Dual concentric gas-gas nozzle

A dual-coaxial, gas-nozzle technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of propellant incombustibility and combustion efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention firstly proposes a double coaxial gas-gas nozzle, which can realize high combustion efficiency under the condition of large flow. The invention provides a double-coaxial gas-gas nozzle and a design method thereof, which can ensure efficient and stable combustion of the propellant, and the design method is simple and effective. The engine with double coaxial nozzles can greatly reduce the number of nozzles in the head.

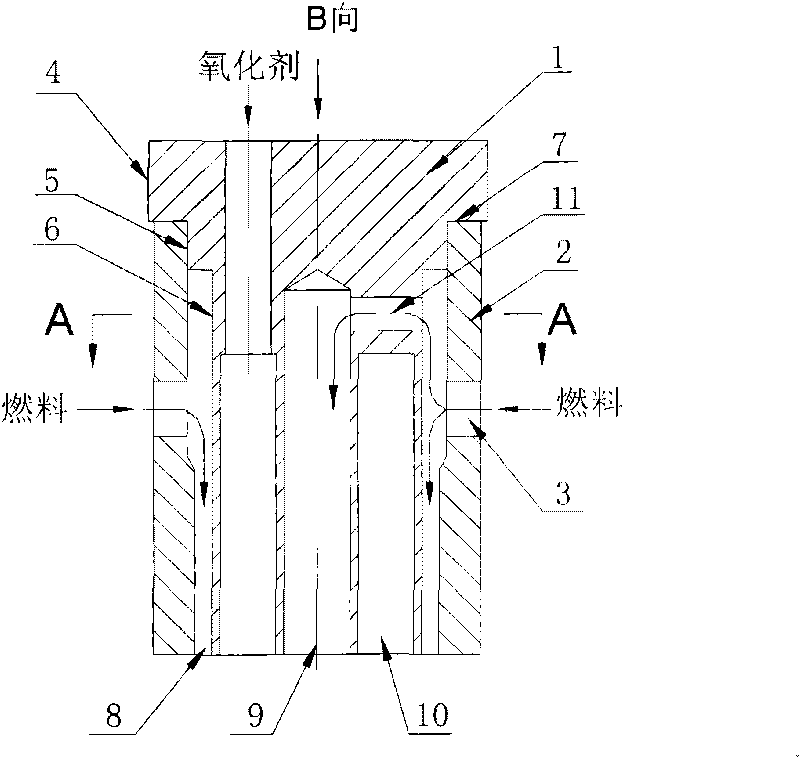

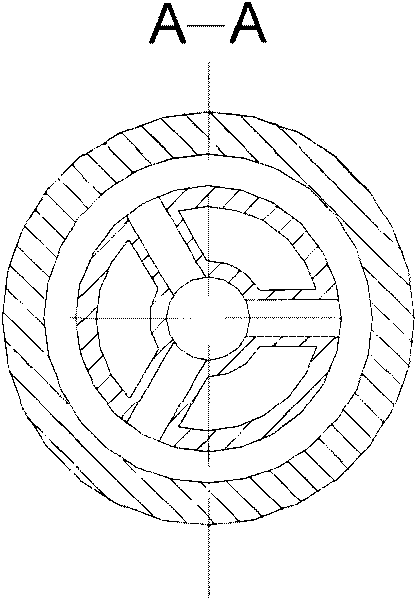

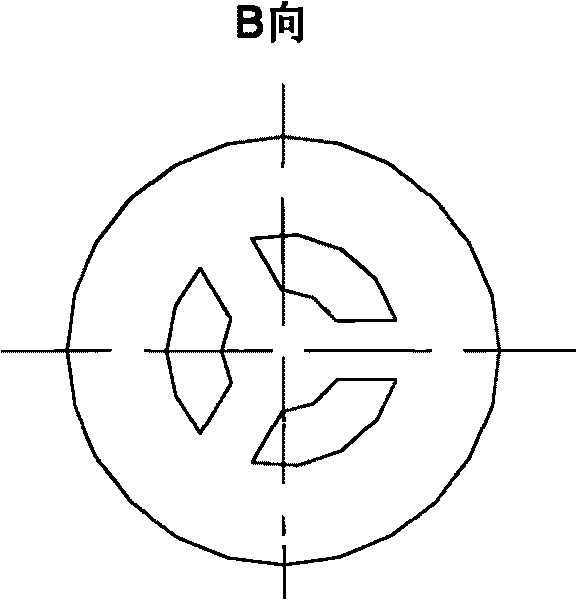

[0016] Such as figure 1 , 2 , the double-coaxial air-gas nozzle shown in 3, comprises nozzle main body (1) and cylindrical sleeve (2), and nozzle main body (1) is cylindrical, by the upper section (4), middle section (5) of decreasing outer diameter Composed of the lower section (6), the side wall of the cylindrical sleeve is provided with a plurality of through holes (3), and one end of the cylindrical sleeve (2) is connected to the shoulder (7) between the upper section and the middle section of the nozzle body (1) to form a Integral, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com