Oxygen-enriched combustion boiler system with dehydration adjusting performance

A technology of oxygen-enriched combustion and adjustment capability, which is applied in combustion methods, combustion equipment, and direct carbon dioxide emission reduction to achieve the effects of eliminating influence, improving ignition conditions and accelerating the combustion process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

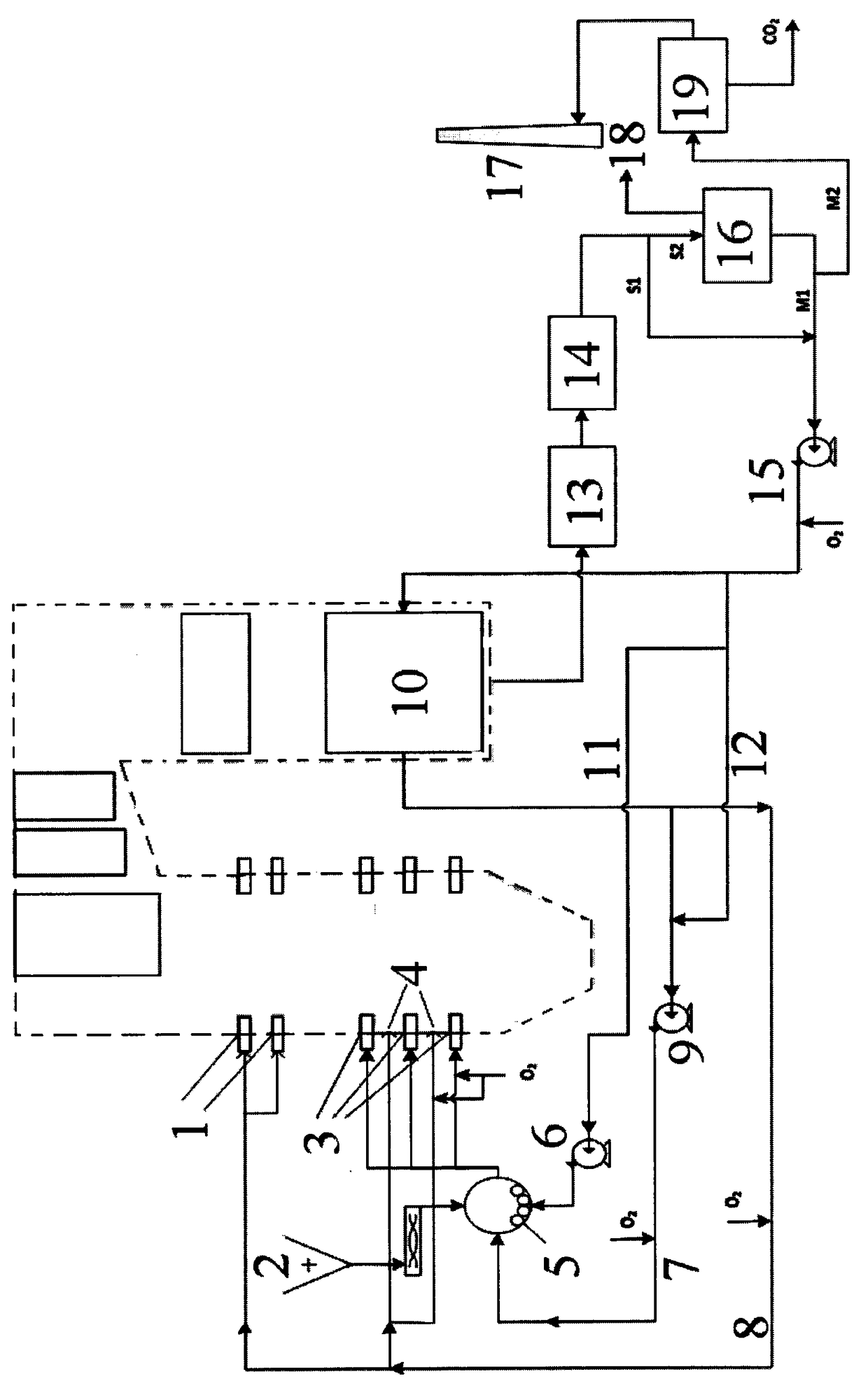

[0019] The present invention is an oxygen-enriched combustion boiler system with dehydration adjustment capability, such as figure 1 As shown, it includes boiler body, burner nozzle, pulverizing equipment 5, flue gas recirculation fan 15, primary fan 9, sealing fan 6, dust removal device 13, desulfurization device 14, dehydration device 16, primary recirculation flue 7 , secondary recirculation flue 8, sealed air duct 11, temperature regulating air duct 12, dehydration regulating flue S1, dehydration inlet flue S2, dehydration recirculation flue M1, dehydration exhaust flue M2, CO 2 The processing device 19 and other connecting pipes in the boiler system; the boiler body is provided with a gas preheater 10 and a burner; the gas preheater 10 can be a one-stage gas preheater or a multi-stage gas preheater. In this embodiment, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com