Scroll compressor and air conditioner

A technology of scroll compressors and compression chambers, applied in machines/engines, rotary piston machinery, mechanical equipment, etc., can solve problems such as increasing compressor compression power, affecting compressor performance, reducing production efficiency, etc., to achieve avoidance performance The effect of reduction, low cost, and low processing technology requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

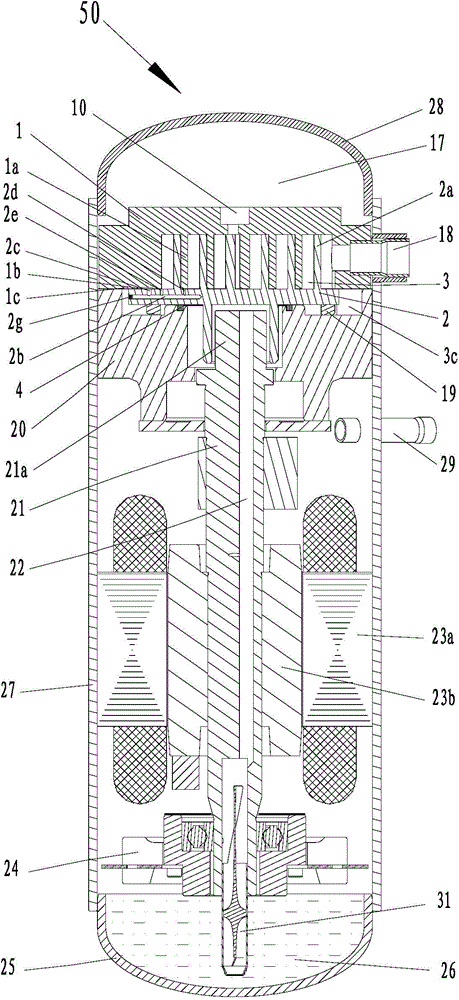

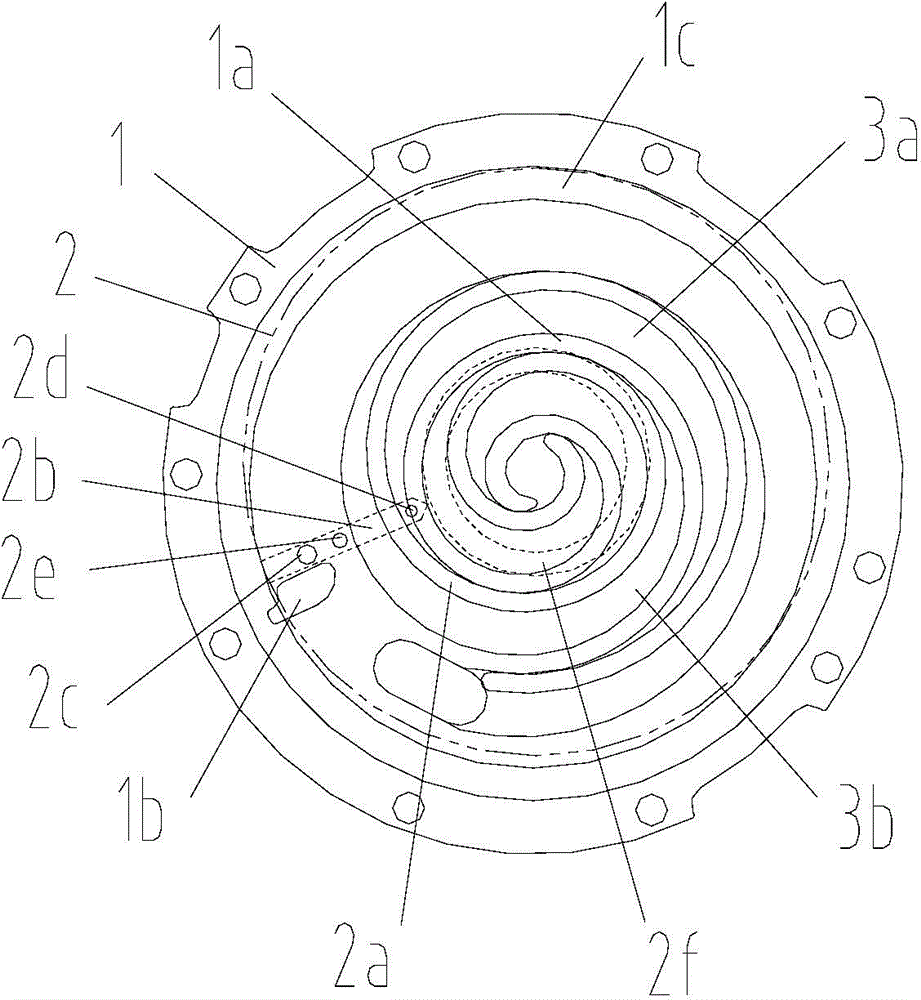

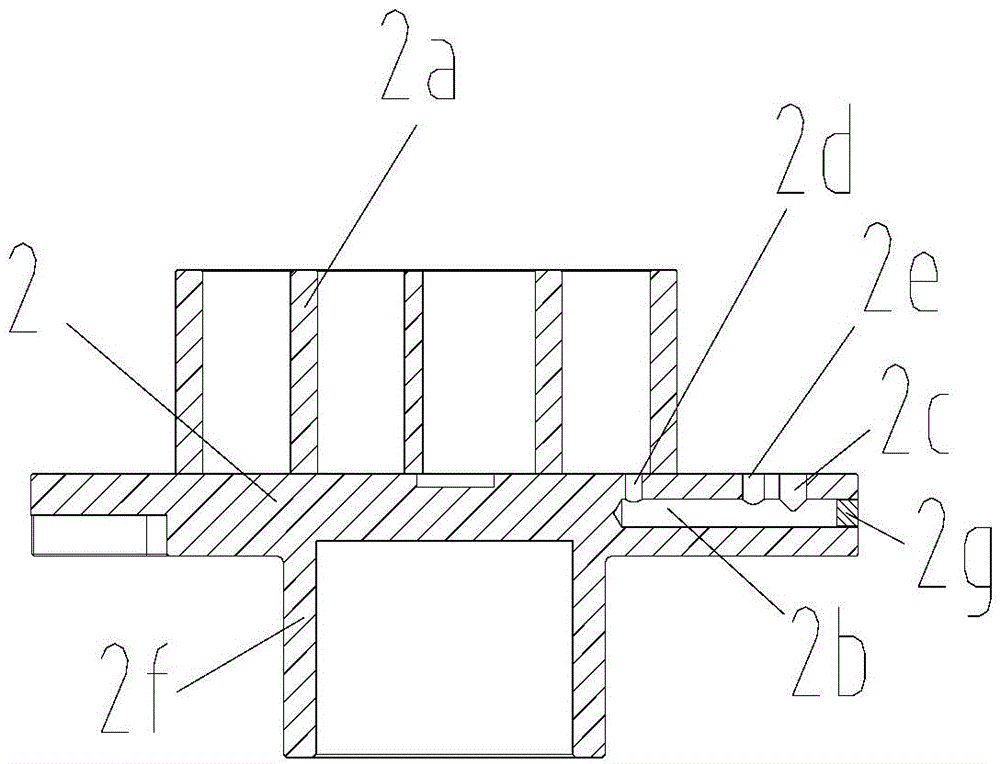

[0042] Such as Figure 1 to Figure 4 As shown, the movable scroll 2 is provided with a third communication hole 2e communicating with the medium-pressure fluid passage 2b in the axial direction. The third communication hole 2e is intermittently connected to the outer line side compression chamber 3b during the operation cycle. The first groove 1b communicates with the second groove 1c. The medium pressure fluid passage 2b of the movable scroll 2, the first communication hole 2c, the second communication hole 2d, the third communication hole 2e, the sealing device 2g and the first groove 1b and the second groove 1c of the fixed scroll 1 constitute The back pressure, oil circuit connection passage. The compression starts when the inner profile of the orbiting scroll and the outer profile of the fixed scroll are closed, and the functions and implementation methods of each component will be described below.

[0043] As the orbiting scroll 2 proceeds, when the compression cavity ...

Embodiment 2

[0045] refer to figure 1 , Figure 5 to Figure 7 Compared with Embodiment 1, the movable scroll 2 reduces the design of the third communication hole 2e, and increases the fourth communication hole 2h (through hole) on the bottom plate of the movable scroll. Compared with the first groove 1d on the fixed scroll 1, the implementation Example 1 does not communicate with the second groove 1c, but increases the angle of communication with the fourth communication hole 2h.

[0046] The movable scroll 2 is also provided with a fourth communication hole 2h communicating with the back pressure chamber 3c in its axial direction, and the first groove 1b is intermittently connected with the first communication hole 2c and the fourth communication hole 2h during the operation cycle. connected. The fourth communication hole also intermittently communicates with the outer line side compression chamber 3b, and the first groove 1b does not communicate with the second groove 1c.

[0047] The...

Embodiment 3

[0050] refer to figure 1 , Figure 8 to Figure 10 Compared with Embodiment 1, the moving scroll 2 has a reduced design of the third communication hole 2e, and increased the high-pressure oil drainage hole 2i, the first oil drainage channel 2j and the oil drainage hole 2k. The shape of the first groove 1b is changed on the fixed scroll 1 to ensure the connection with the communication hole of the moving disk according to the design angle, and the oil communication groove 1f is added.

[0051] The movable scroll 2 is also provided with a high-pressure oil drainage hole 2i, a first oil-guiding passage 2j and an oil-guiding hole 2k, and the high-pressure oil drainage hole 2i is connected to the oil supply system of the compressor and the first oil-guiding passage 2j, respectively. An oil introduction channel 2j communicates with the oil introduction hole 2k, and the oil introduction hole 2k intermittently communicates with the outer line side compression chamber 3b during the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com