Little oil burner of double-sided ignition combination blunt body

A technology of micro-oil ignition and double-sided ignition, which is applied to burners, burners for burning powder fuel, combustion methods, etc. process, effect of prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

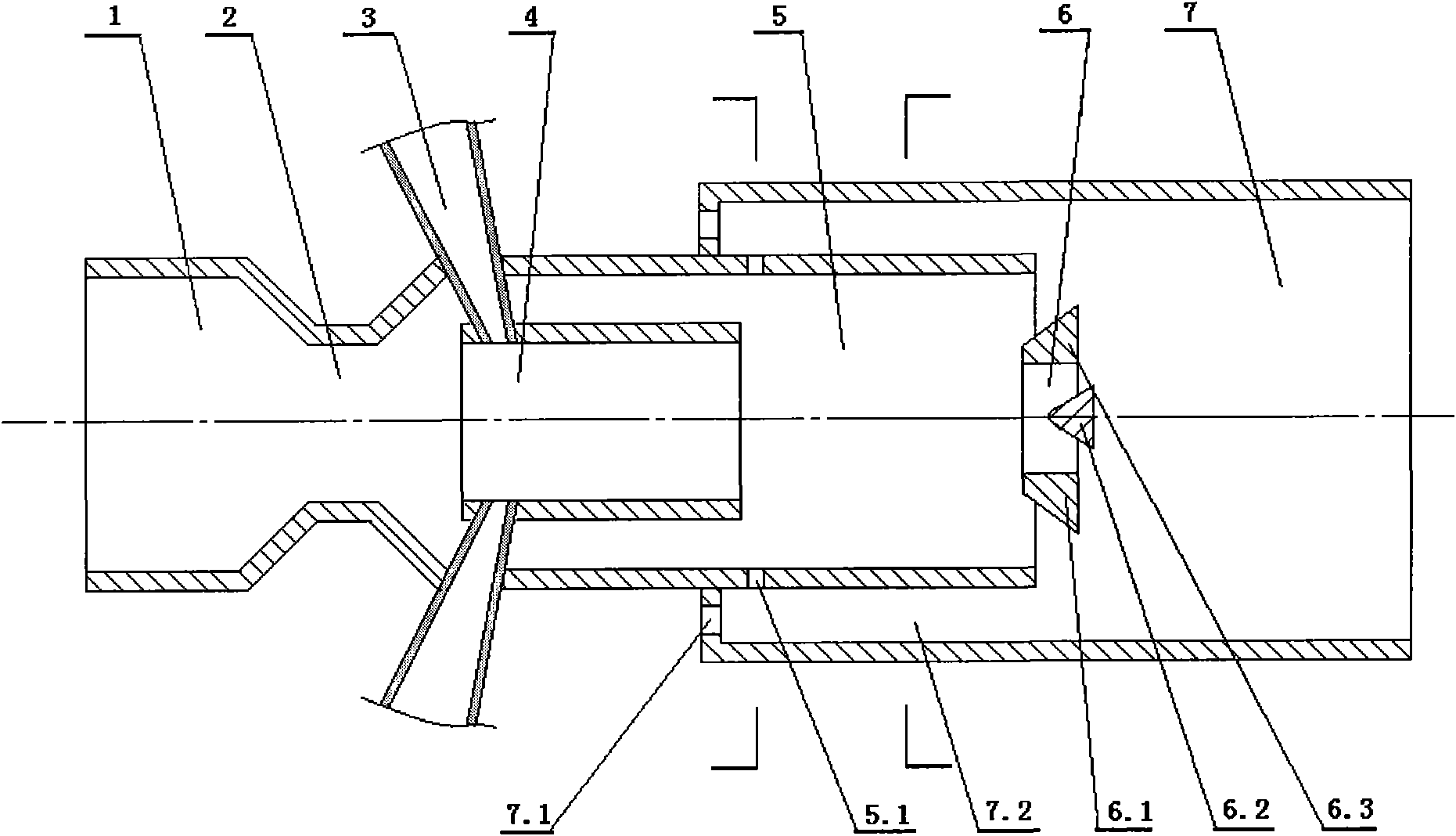

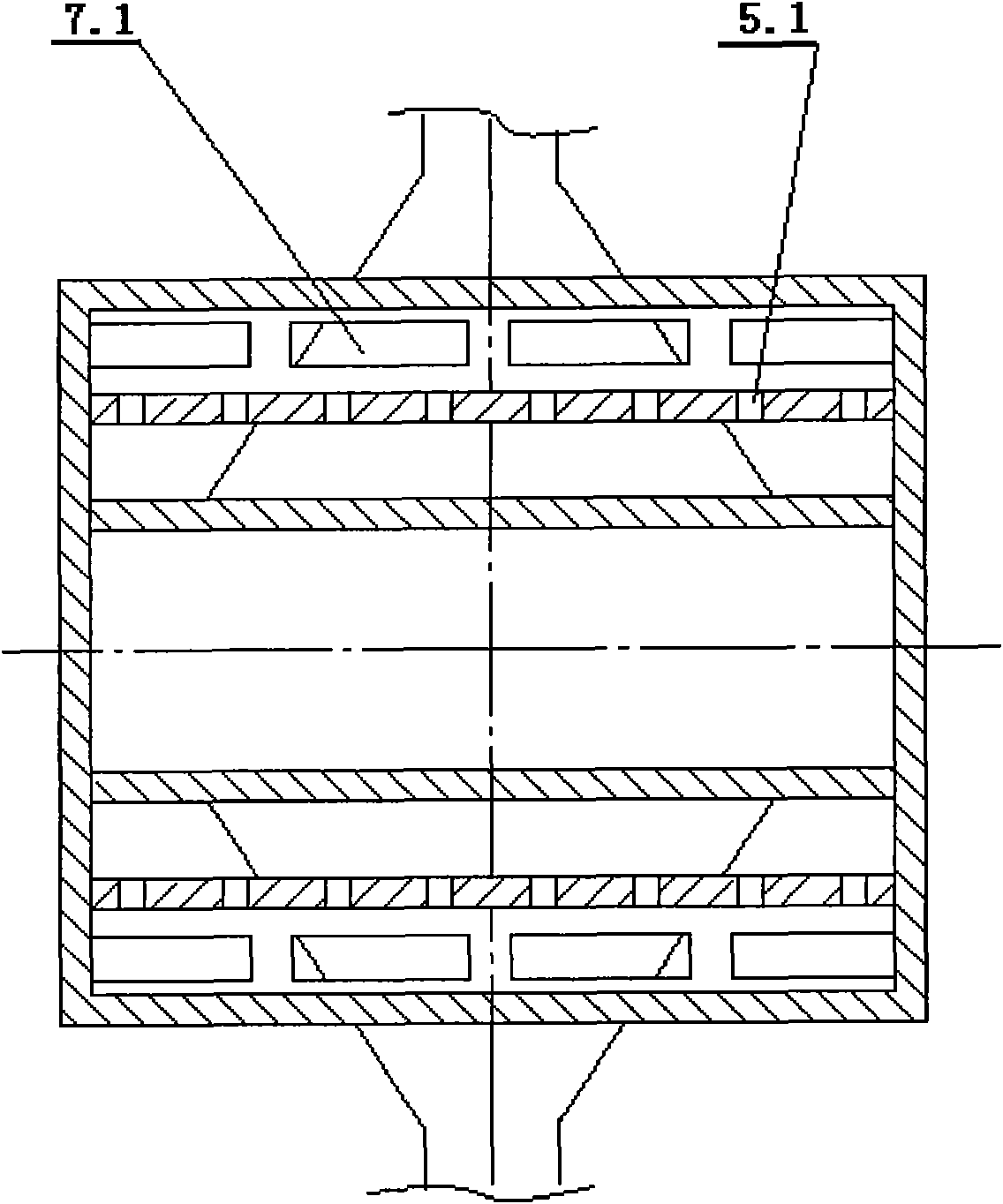

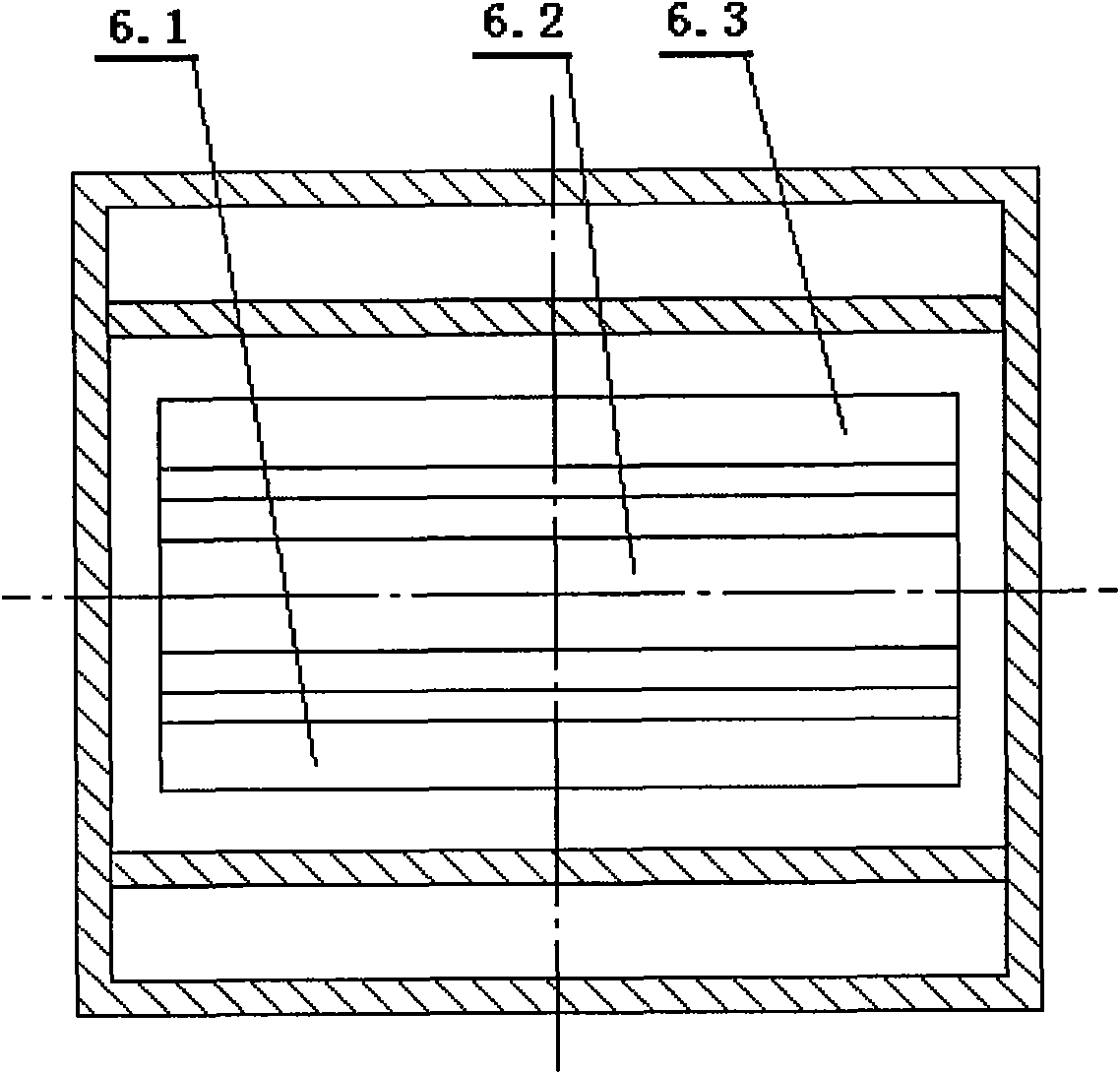

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a rectangular cross-section primary air channel 1, a pulverized coal concentrator 2, a primary pulverized coal combustion chamber 4, a secondary pulverized coal combustion chamber 6 and a tertiary pulverized coal combustion chamber, which are successively connected and whose central axes coincide. 7. The pulverized coal concentrator 2, which is composed of a variable-diameter pipe at the throat formed by the primary air duct 1, communicates with the secondary pulverized coal combustion chamber 5, and the primary pulverized coal combustion chamber 4 is installed in the secondary pulverized coal combustion chamber In 5, secondary pulverized coal combustion chamber 5 stretches in tertiary pulverized coal combustion chamber 7. The third-stage pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com