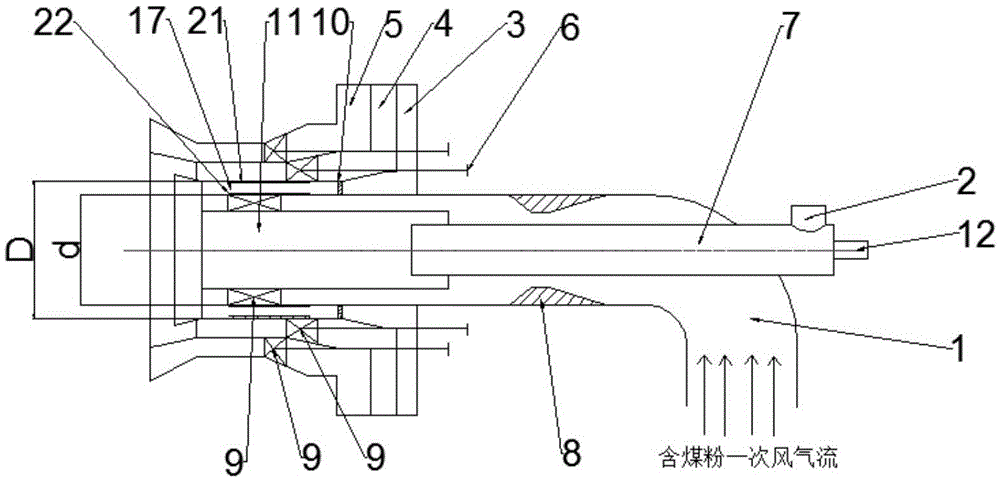

Two-stage-adjustable steam plasma swirl burner

A technology of swirl burner and plasma, which is applied in the direction of burner, burner, combustion type, etc. for burning powder fuel, can solve the problem of excessive NOx generation, achieve strong industrial practicability, rational use of resources, and solve the problem of combustion Difficult to stabilize effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

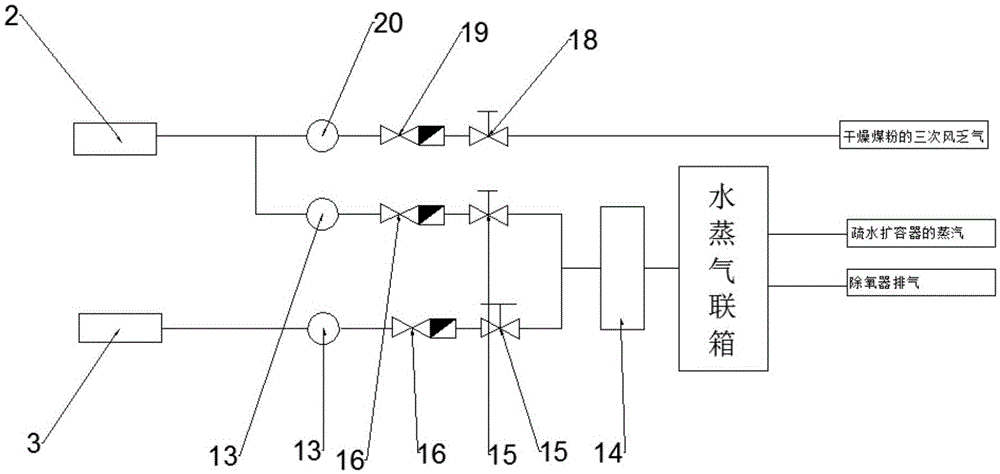

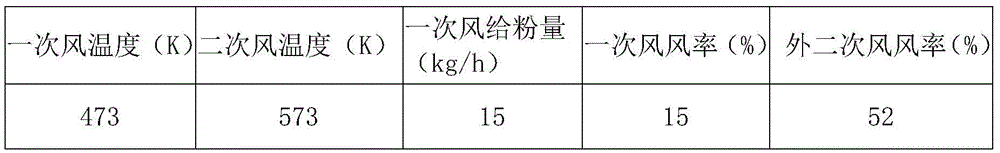

Embodiment 1

[0032] Keep the powder feed rate of the powder feeder at 15kg / h, and the total air volume at 134.8kg / h, of which the primary air volume accounts for 15% of the total air volume, and the external secondary air volume accounts for 52% of the total air volume. For the plasma generator, the jet gas temperature and air volume of the plasma generator meet the experimental requirements by controlling the power and air intake of the plasma generator. The adjustable range of the first-stage plasma air volume is 0-30% of the primary air volume, that is, 0-4.5% of the total air volume. By adjusting the water vapor control valve, the water vapor content in the first-stage plasma air can be changed from 0 to 100%, the temperature is controlled at about 4500K; the adjustable range of the second-stage plasma air volume is 0-10% of the primary air, and the temperature is controlled at about 1500K; the rest of the air volume is controlled as the internal secondary air, the horizontal furnace T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com