High-power array low-concentration gas pulse combustion method and device

A low-concentration gas and pulsating combustion technology, which is applied in the field of gas combustion, can solve the problems of small output power of a single pulsating combustion device, and achieve the effects of saving investment costs, ensuring stable combustion, and saving industrial sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

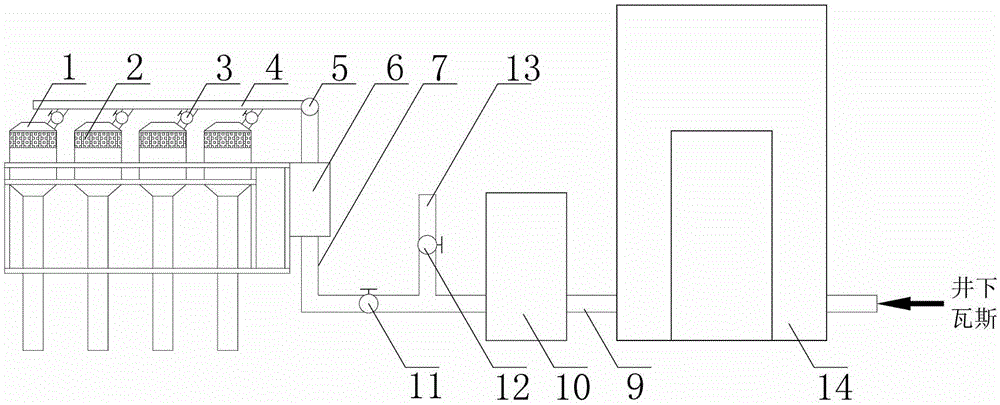

[0046] refer to figure 1 , figure 2 and image 3 In this embodiment, the high-power array type low-concentration gas pulse combustion device is applied to the "fire tube type" energy recovery and utilization method, including the following steps:

[0047] 1. Install the high-power array type low-concentration gas pulsation combustion device 8 on the gas utilization pipeline 9 leading from the coal mine gas drainage pump station 14 .

[0048] 2. Connect the tail of the pulsation combustion unit 1 of the high-power array low-concentration gas pulsation combustion device 8 to one side of the boiler.

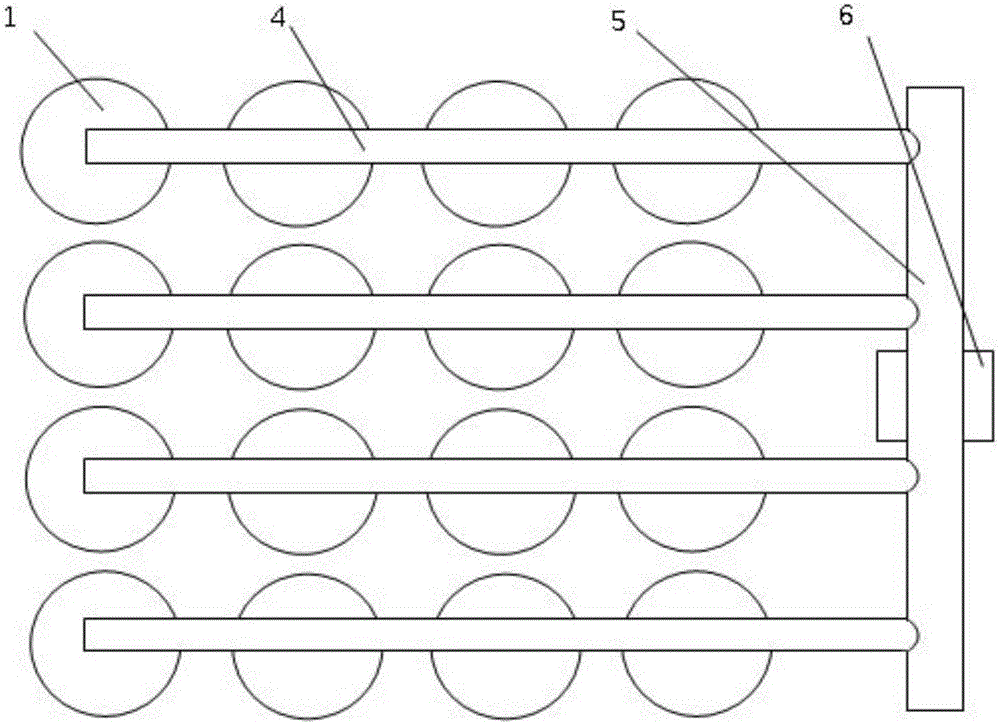

[0049] 3. When working, open the valve 11, the low-concentration gas in the gas utilization pipeline 9 passes through the flame arrester 10, enters the high-power array low-concentration gas pulsating combustion device 8, and passes through the main supply pipe 7 and distribution main pipe 5 in sequence And intake branch pipe 4 enters in the pulse combustion unit 1 to carry out ...

Embodiment 2

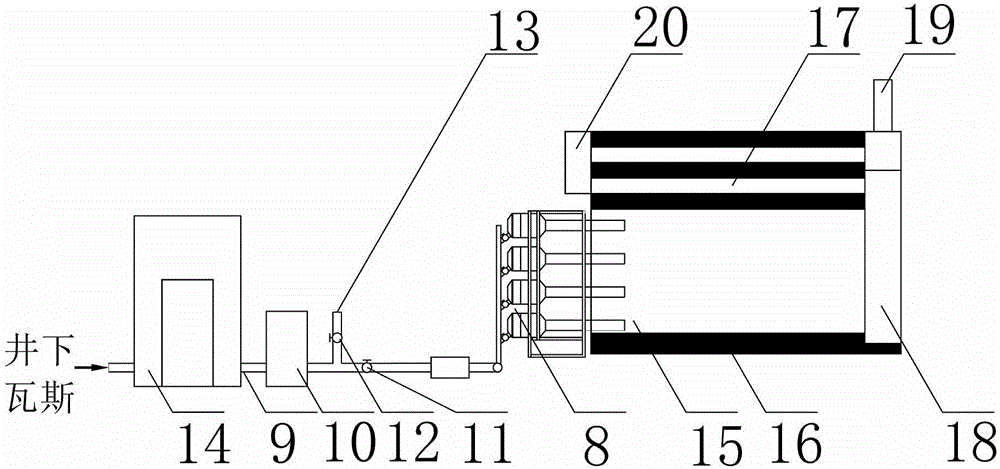

[0052] refer to figure 1 , figure 2 and Figure 4 In this embodiment, the high-power array type low-concentration gas pulse combustion device is applied to the "water pipe type" energy recovery and utilization method, including the following steps:

[0053] 1. Install the high-power array type low-concentration gas pulsation combustion device 8 on the gas utilization pipeline 9 leading from the coal mine gas drainage pump station 14 .

[0054] 2. Connect the tail of the pulsation combustion unit 1 of the high-power array low-concentration gas pulsation combustion device 8 to the bottom of the boiler.

[0055] 3. When working, open the valve 11, the low-concentration gas in the gas utilization pipeline 9 passes through the flame arrester 10, enters the high-power array low-concentration gas pulsating combustion device 8, and passes through the main supply pipe 7 and distribution main pipe 5 in sequence And intake branch pipe 4 enters in the pulse combustion unit 1 to carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com