A Premixed Strong Swirl Flame Diffusion Burner

A technology of diffusion combustion and swirler, which is used in burners, gas fuel burners, combustion methods, etc., can solve the problems of increasing the premixed gas opening angle, increasing the combustion range, and small heating area, and achieves improved combustion. Efficiency, increase the heating area, and the effect of expanding the combustion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

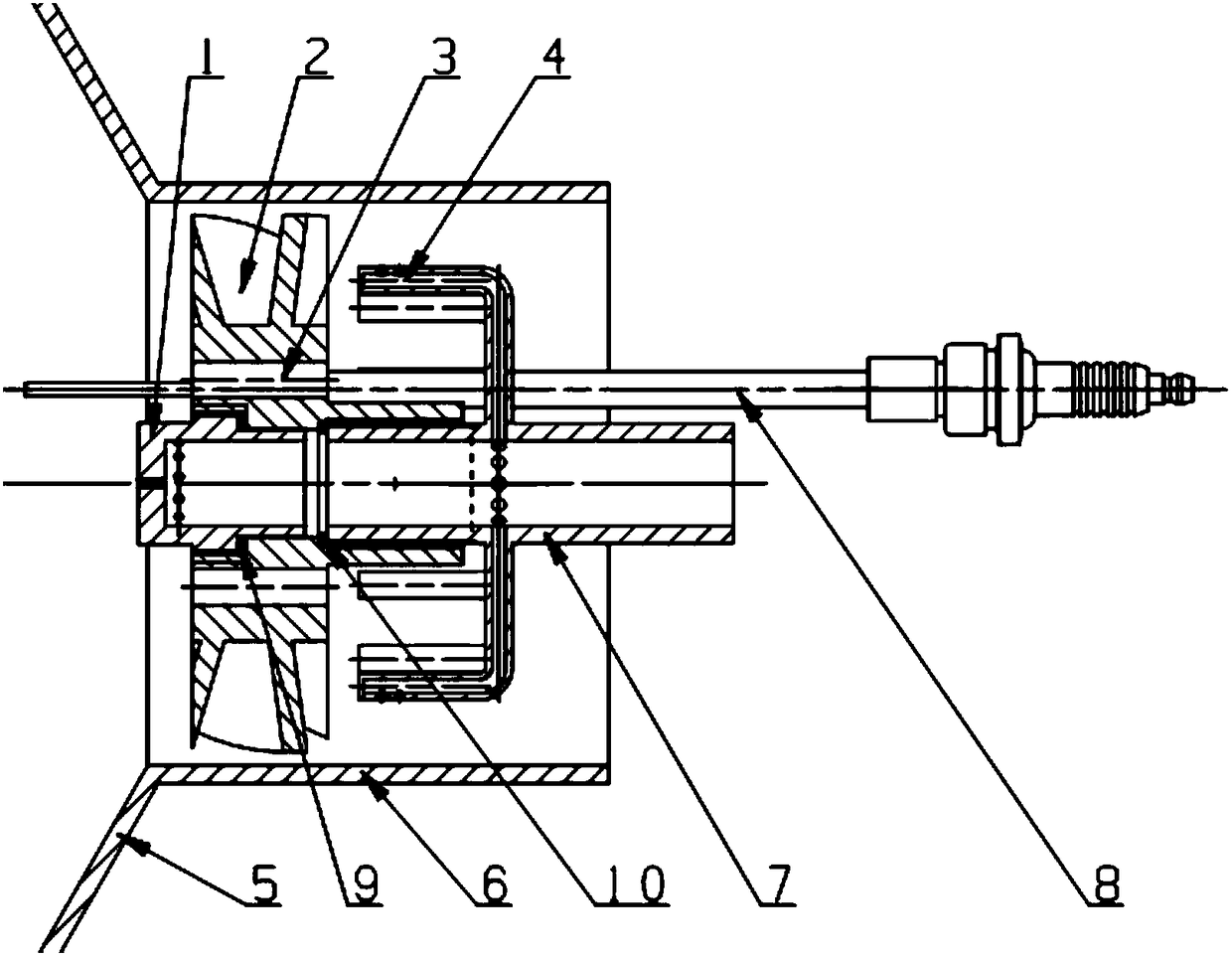

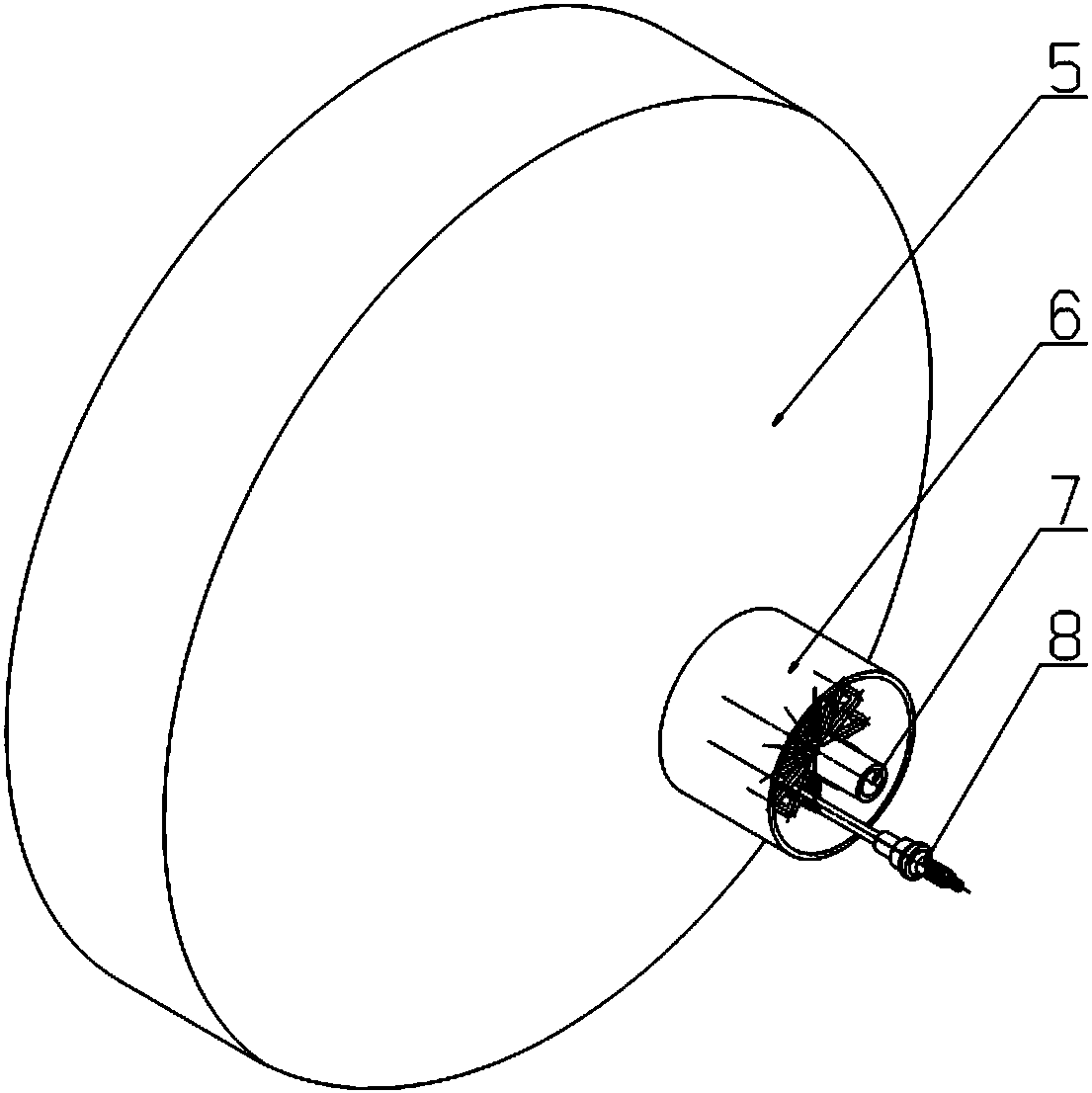

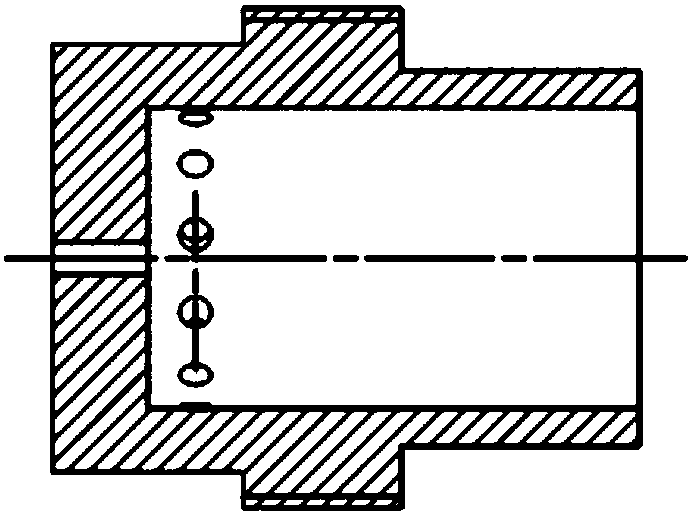

[0030] Such as figure 1As shown in this embodiment, a premixed strong swirling flame diffusion burner adopts a centrally graded design structure and is made of stainless steel as a whole. The burner part includes: a pre-combustion stage nozzle 1, a swirler 2, The pre-combustion stage air hole 3 and the main combustion stage nozzle 4, as well as the fuel pipeline 7 for supplying fuel, the air pipeline 6 for supplying air, the electric spark igniter 8 for starting the burner and the casing of the combustion chamber for the combustion reaction process 5. The gaseous fuel is fed into the device through the fuel pipeline 7, and a part of the fuel directly enters the combustion chamber through the pre-combustion stage nozzle 1 to carry out diffusion combustion with the pre-combustion stage air passing through the pre-combustion stage air hole 3; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com