Combustion apparatus capable of controlling temperature of output heat source

A technology of combustion device and heat source temperature, which is applied to burners, combustion methods, combustion types, etc., can solve the problems of limited improvement of combustion efficiency, small combustion range, and increased device cost, and achieves combustion efficiency, energy saving, environmental protection, and combustion. The effect of maximizing efficiency and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

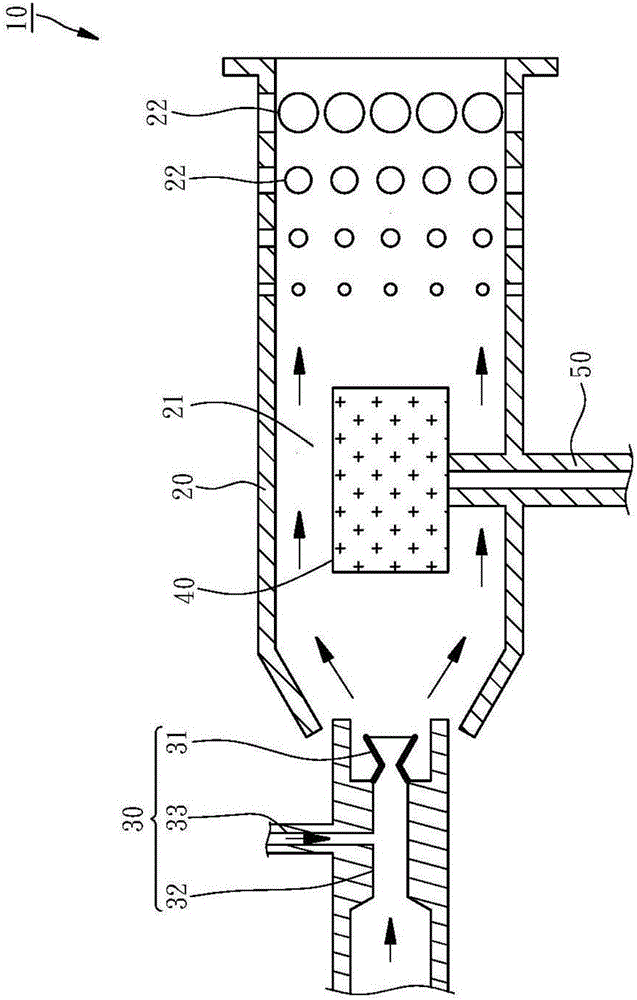

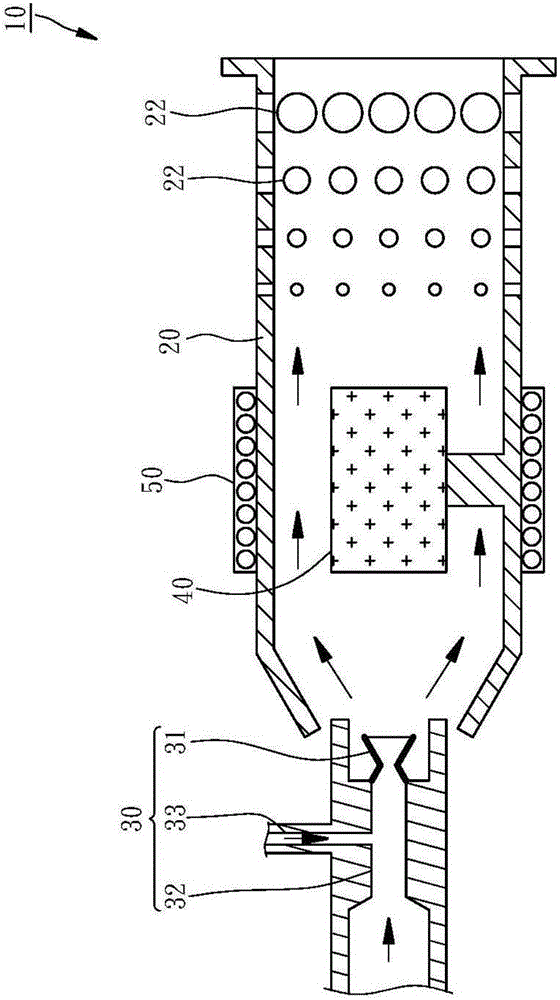

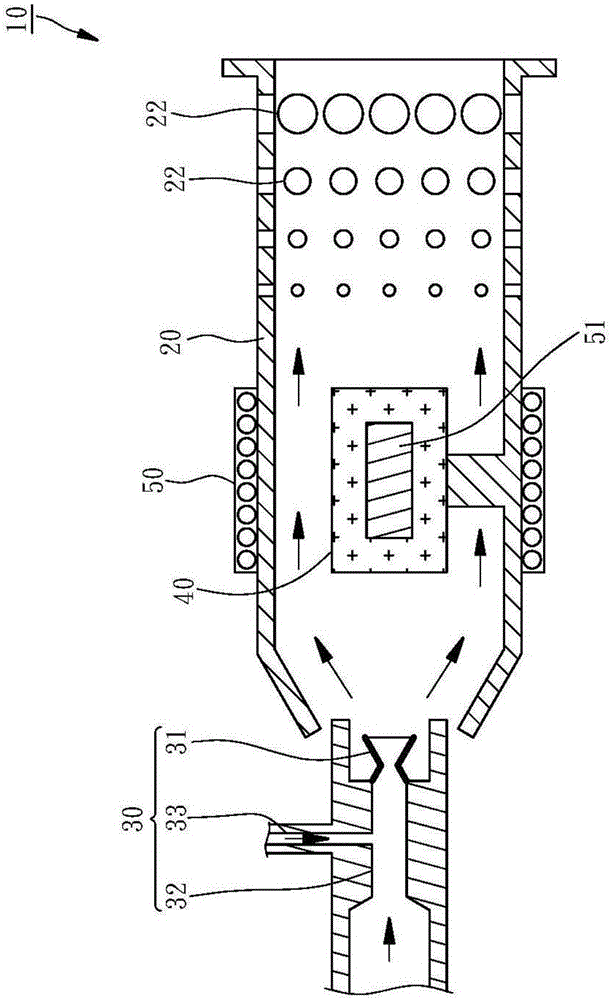

[0021] In order to better understand the characteristics of the present invention, the preferred embodiment of the present invention provides a combustion device 10 with controllable output heat source temperature, such as figure 1 As shown, it includes an igniter 40 disposed inside a first combustion chamber 20 , and a heating unit 50 disposed within the first combustion chamber 20 .

[0022] The first combustion chamber 20 is arranged in a tubular shape with openings at both ends. A fuel supplier 30 is arranged at one end opening of the first combustion chamber 20 . The first combustion chamber 20 is provided with a plurality of Through hole 22. In addition, the fuel supplier 30 has a fuel nozzle 31 , a fuel passage 32 connected to the fuel nozzle 31 , and a gas passage 33 communicating with a middle sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com