Method for Improving Effective Thermal Efficiency of Engine and Power Transmission Mechanism Prepared therefor

A technology of engine power and transmission mechanism, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problem of small increase in the effective thermal efficiency of the engine, achieve the effects of fewer parts, facilitate combustion and compression ratio, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

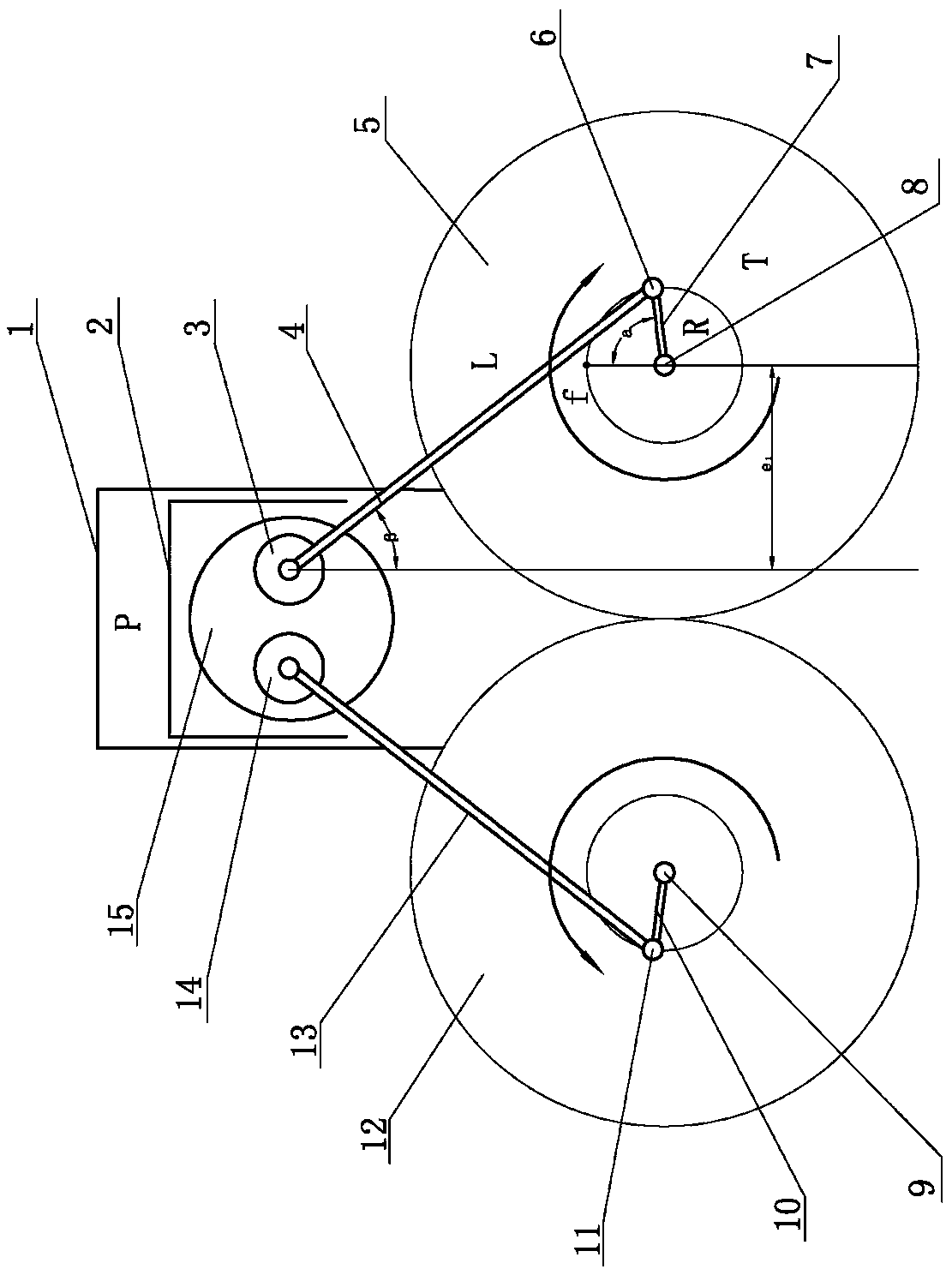

[0026] The present invention will be further described with reference to the accompanying drawings.

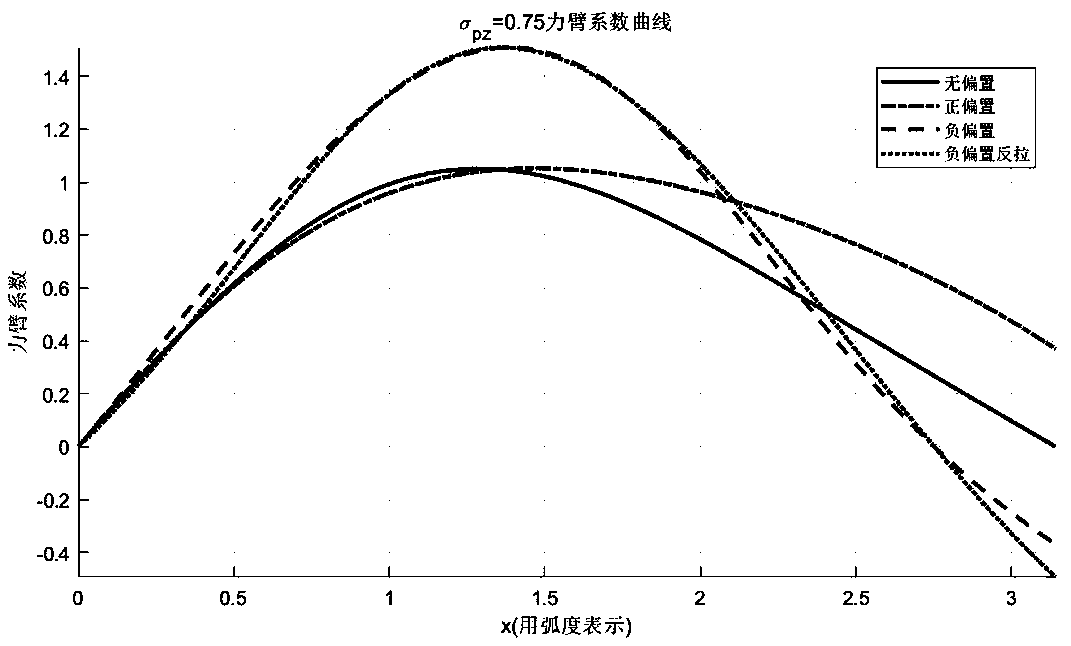

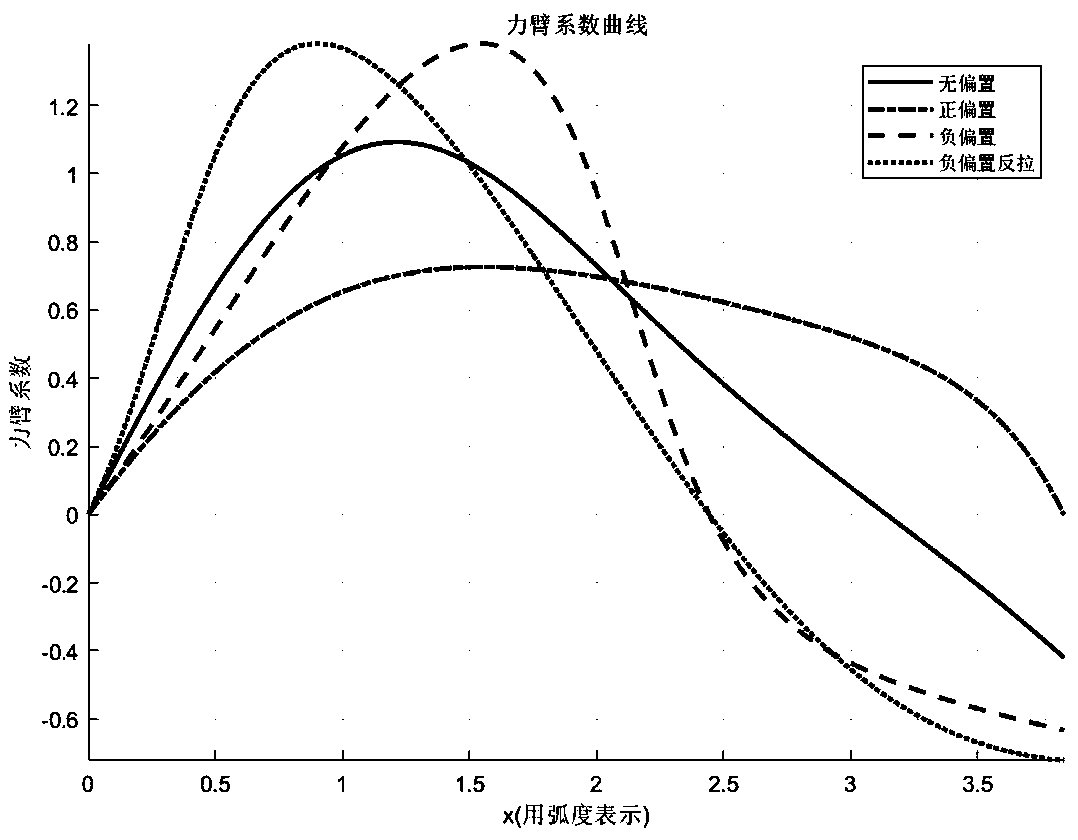

[0027] A method for improving the effective thermal efficiency of the engine according to the present invention, the eccentricity of the engine power transmission mechanism is set, the eccentricity is the distance between the axis of the crankshaft and the axis of the connecting end of the piston rod and the crank connecting rod, and the connecting end of the piston rod and the crank connecting rod Located above the center point of the crankshaft, or the eccentricity is the distance between the axis of the crankshaft and the axis of the connecting end of the pin on the slider and the connecting end of the crank connecting rod, or the distance between the axis of the crankshaft and the axis of the connecting end of the piston and the connecting rod of the crank connecting rod;

[0028] Set the eccentricity e greater than the crank radius R;

[0029] arrange the two crankshafts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com