Air duct ignition burner

An ignition burner and burner technology are applied in the field of ignition devices of boilers, which can solve the problems affecting the normal use of the ignition burner, the burning loss of the ignition burner, the burning loss of the ignition air duct, etc., so as to achieve the burning loss of the ignition air duct and the combustion The effect of less self-burning loss, stable combustion and less self-burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

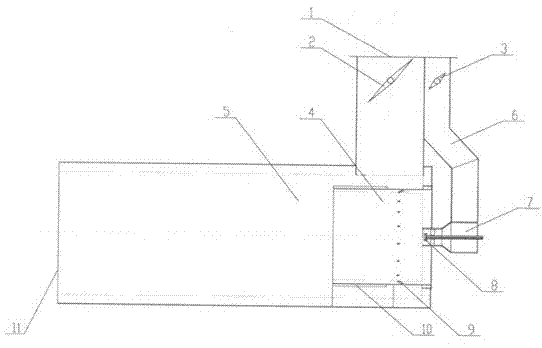

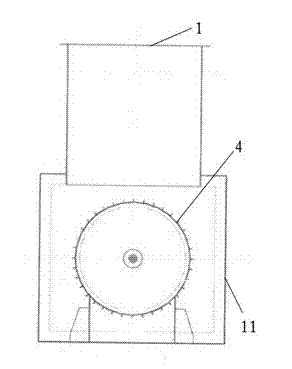

[0031] Example 1 as figure 1 and figure 2 As shown, the air duct ignition burner of the present invention includes an inlet air duct 1 and an outlet air duct 11, the inlet air duct 1 and the outlet air duct 11 are connected to each other, and are all connected to the hot primary air duct, and the outlet air duct The inner pre-combustion chamber 4 is arranged in the road 11, and an oil (gas) burner 7 is arranged in the said inner pre-combustion chamber 4. Of course, a plurality of them can be set according to actual needs. The oil (gas) burner 7 is provided with There are 8 burners. A burner air duct 6 is connected to the oil (gas) burner 7 , a burner baffle 3 is arranged in the burner air duct 6 , and a main air duct baffle 2 is arranged in the inlet air duct 1 . One end of the inner pre-combustion chamber 4 close to the oil (gas) burner 7 is circumferentially arranged with a plurality of wall-adhering air nozzles 9, and the wall-adhering air nozzles 9 communicate with the ...

Embodiment 2

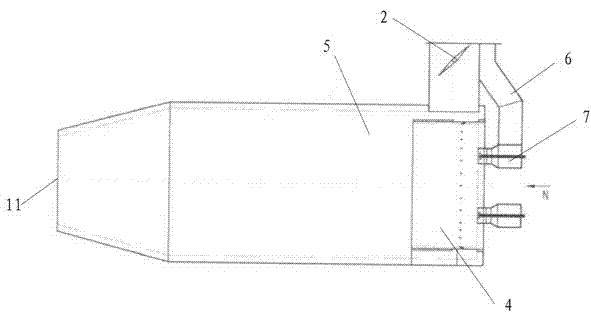

[0032] Example 2 as image 3 , Figure 4 and Figure 5 As shown, its structure is similar to that of Embodiment 1, the difference is that there are two oil (gas) burners 7, and of course there can be more than one according to actual needs. This embodiment is an ignition start-up system for a 300MW circulating fluidized bed, wherein the boiler is equipped with two air duct ignition burners, each air duct ignition burner is equipped with two oil burners, and the output of a single oil gun is 1900Kg / h.

[0033] The air duct ignition burner of the present invention has a simple structure and is easy to operate, and it has stable combustion during operation; the burning loss of the ignition air duct and the burner itself is small, and it can also be used as a non-combustion device for a preheating boiler; the structure is stable Reliable, not easy to be damaged by spontaneous combustion, long service life, and conducive to popularization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com