Pulverized coal distributor allowing double angles to be adjusted

A distributor and pulverized coal technology, which is applied in the direction of block/powder supply/distribution, supply configuration, combustion method, etc., can solve the problems of deflection of flame in the furnace, deviation of steam temperature, high air flow velocity, etc., and improve safety Sex and economy, good ignition condition and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

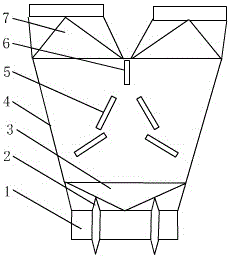

[0015] As shown in the figure, there is a pulverized coal inlet 1 in the lower part of the middle casing 4, and two spindle-shaped baffles 2 are installed in the pulverized coal inlet, a diffusion pipe section 3 is arranged in the lower part of the middle casing, and two symmetrical The pulverized coal outlet 7 is provided with an intermediate partition 6 between the two pipes of the pulverized coal outlet, and a louver 5 is installed in the middle casing cavity.

[0016] The inner wall of the pulverized coal inlet, the diffusion pipe section, the middle casing, and the pulverized coal outlet are lined with wear-resistant ceramics, and the louvers and intermediate partitions are integrally fired from wear-resistant ceramics;

[0017] The number of louvers on one side is 1-3, and they are symmetrically arranged on the left and right inside the middle casing, and the inclination angle can be adjusted.

[0018] The middle partition is arranged vertically at the pulverized coal ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com