System for increasing pulverizing and drying output force during doped lignitous coal burning of burning bituminous coal boiler

A combustion process and boiler technology, applied in the direction of dry gas arrangement, drying, dryer, etc., can solve problems such as poor operating economy and hidden safety hazards, and achieve the effects of improving combustion efficiency, increasing safety, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

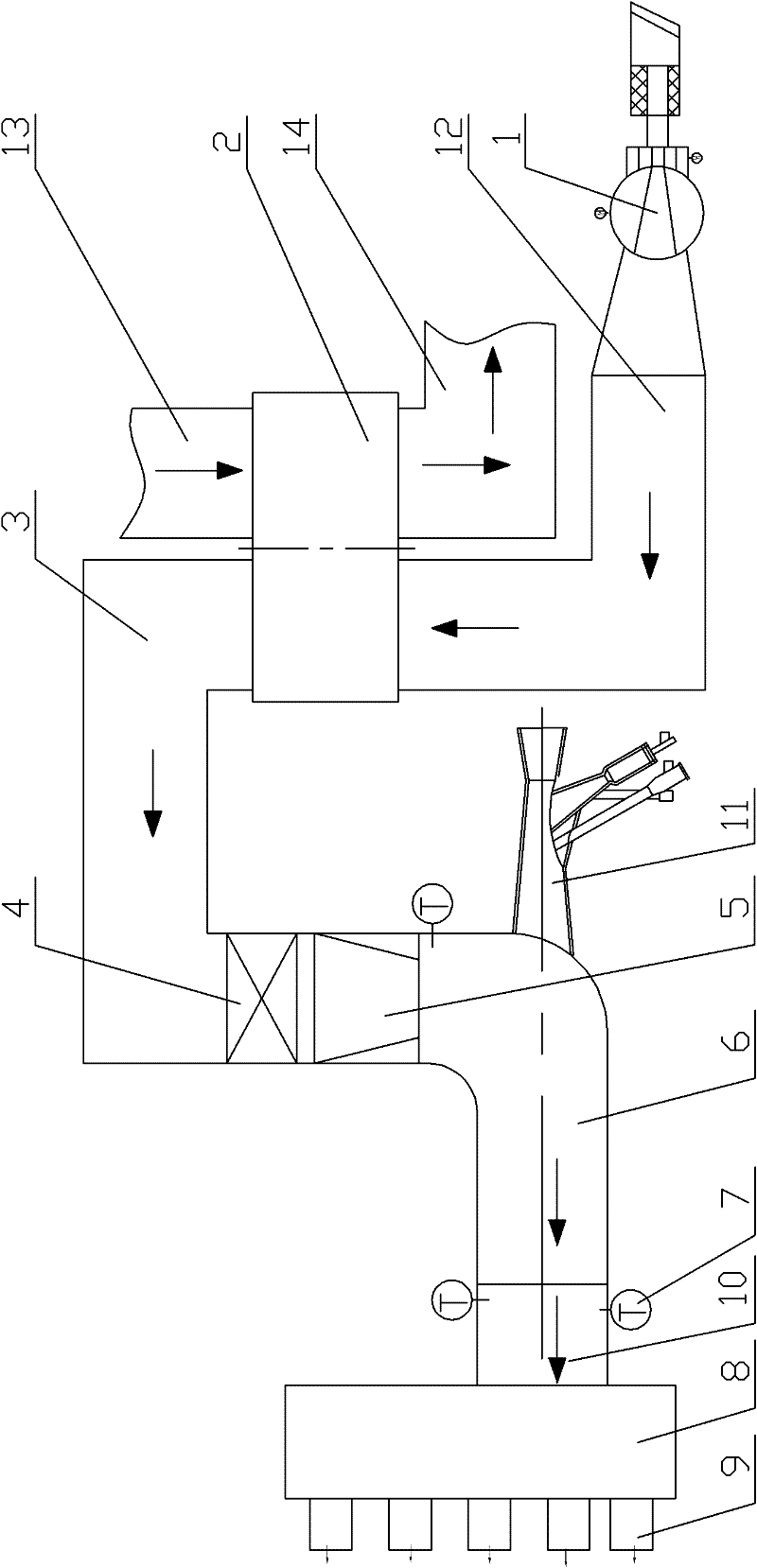

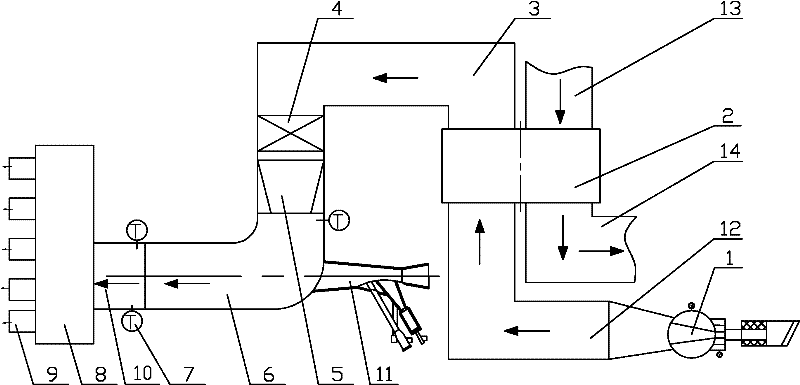

specific Embodiment approach 1

[0007] Specific implementation mode 1: Combination figure 1 Explain that the system of this embodiment includes a primary fan 1, a rotary air preheater 2, a first section of a hot primary air duct 3, a hot primary air duct exit cut-off door 4, a heaven and earth connection piece 5, and a hot primary air duct The second section 6, the hot primary air main pipe 8, the third section 10 of the hot primary air pipe, the cold primary air pipe 12, and the multiple hot primary air distribution pipes 9; the system also includes a micro-oil ignition small oil gun 11 and at least two A thermocouple 7; the second section 6 of the hot primary air duct is a 90° elbow, the outlet end of the primary fan 1 is connected to the inlet end of the cold primary air duct 12, and the outlet end of the cold primary air duct 12 is preheated with the rotary air The primary air inlet end of the air preheater 2 is in sealed communication, the primary air outlet end of the rotary air preheater 2 is in sealed...

specific Embodiment approach 2

[0008] Specific implementation manner two: combination figure 1 It is explained that the material of the second section 6 of the hot primary air duct described in this embodiment is heat-resistant steel.

[0009] The heat-resistant steel in this embodiment is 304 heat-resistant steel.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 It is explained that the third section 10 of the hot primary air duct of this embodiment is provided with two thermocouples 7 for measuring the temperature of the hot primary air, which has the advantage of accurate temperature measurement. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com