Duct burner for diesel engine

A burner and diesel engine technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of high difficulty in precise adjustment of the power of the post-combustion burner and low heating power, so as to improve the ignition conditions of fuel and strengthen the atomization effect , good burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with specific embodiments.

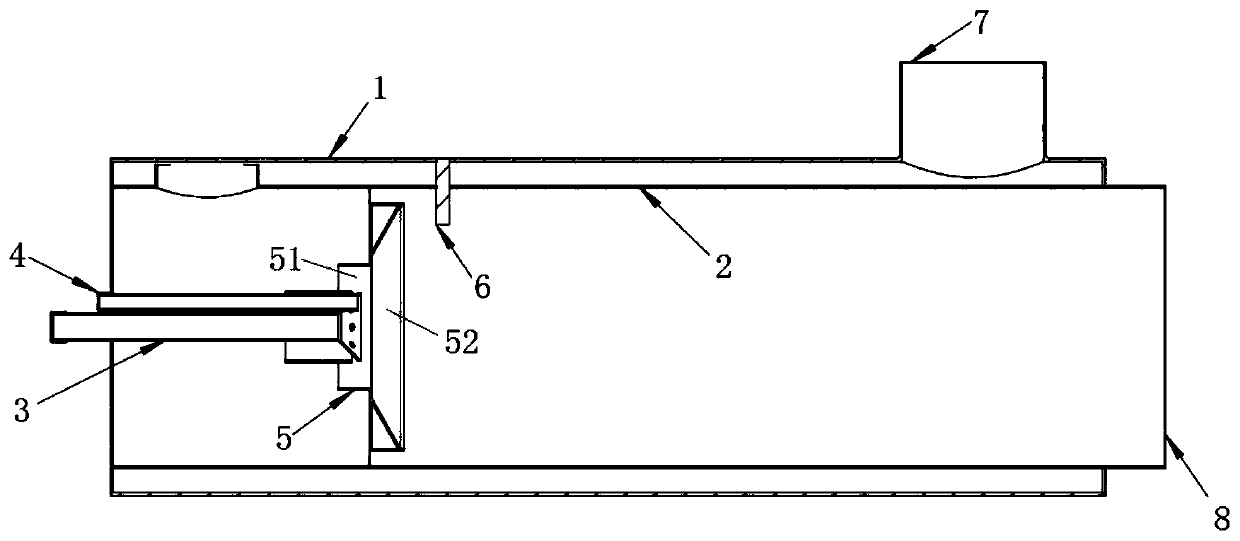

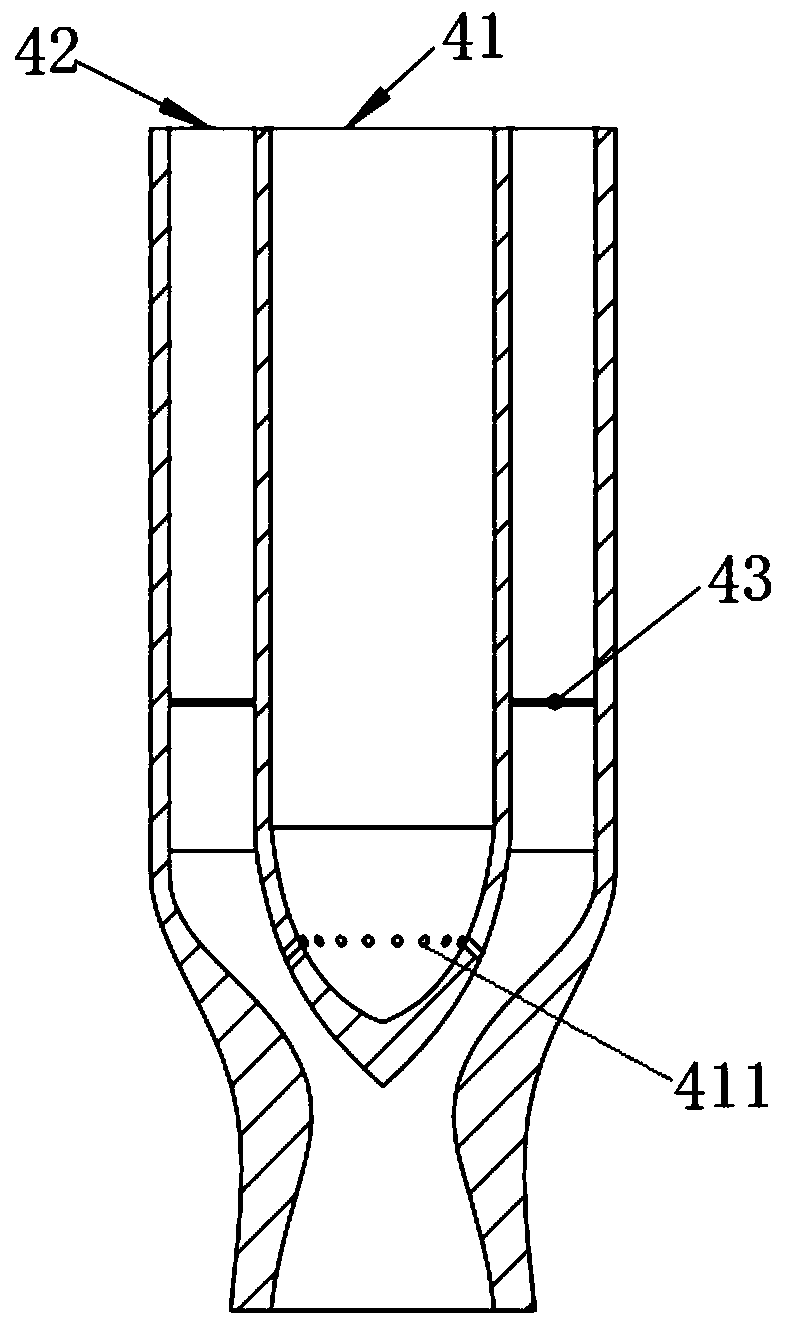

[0023] figure 1 This embodiment provides a structural schematic diagram of a post-combustion burner for a diesel engine. The post-combustion burner for a diesel engine includes a burner outer cylinder wall 1, a burner inner cylinder wall 2, an oil gun 3, and an ignition gun 4 , Stabilizer 5, Fire detection device 6, etc.

[0024] Among them, the burner inner cylinder wall 2 is a cylinder with one end sealed and the other open. A hole is opened on the cover plate at one end of the seal, so that the ignition gun 3 and the oil gun 4 can pass through. A hole is opened on the side wall on the side close to the oil gun 4 as an inlet 71 for the inner layer of flue gas. The open end of the burner inner cylinder wall 2 serves as a flue gas outlet 8.

[0025] The burner outer cylinder wall 1 is sleeved outside the combustor inner cylinder wall 2, and the two end seals of the burner outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com