Dual-injection turbulent jet ignition pre-chamber device for spark ignition engine

A technology of turbulent jet flow and pre-combustion chamber, which is applied to fuel injection devices, combustion engines, internal combustion piston engines, etc., and can solve problems such as the inability to stably form jet flames, misfires, and deterioration of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

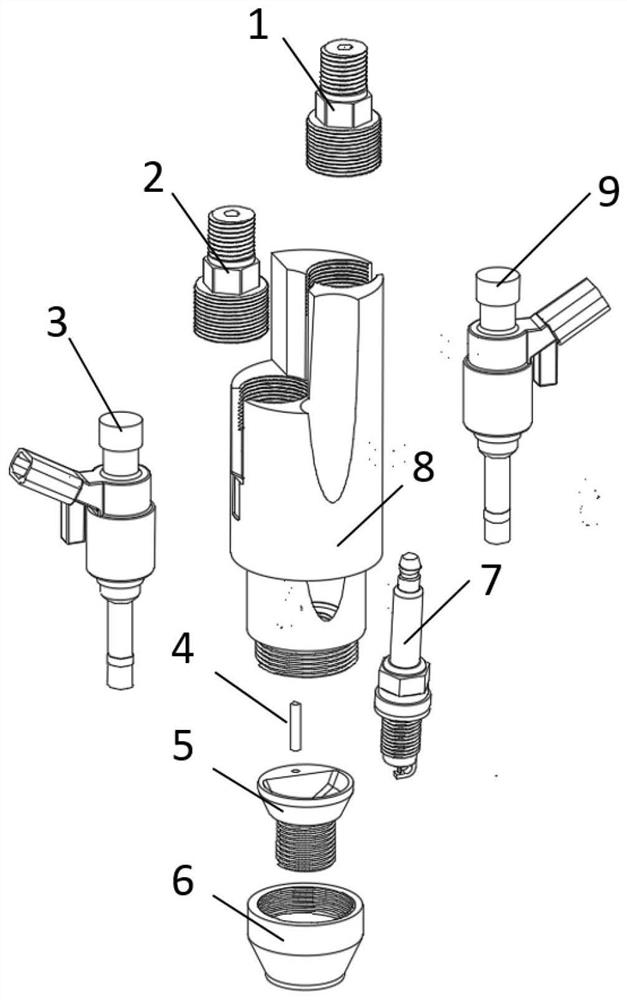

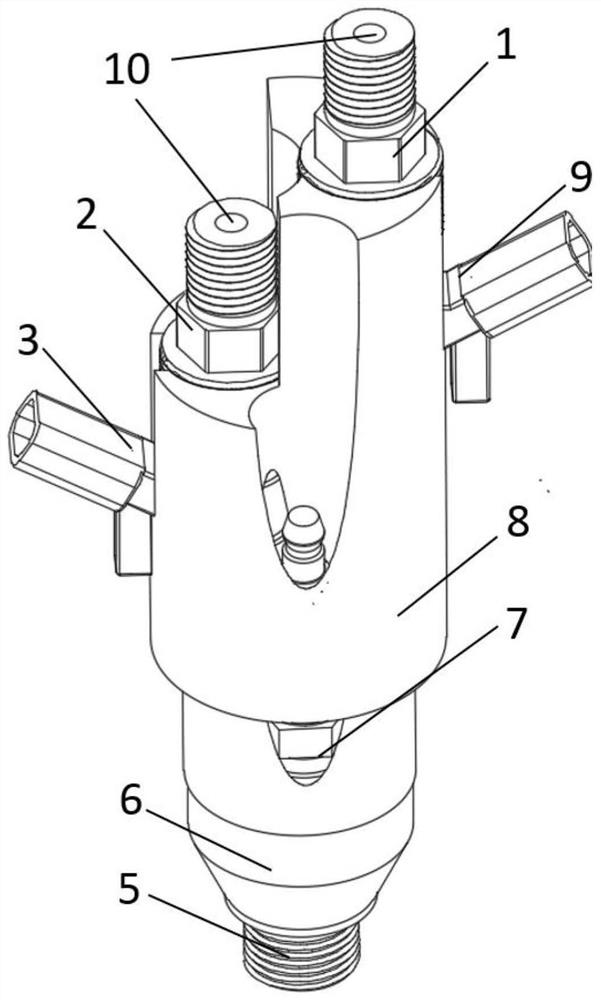

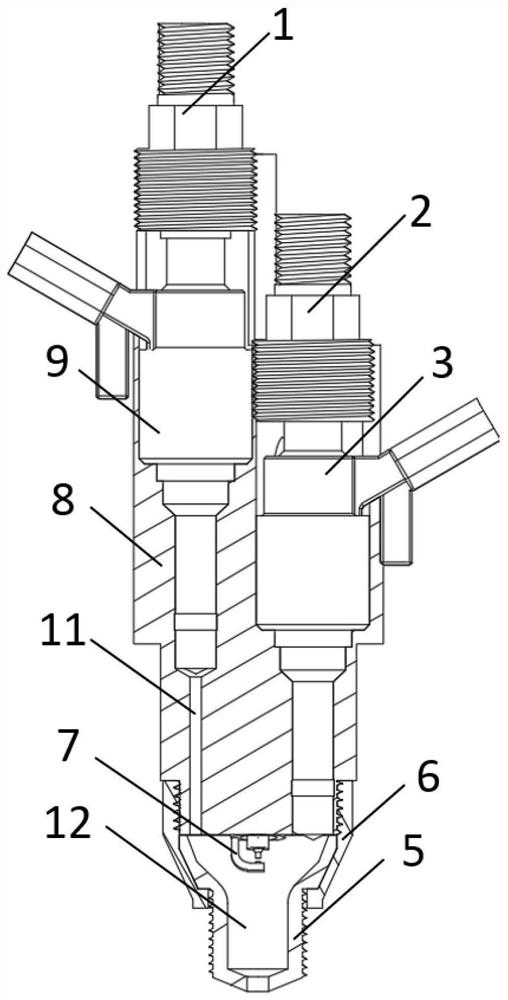

[0022] The present invention proposes a multi-mode turbulent jet ignition pre-combustion chamber device for an ignition type engine, which mainly consists of compression bolts 1, 2, fuel injector 3, gas injector 9, compression bolt through hole 10, air channel 11. The pre-chamber upper cavity 8, the pre-chamber inner cavity 12, the pre-chamber nozzle 5, the pre-chamber nozzle pressing part 6, the spark plug 7, the positioning pin 4 and other parts. All structures and working principles of the pre-chamber device will be described in detail below with reference to the accompanying drawings.

[0023] attached figure 1 Exploded view of the parts of the multi-mode turbulent jet ignition pre-chamber device proposed by the present invention. Both ends of the compression bolt are threaded and have a through hole, and the thread at one end is connected to the upper chamber 8 of the pre-chamber, and is used to fix and seal the fuel injector 3 and the gas injector 9 on the upper chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com