Air-assisted jet flow flame ignition device and ignition method thereof

A flame ignition and air-assisted technology, applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of slow flame propagation speed and unstable combustion in the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

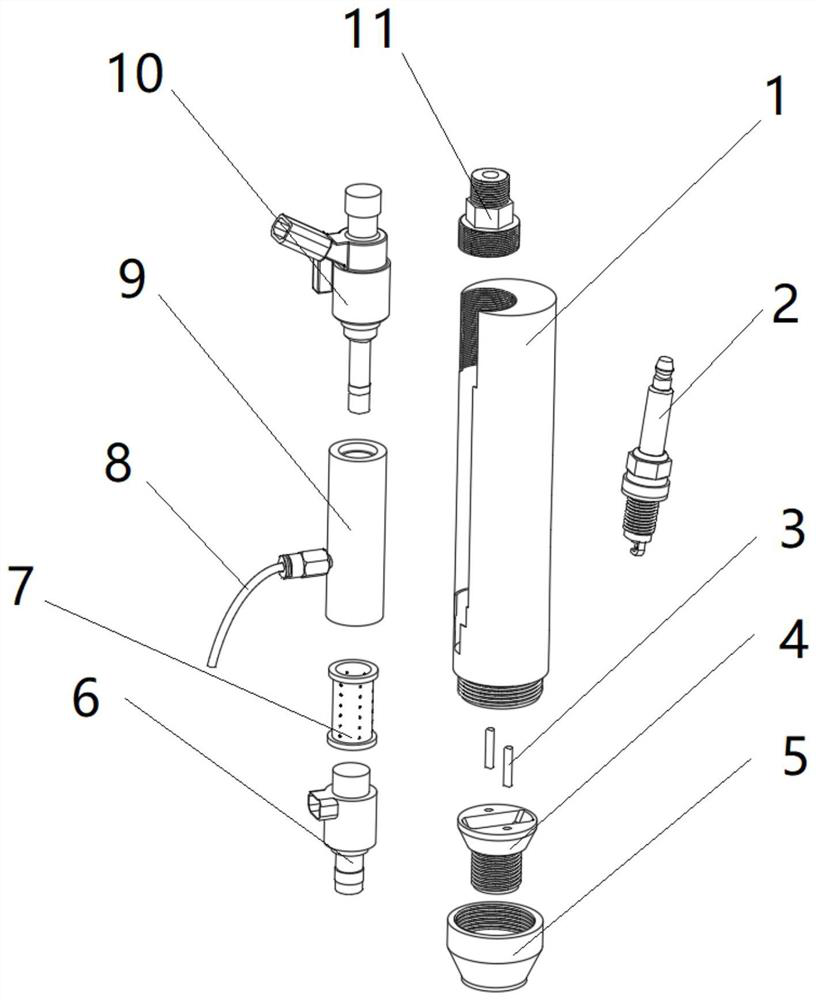

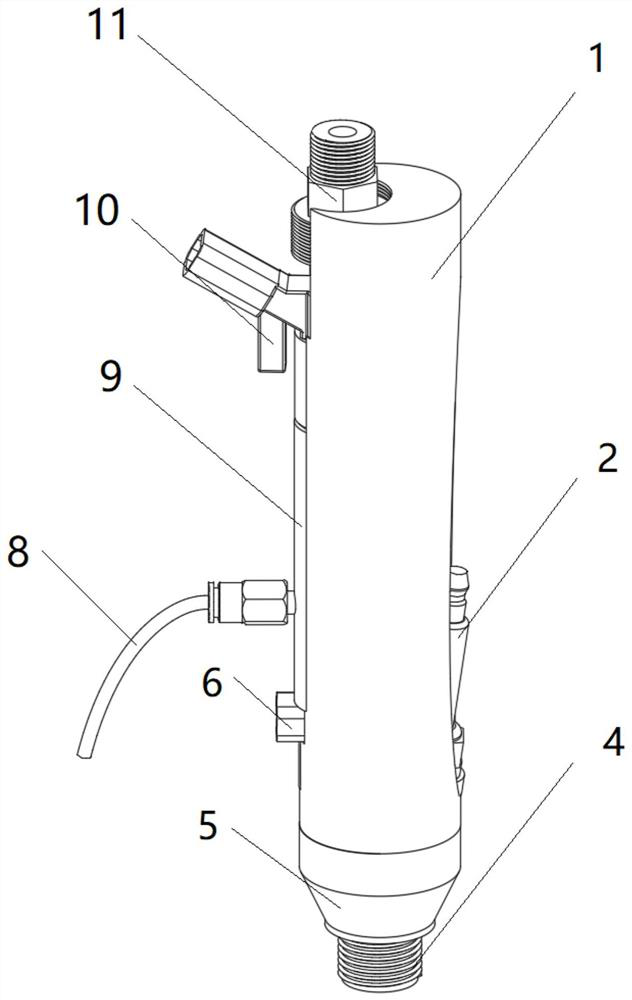

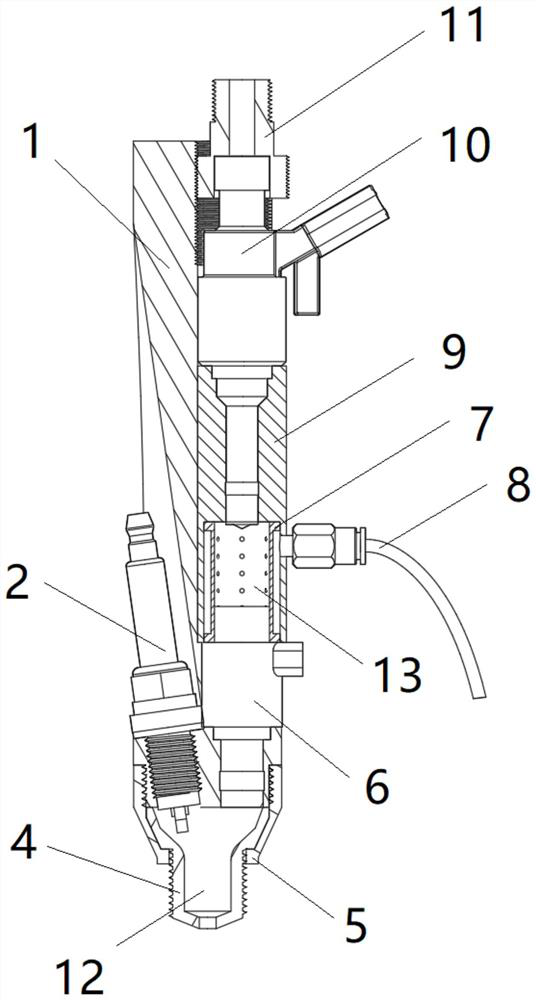

[0024] figure 1 It is an exploded view of the parts of the device of the present invention, which contains 10 parts in total, and is divided into three parts according to the functions: the housing, the fuel-air premixing unit and the pre-combustion chamber. Wherein the function of the housing 1 is to provide installation positions for other parts. The function of the fuel-air premixing unit is to provide pre-mixed air for the pre-combustion chamber. Including fuel injector 10, air injection valve 6, premixing sleeve inner core 7, premixing sleeve 9 and injector fastening bolt 11. The function of the pre-chamber is to provide the flame jet to the main combustion chamber. Contains spark plug 2, pre-chamber nozzle 4, positioning pin 3 and nozzle pressing piece 5.

[0025] During the installation process, the injection valve 6, the inner core 7 of the premixing sleeve, the premixing sleeve 9 and the fuel injector 10 are placed in sequence, and these four parts are pressed toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com