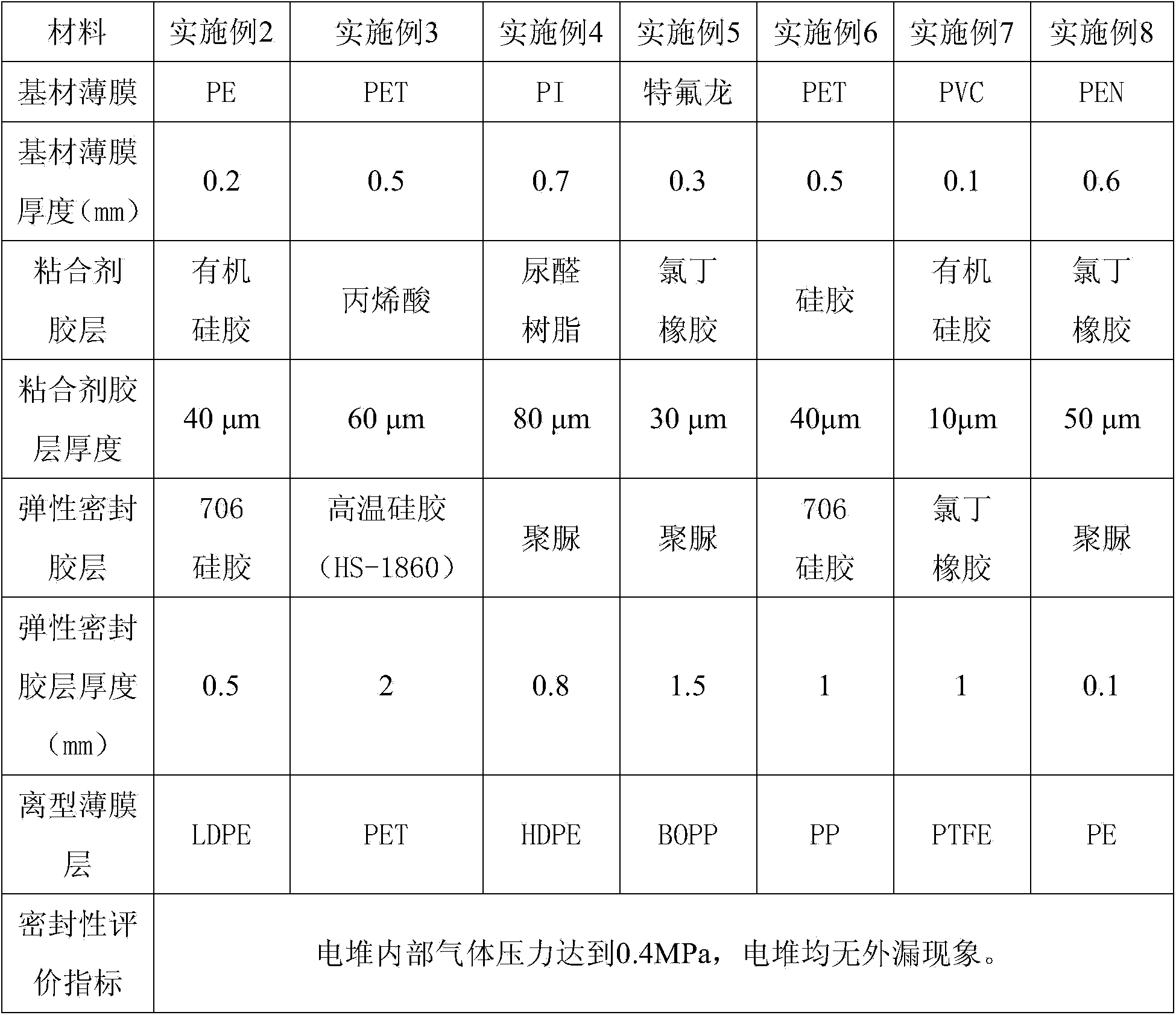

[0035] A fuel cell sealing material, its basic structure and preparation method are the same as in Example 1, and the sealing test method is also the same as in Example 1, the differences are shown in Table 1.

[0036] Table 1

[0037]

[0038] The composition of the materials used in the present invention is not limited to the materials listed in the above table, the thickness of each layer and the selection of materials can be selected by those skilled in the art according to the needs and actual requirements on the mechanical strength of the materials. The gas pressure of the sealing material prepared in the above-mentioned Example 2 reaches 0.4 MPa inside the stack, and the stack has no leakage phenomenon, and the sealing properties of the fuel cell sealing material prepared in Example 3, when the gas pressure is 0.5 MPa, There is no leakage of the stacks. When the gas pressure is 0.6MPa, there is only a little leakage of the stacks. When the gas pressure is 0.7MPa, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com