Patents

Literature

48results about How to "Maximize combustion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

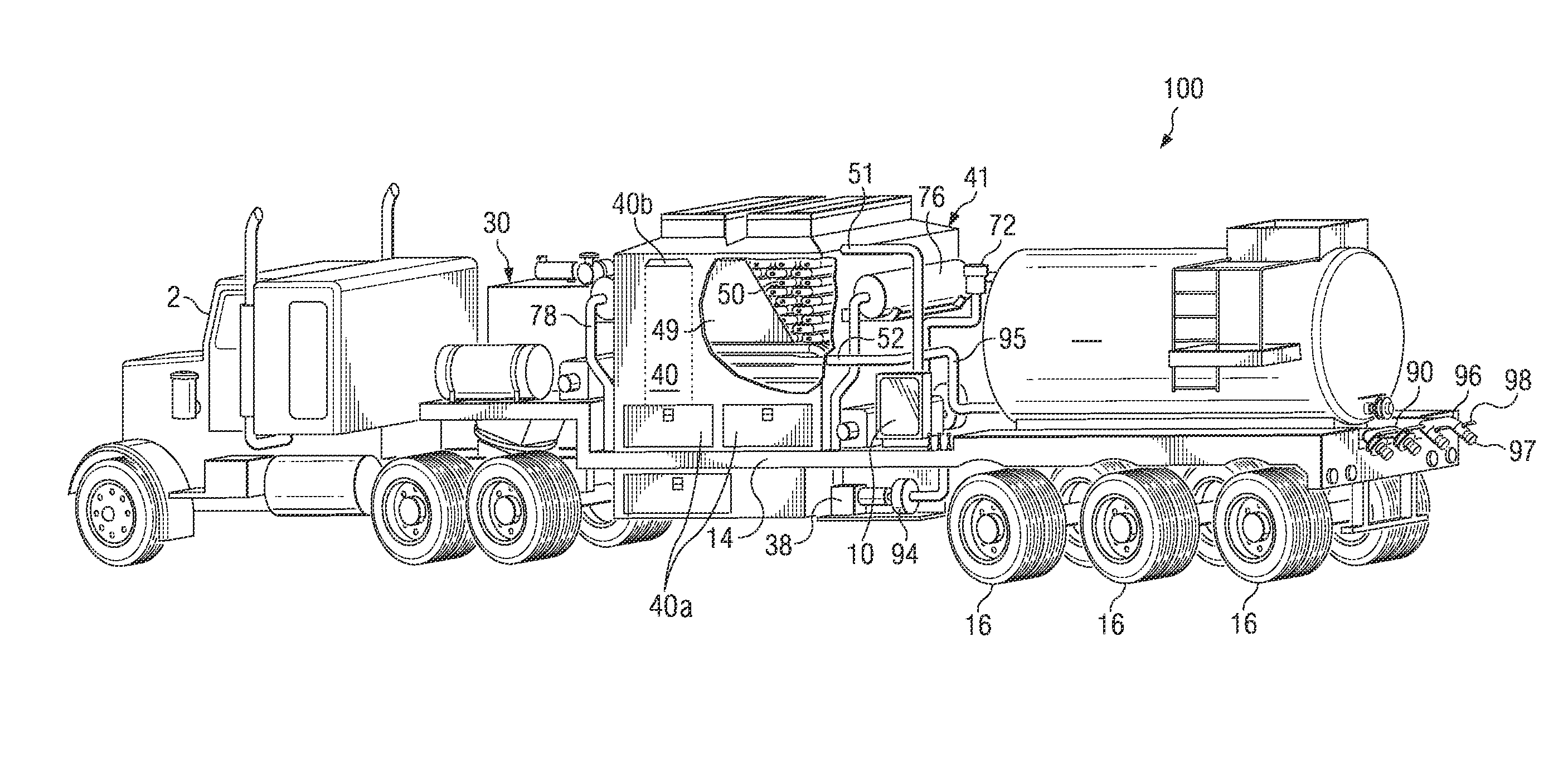

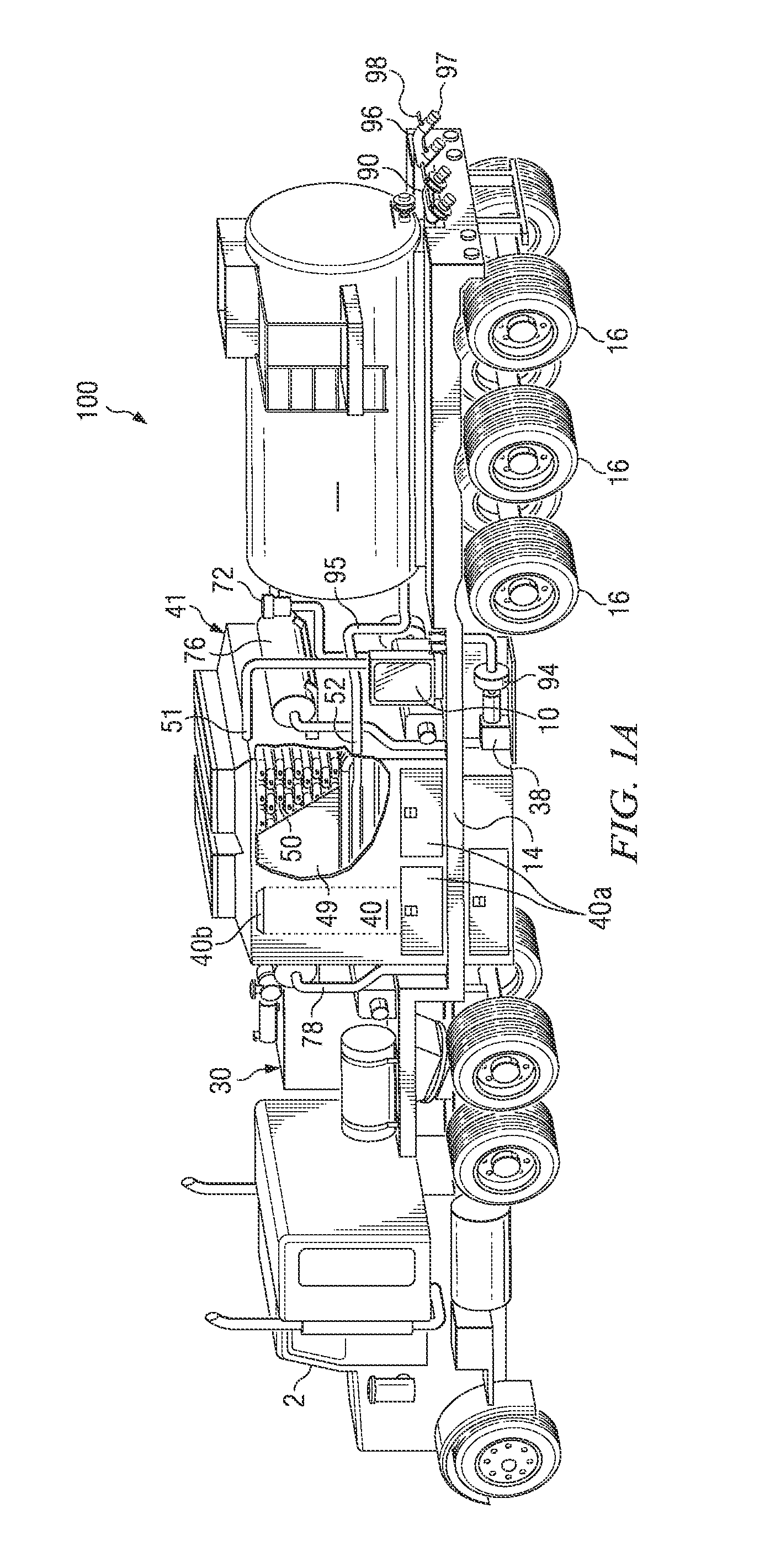

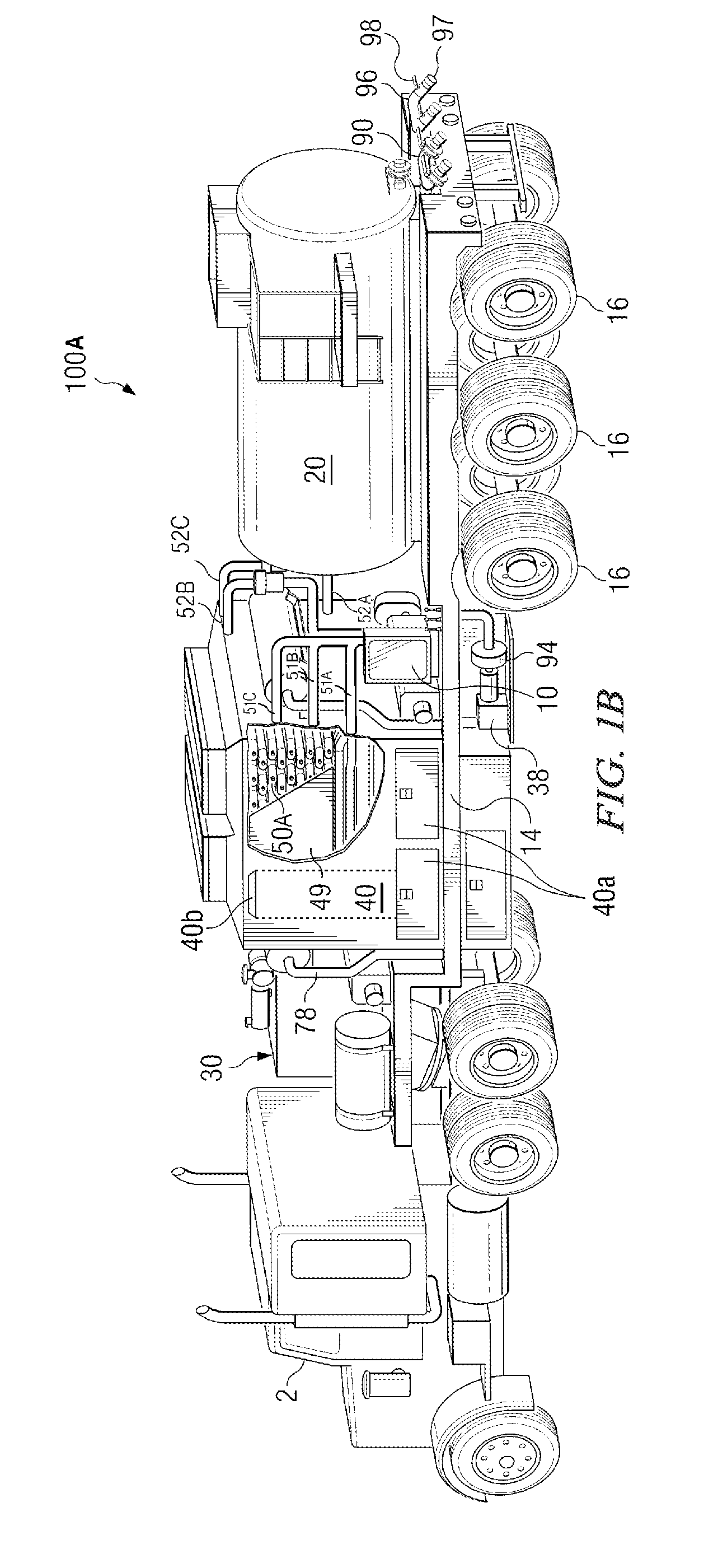

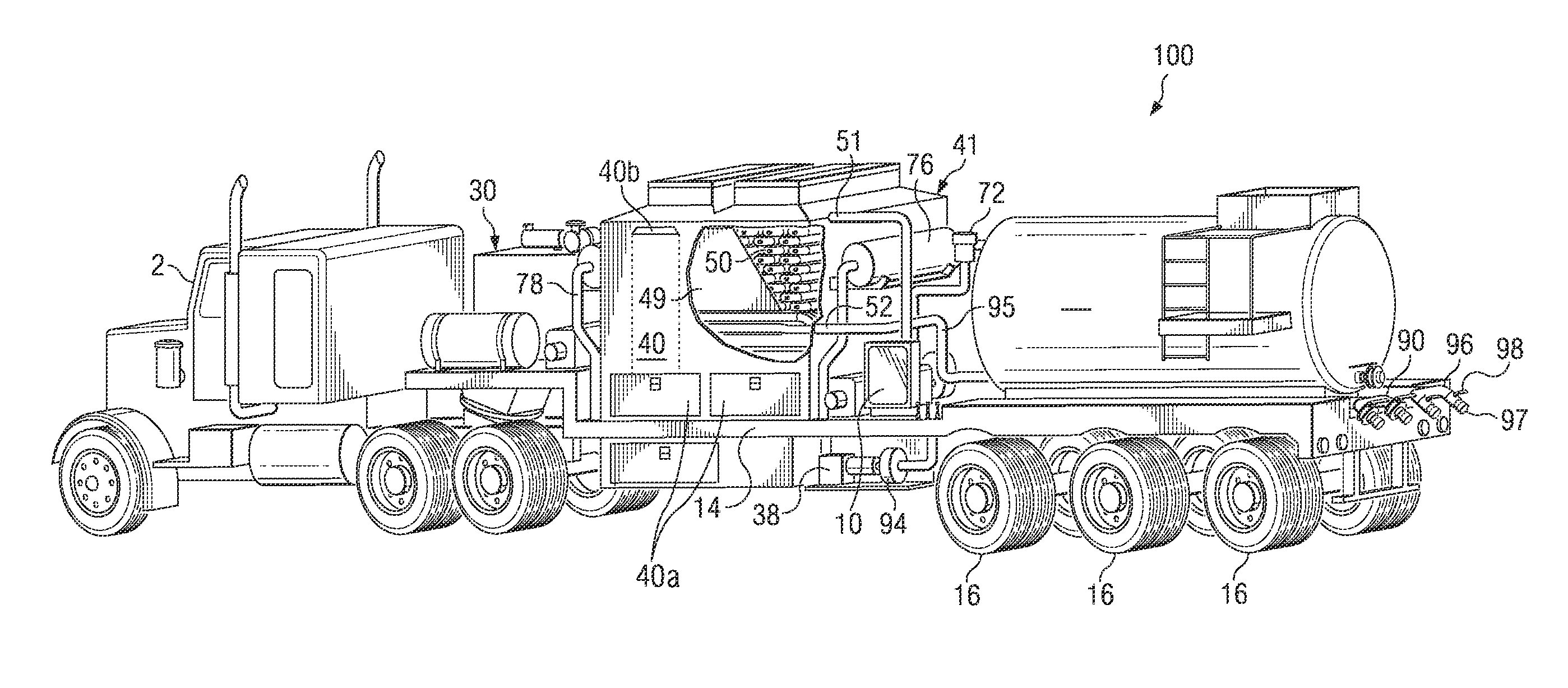

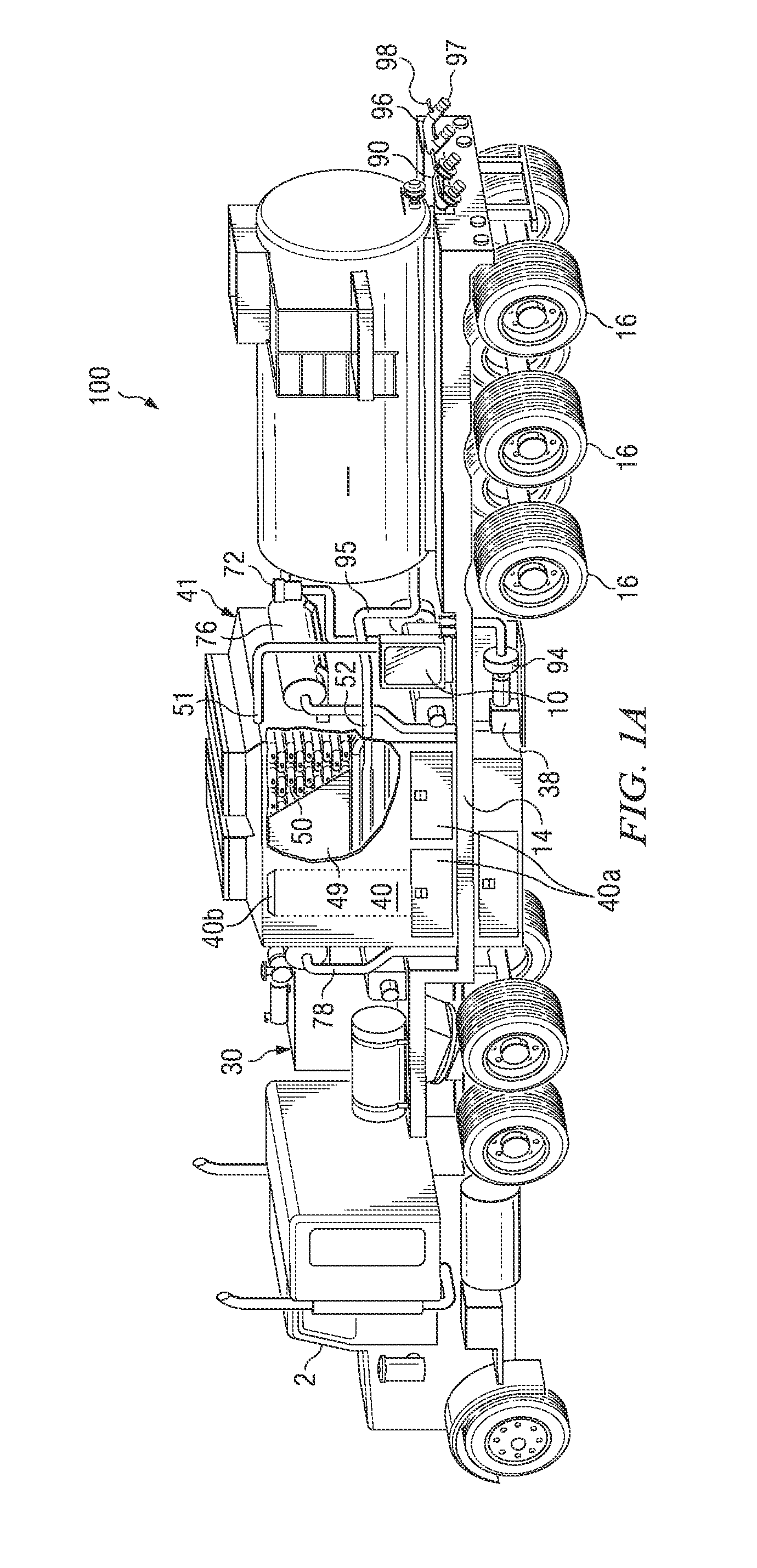

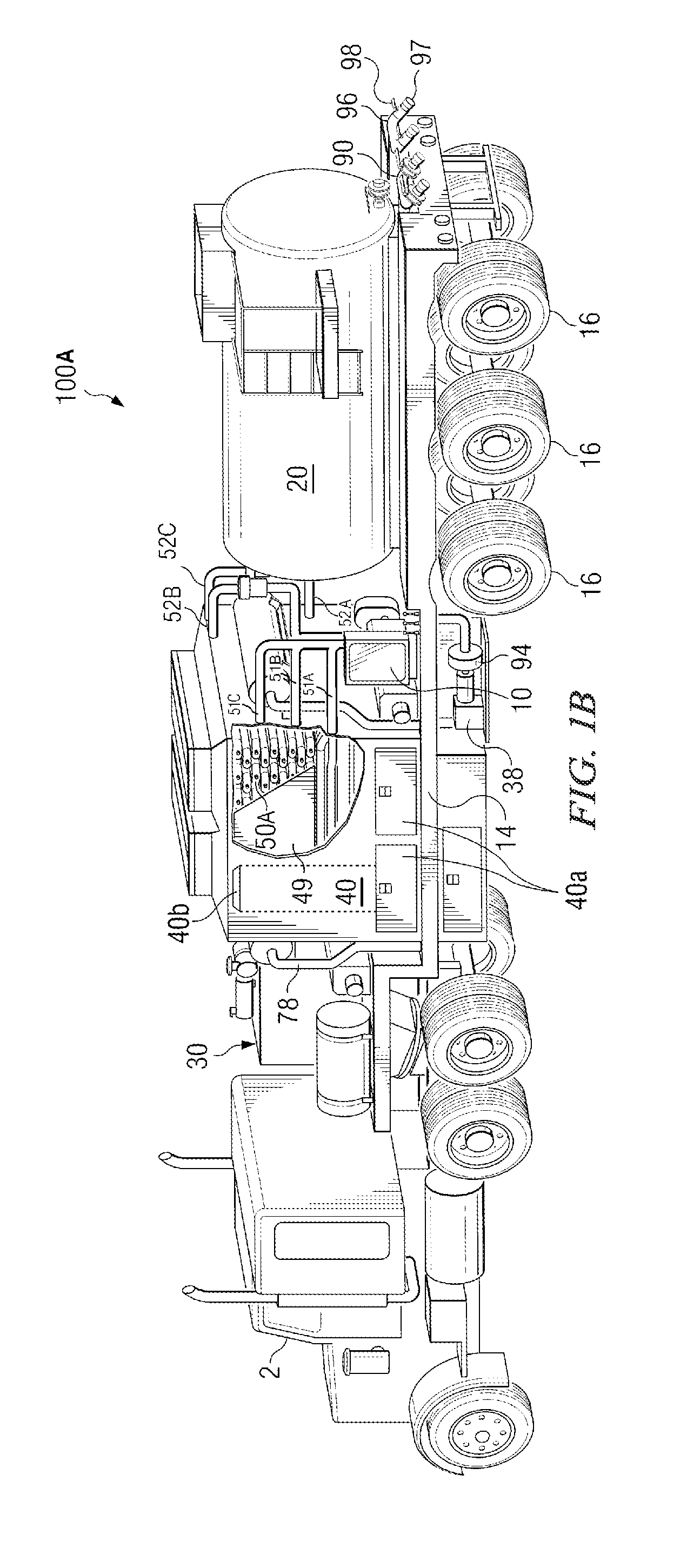

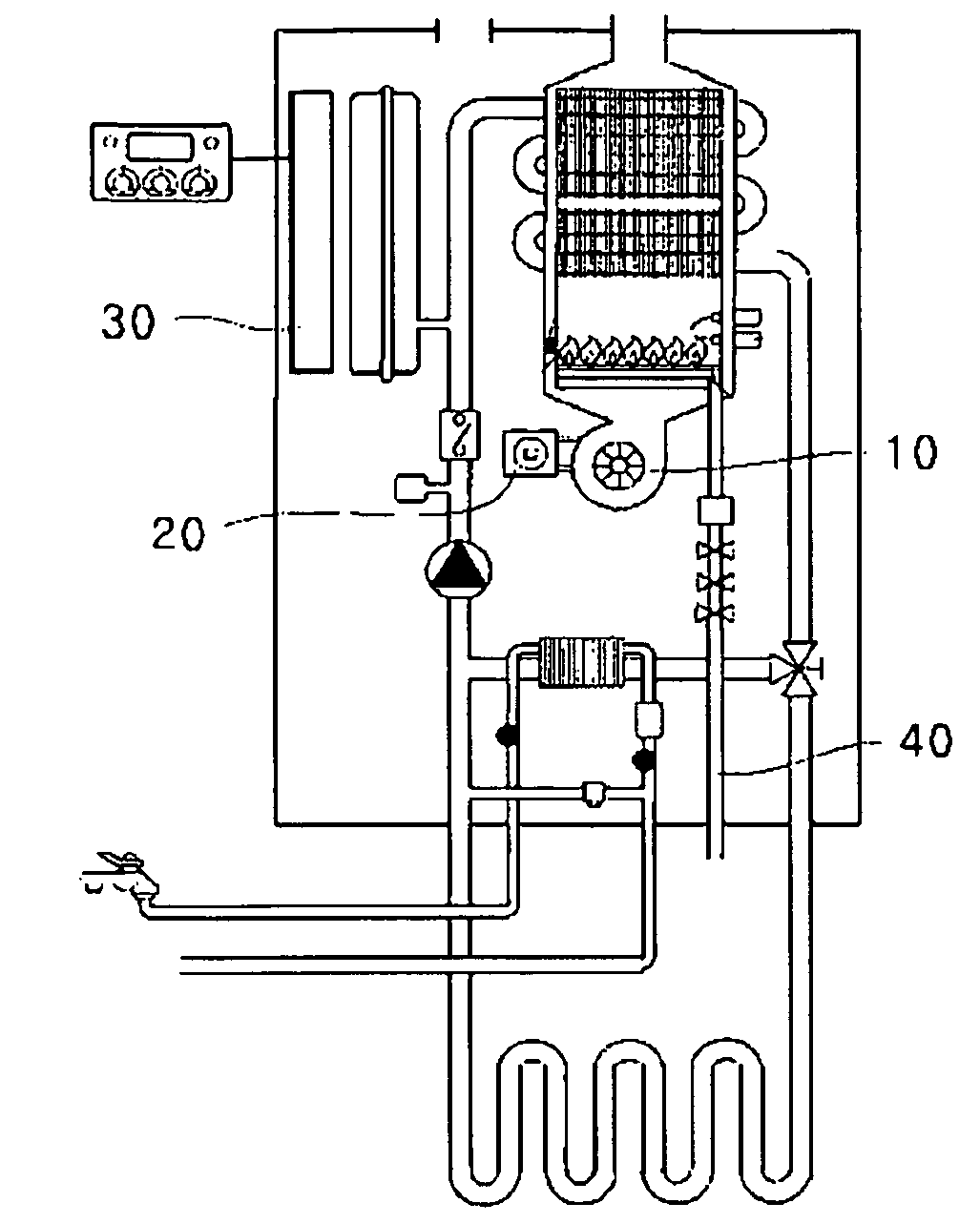

Frac water heating system and method for hydraulically fracturing a well

InactiveUS20140144641A1Safely and continuously heatingMaximize atomization and combustionInsulationFluid removalCombustion chamberFuel tank

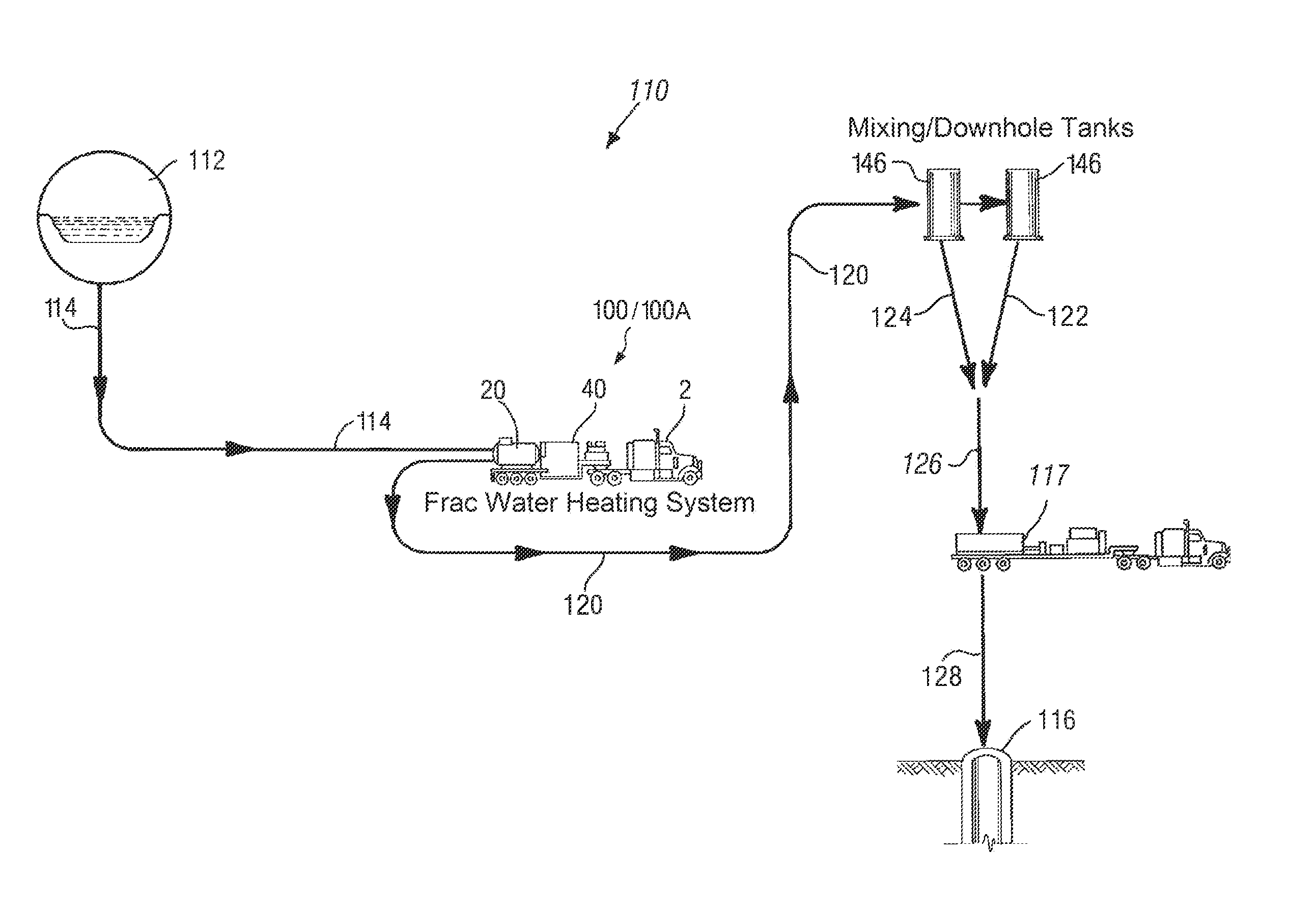

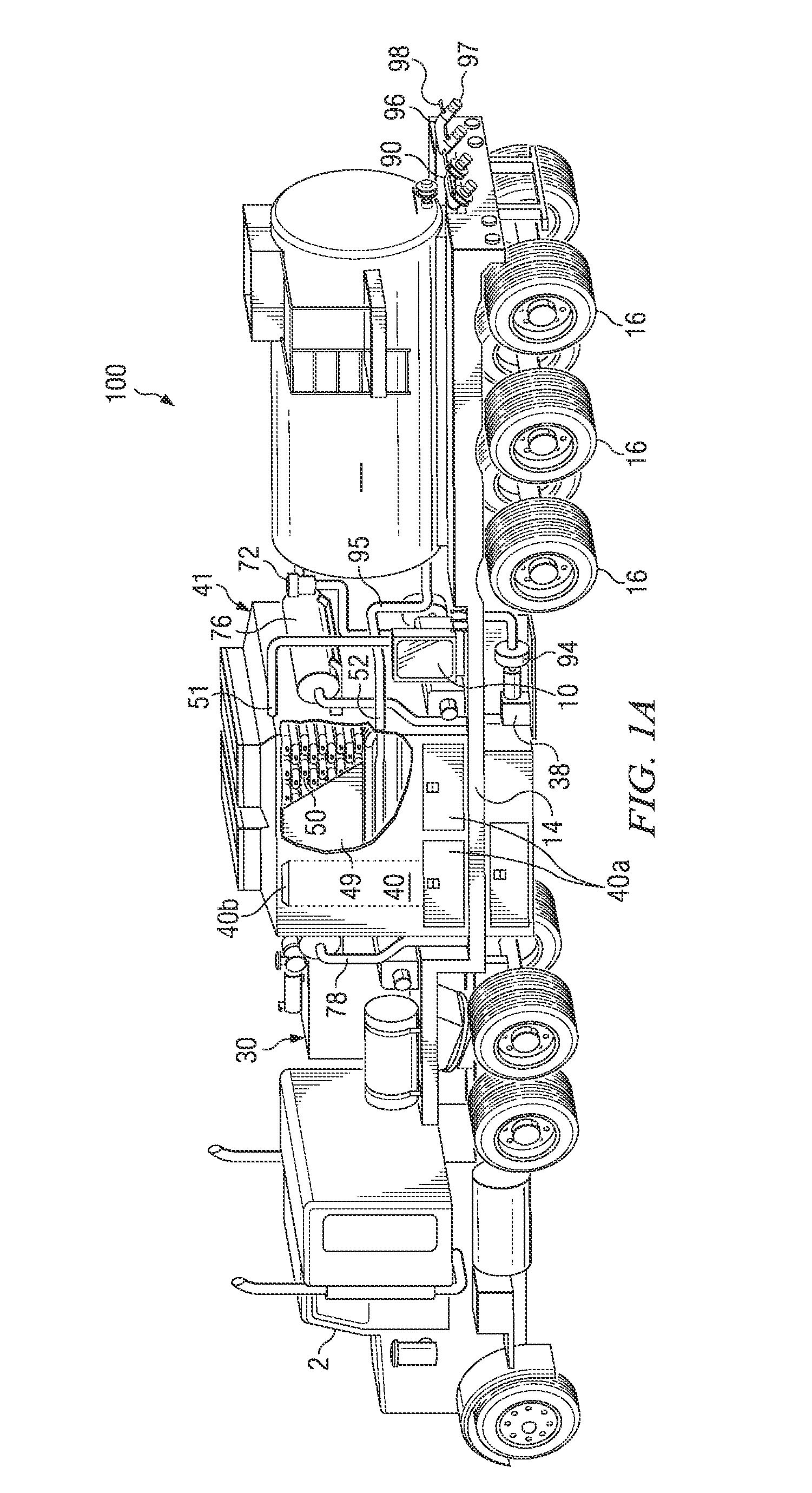

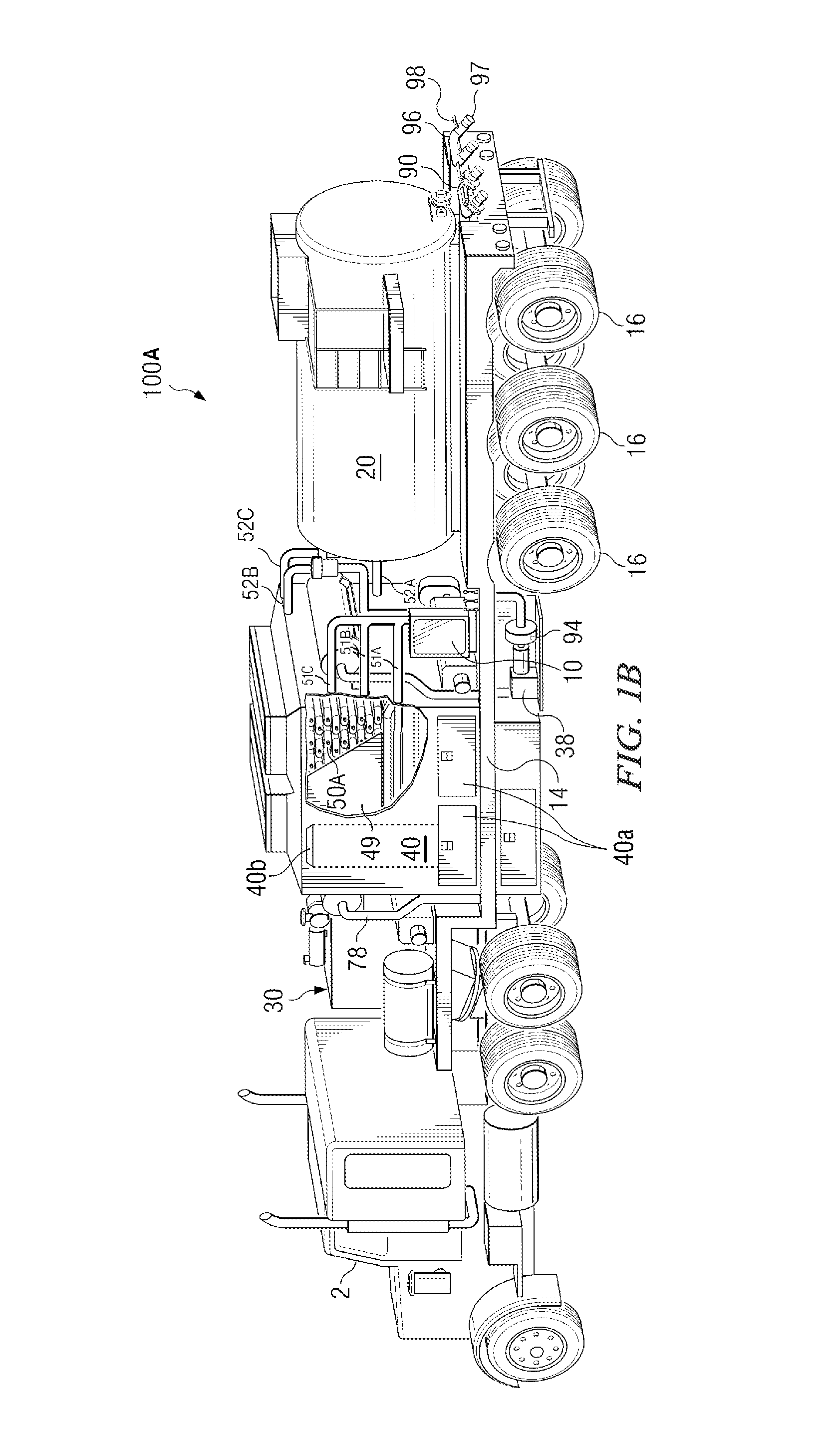

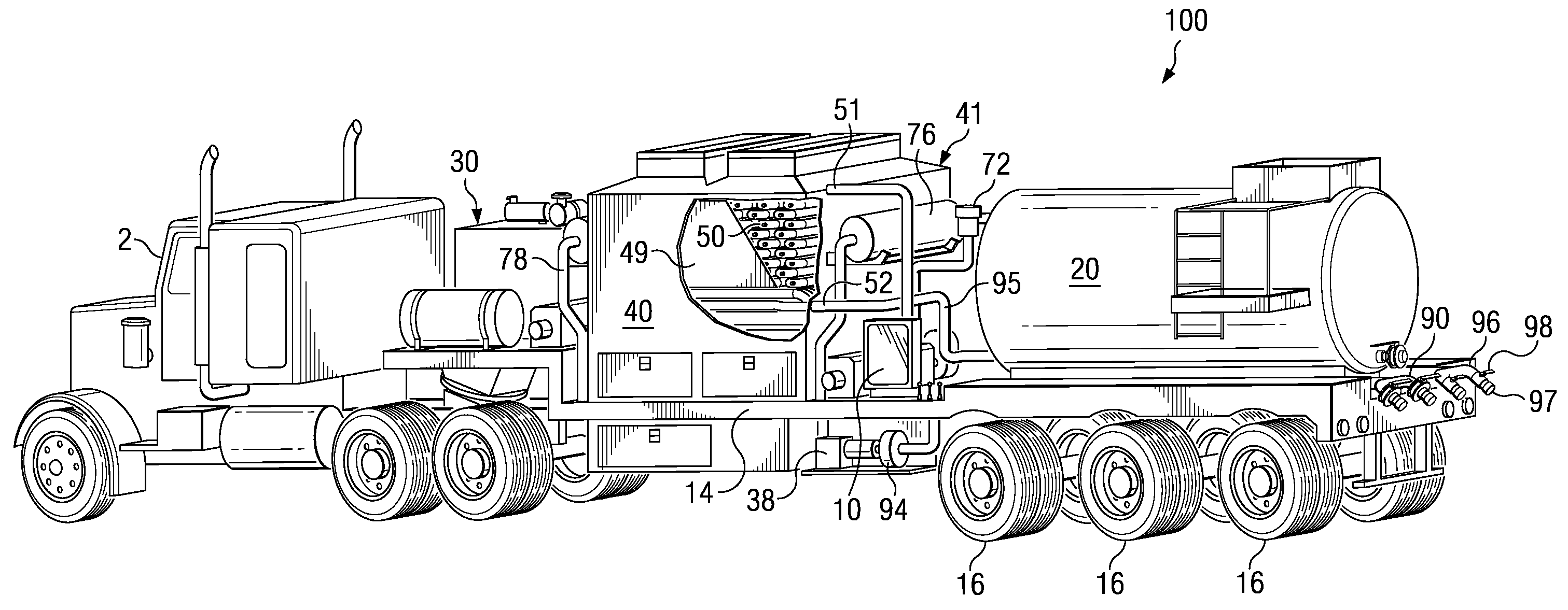

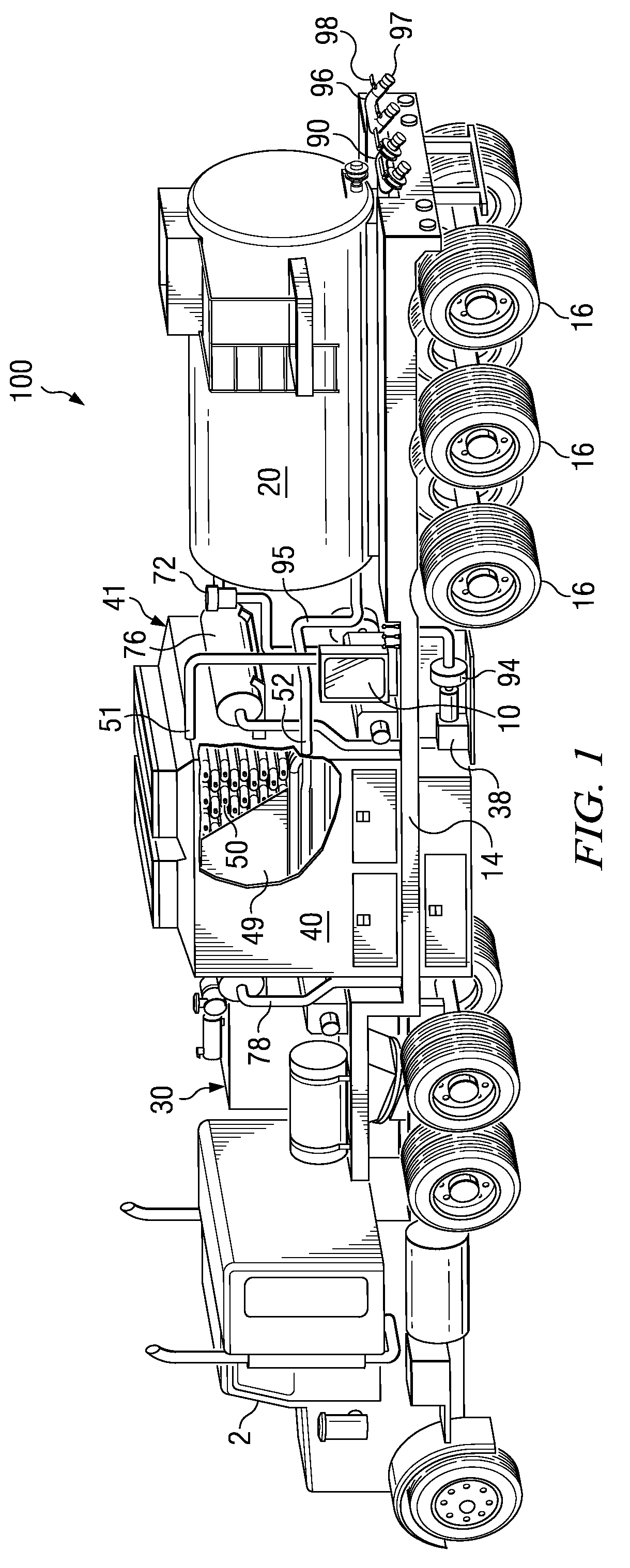

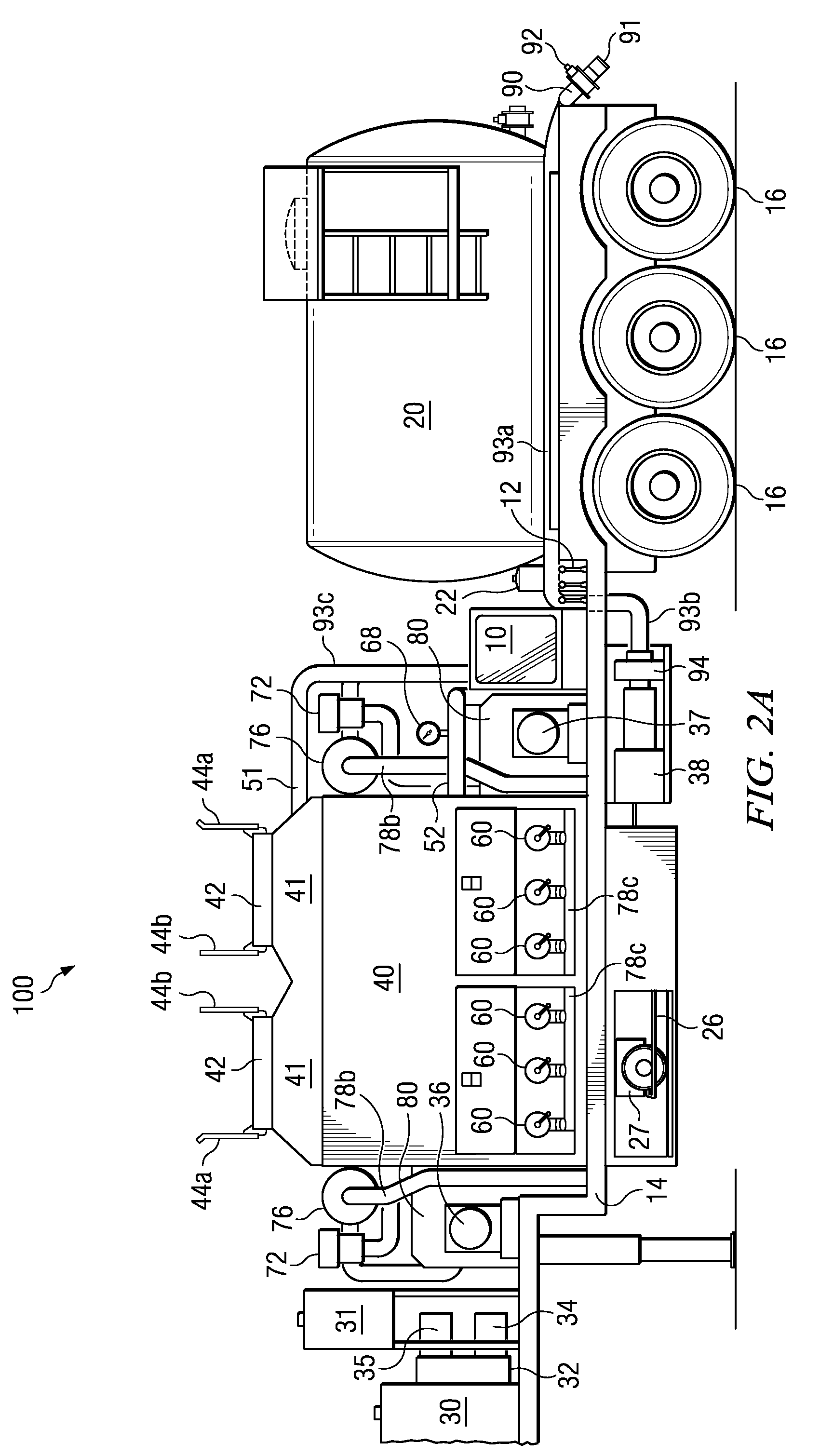

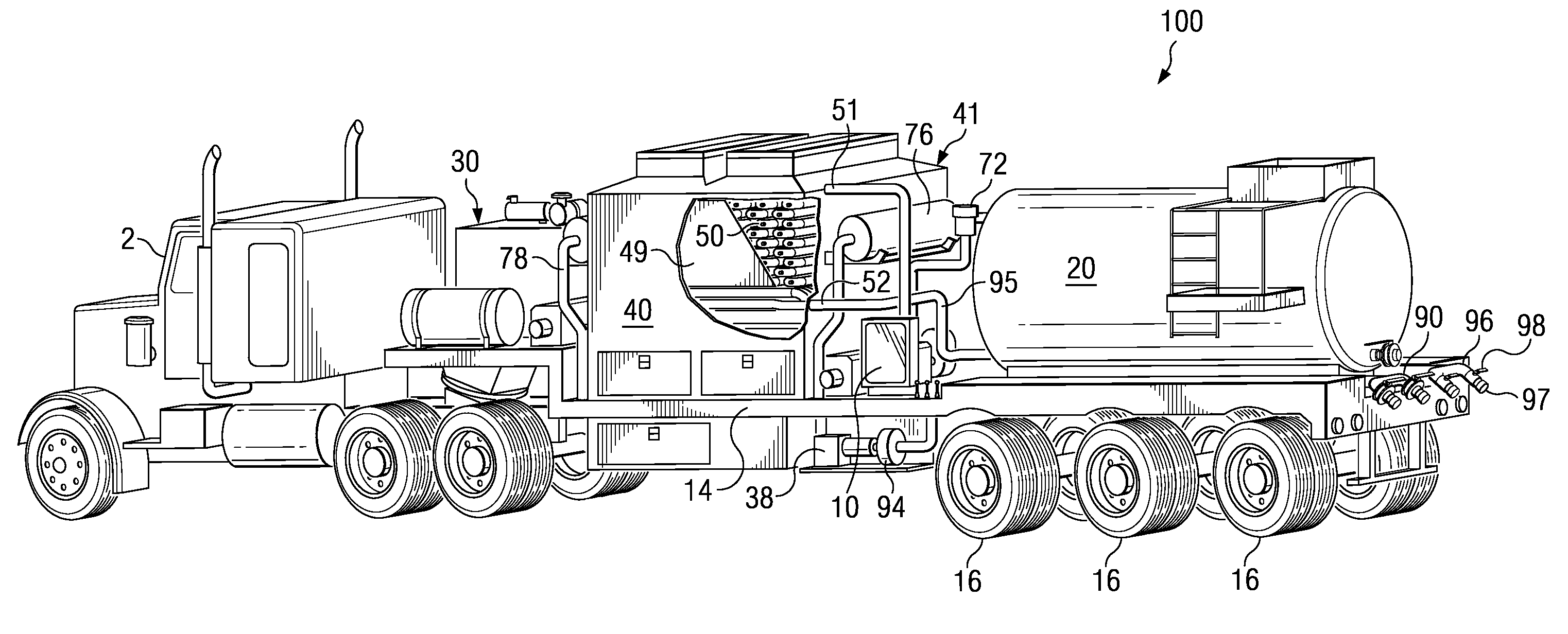

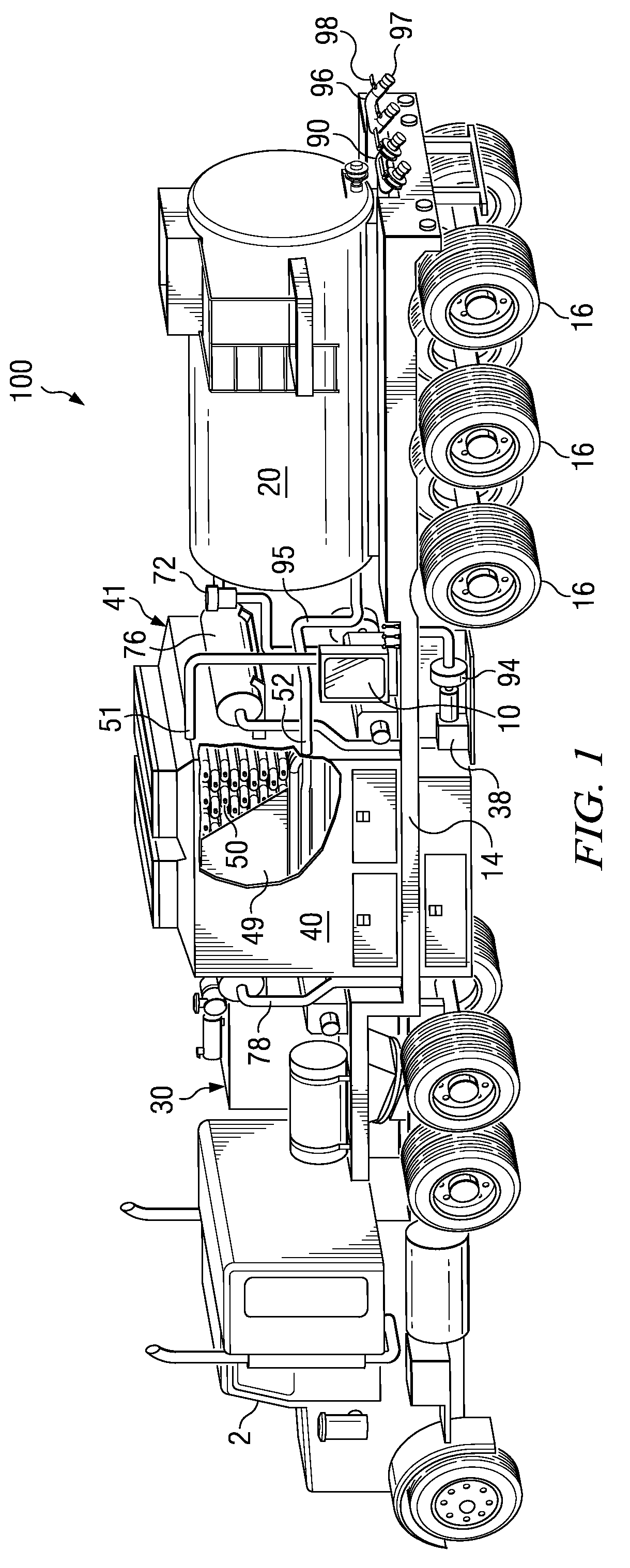

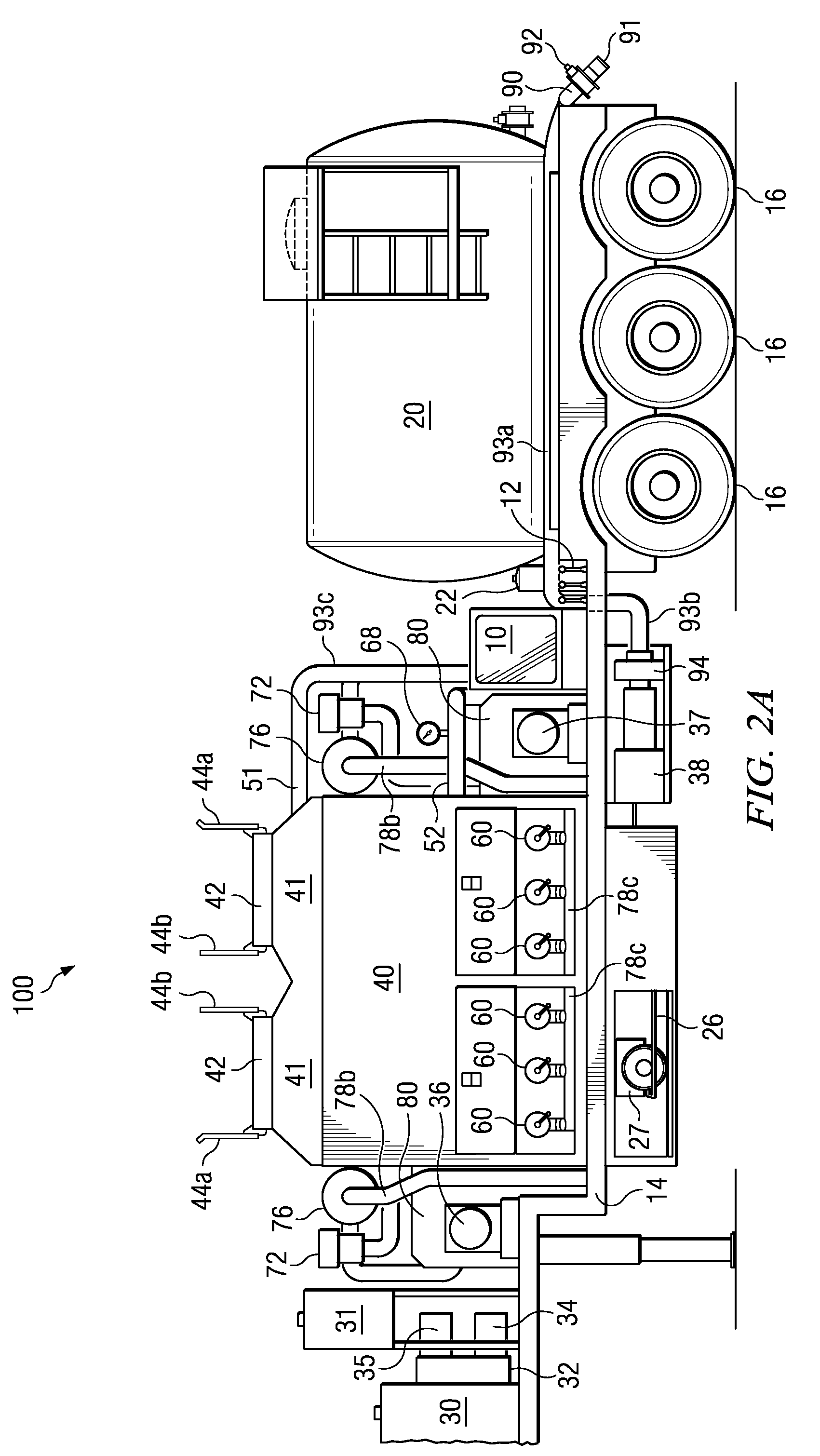

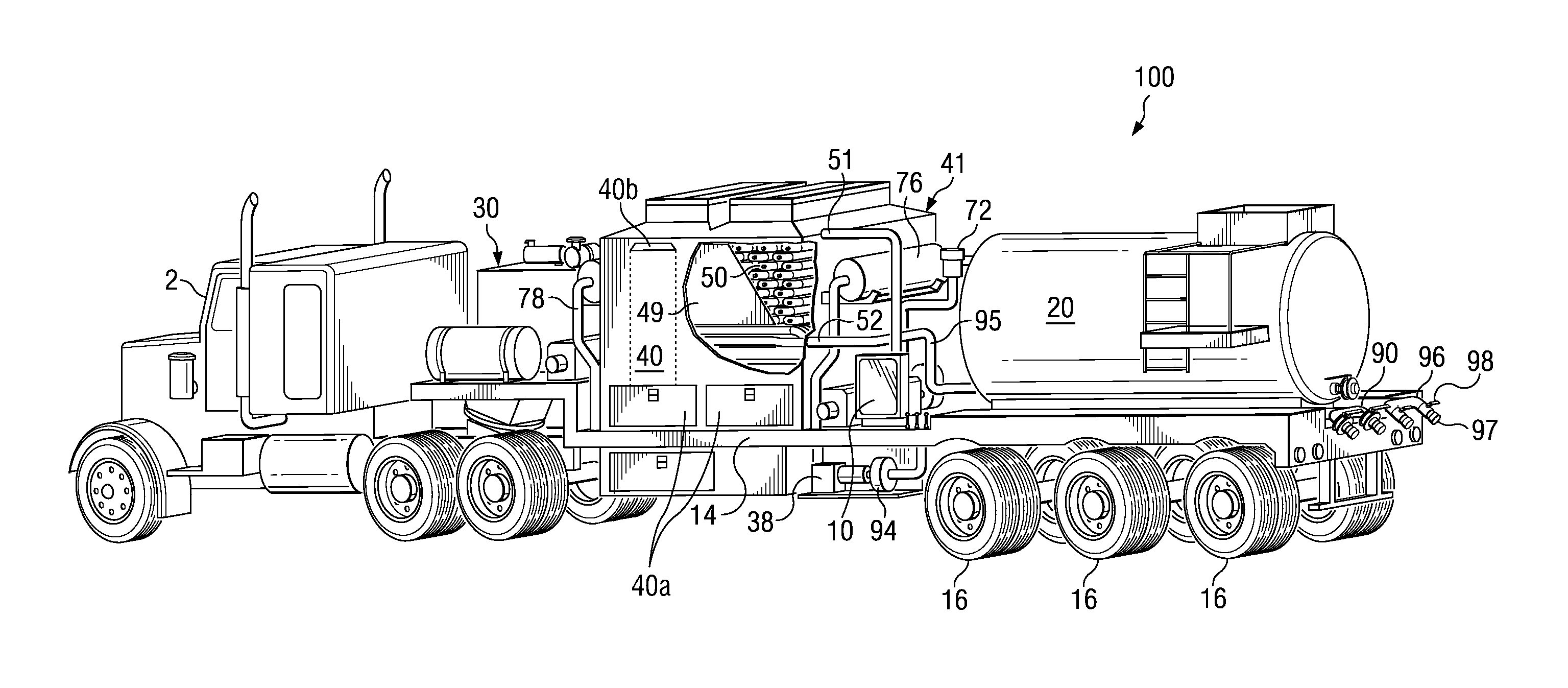

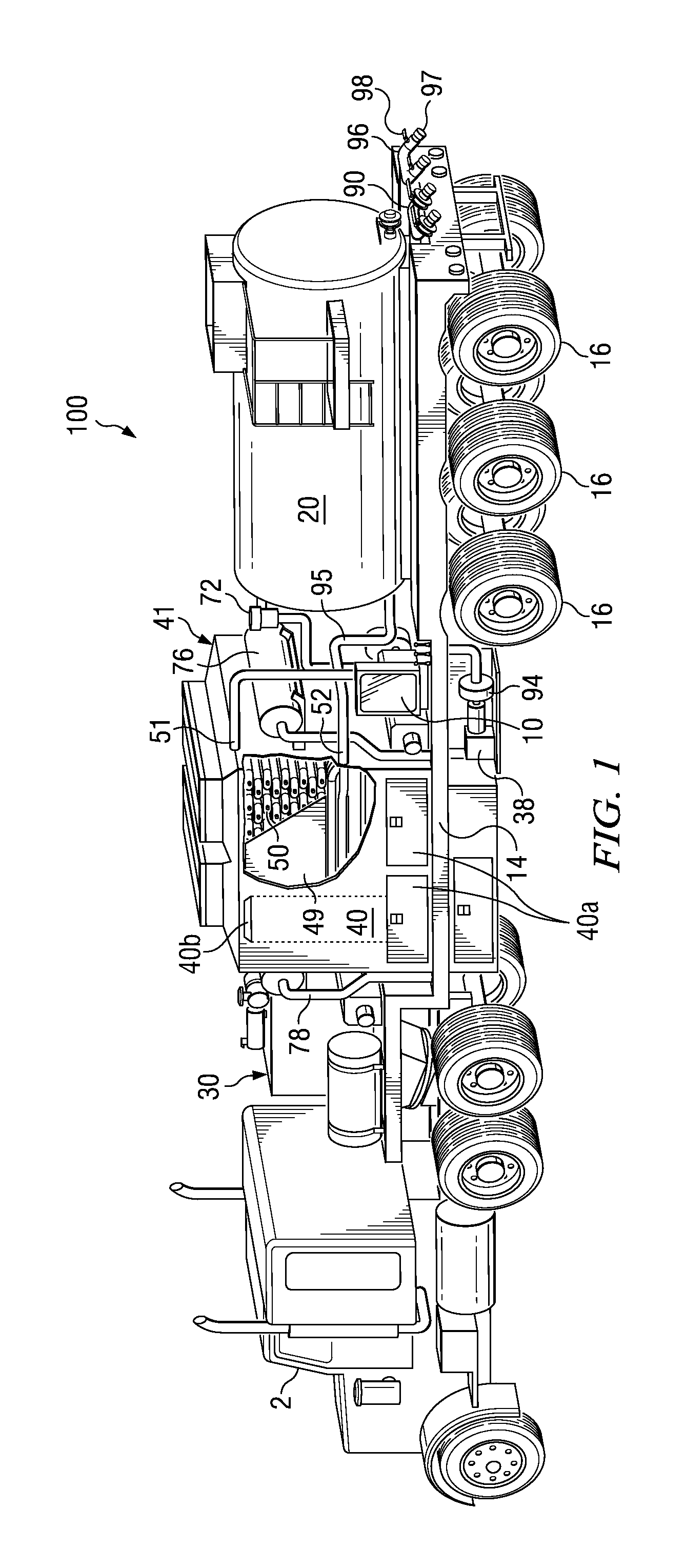

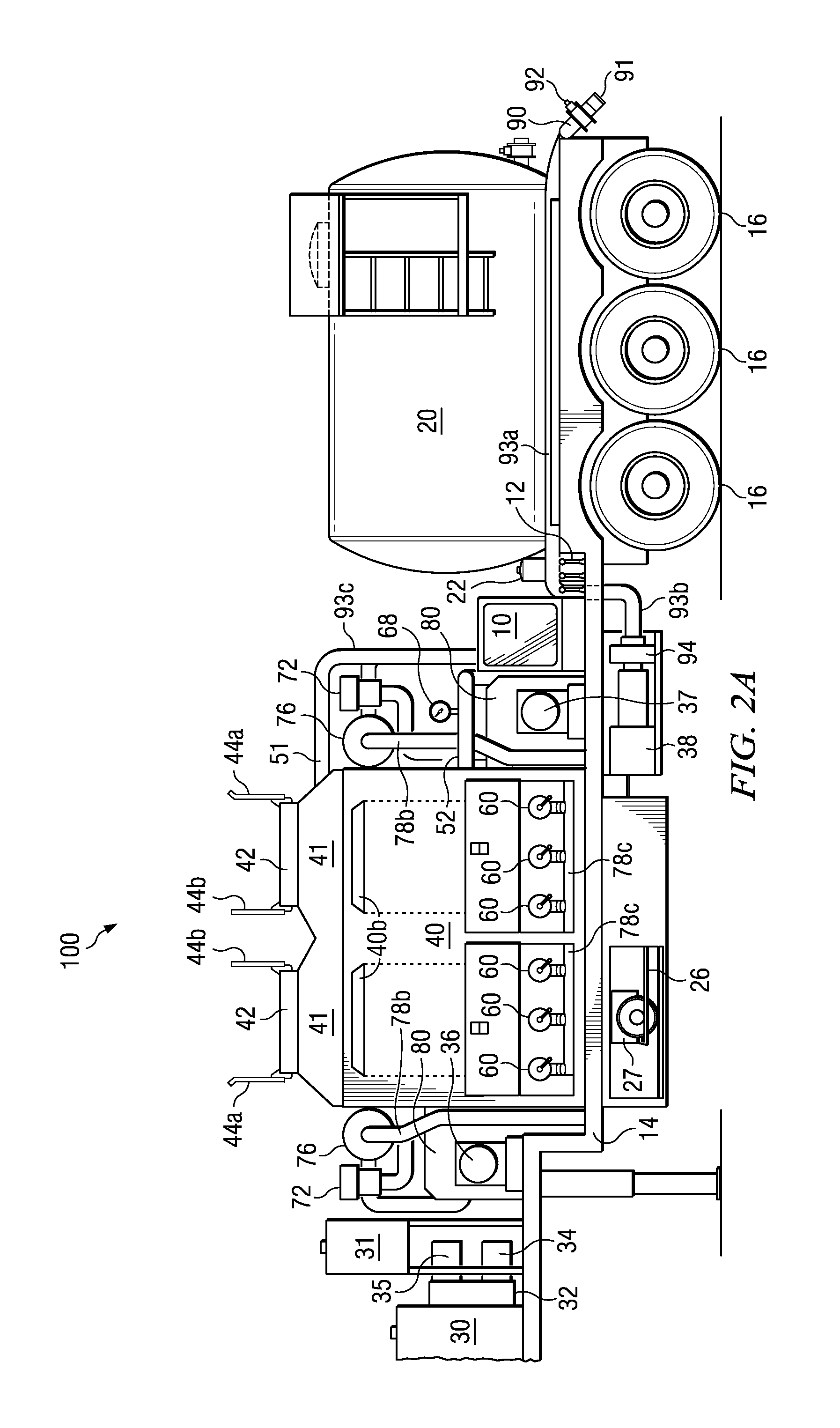

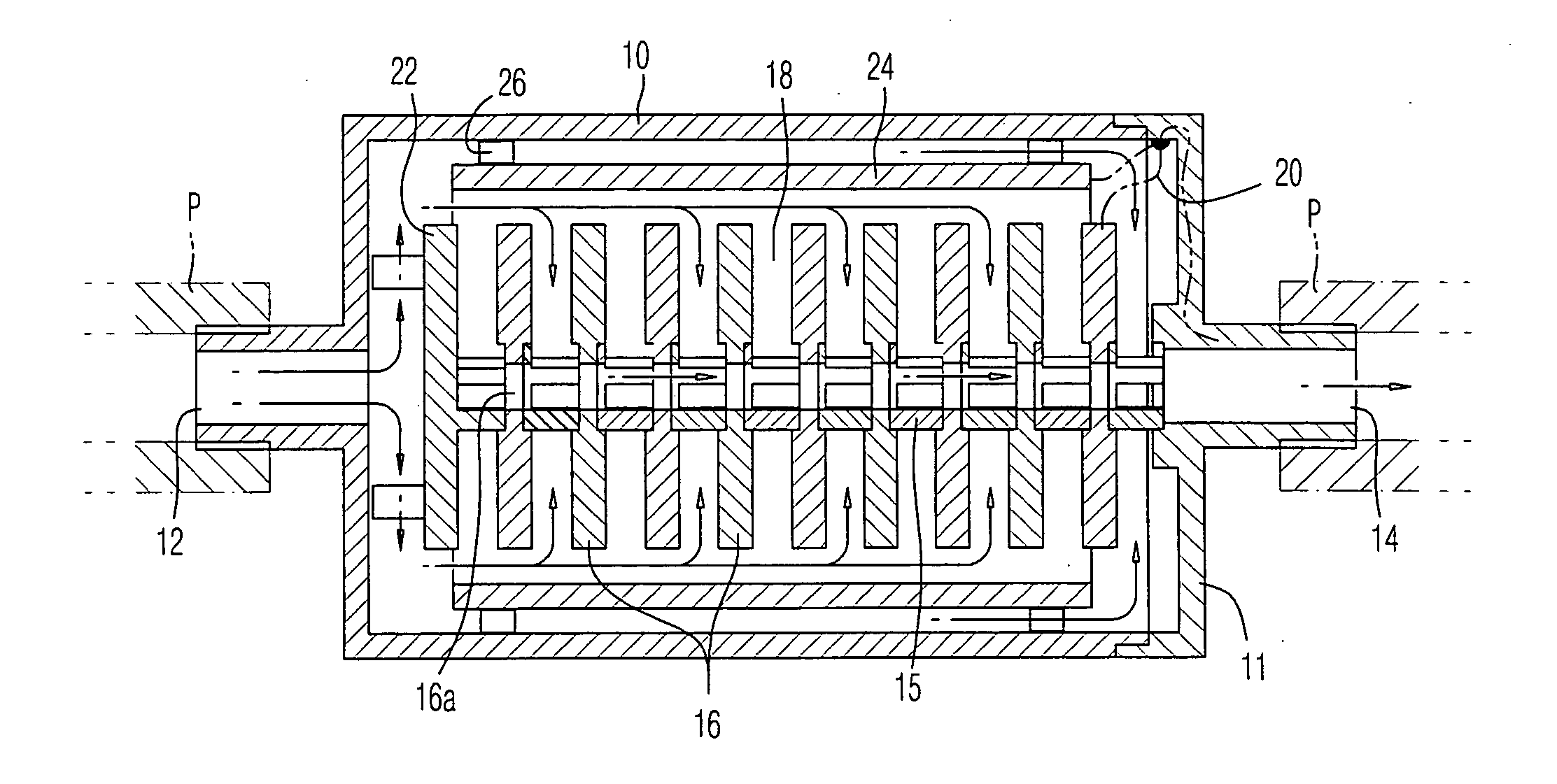

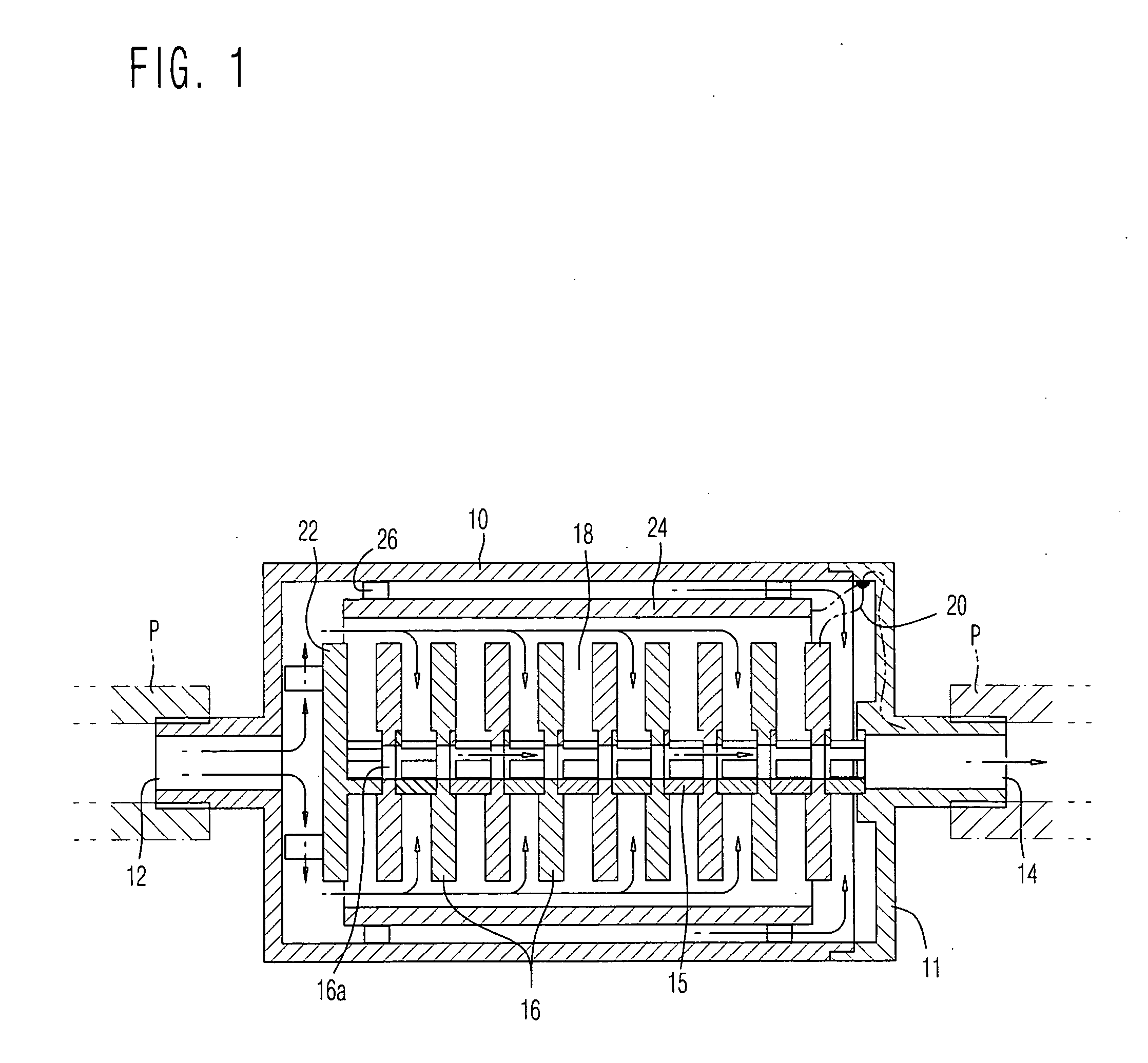

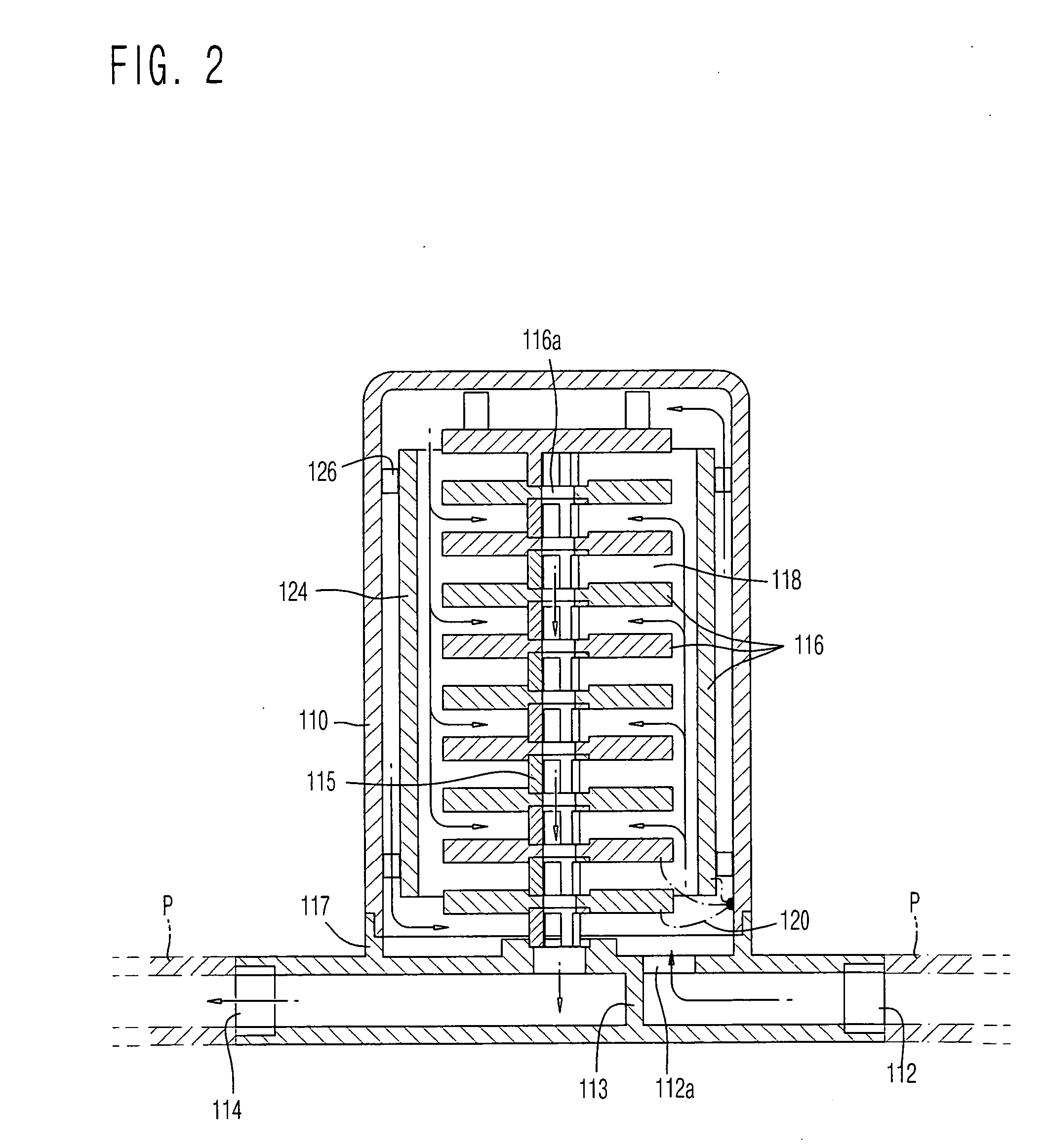

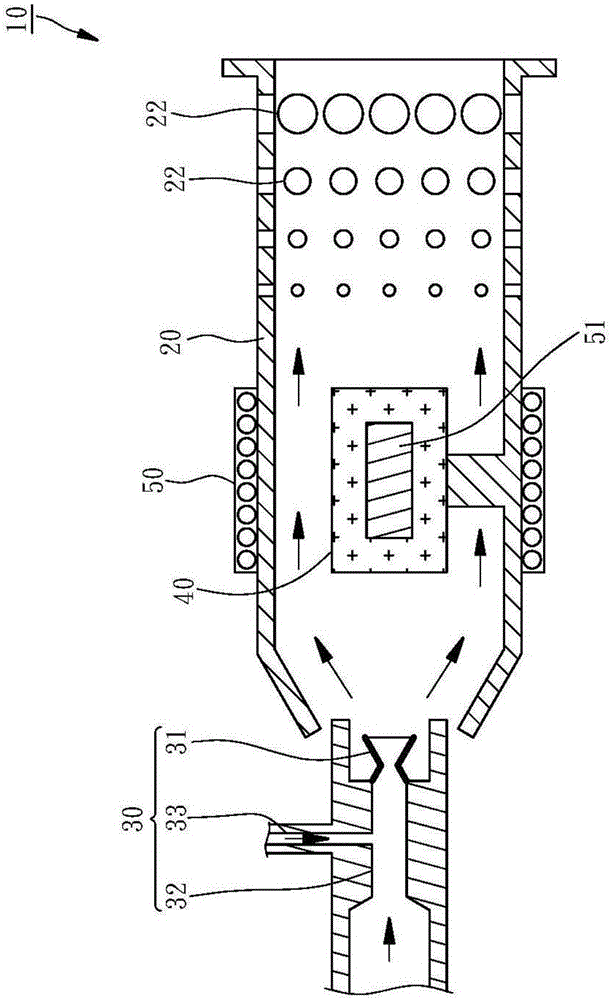

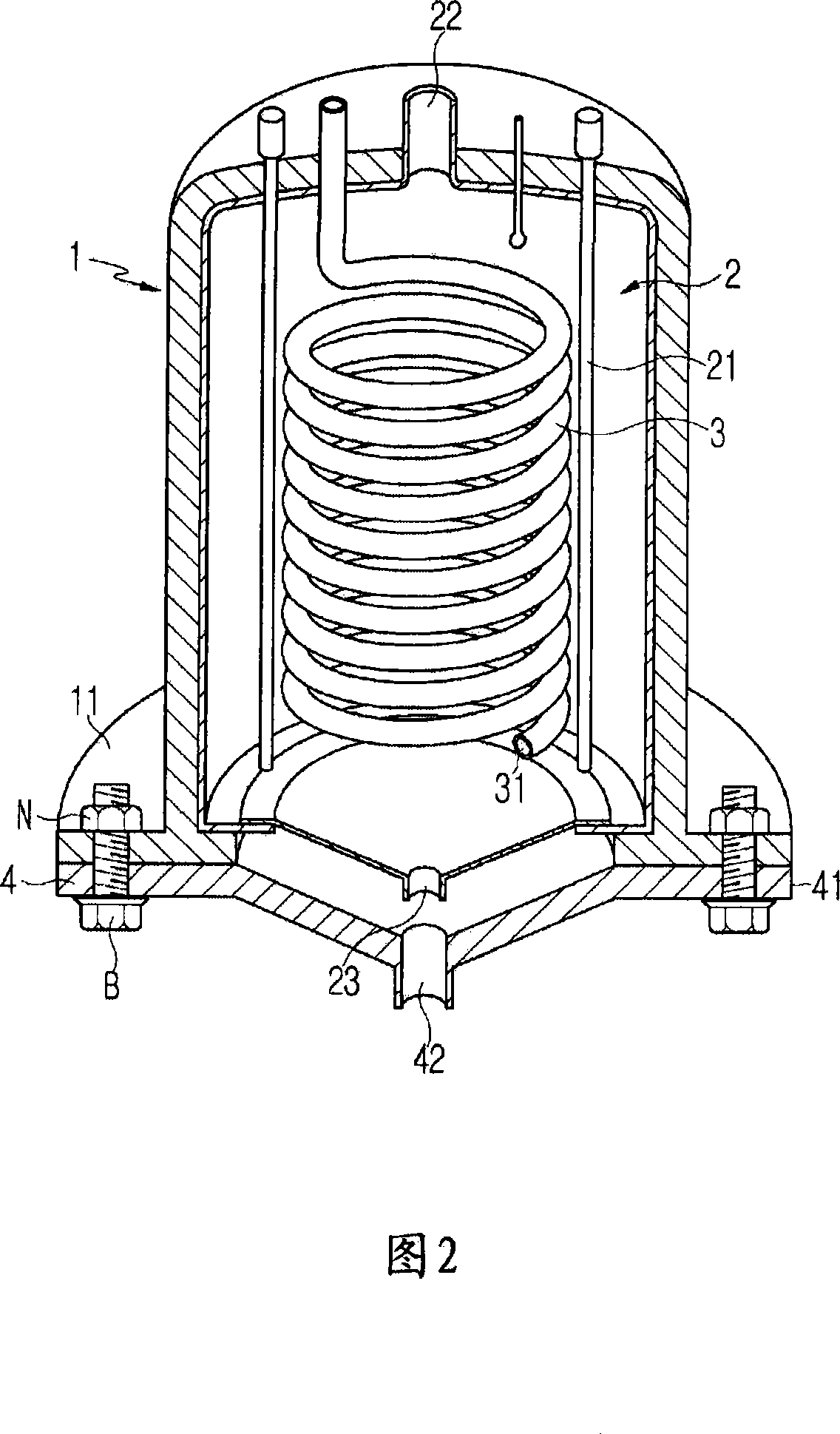

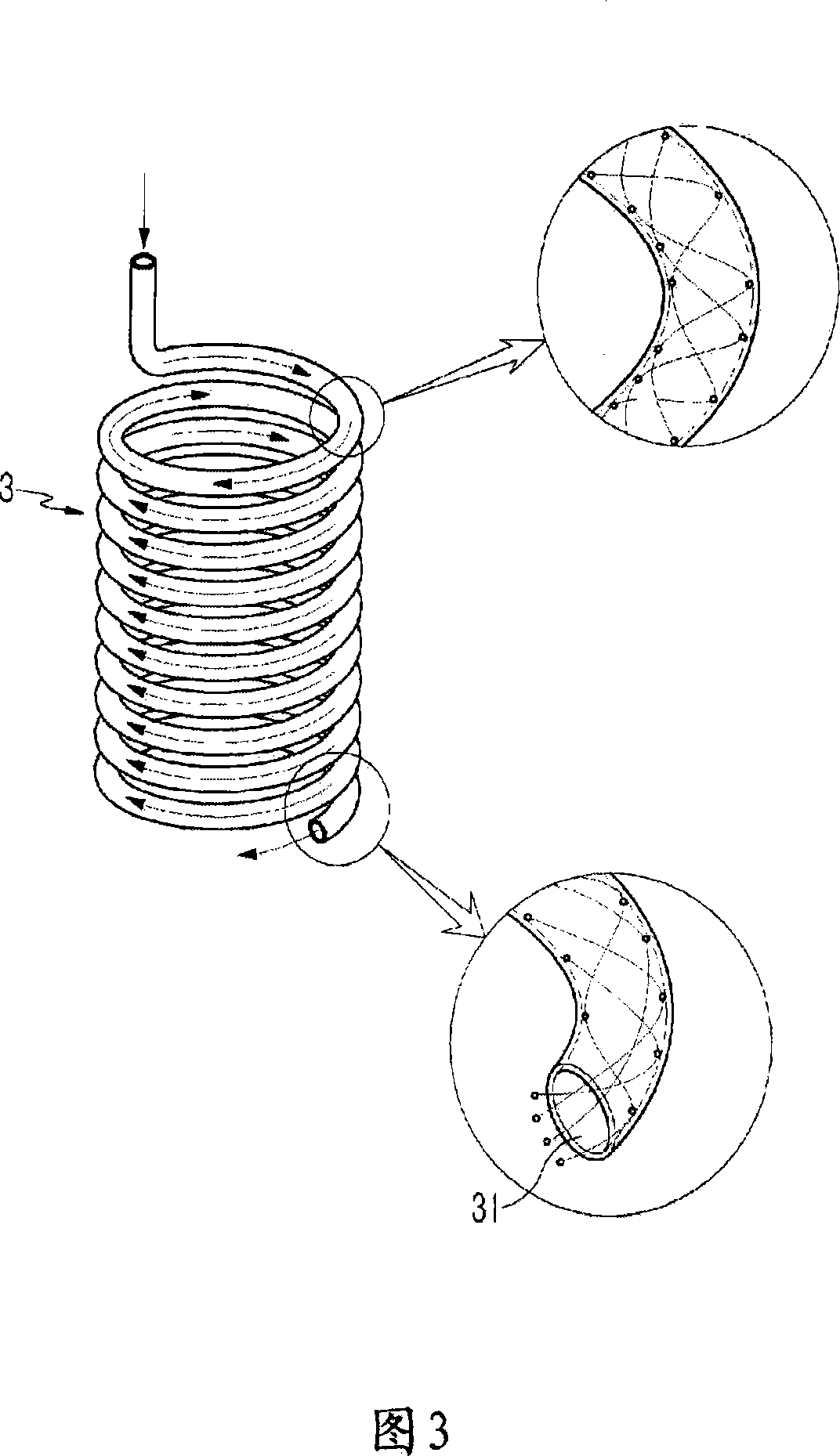

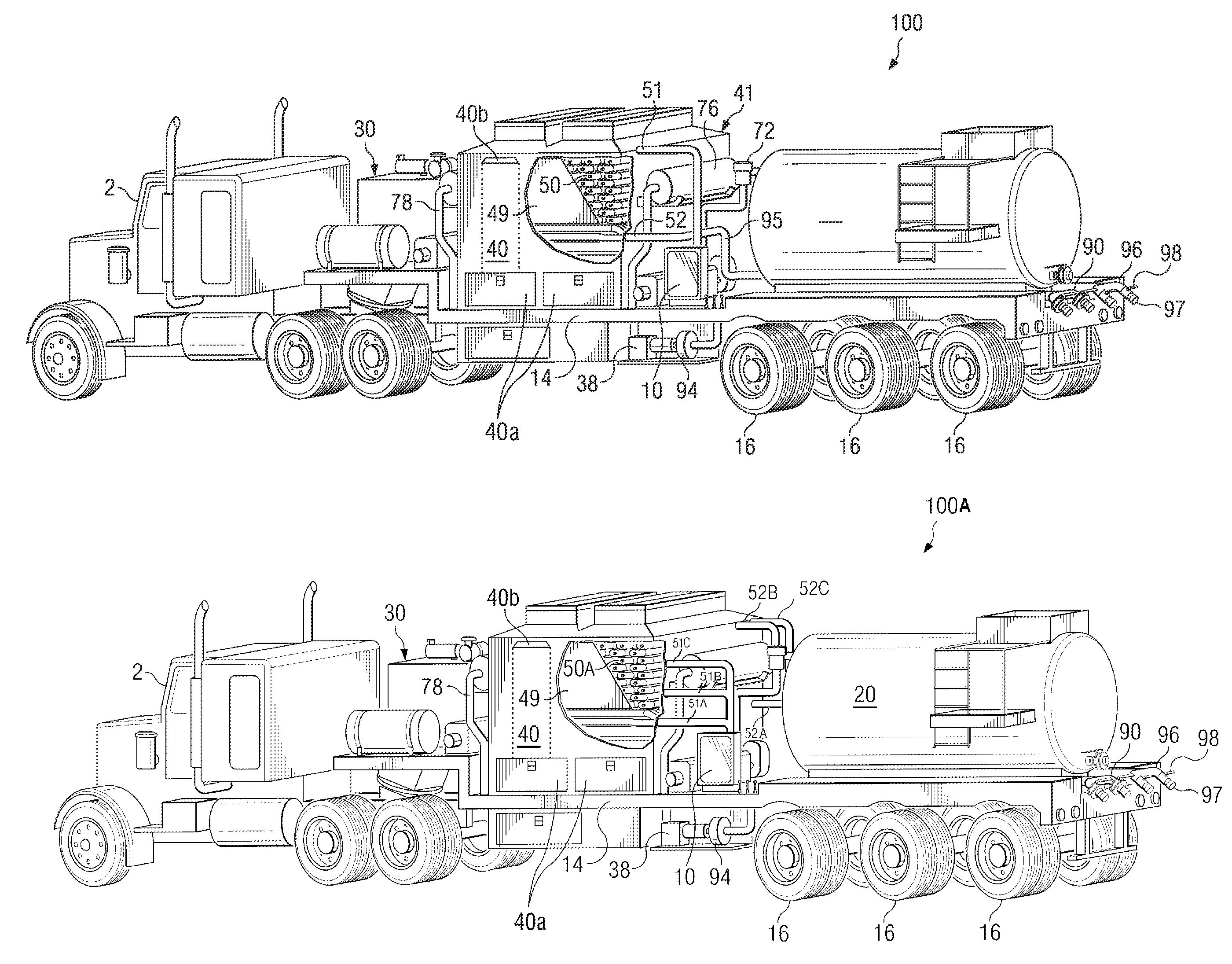

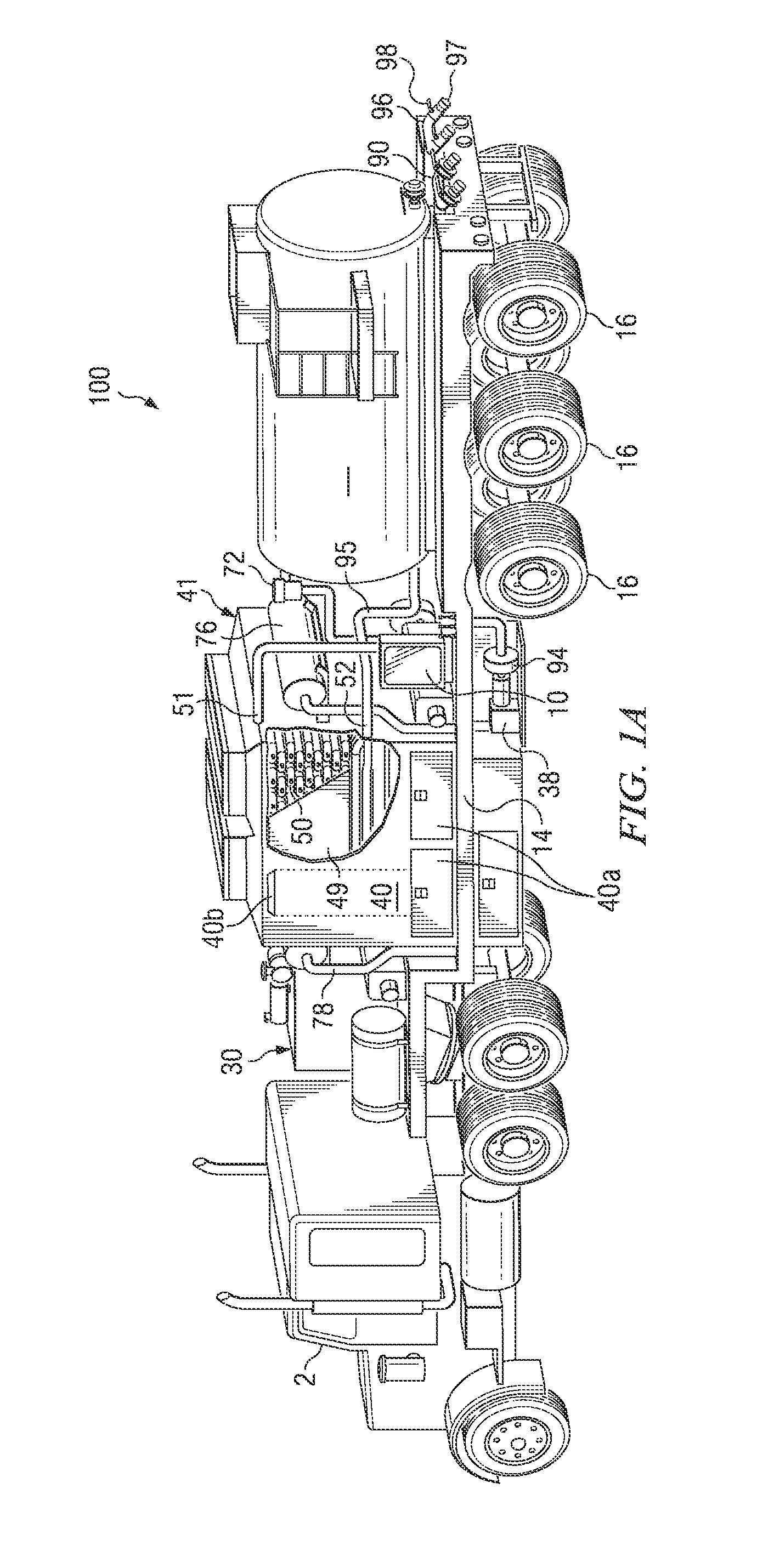

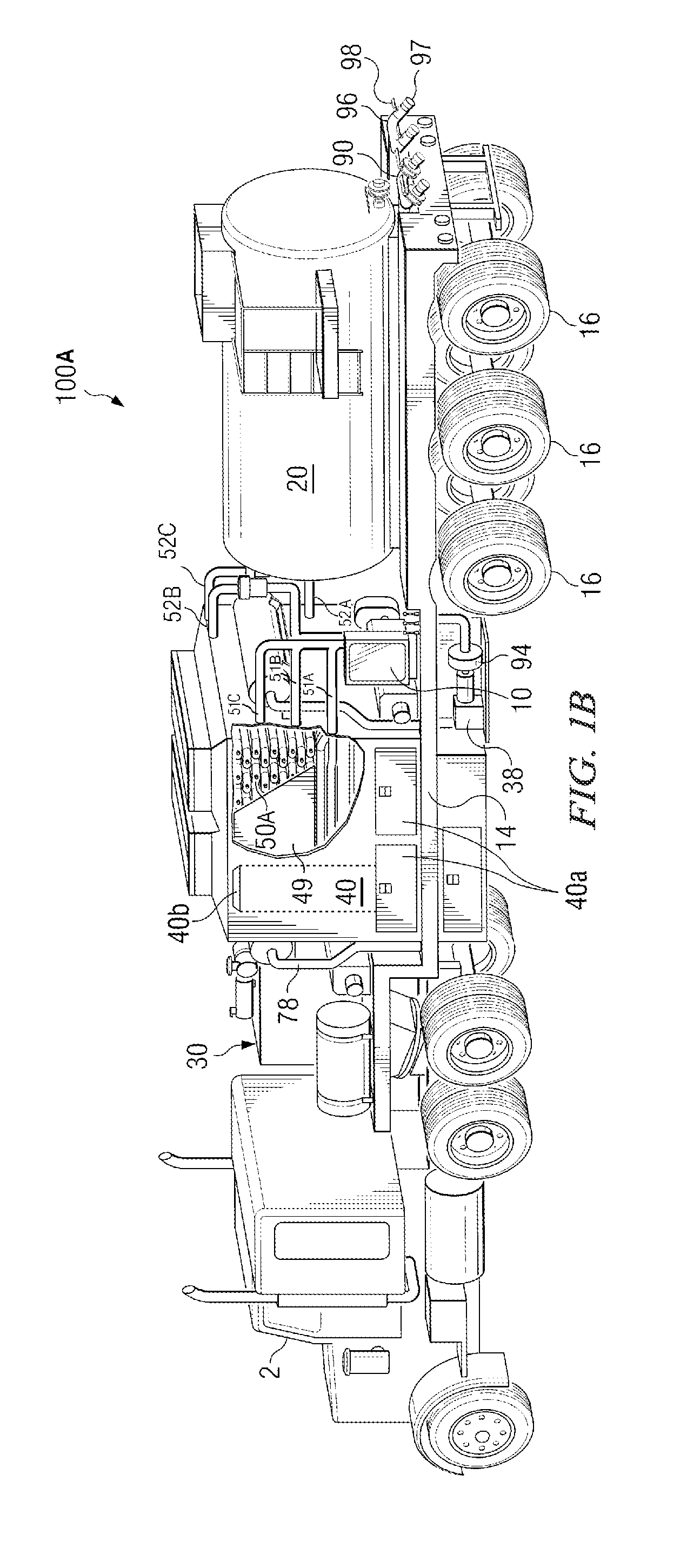

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an improved frac water heating system. The present invention is a self-contained unit which is easily transported to remote locations. In one embodiment, the present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. In another embodiment, the present invention includes multiple, single-pass heat exchanger units arranged in a vertically stacked configuration. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in all weather environments. In a preferred embodiment, the improved frac water heating system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

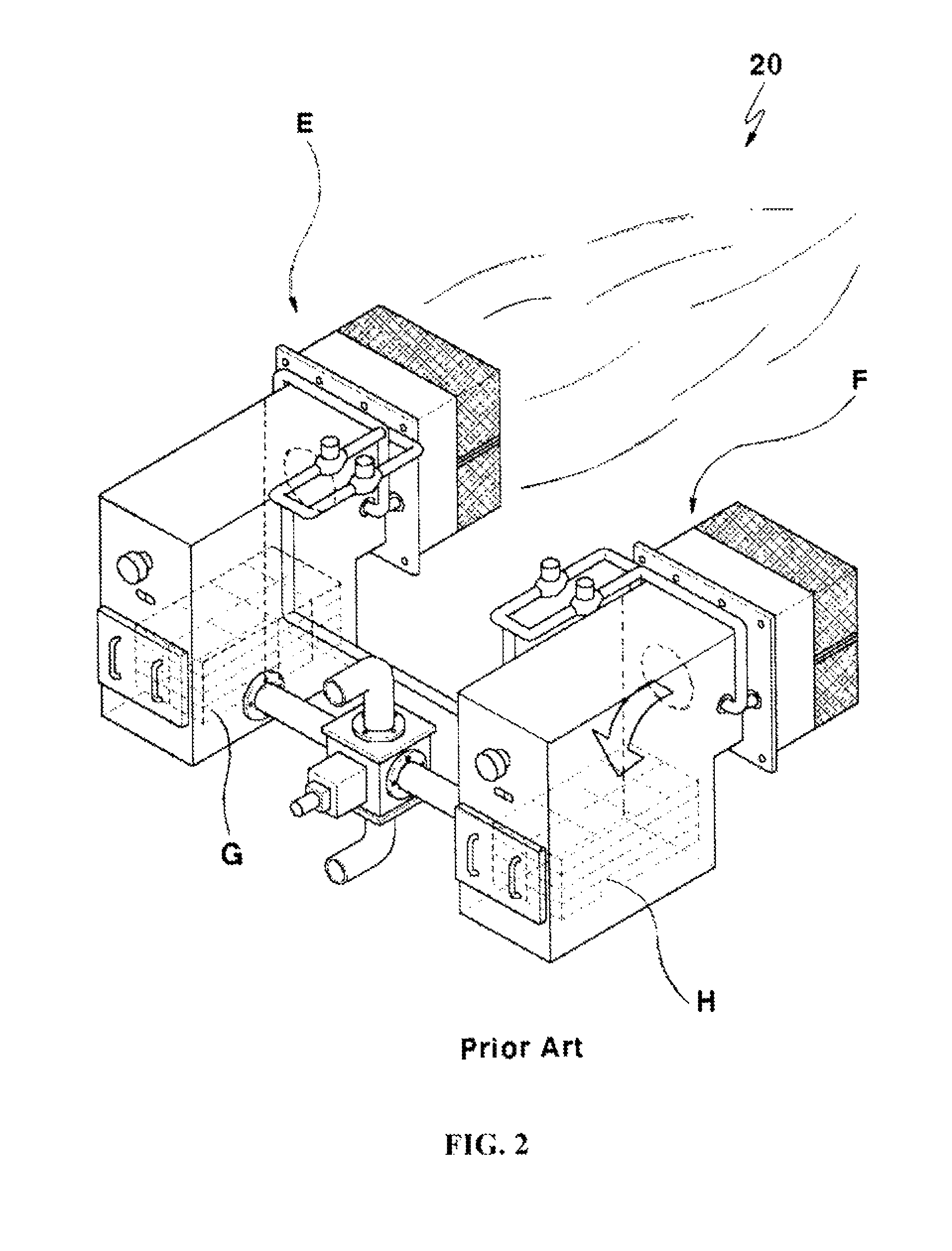

Oil-fired frac water heater

ActiveUS20100000508A1Maximize atomization and combustionMaximize combustionAir-treatment apparatus arrangementsAir heatersFuel tankEngineering

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an oil-fired heat exchange system. The present invention is a self-contained unit which is easily transported to remote locations. The present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in ail weather environments. In a preferred embodiment, the oil-fired heat exchanger system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

Oil-fired frac water heater

ActiveUS8534235B2Maximize atomization and combustionMaximize combustionAir-treatment apparatus arrangementsAir heatersFuel tankHydraulic fracturing

Owner:CHANDLER RONALD L

Frac water heater and fuel oil heating system

InactiveUS20130189629A1Maximize atomization and combustionMaximize combustionBurnersLiquid fuel feeder/distributionCombustion chamberFuel oil

An accessory heat exchanger unit for heating the fuel oil used by the frac oil heater system of the invention prior to combustion. The accessory heat exchanger unit receives and distributes the fuel oil through a plurality of heat exchanger tubes prior to directing the oil to the combustion chamber. The unit also includes an inlet for receiving heated treatment fluid from the frac water heater system of the present invention. The heated treatment fluid passes over the plurality of heat exchanger tubes of the accessory heat exchanger unit prior to being directed to the outlet of the accessory heat exchanger unit. By heating the fuel oil prior to combustion, the accessory heat exchanger unit greatly improves the viscosity and flow rate of the fuel oil, thereby allowing cheaper, less cold-tolerant grades of fuel oil to be used in extreme cold climates with no degradation in the operation of the frac water heater system of the present invention.

Owner:CHANDLER RONALD L

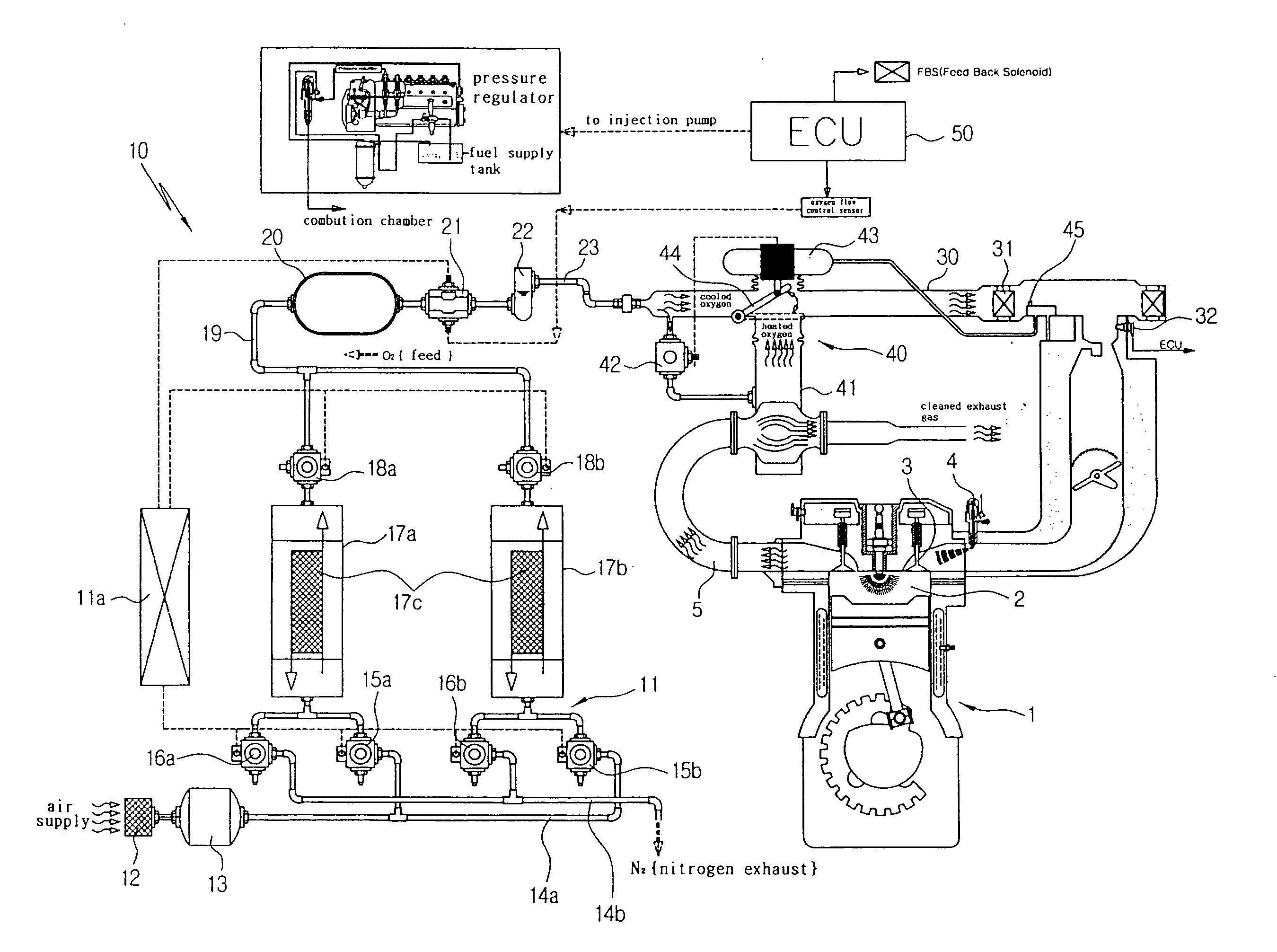

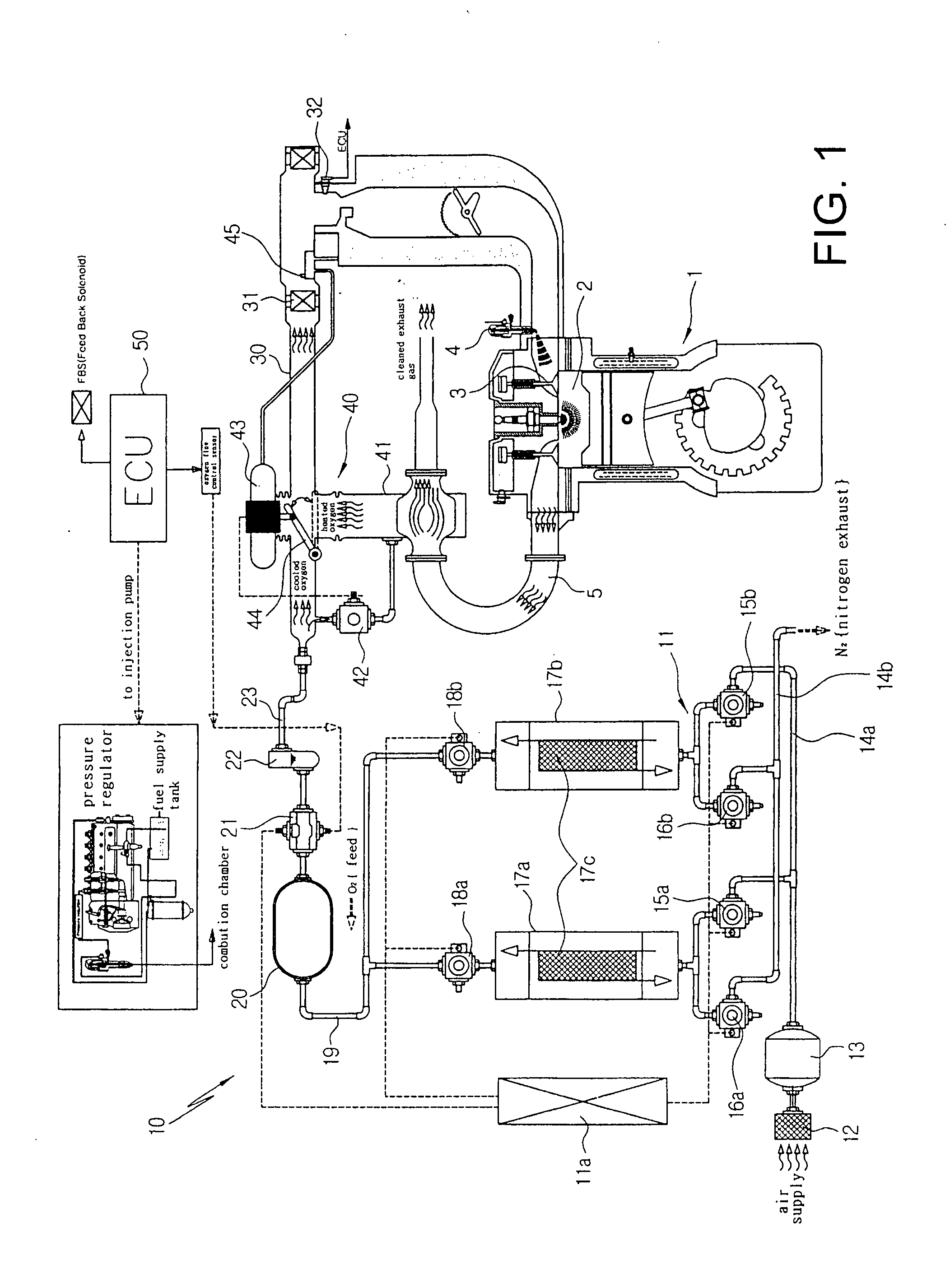

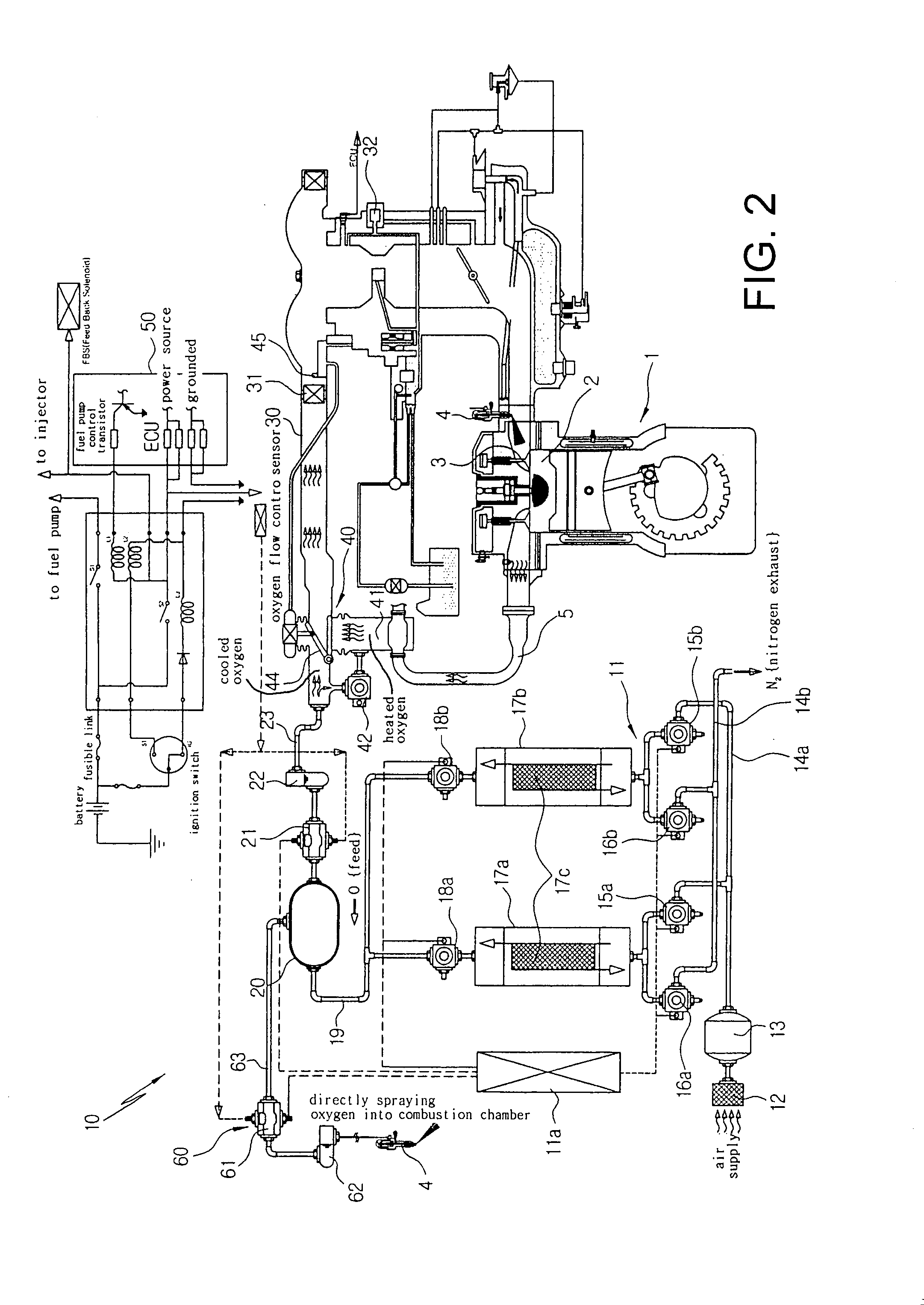

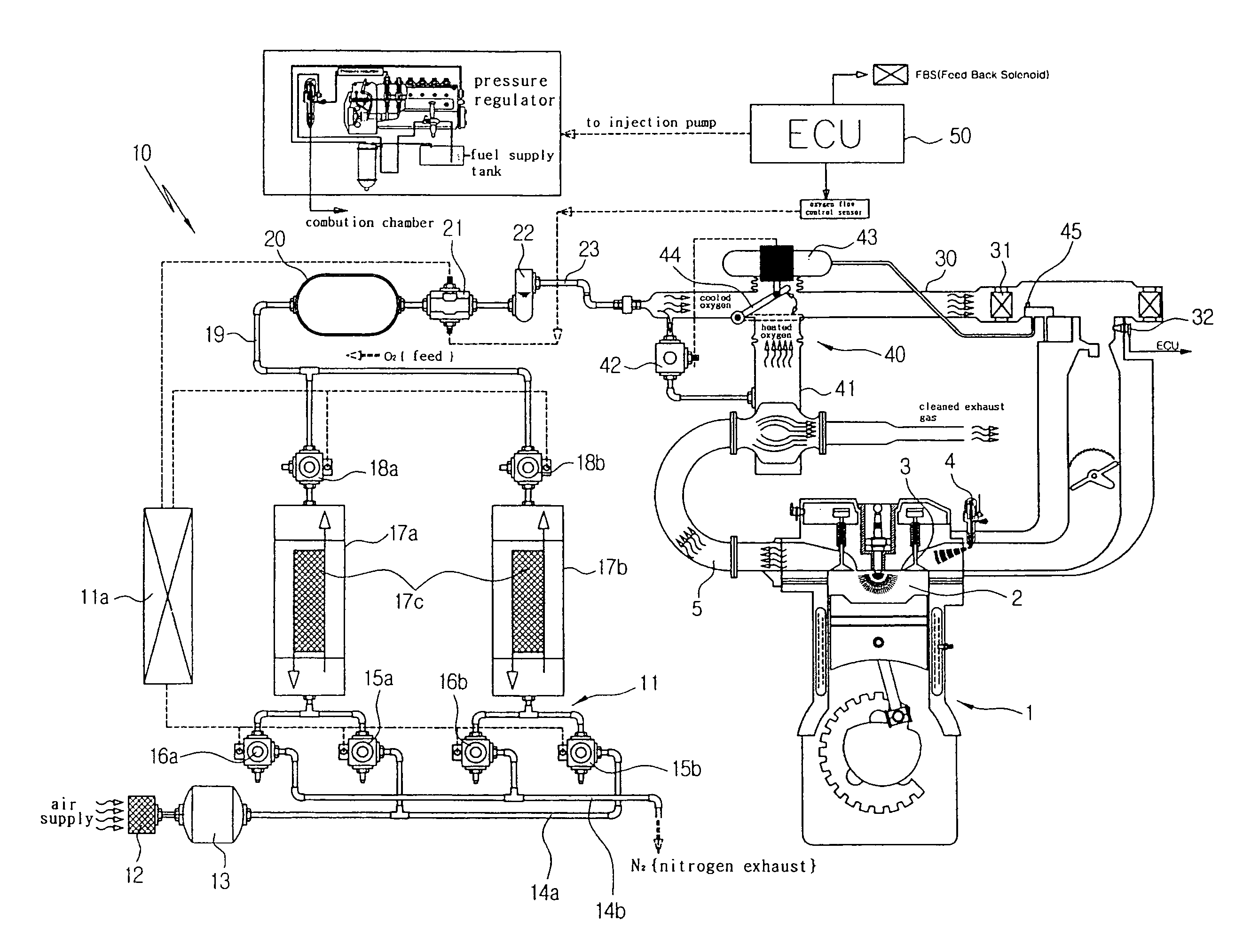

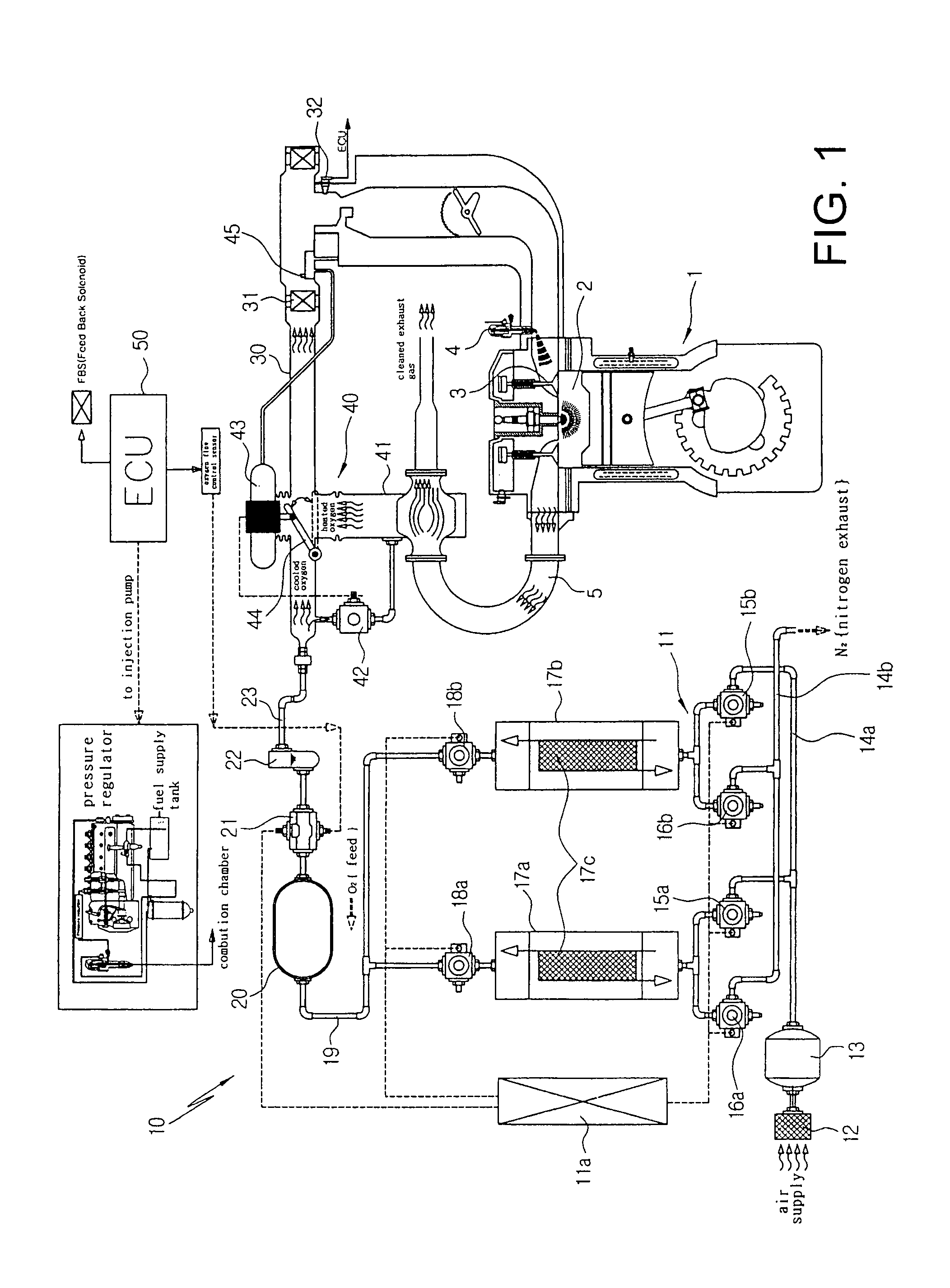

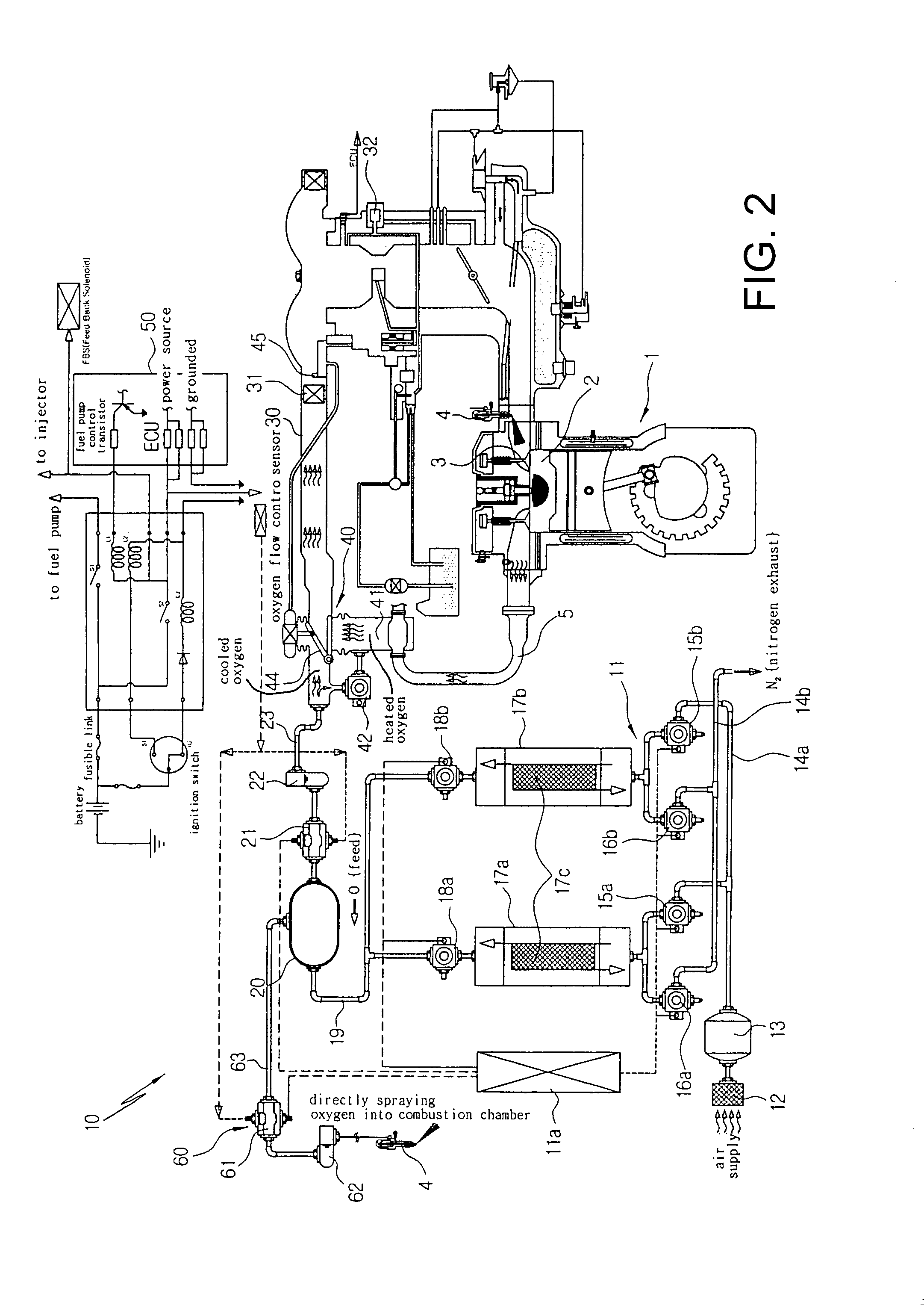

Low-Fuel Consumption and Low Pollution Combustion System for Supplying Vehicle Engine With Mixture of Fuel and Oxygen

InactiveUS20070266995A1Maximize combustion efficiencySave fuelElectrical controlInternal combustion piston enginesCombustion chamberEngineering

A low-fuel consumption and low-pollution combustion system supplies an engine with a mixture, in which oxygen contained in air is separated from nitrogen through a PSA (pressure swing adsorption) whereby oxygen having purity above 95% and a fuel mixture is fed into and burned in the combustion chamber obtaining a desired engine output with low-fuel consumption. Nitrogen is previously removed so that nitride oxide can be minimized during combustion procedure and CO and toxic gas derived from incomplete combustion can be minimized. The system obtains high engine output and low-fuel consumption by reducing toxic gas derived from incomplete combustion. The system includes an oxygen separator for separating oxygen from nitrogen by introducing external air into adsorption towers with predetermined pressure while storing the oxygen separated from the nitrogen in an oxygen storage tank and exhausting the nitrogen.

Owner:KOREA ENVIRONMENT TECH

Frac water heating system and method for hydraulically fracturing a well

InactiveUS20140144393A1Safely and continuously heatingMaximize atomization and combustionFluid removalHeat exchanger casingsCombustion chamberFuel tank

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an improved frac water heating system. The present invention is a self-contained unit which is easily transported to remote locations. In one embodiment, the present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. In another embodiment, the present invention includes multiple, single-pass heat exchanger units arranged in a vertically stacked configuration. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in all weather environments. In a preferred embodiment, the improved frac water heating system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

Low-fuel consumption and low pollution combustion system for supplying vehicle engine with mixture of fuel and oxygen

InactiveUS7543577B2Quantity minimizationMaximize combustion efficiencyElectrical controlInternal combustion piston enginesCombustion chamberNitrogen gas

A low-fuel consumption and low-pollution combustion system supplies an engine with a mixture, in which oxygen contained in air is separated from nitrogen through a PSA (pressure swing adsorption) whereby oxygen having purity above 95% and a fuel mixture is fed into and burned in the combustion chamber obtaining a desired engine output with low-fuel consumption. Nitrogen is previously removed so that nitride oxide can be minimized during combustion procedure and CO and toxic gas derived from incomplete combustion can be minimized. The system obtains high engine output and low-fuel consumption by reducing toxic gas derived from incomplete combustion. The system includes an oxygen separator for separating oxygen from nitrogen by introducing external air into adsorption towers with predetermined pressure while storing the oxygen separated from the nitrogen in an oxygen storage tank and exhausting the nitrogen.

Owner:KOREA ENVIRONMENT TECH

Frac water heating system and method for hydraulically fracturing a well

InactiveUS20140144394A1Safely and continuously heatingMaximize atomization and combustionFluid removalHeat exchanger casingsCombustion chamberFuel tank

The present invention overcomes many of the disadvantages of prior art mobile oil field heat exchange systems by providing an improved frac water heating system. The present invention is a self-contained unit which is easily transported to remote locations. In one embodiment, the present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system. In another embodiment, the present invention includes multiple, single-pass heat exchanger units arranged in a vertically stacked configuration. The rig also includes integral fuel tanks, hydraulic and pneumatic systems for operating the rig at remote operations in all weather environments. In a preferred embodiment, the improved frac water heating system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system includes a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

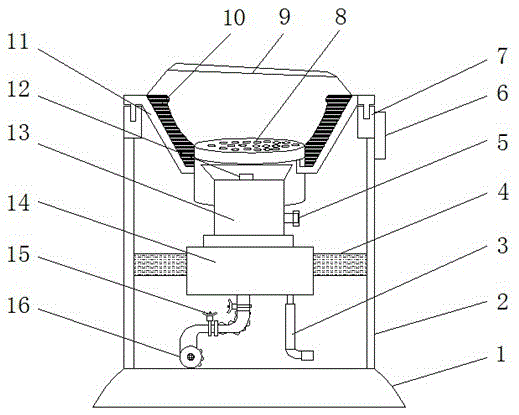

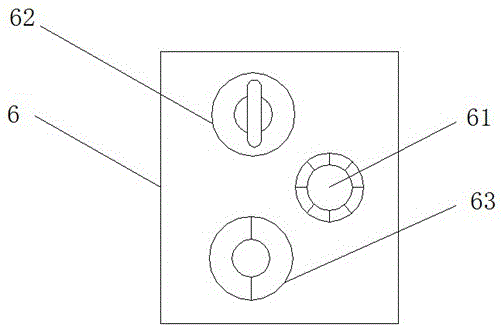

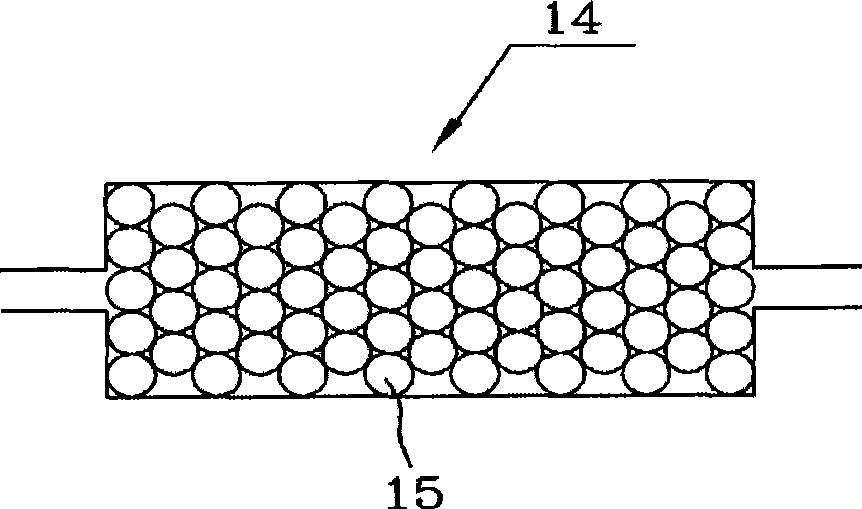

Fluid treatment apparatus

ActiveUS20070048199A1Maximize combustion efficiencyPrevent scalingCellsWater/sewage treatment by electrochemical methodsCircular discCombustion

Disclosed is a fluid treatment apparatus capable of maximizing a contact area between a fluid and an electrode in the apparatus to improve a performance such as corrosion resistance and combustion efficiency The fluid treatment apparatus includes a housing having an inlet port and an outlet port for the water at both ends of the housing, and at least one first electrode installed in the housing for generating a potential difference through delivery of electrons at a contact surface between the fluid and the electrode, in which the first electrode is formed in a disc shape, and has a water passing hole formed in a center portion of the first electrode, and in which the first electrodes are arranged in parallel in a direction perpendicular to a main flow direction of the fluid, so as to form a channel between the first electrodes to branch and guide a main flow.

Owner:LEE SANG JIN

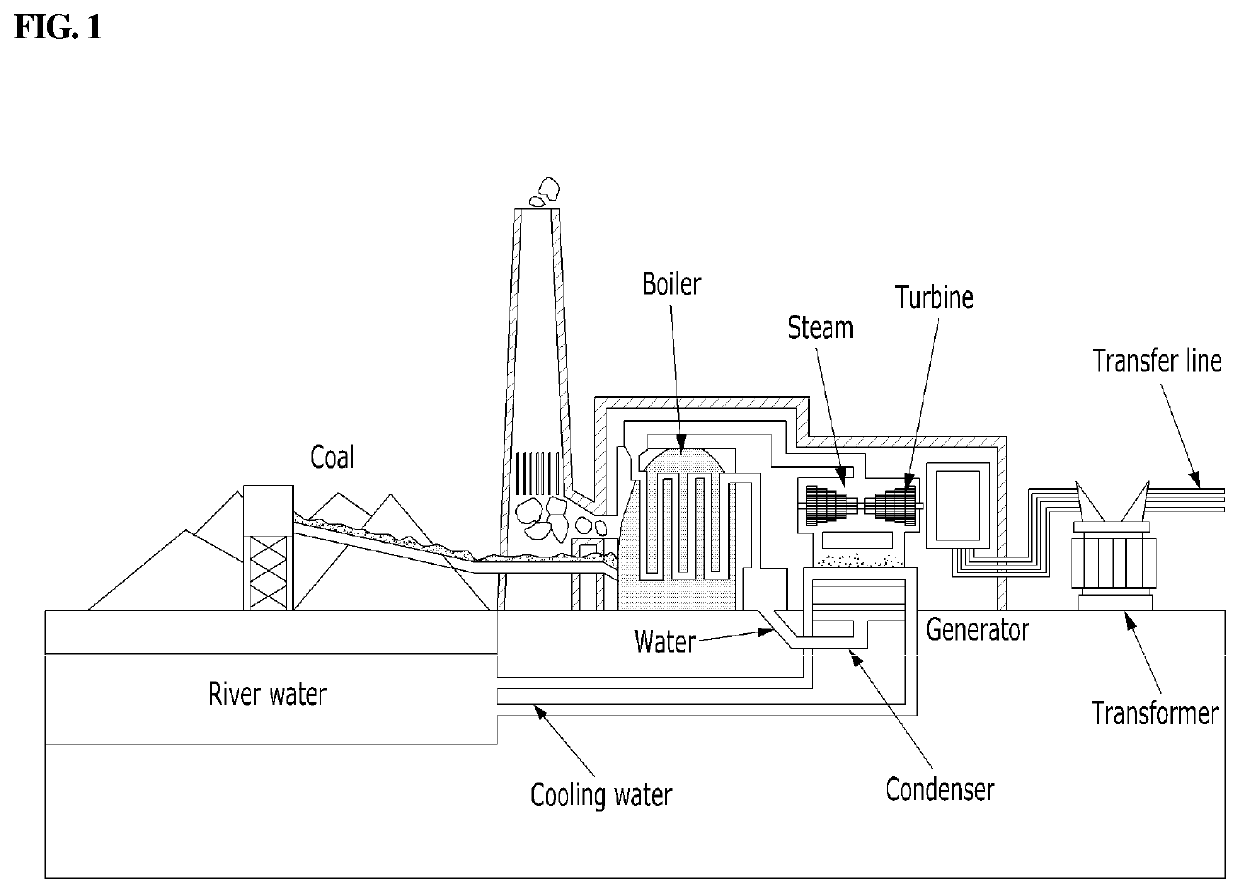

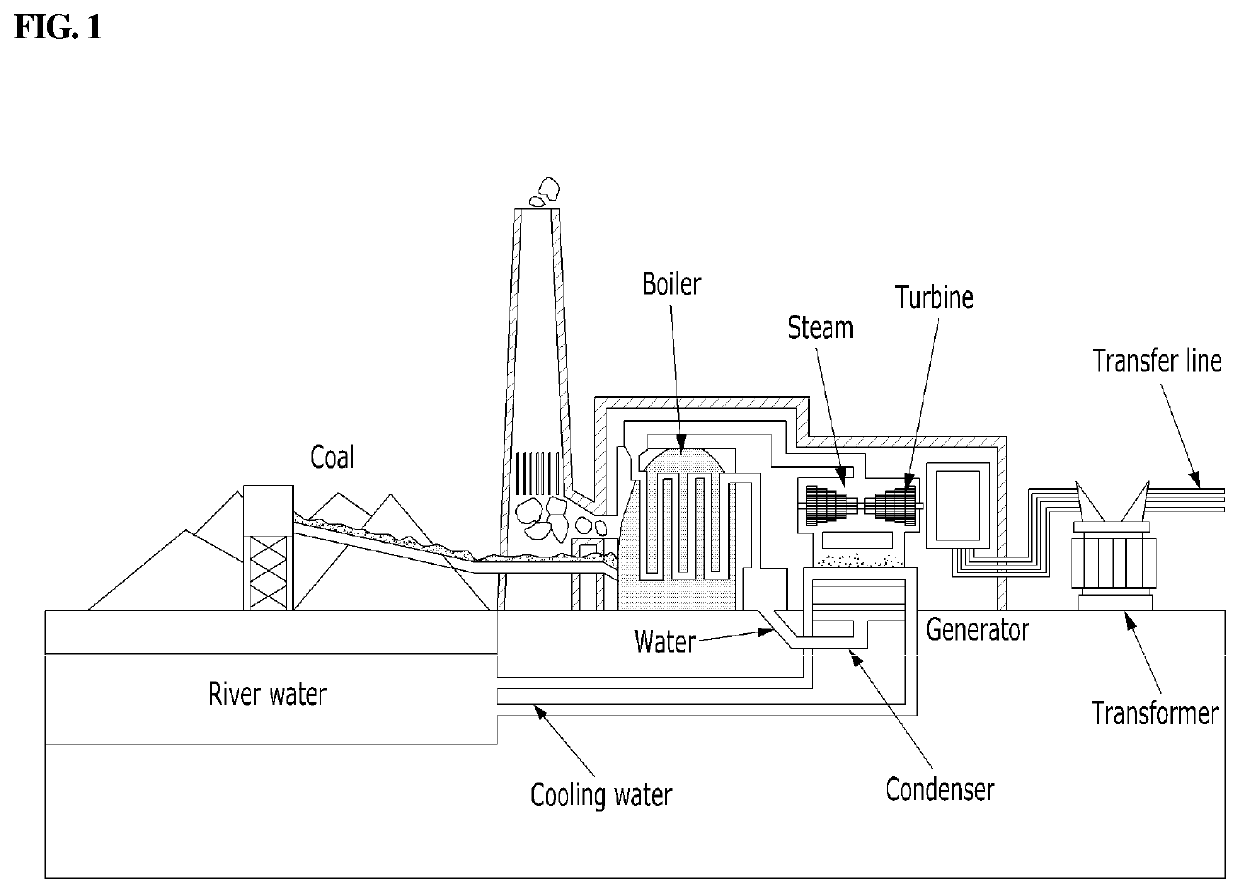

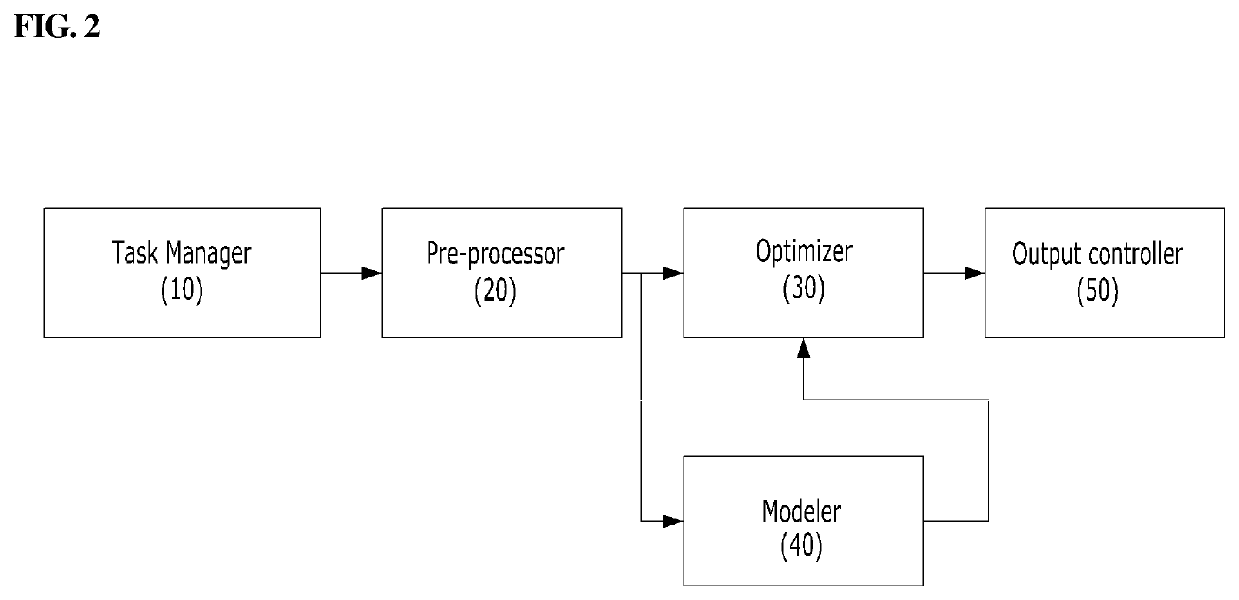

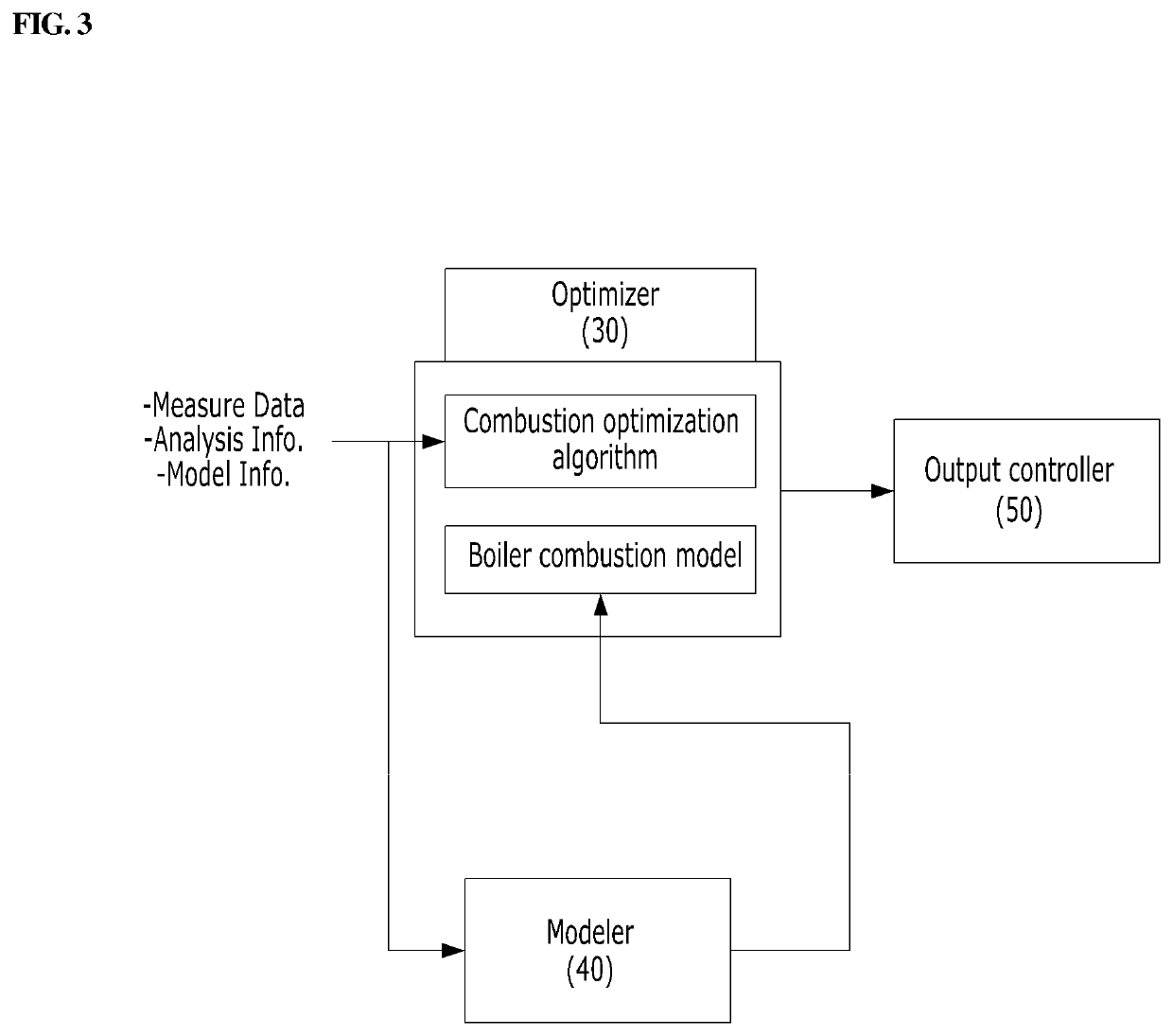

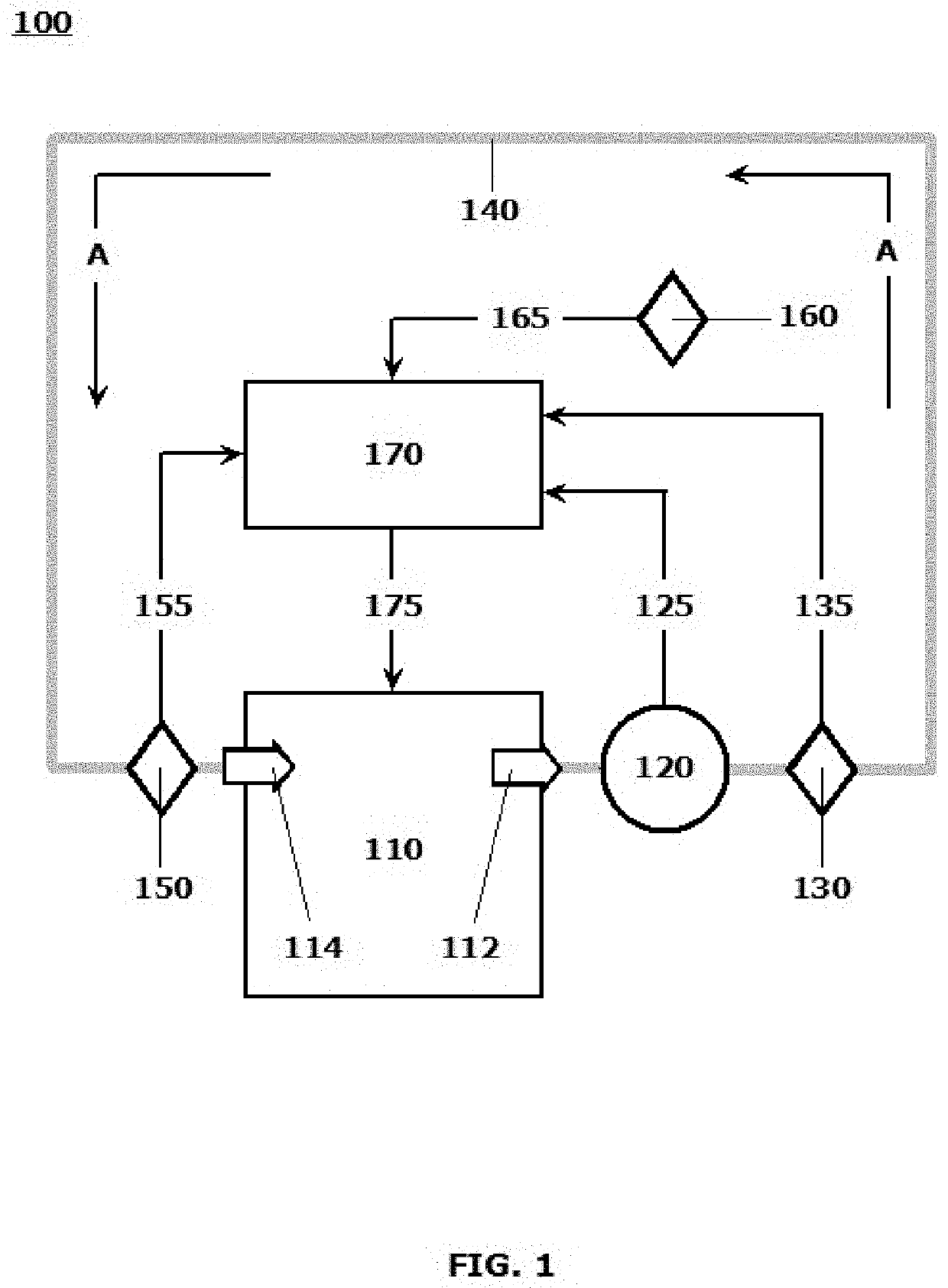

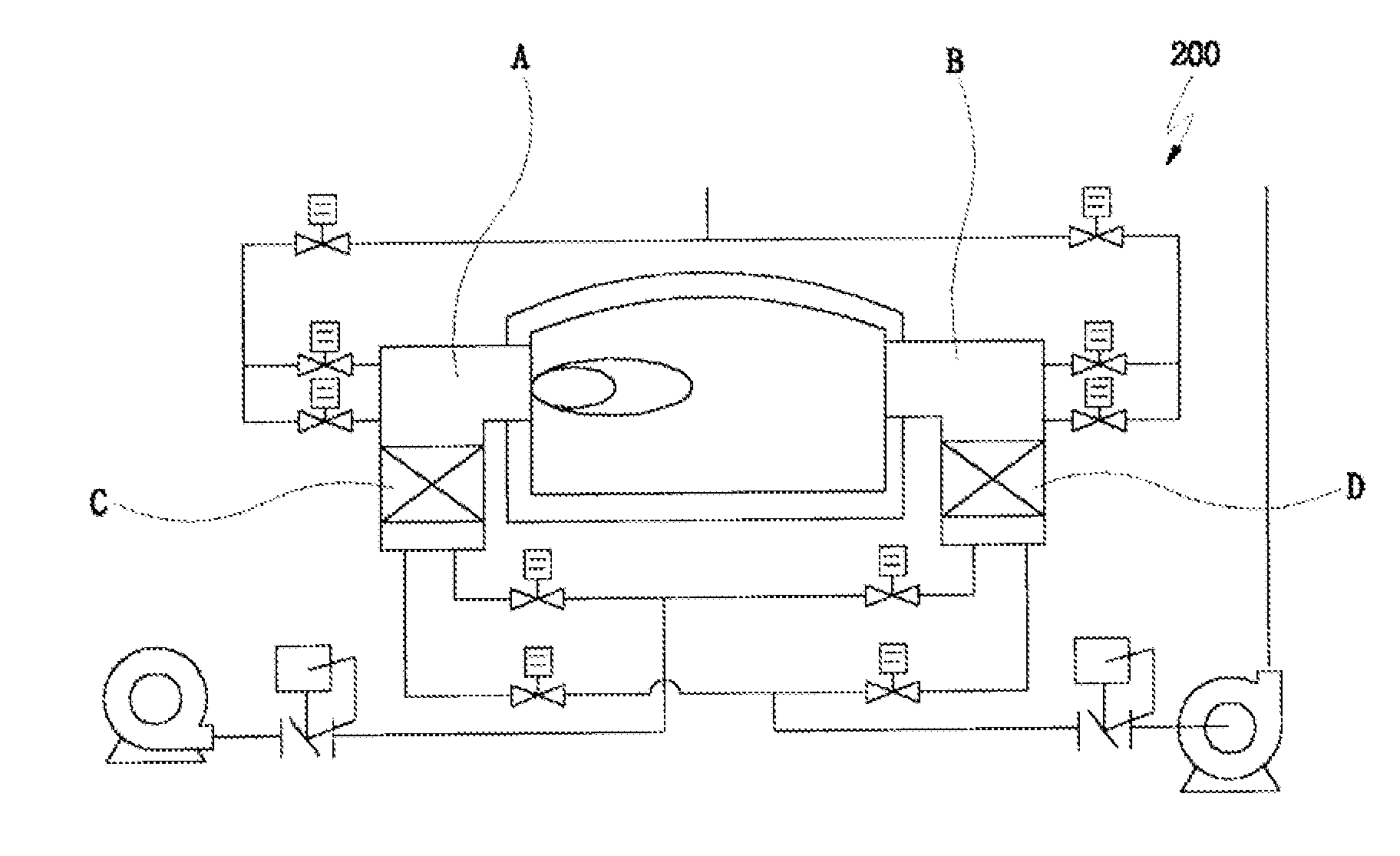

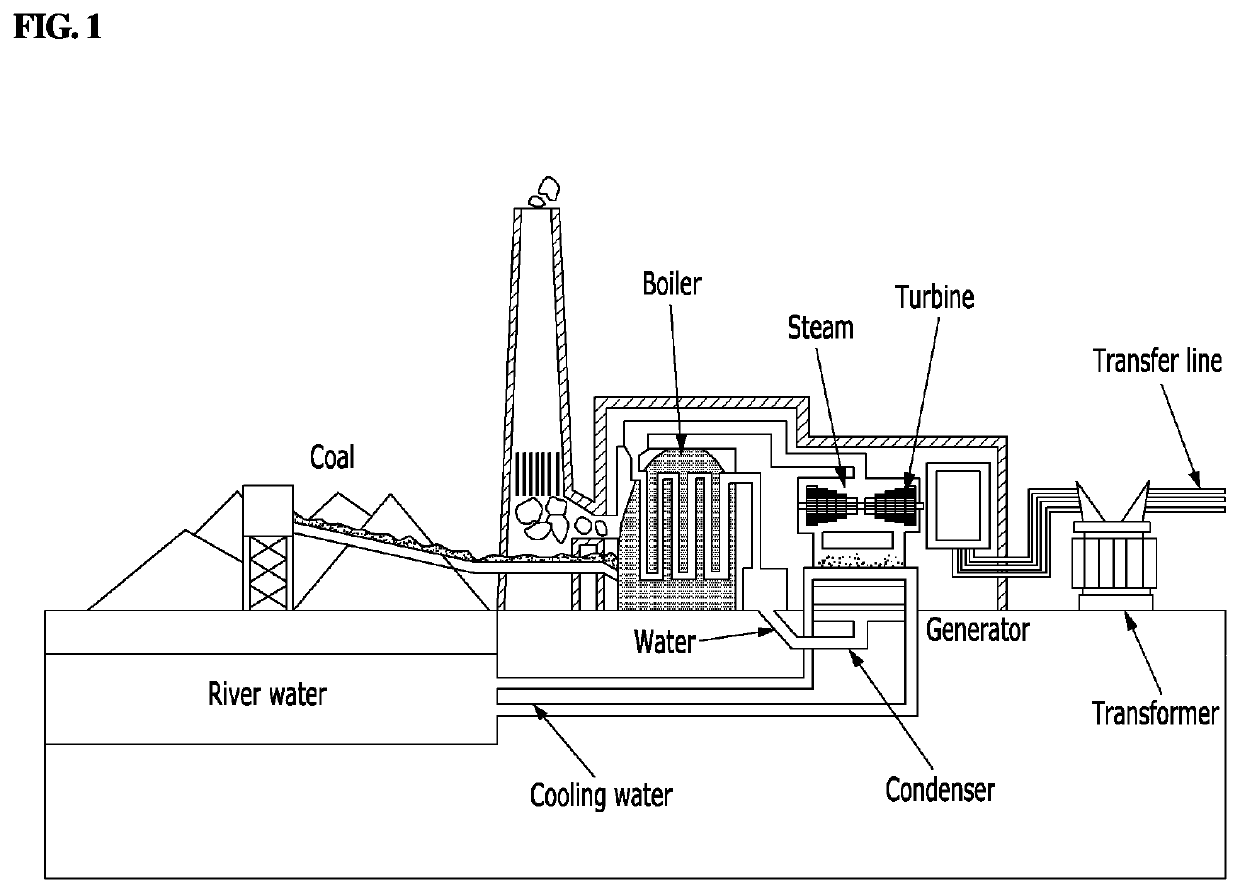

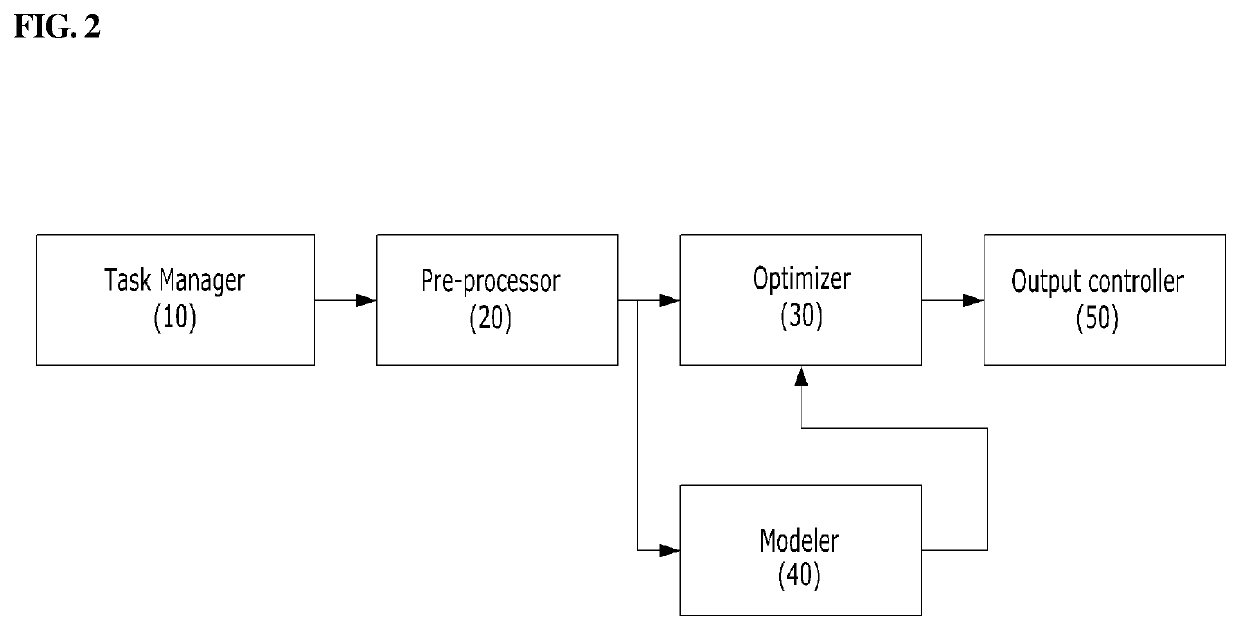

System and method for optimizing combustion of boiler

ActiveUS20200175435A1Maximize combustion efficiencyMinimizationSimulator controlForecastingPower stationData modeling

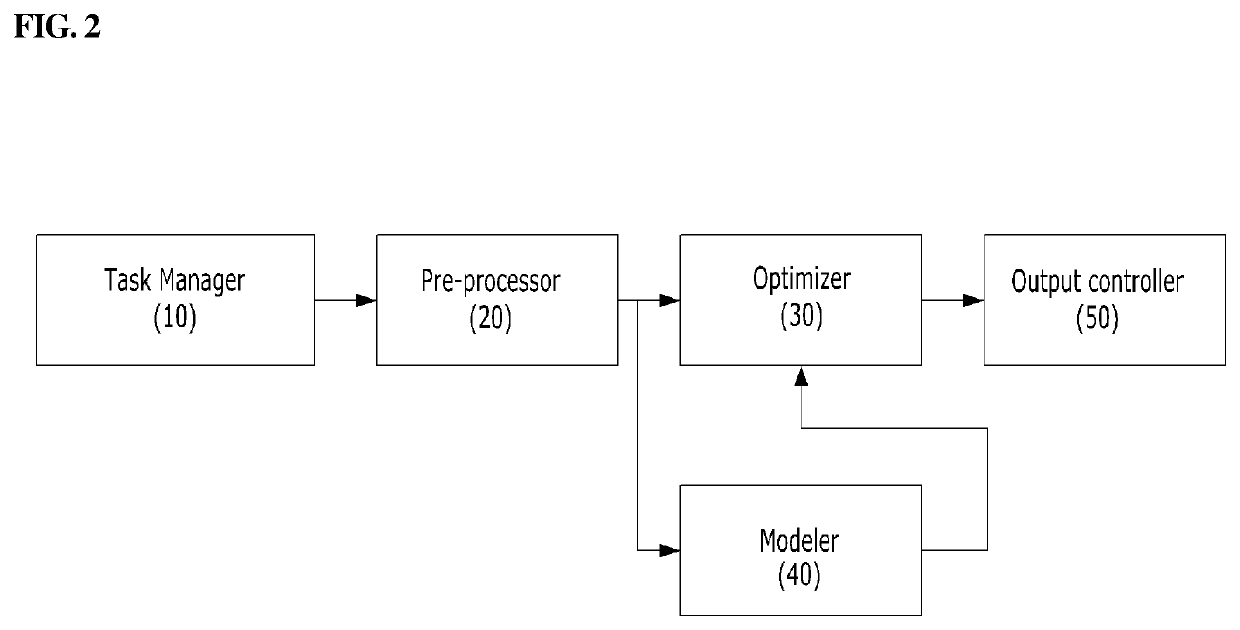

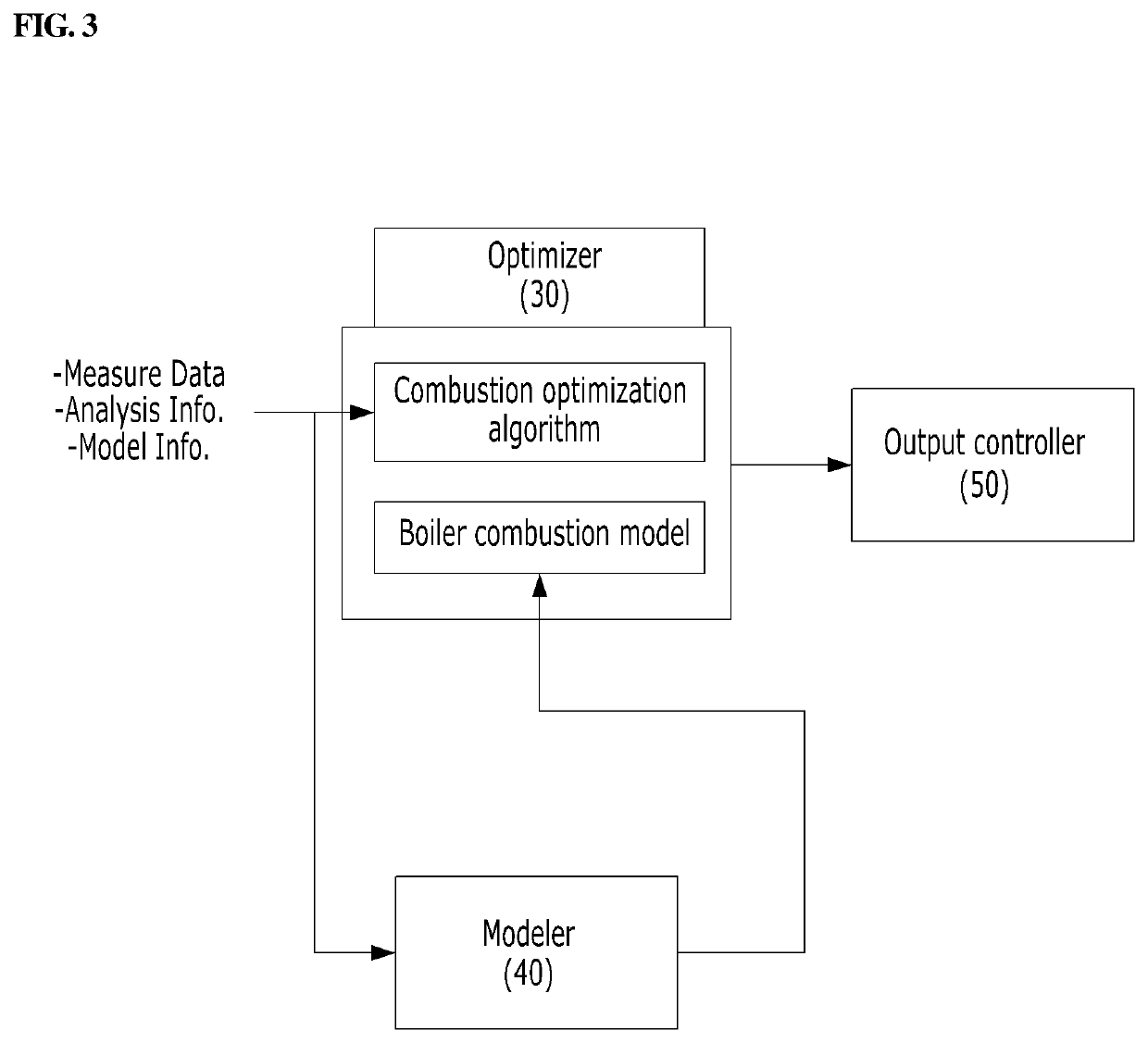

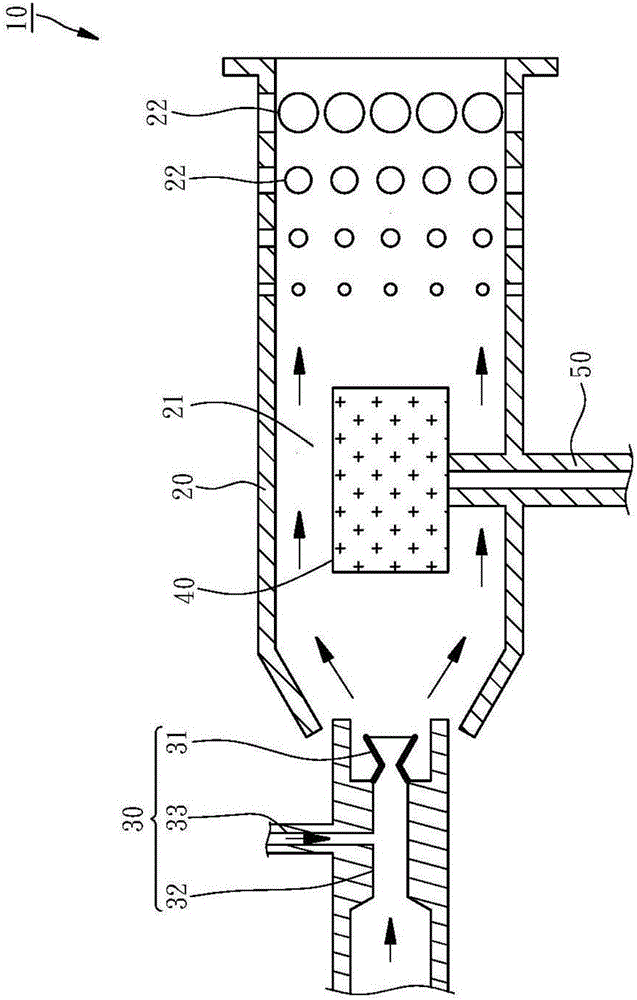

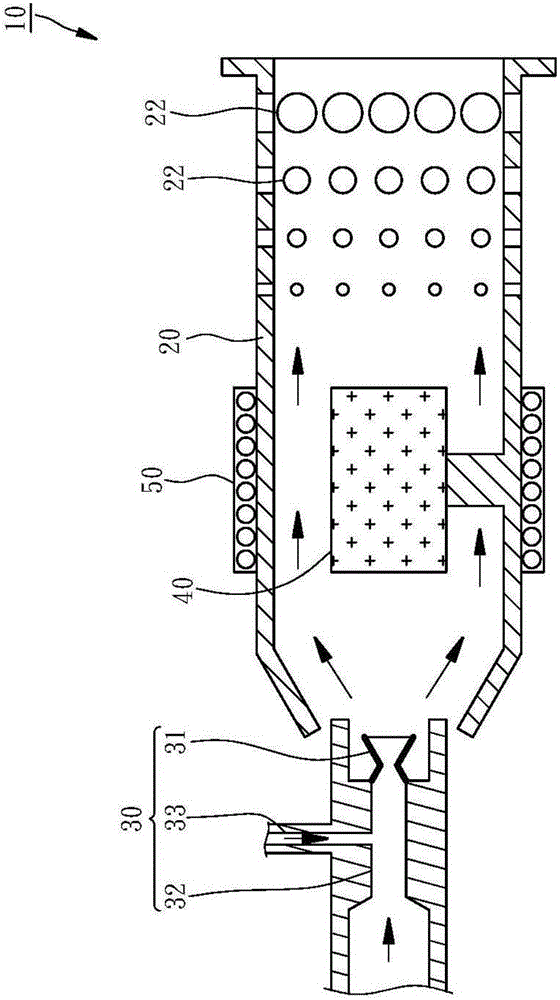

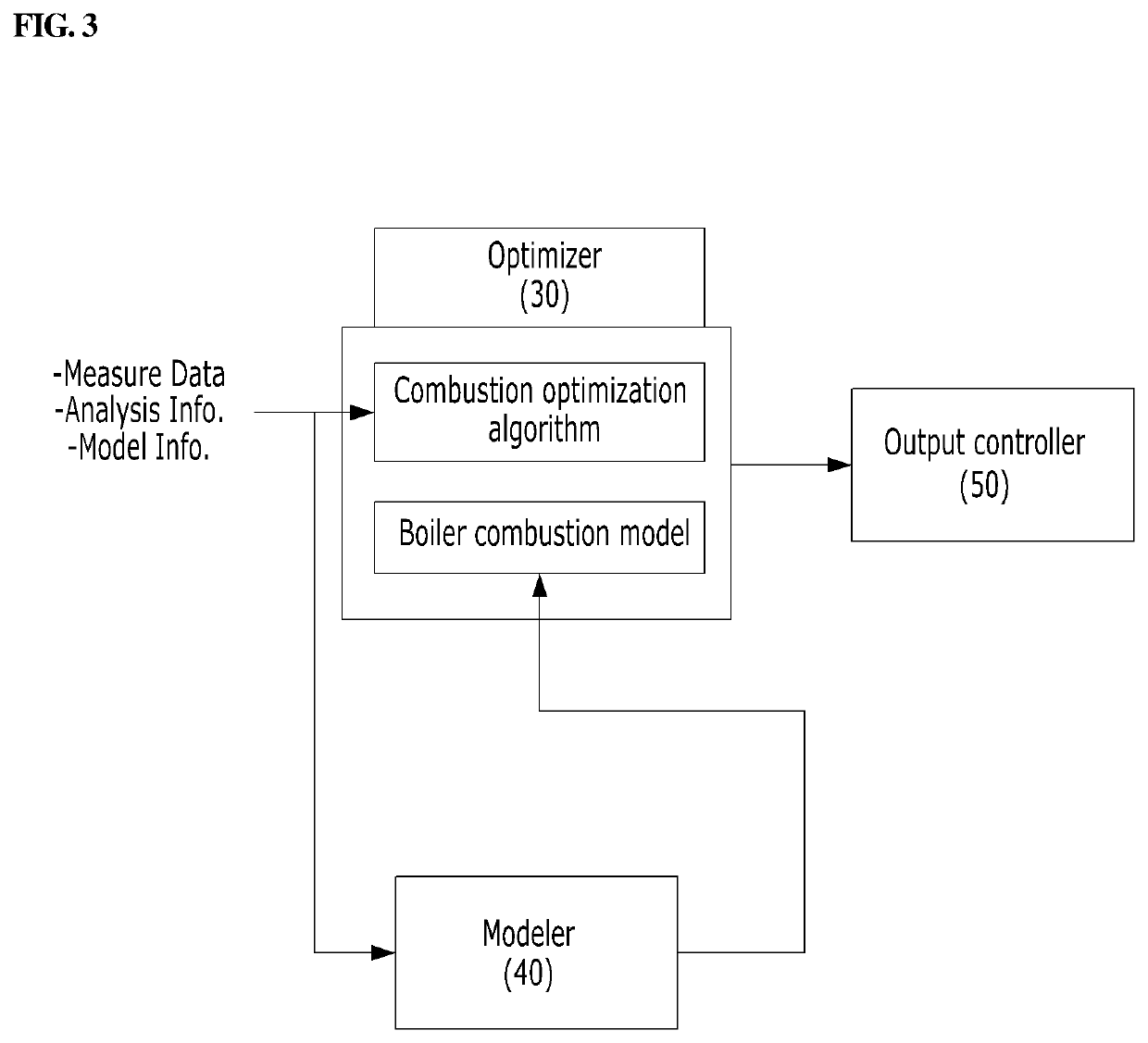

A system for controlling a boiler apparatus in a power plant to combust under optimized conditions, and a method for optimizing combustion of the boiler apparatus using the same are provided. The boiler control system may include a task manager configured to collect information on a current operating state of a boiler and determine whether to perform a combustion optimization operation for the boiler, a pre-processor configured to preprocess data collected from the boiler and supply the pre-processed data, a modeler configured to create a boiler combustion model on the basis of the pre-processed data received from the pre-processor, an optimizer configured to receive the boiler combustion model from the modeler and perform the combustion optimization operation for the boiler using the boiler combustion model to calculate an optimum control value, wherein the pre-processed data is supplied to the modeler and the optimizer by the pre-processor, and an output controller configured to receive the optimum control value from the optimizer and control an operation of the boiler by reflecting the optimum control value to a boiler control logic.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Combustion apparatus capable of controlling temperature of output heat source

InactiveCN106257138AMaximize combustion efficiencyCombustion efficiency, energy saving and environmental protectionBurnersTemperature resistanceHigh energy

The invention relates to a combustion apparatus capable of controlling the temperature of an output heat source. The combustion apparatus includes an igniter which is made from a high temperature resistance material having a high-energy density and is arranged in a first combustion chamber, a heating unit which is arranged outside the first combustion chamber and is used to heat the igniter to allow the temperature of a surface of the igniter to be higher than a fire point of an atomized fuel; a mixer which is arranged on the outer periphery of the first combustion chamber, has a second combustion chamber arranged on the outer periphery of a flame outlet of the first combustion chamber, and is used for supplying gas. Accordingly, the atomized fuel can contact the surface of the igniter in the first combustion chamber, and is ignited and combusts instantly, and then the atomized fuel enters the second combustion chamber, the vaporization of the fuel is completed, the combustion efficiency is maximized, and the temperature of the output heat source is adjusted through a gas supplying action of the mixer.

Owner:NAT CHIN YI UNIV TECH +1

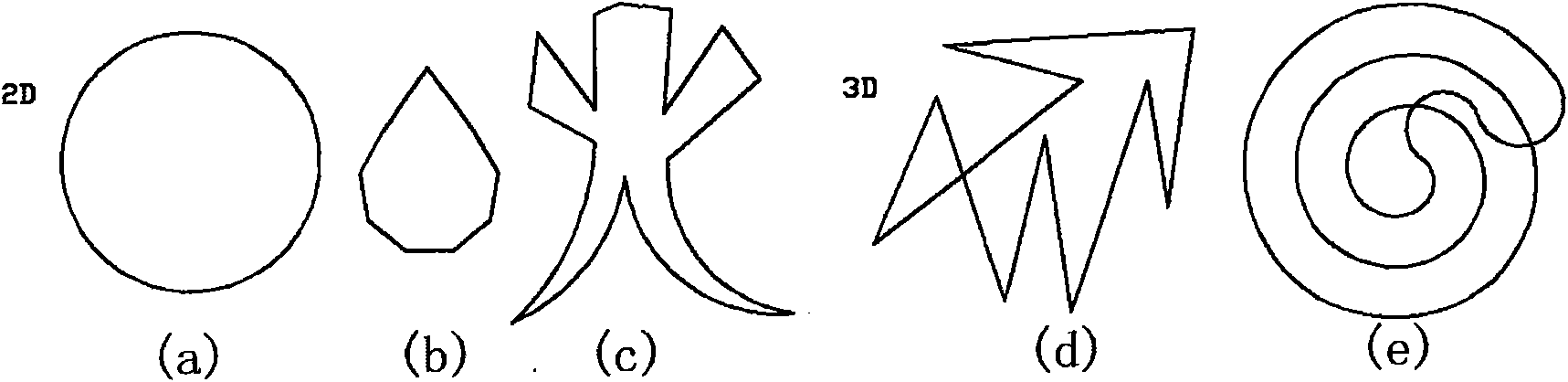

Gas Combustion Arrangement Using Circular Stream

InactiveUS20080196640A1Maximize combustion efficiencySuppressing environmentalSolid fuel combustionIncinerator apparatusGas passingProcess engineering

Disclosed is a gas combustion arrangement using a circular stream, which is capable of fully burning gas discharged from waste incinerated (by flame-broiling, high-temperature, thermal decomposition, etc.) in an incinerator provided at a front stage of the gas combustion arrangement by passing the discharged gas through a coil-shaped circular combustion pipe heated at a predetermined temperature.The present invention provides a gas combustion arrangement using a circular stream, which is capable of maximizing a combustion efficiency by prolonging stay of discharged gas, which is introduced through a coil-shaped combustion pipe, inside the gas combustion arrangement as the discharged gas is burned, forming a circular stream, inside and outside the coil-shaped combustion pipe, and burning the discharged gas through direct contact with internal and external surfaces of the combustion pipe with high temperature.

Owner:MEDEXPIA

Combustion pursuing device

InactiveCN101776029AShorten exhaust timeImprove the condition of the exhaustRocket engine plantsAviationCombustion

The invention relates to a combustion pursuing device, which comprises a closed pipeline body, barriers and ignition devices, wherein the barriers inside the pipeline body divide the pipeline body into a plurality of division areas; one-way air intake pipelines are connected into the pipeline body from the wall surface of the pipeline body; a premixed fuel is sprayed into each division area of the pipeline body through each one-way air intake pipelines; different positions in the pipeline body are provided with one or more groups of the ignition devices which are used for igniting the premixed fuel for combustion, and a plurality of groups of ignitions can be synchronous or asynchronous; the wall surface of each division area of the pipeline body is provided with flame outlets which are used for outputting flames and exhausting burnt gasses and can output one ro more groups of the flames. The combustion pursuing device has a simple structure and strong functions, can meet requirements on high-frequency and high-energy ignitions, and overcomes the difficulties in continuous ignition and the conversion from deflagration to detonation, and simultaneously the arrangement of the flame outlets can hardly be influenced by geometrical factors and has flexibility beyond comparison. The combustion pursuing device can be used as an ignition device and a device which needs high-frequency and high-energy ignition of a pulse detonation engine, and is applied in the fields of electric power, motive power or aerospace and the like.

Owner:SHANGHAI UNIV

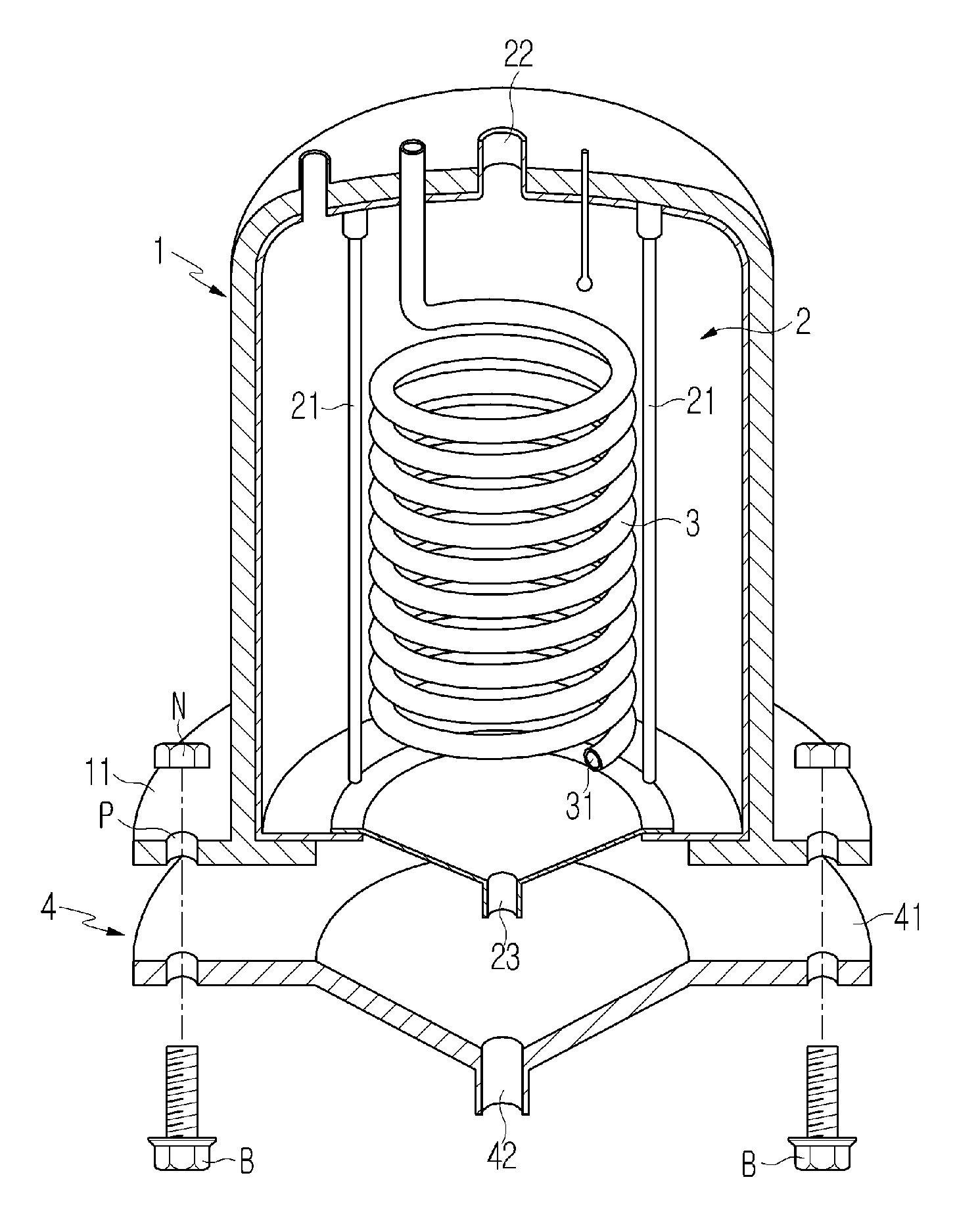

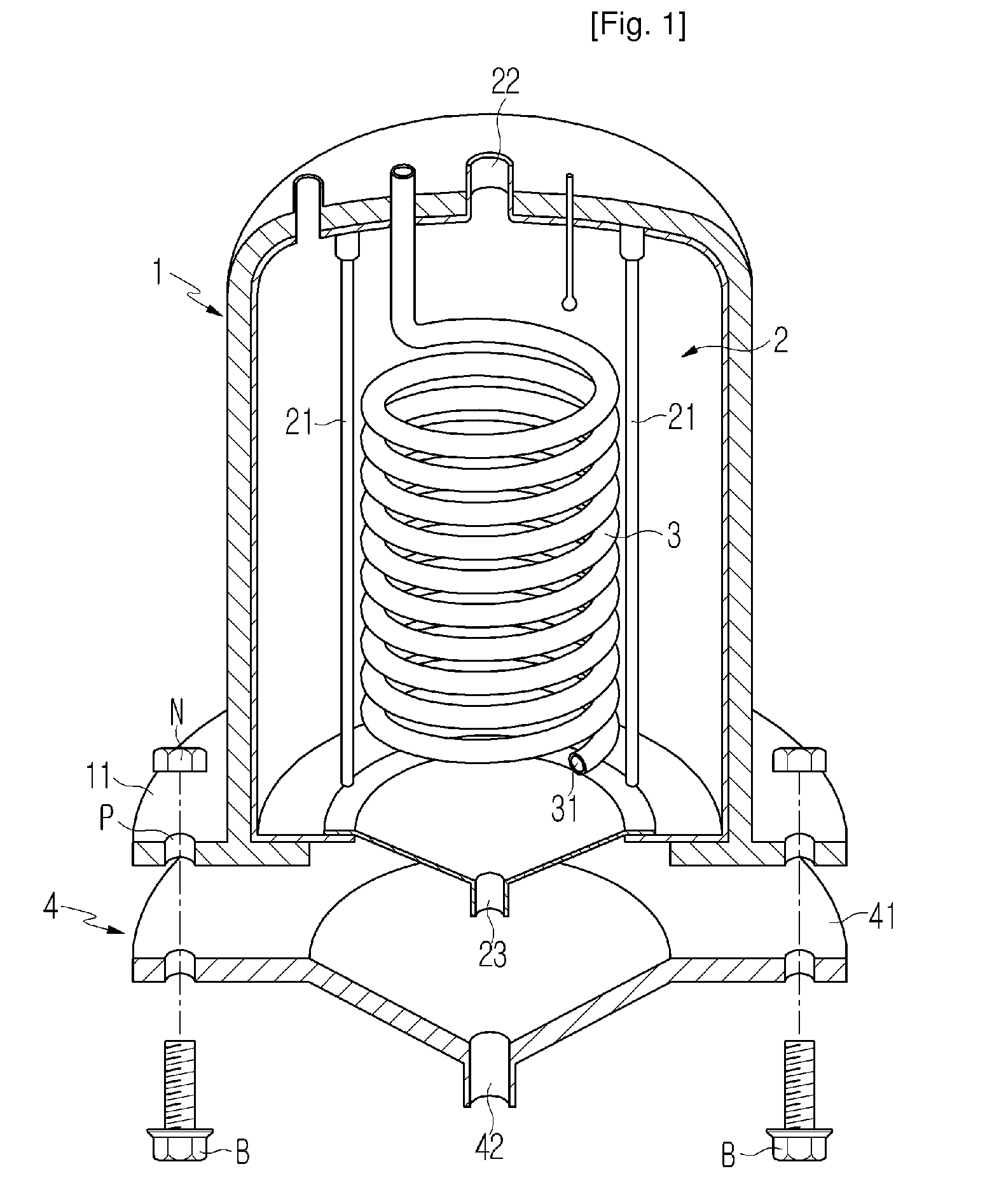

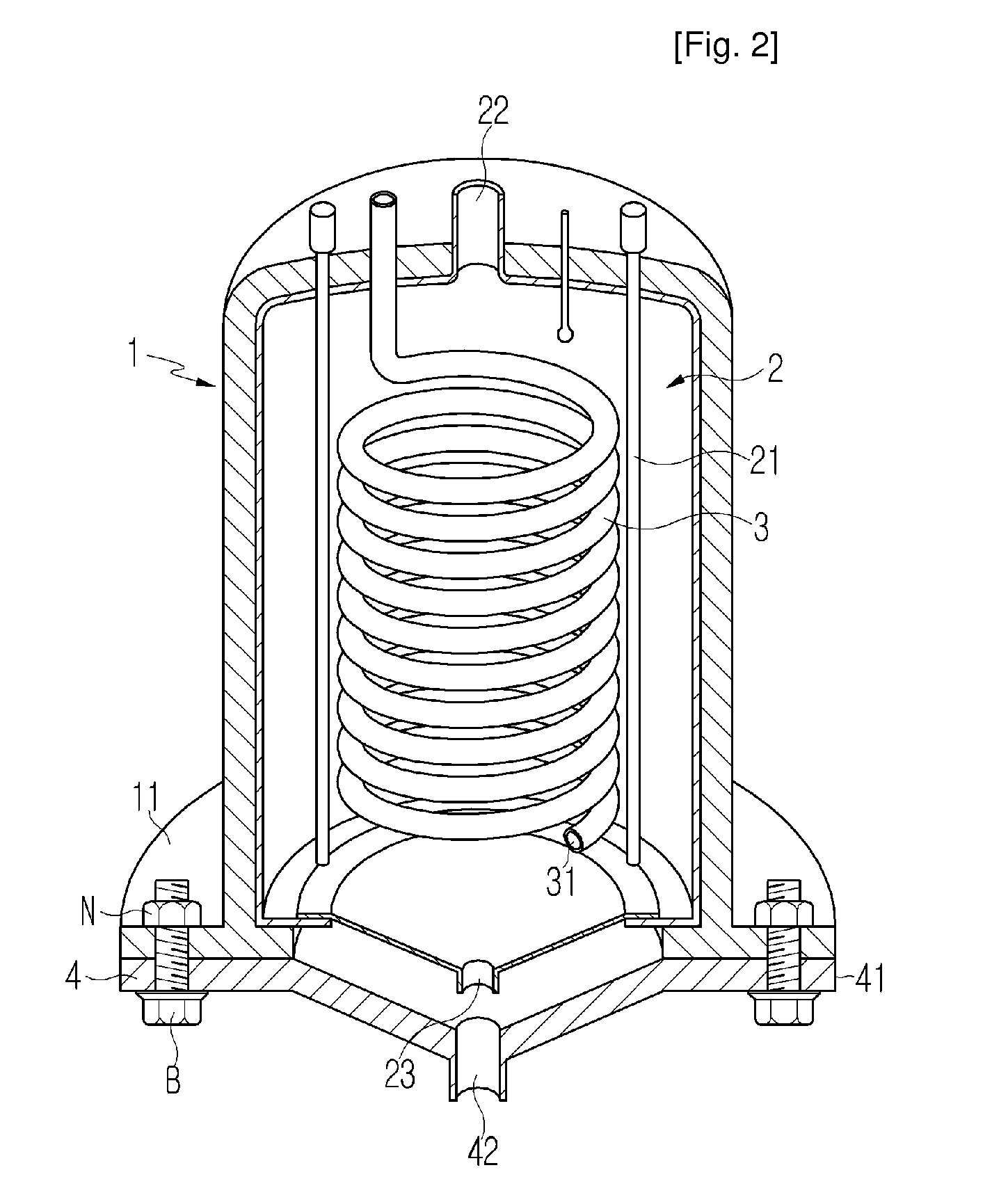

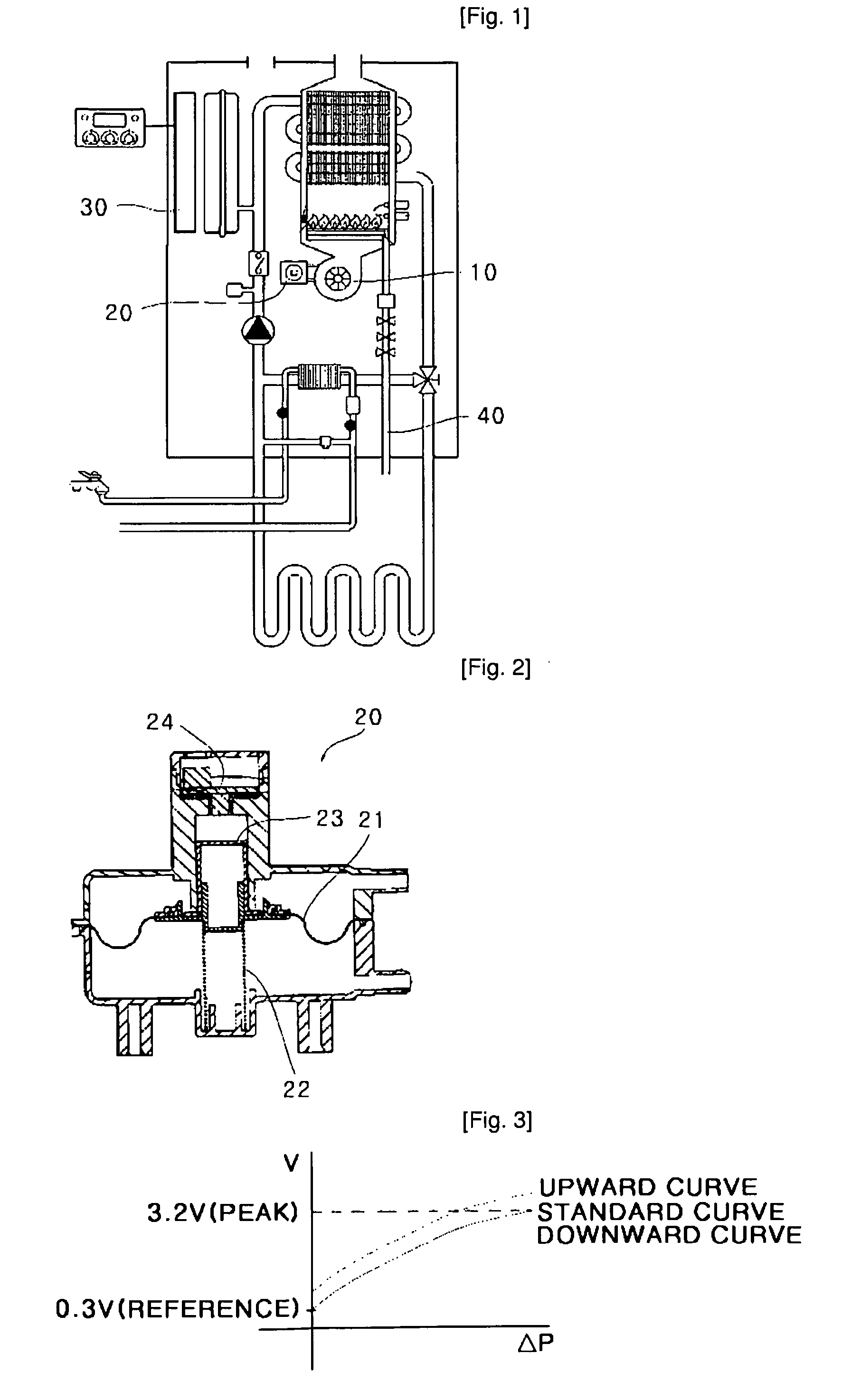

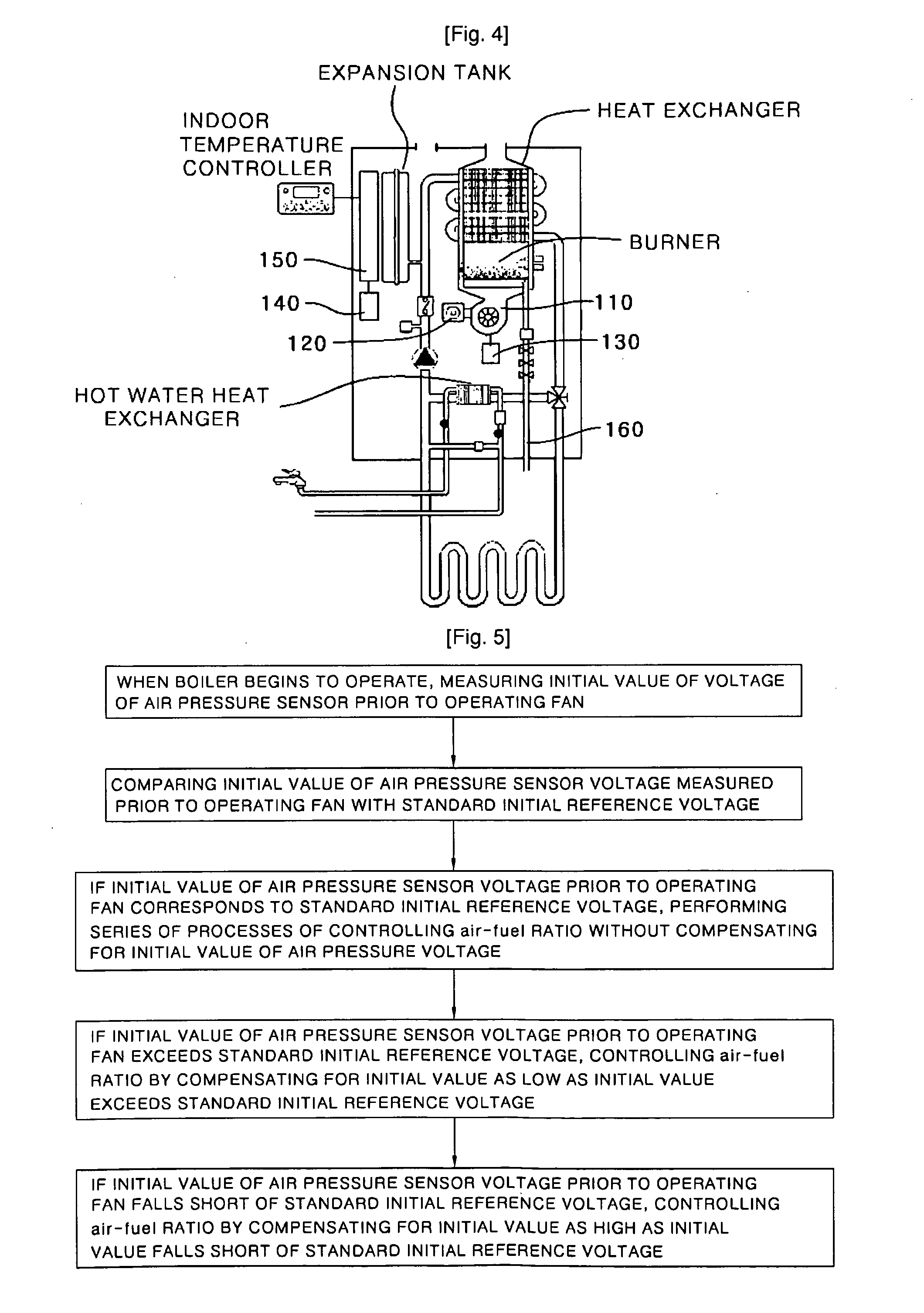

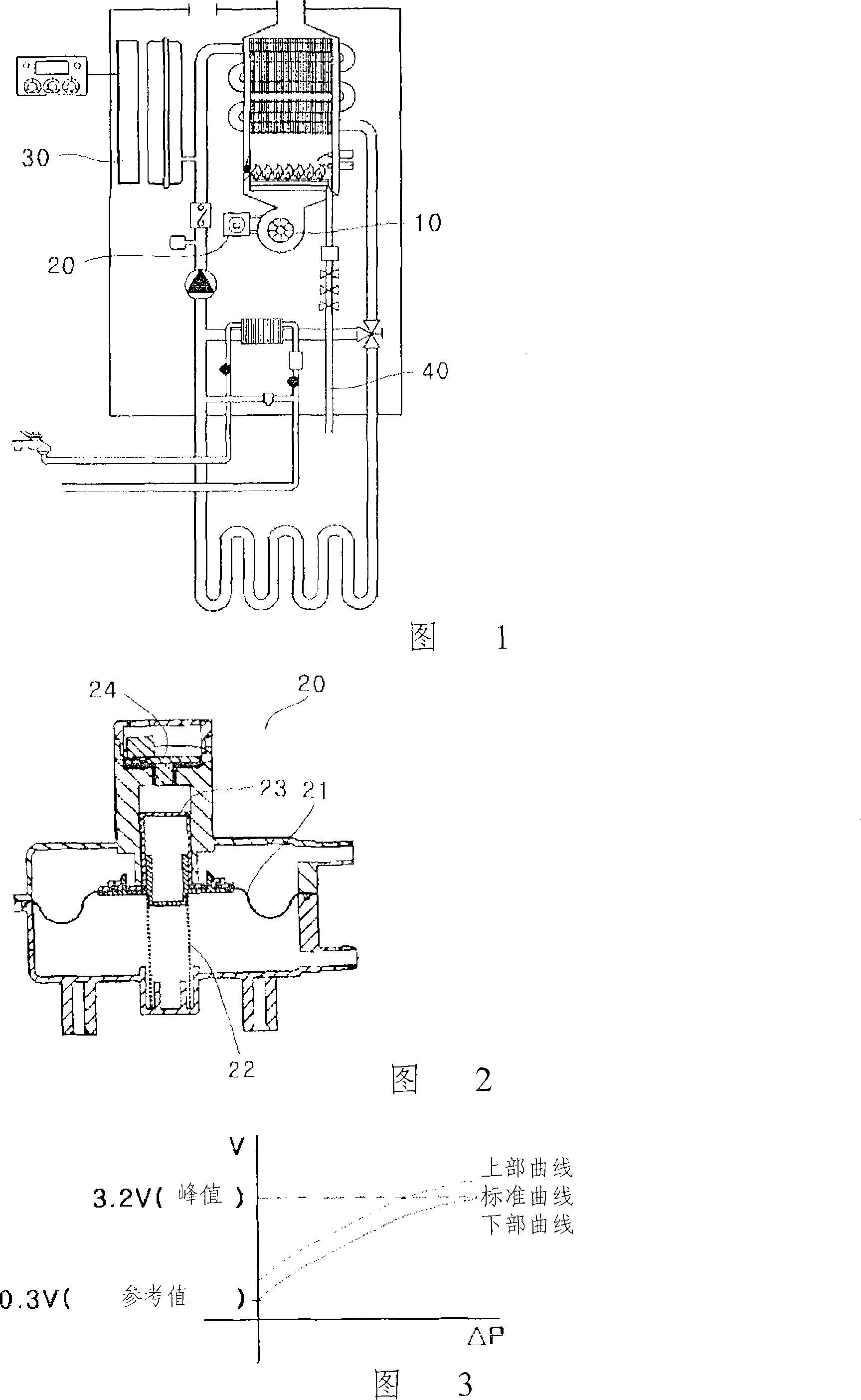

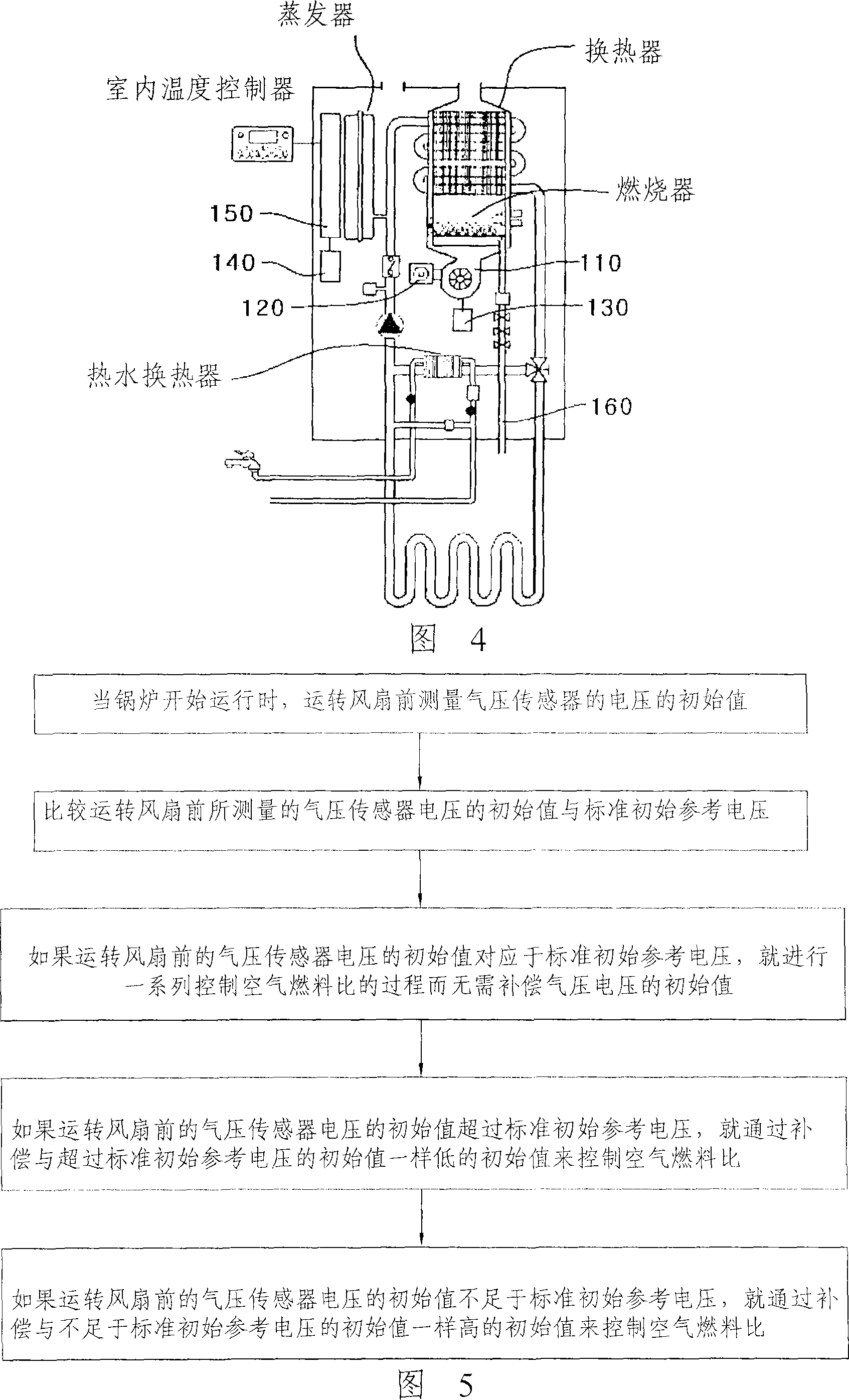

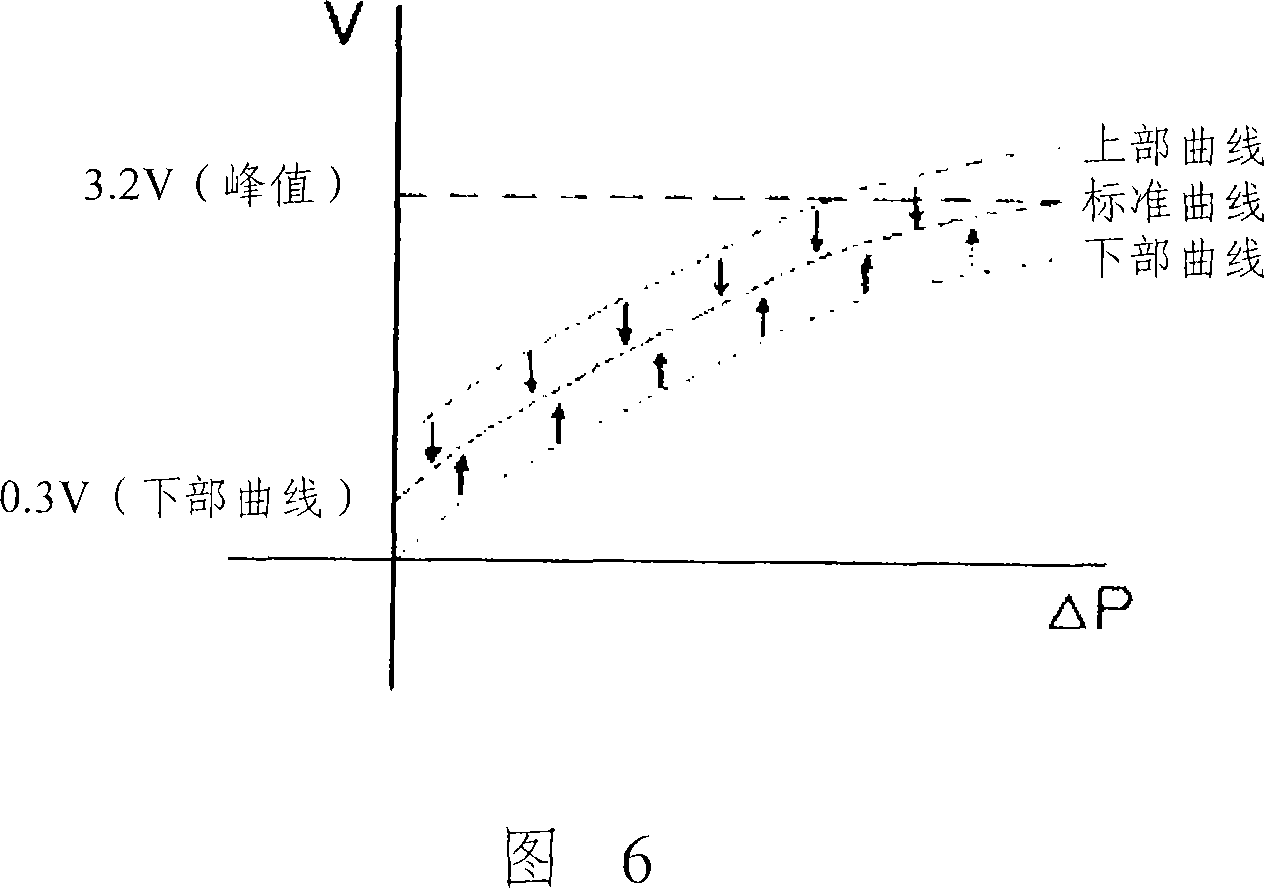

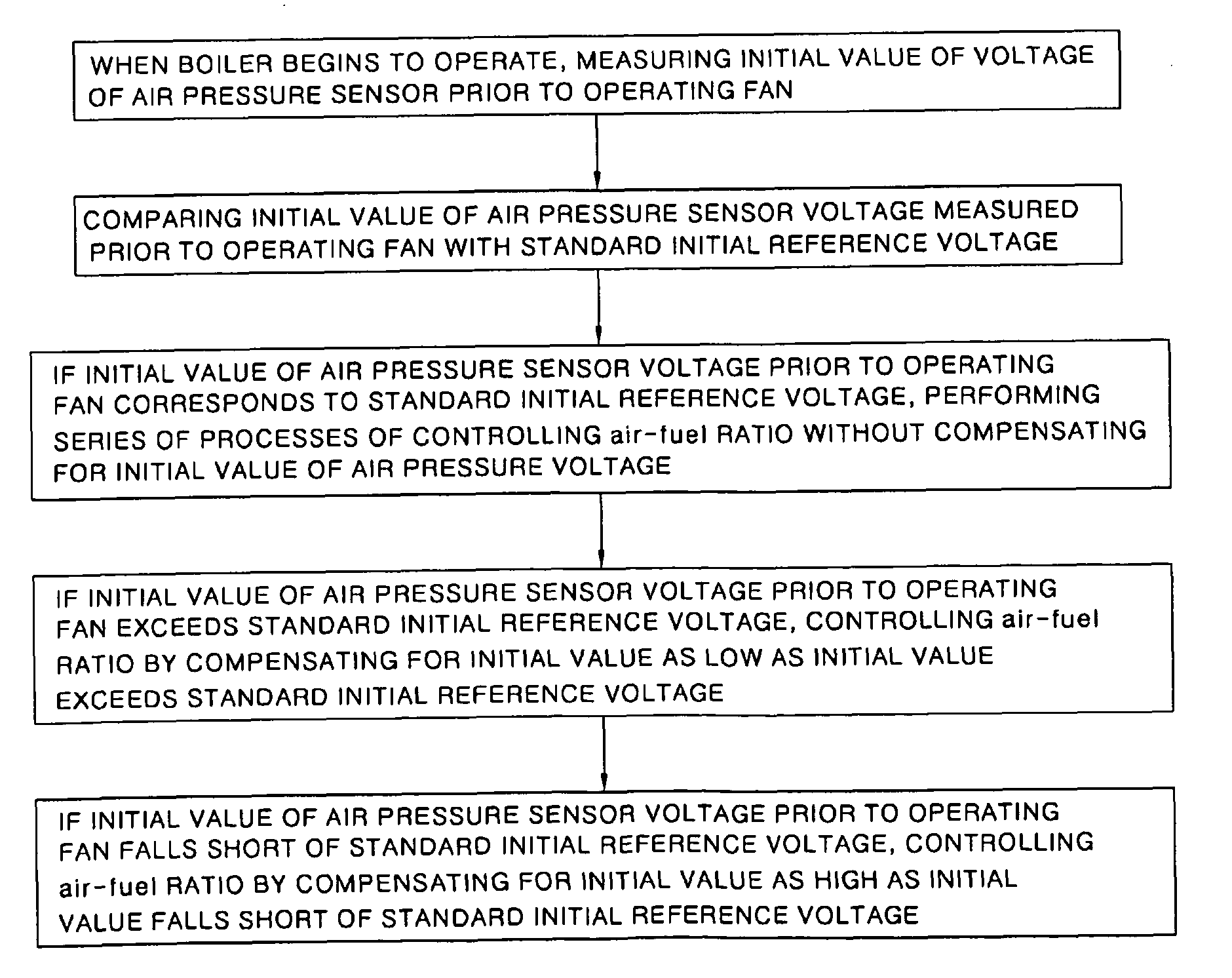

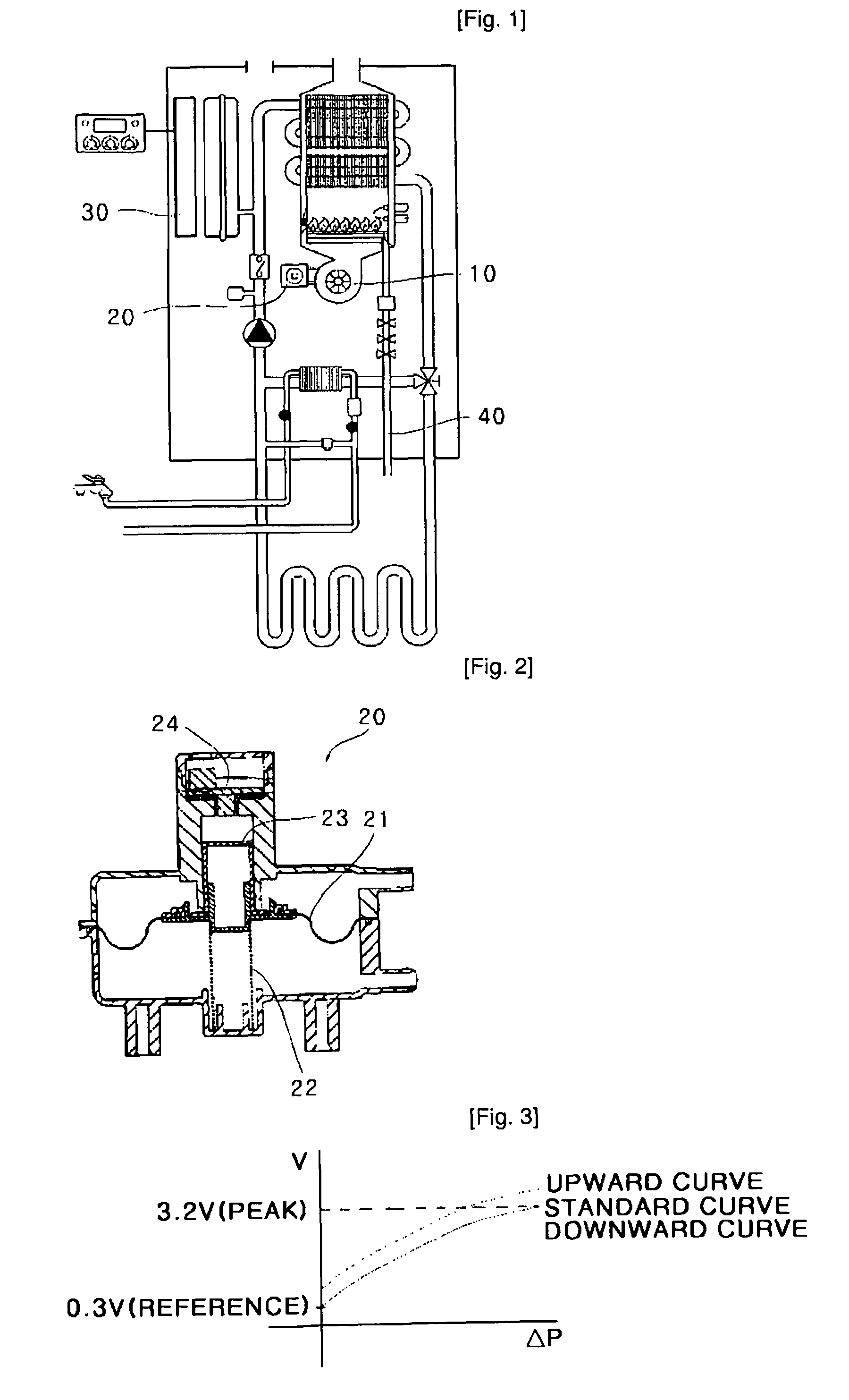

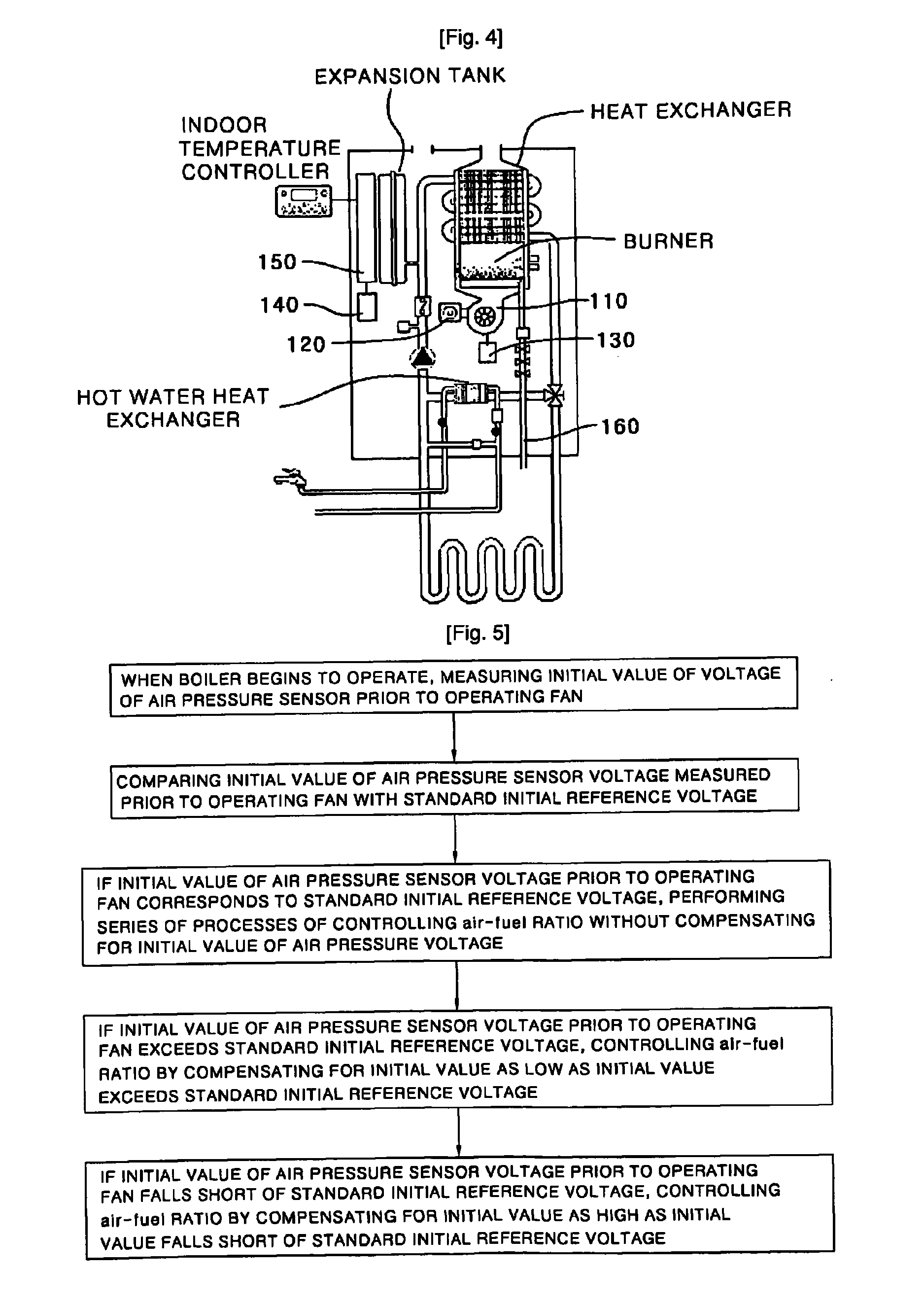

Boiler and method for controlling air and fuel ratio using air pressure sensor

InactiveUS20090308293A1Precise controlMinimize dischargeDC motor speed/torque controlTemperatue controlVoltage referenceAir–fuel ratio

Disclosed is an air-fuel ratio control boiler using a air pressure sensor and method for controlling the air-fuel ratio thereof. The boiler is comprised of a fan, the air pressure sensor, a air pressure sensor voltage measurement unit, a air pressure sensor voltage compensation unit, and a controller, and previously compensates for noise factors caused by deviation (error) of a component property, a constituent, of the air pressure sensor so as to be matched to initial reference voltage prior to operating the fan, thereby maximizing the effectiveness of the air-fuel ratio. Further, the boiler makes it possible not only to exert an optimal fuel efficiency effect due to the maximization of combustion efficiency, but also to minimize discharge of harmful gases, thereby preventing environmental pollution in advance, and thus improving the reliability of products.

Owner:KYUNGDONG ONE CORP

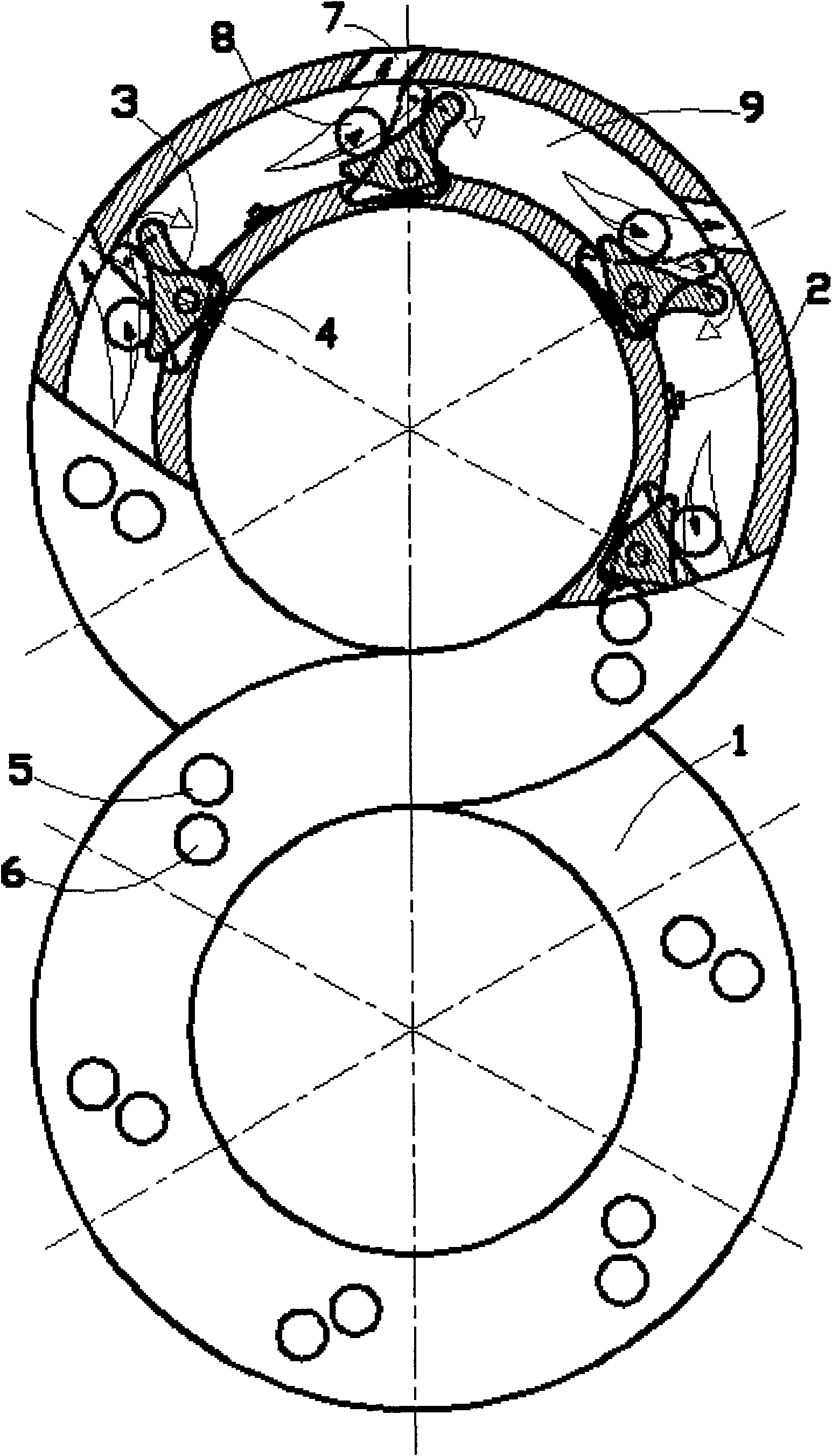

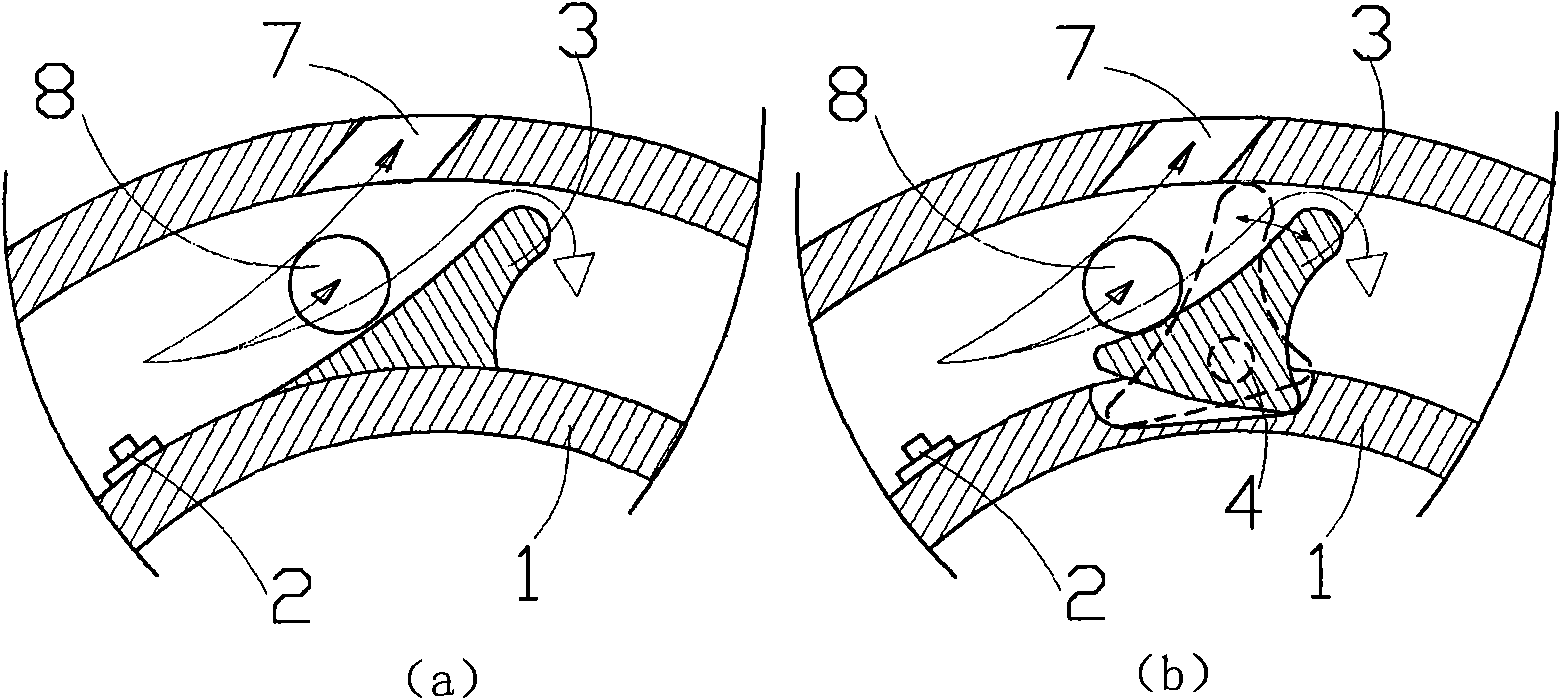

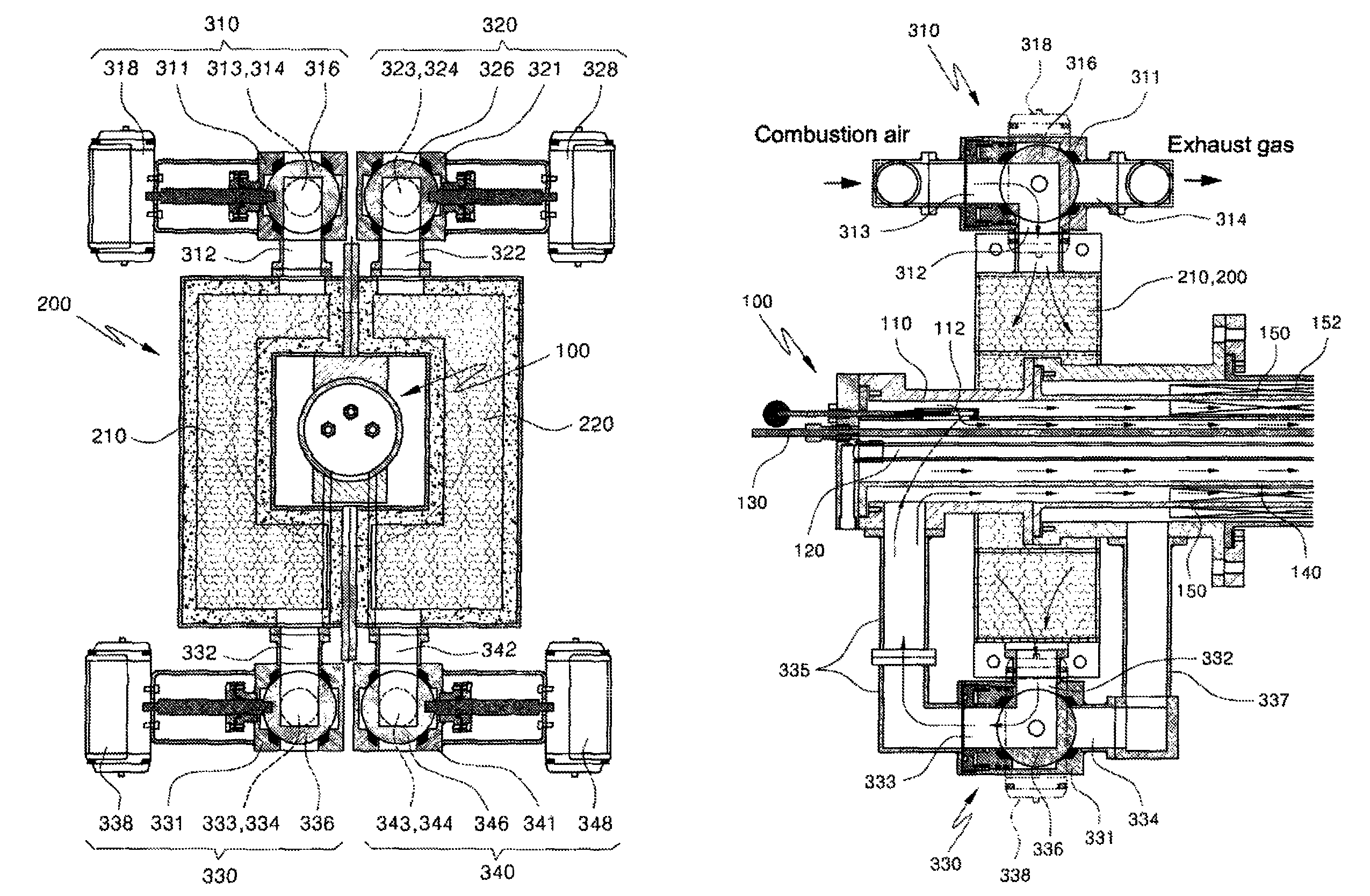

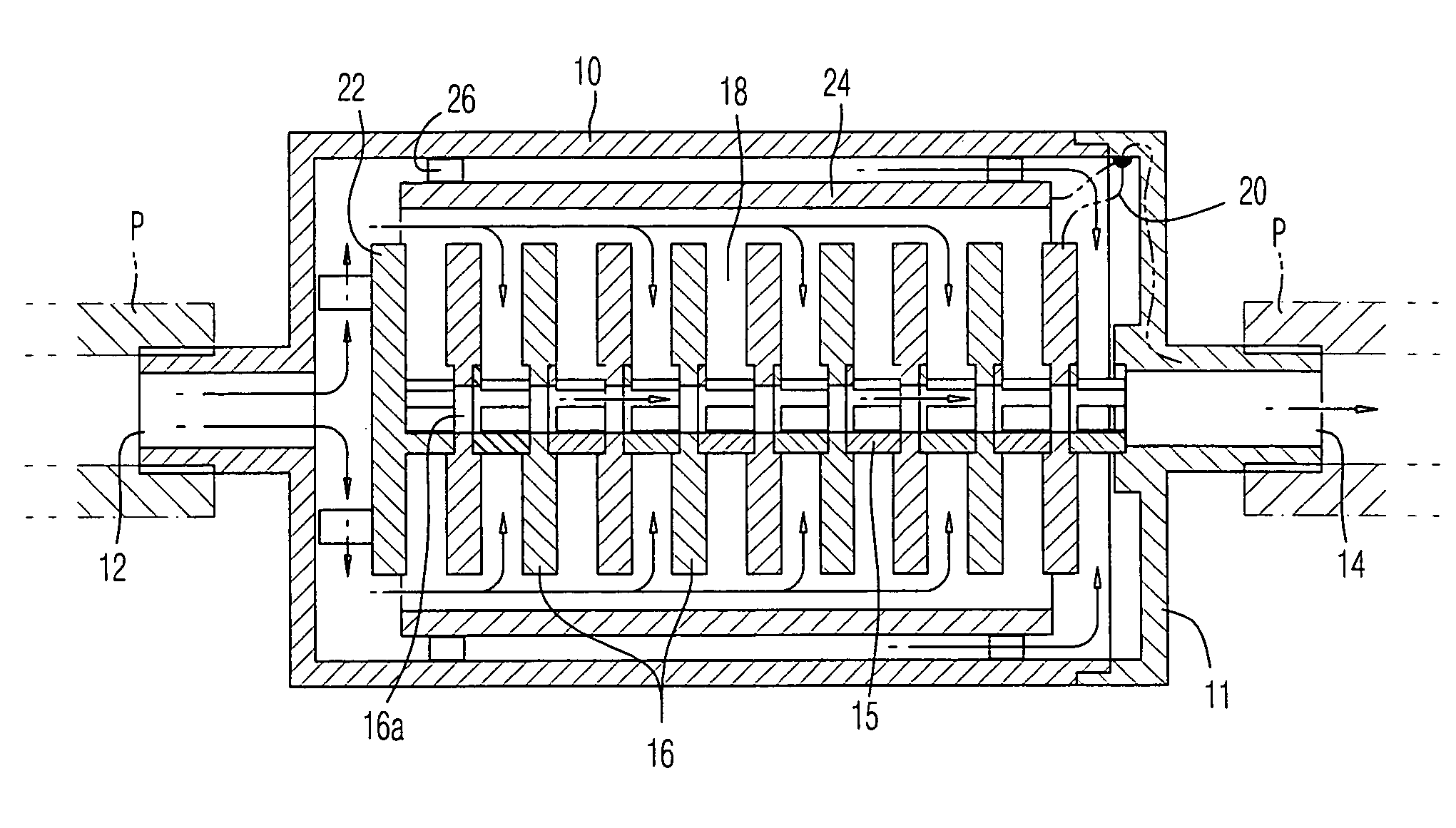

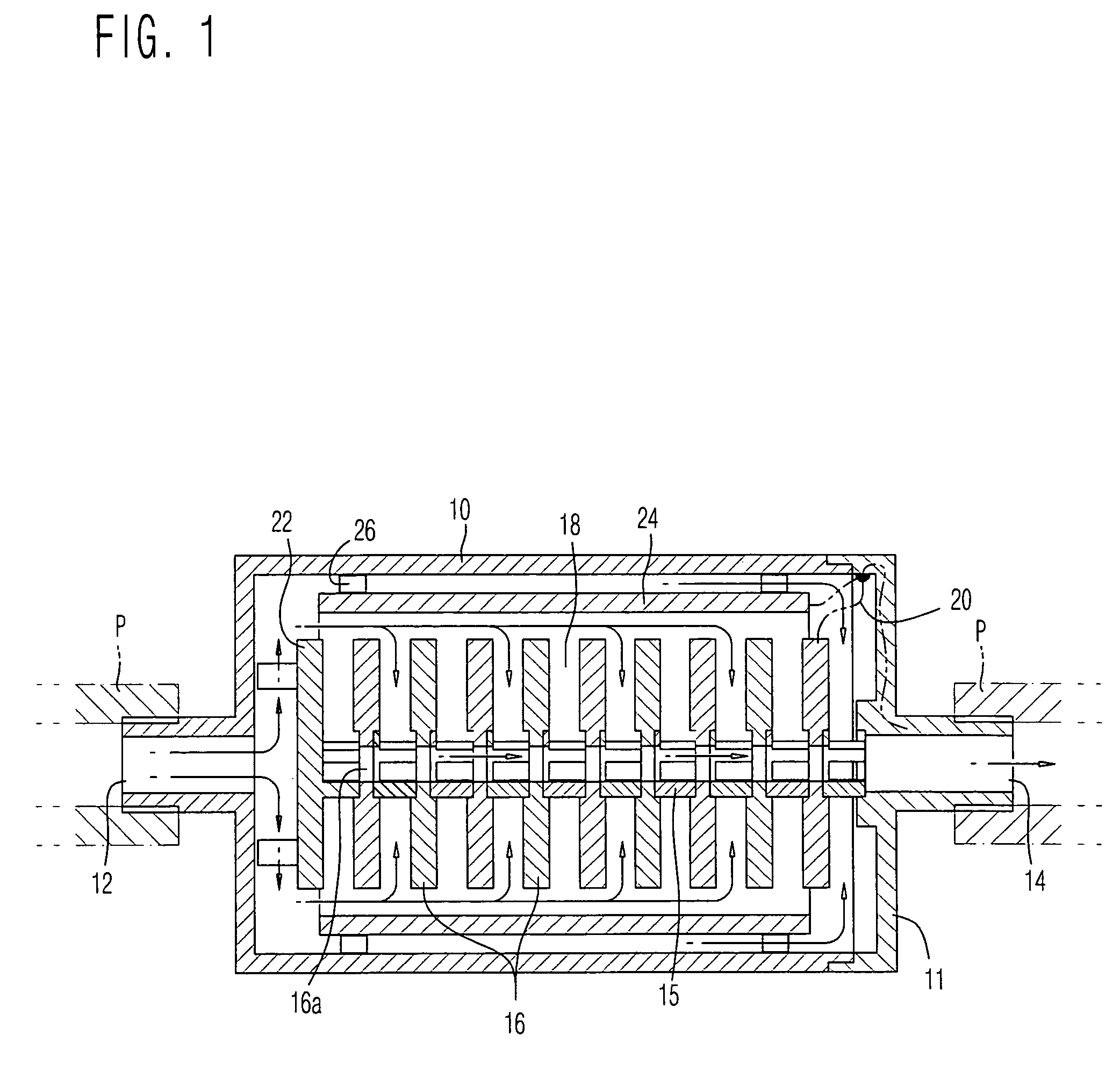

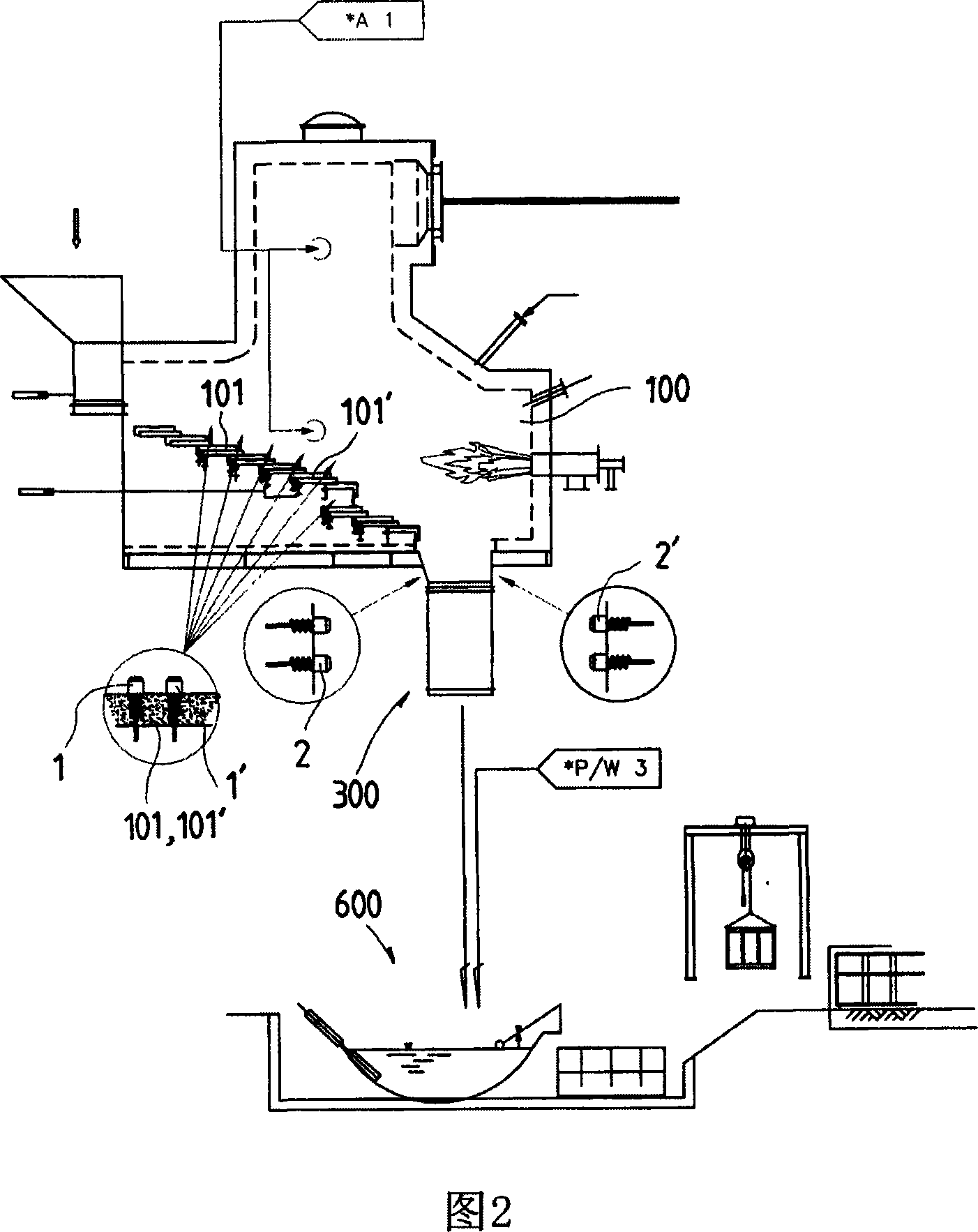

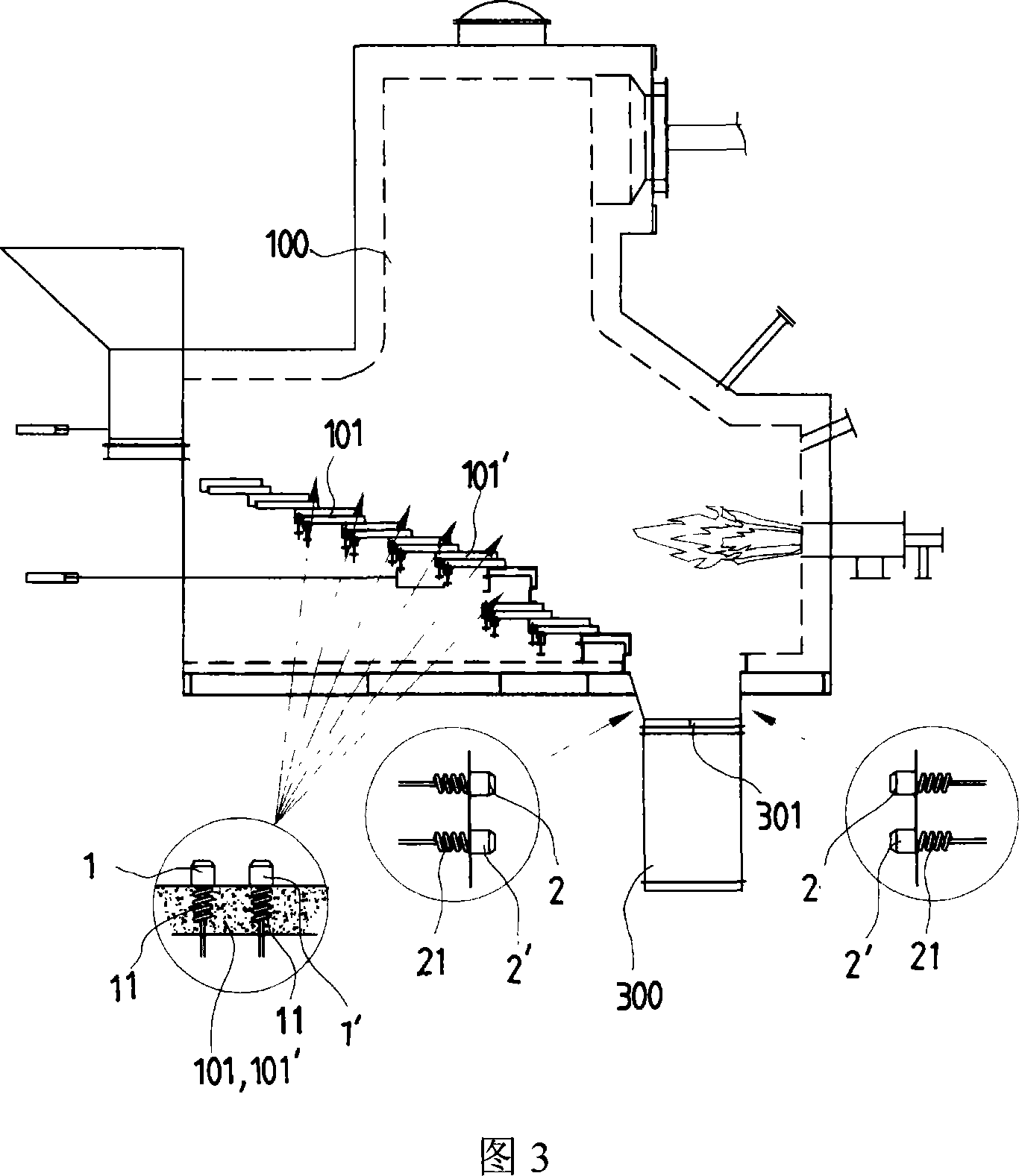

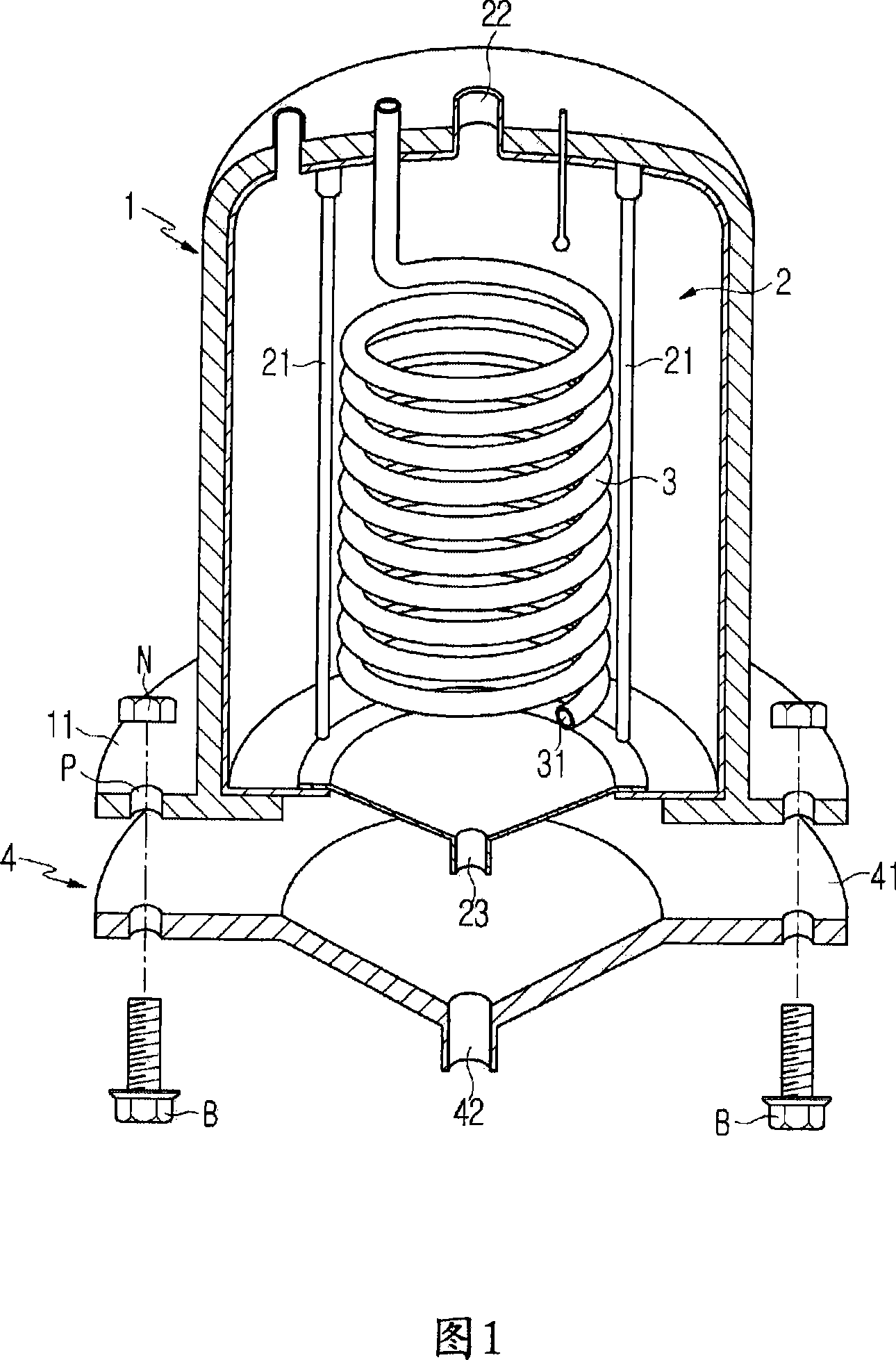

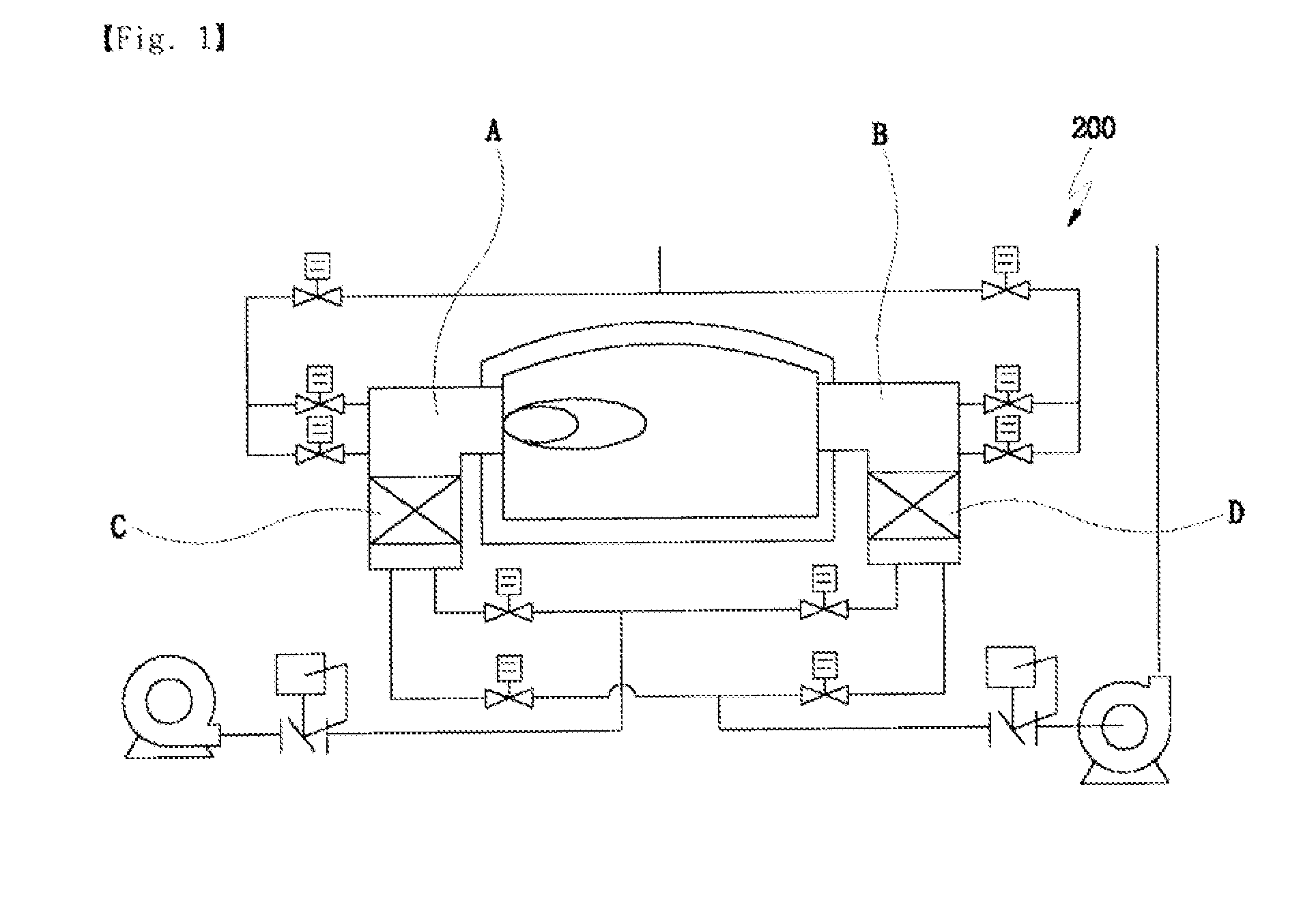

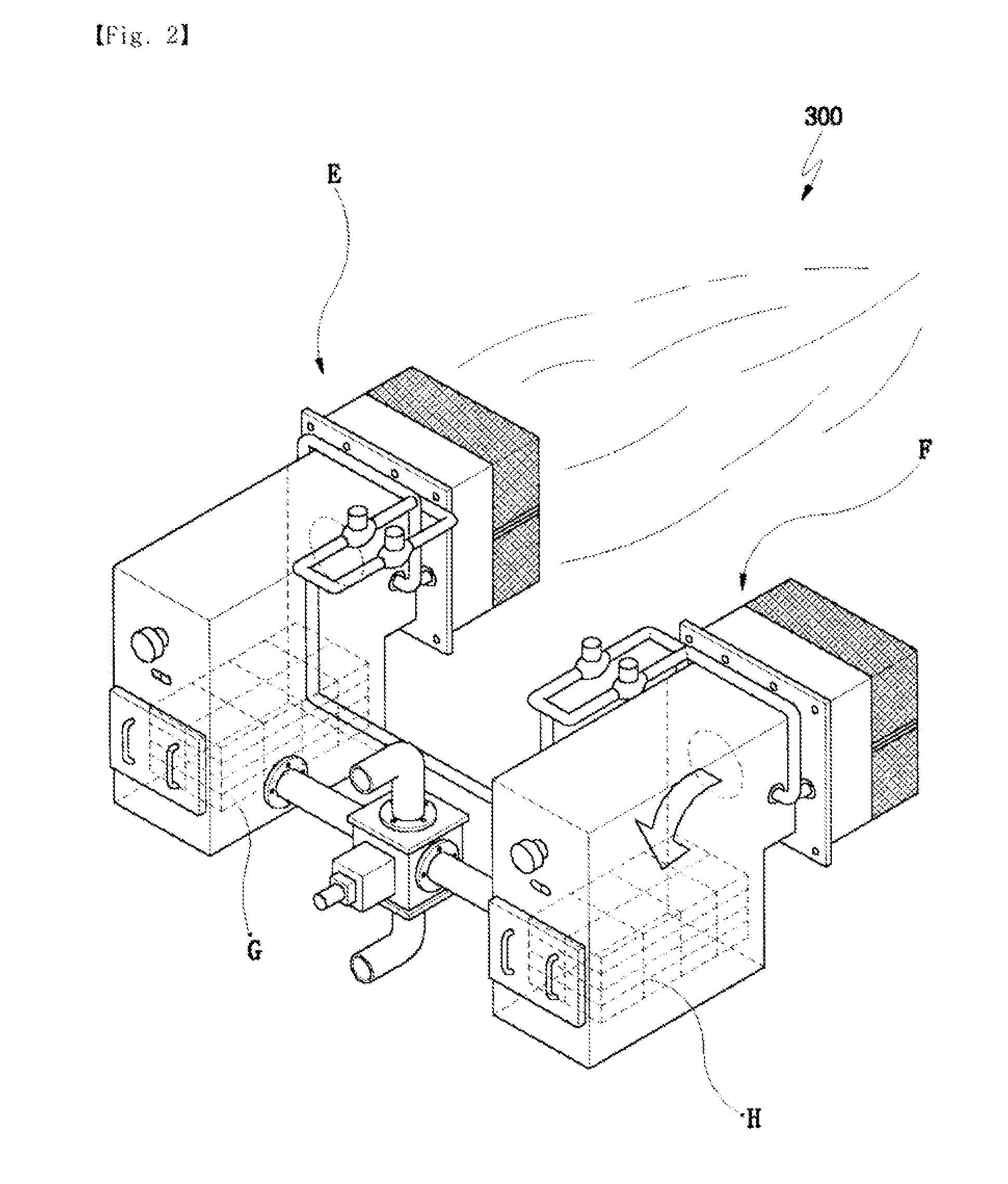

Full time regenerative type single radiant tube burner

ActiveUS8226405B2Simple structureCompact designDomestic stoves or rangesAir supply regulationCombustorEngineering

The present invention relates to a full time regenerative type single radiant tube burner. The full time regenerative type single radiant tube burner includes a radiant tube type burner; a regenerating unit that regenerates exhaust gas heat generated from the burner and is used for preheating the intake combustion air; and an intake and exhaust switching device that passes the intake air and the exhaust gas to the regenerating unit and heat-exchanges them and simultaneously progresses the intake and exhaust processes of the burner to perform the full time combustion.The present invention according to the above configuration operation can perform the full time combustion using the single radiant tube burner to maximize the combustion efficiency, thereby improve the energy efficiency, while the present invention makes the structure of the intake and exhaust switching device 300 simple, can compactly design the burner by mounting the regenerating unit 200, which is integrated with the intake and exhaust switching device, to surround the circumference of the burner body 110 and can manufacture the burner at a small size, such that it can be applied to various environments without limiting the installation space.

Owner:KOREA INST OF ENERGY RES

System and method for optimizing combustion of boiler

ActiveUS20200173649A1Maximize combustion efficiencyMinimizationBoiler controlAdaptive controlPower stationControl engineering

A system for controlling a boiler apparatus in a power plant to combust under optimized conditions, and a method for optimizing combustion of the boiler apparatus using the same are provided. The boiler control system may include a modeler configured to create a boiler combustion model, an optimizer configured to receive the boiler combustion model from the modeler and perform the combustion optimization operation for the boiler using the boiler combustion model to calculate an optimum control value, and an output controller configured to receive the optimum control value from the optimizer, and control an operation of the boiler by reflecting the optimum control value to a boiler control logic.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Fluid treatment apparatus

ActiveUS7867367B2Prevent scalingMaximize combustion efficiencyCellsWater/sewage treatment by electrochemical methodsCombustionPotential difference

A fluid treatment apparatus capable of maximizing contact area between a fluid and electrodes in the apparatus to improve corrosion resistance or combustion efficiency includes a housing having an inlet port and an outlet port for the water at both ends of the housing, and a plurality of first electrodes installed in the housing for generating a potential difference through delivery of electrons at a contact surface between the fluid and the electrodes. The first electrodes are disc shaped and have a water passing hole formed in a center portion. The first electrodes being arranged in parallel in a direction perpendicular to a main flow direction of the fluid, so as to form a channel between the first electrodes to branch and guide a main flow.

Owner:LEE SANG JIN

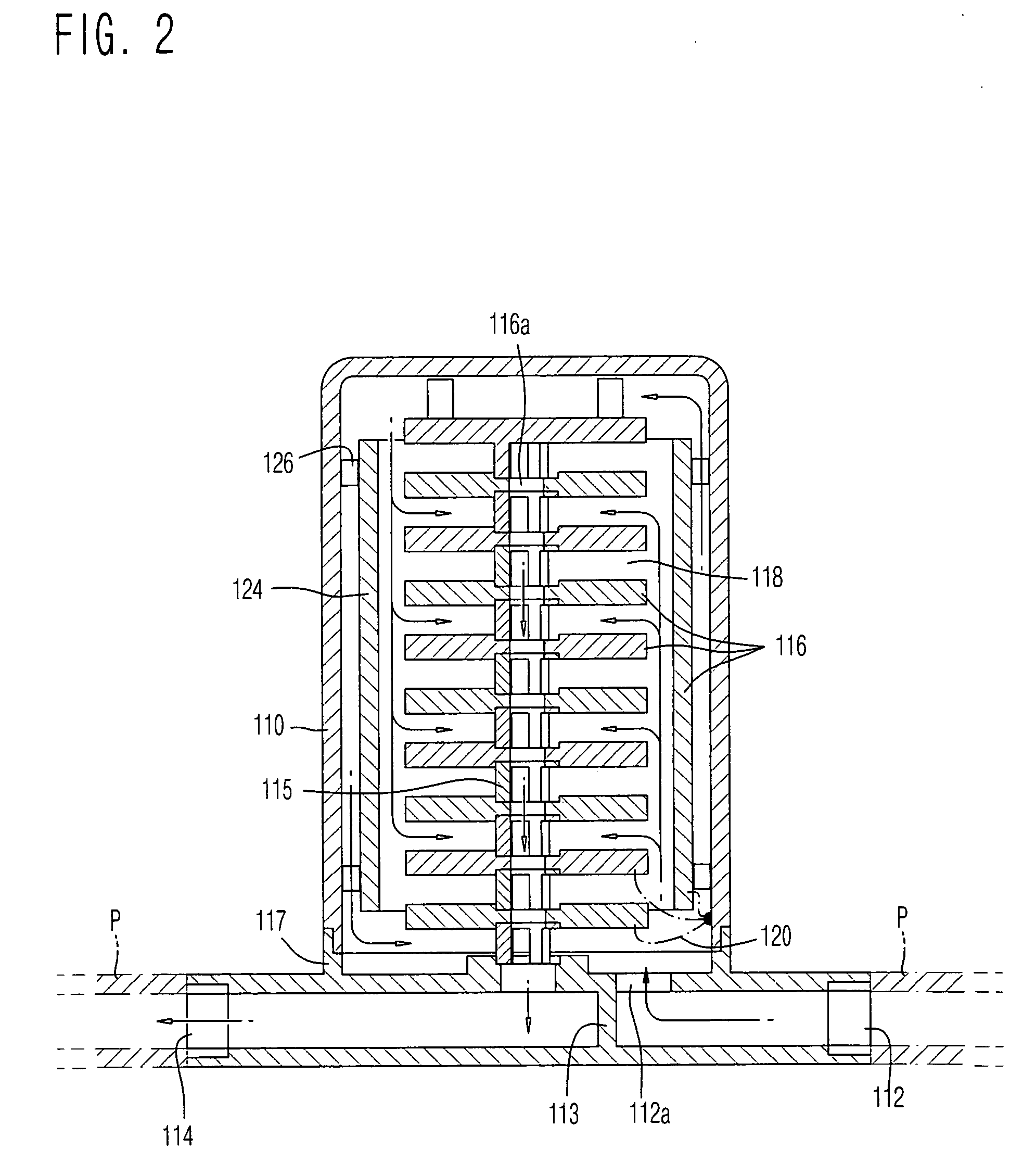

Combustion apparatus for r.p.f boiler

InactiveCN101169241AMaximize combustion efficiencyImprove combustion efficiencySolid fuel combustionNon-combustible gases/liquids supplyCycloneWarm water

The invention relates to a solid fuel boiler for combusting solid fuel and utilizing the generated heat, in particular, relates to a combustion train for the solid fuel boiler, which is characterizedin that combustion efficiency is enhanced by arranging a screw air nozzle on the combustion furnace and ash is combusted again; the solid fuel is combusted in the combustion furnace, and the heat andpyrogenic distillation gas are recovered and utilized by re-combustion to produce warm water and hot wind. The inflamed gases can be discharged outwardly through a subarid absorptive tower and a filter collector; a screw air nozzle is disposed on the downstepped grate for burning solid fuel in the combustion furnace to make the combustion air generate cyclone and be fed into the combustion furnace. An air nozzle for supplying combustion air to re-combust the solid fuel of incomplete combustion is disposed at the two sides of the inlet for discharging the combustion ash.

Owner:KOREA ENARGY +6

Boiler and method for controlling air and fuel ratio using air pressure sensor

InactiveCN101166938AImprove precise controlEmission reductionAir supply regulationCombustion ventilatorsFuel efficiencyVoltage reference

The invention discloses an air-fuel ratio control boiler using an air pressure sensor and a method for controlling the air-fuel ratio thereof. The boiler includes a fan, an air pressure sensor, an air pressure sensor voltage measuring device, an air pressure sensor voltage compensation device, and a controller, and compensates in advance the component performance of the air pressure sensor, the noise factor caused by the deviation (error) of the composition, so that it Matches the initial reference voltage before running the fan to maximize the efficiency of the air-to-fuel ratio. In addition, the boiler makes it possible not only to exert the best fuel efficiency effect due to the maximization of combustion efficiency, but also to minimize the emission of harmful gases, thereby preventing environmental pollution in advance, and thus improving product reliability sex.

Owner:(株)庆东ONE

Energy-saving gas boiler

InactiveCN105650867AMaximize combustion efficiencyIncrease profitMechanical apparatusWater heatersThermal insulationEngineering

The invention discloses an energy-saving gas boiler which comprises a boiler base, a boiler housing body, a main gas pipe, a burner seat, a thermal-insulation partition board and an atomization mixing device, wherein the boiler housing body is mounted above the boiler base; a control panel is mounted at the upper part of the right surface wall of the boiler housing body; an air pipe buckle and a hydraulic telescopic base are arranged above an air blower; the main gas pipe is mounted on the right side of the bottom of the hydraulic telescopic base; and the atomization mixing device is mounted above the hydraulic telescopic base. Compared with a traditional boiler, the energy-saving gas boiler realizes maximum combustion and utilization efficiency of gas, can control the size of a flame through an adjusting knob, adopts a double-layer structure, maximizes the utilization of heat energy for gas combustion and increases the energy utilization rate owing to the arrangement of the thermal-insulation partition board, and is more convenient to use owing to a reasonable structural design.

Owner:刘发民

Gas combustion arrangement using circular stream

InactiveCN101218472AExtended stayMaximize combustion efficiencyIncinerator apparatusCombustionGas passing

Owner:美迪克斯派股份公司

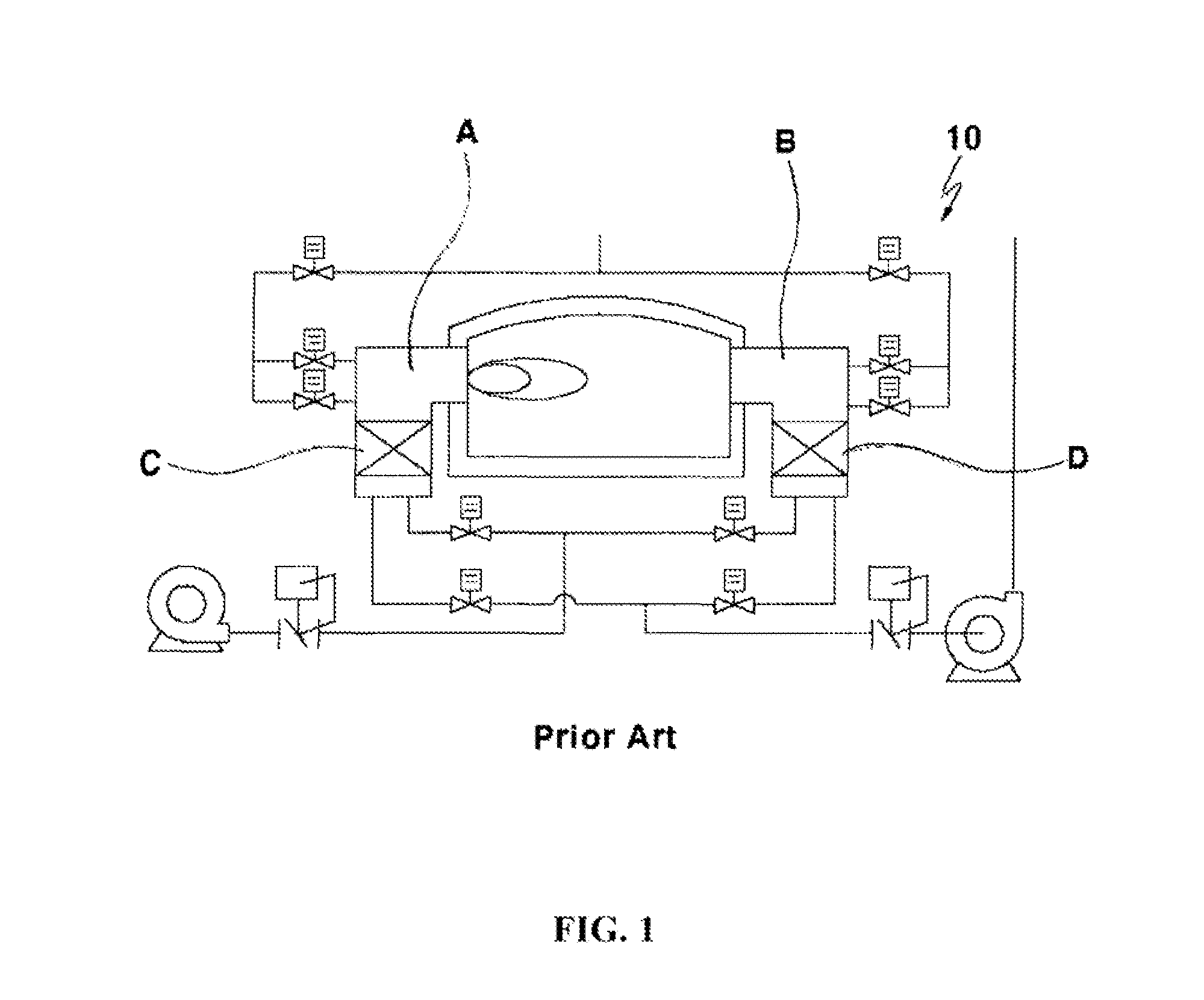

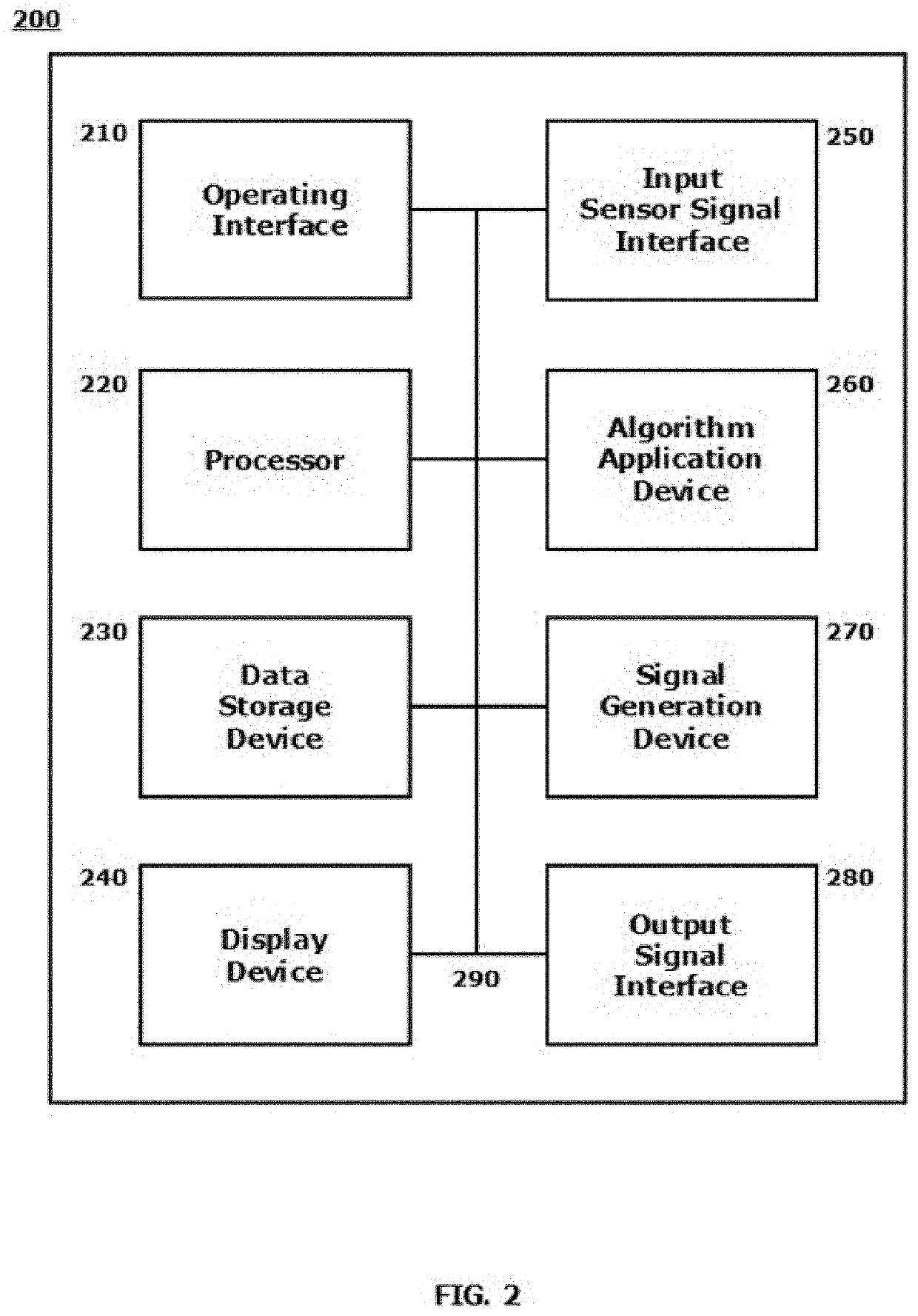

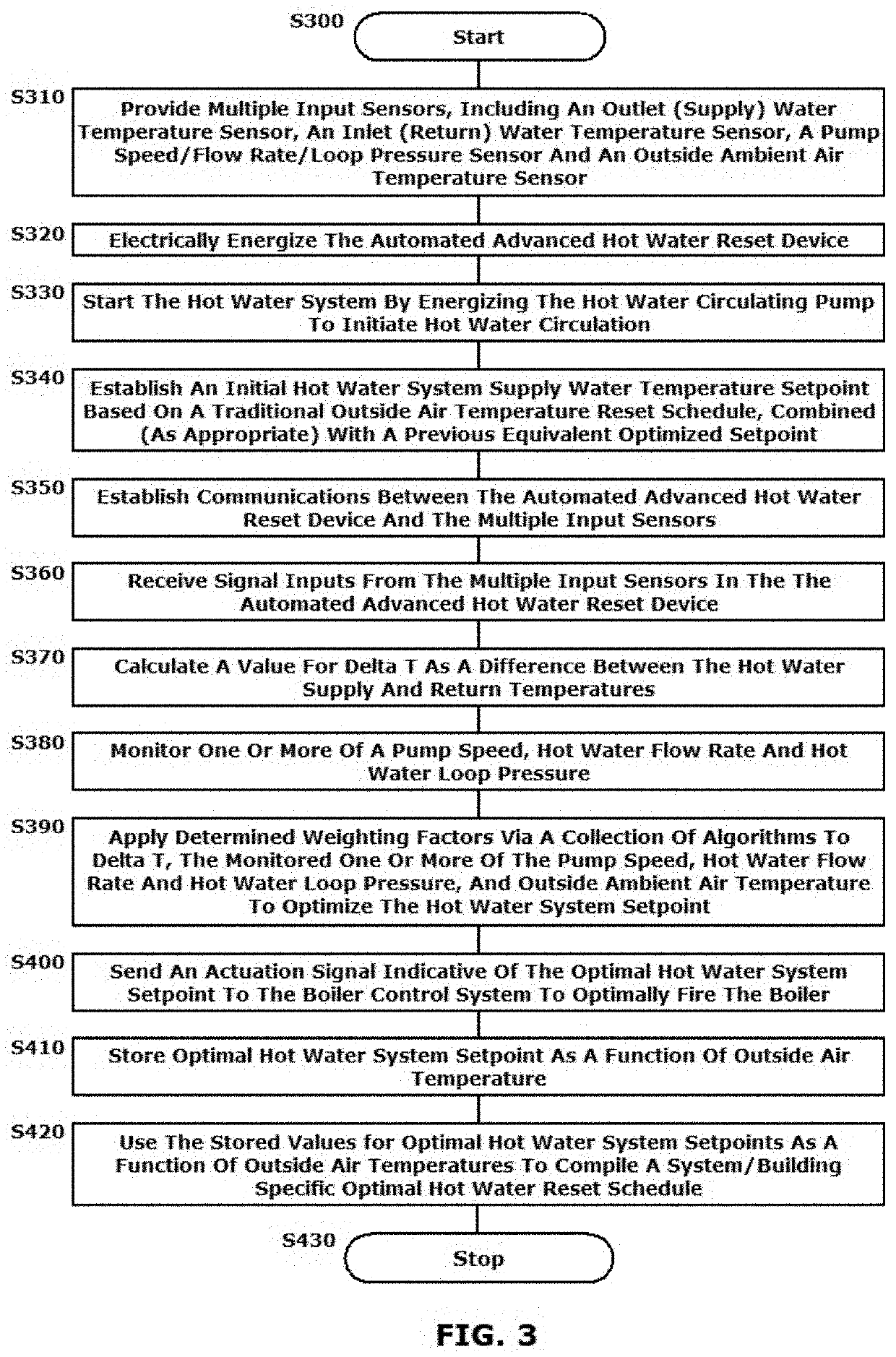

Systems and methods for implementing an advanced energy efficient boiler control scheme

PendingUS20200271329A1Maximize combustion efficiencyImprove comfortCentral heating componentsAir heatersProcess engineeringBuilding automation

Automated systems, methods, techniques, processes, products and product components are provided to implement an advanced and energy efficient hot water heating system control scheme that incorporates an advanced hot water reset for the boilers, including condensing boilers in hydronic systems. The advanced controls are provided to substantially enhance combustion (heating) efficiency for the boilers. The disclosed schemes replace conventional linear hot water reset with a device which can stand alone or integrate with boiler control technology or an existing building automation system to create a unique (non-linear) boiler reset curve based on various inputs. The schemes allow boiler control systems to learn and adapt over time maximizing the efficiency of a condensing boiler plant, by providing an independent, intelligent, economical, monitorable and manipulable solution eliminating the need of a head end BAS control system.

Owner:AUMEN NICHOLAS E +1

Frac water heating system and method for hydraulically fracturing a well

InactiveUS9103561B2Maximize atomization and combustionMaximize combustionFluid removalHeat exchanger casingsCombustion chamberForced-air

The present invention provides an improved frac water heating system to fracture a subterranean formation at a remote work site to produce oil and gas. The present invention includes a single-pass tubular coil heat exchanger contained within a closed-bottom firebox having a forced-air combustion and cooling system to heat the treatment fluid. In another embodiment, the invention includes multiple, single-pass heat exchanger units arranged in a vertically stacked configuration to heat the treatment fluid. In a preferred embodiment, the improved frac water heating system is used to heat water on-the-fly (i.e., directly from the supply source to the well head) to complete hydraulic fracturing operations. The present invention also includes systems for regulating and adjusting the fuel / air mixture within the firebox to maximize the combustion efficiency. The system may also include a novel hood opening mechanism attached to the exhaust stack of the firebox.

Owner:CHANDLER RONALD L

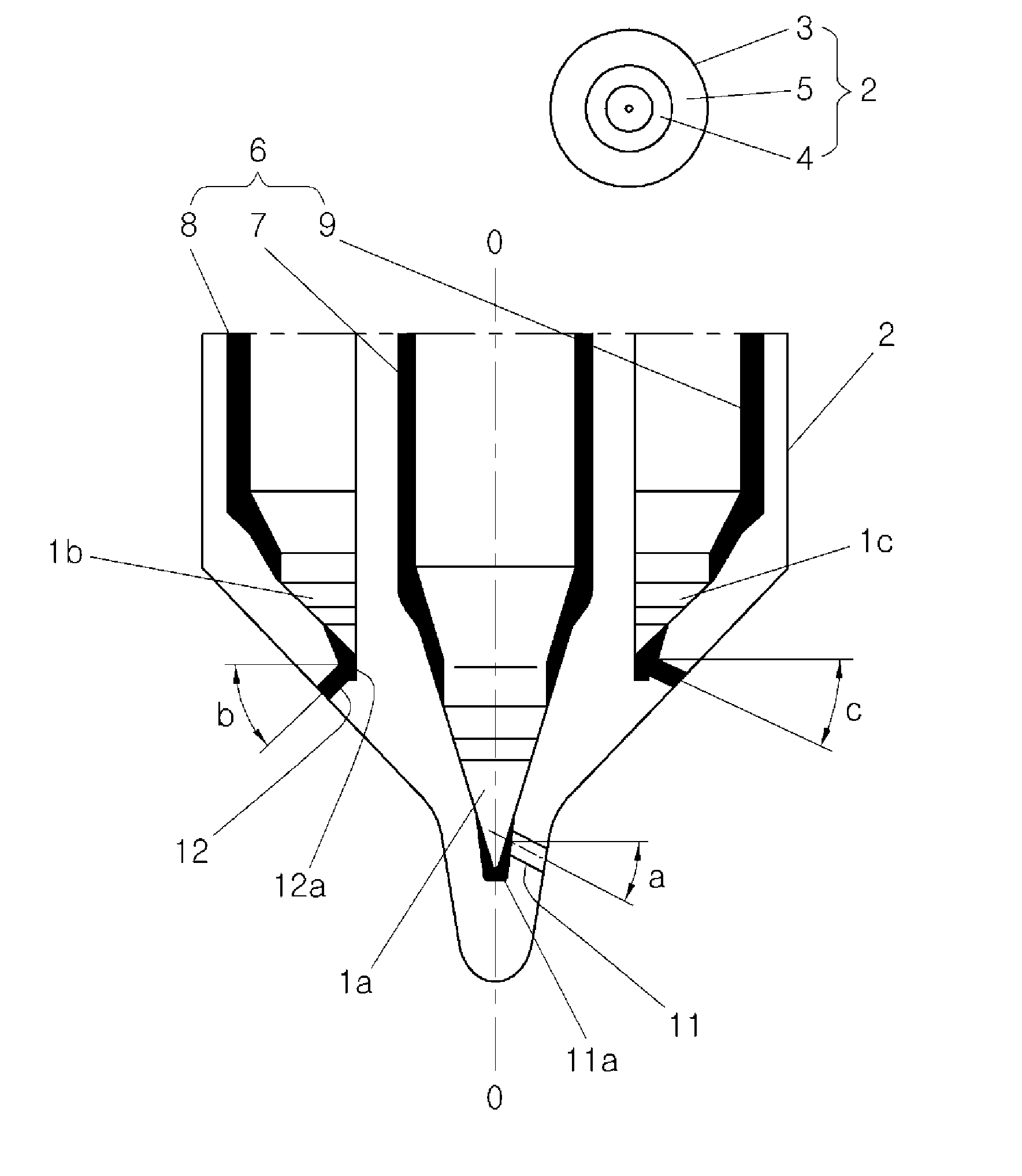

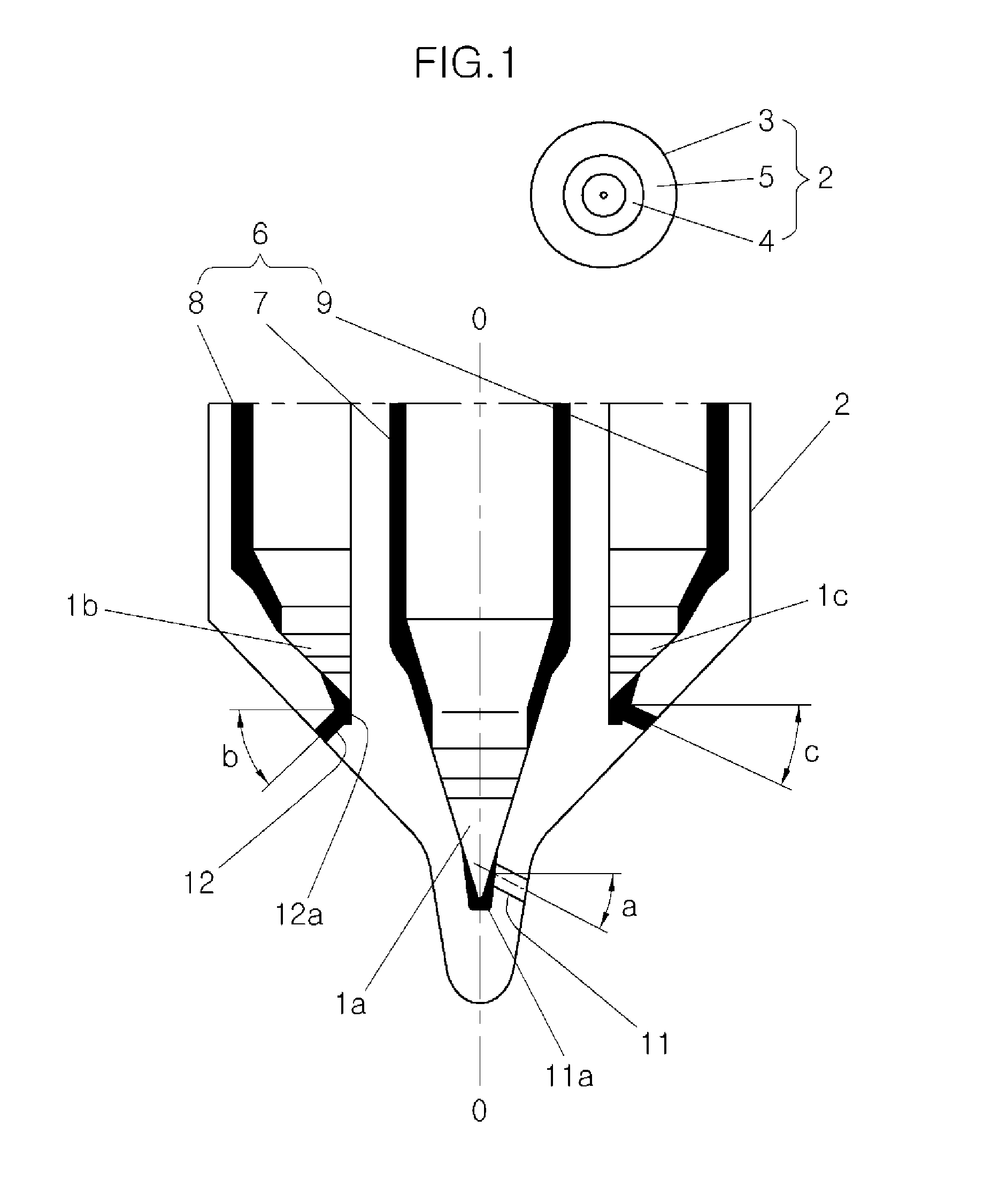

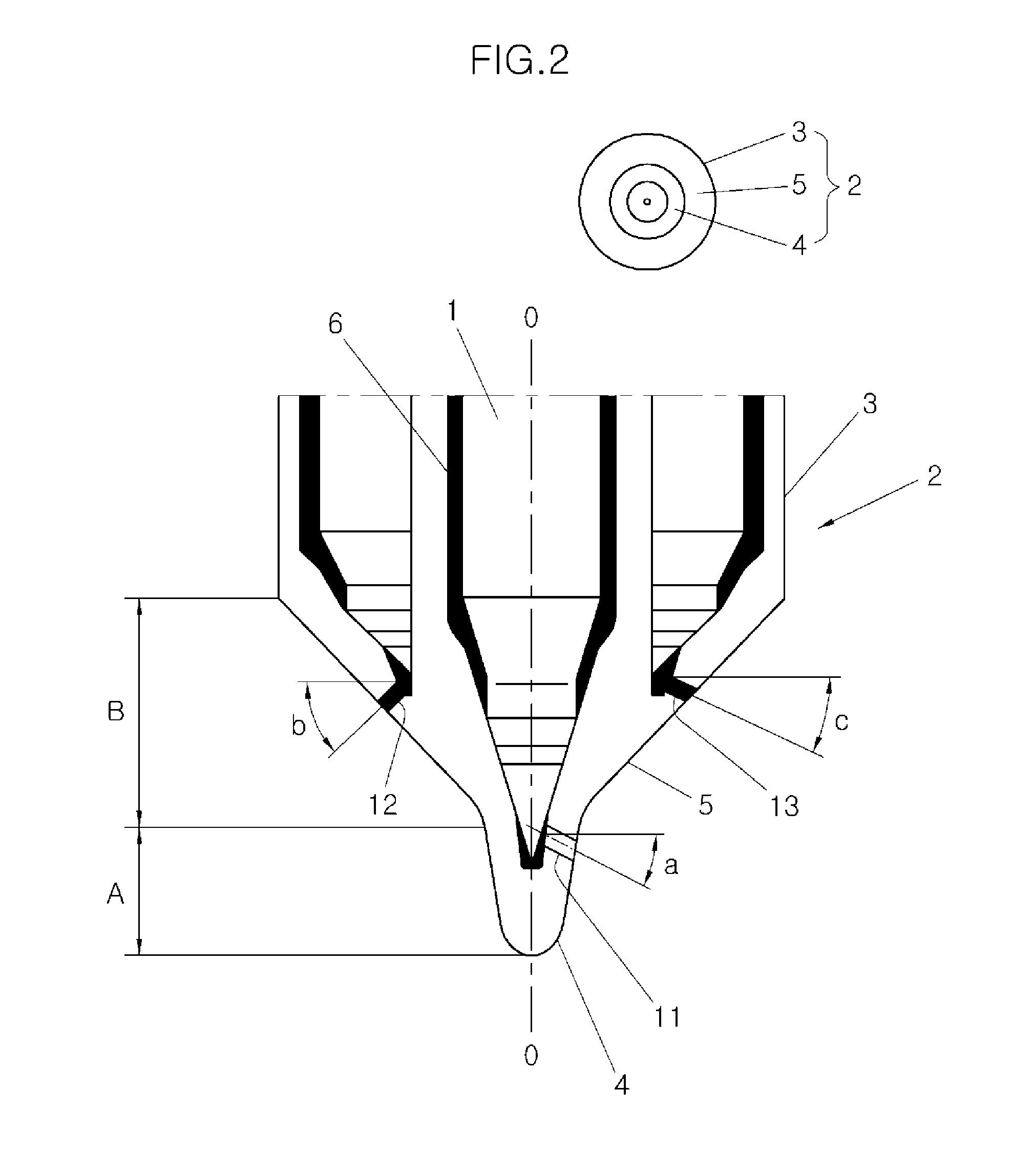

Multi-sac injector

InactiveUS20130112780A1Maximize engine combustion efficiencyReduce pollutantsMachines/enginesFuel injecting pumpsLow loadEngineering

A multi-sac injection includes a main sac located at the center of a nozzle such that an injected fuel formed a low load cone angle to inject a fuel for pre-mixed combustion, and sub-sacs located at sides of the nozzle such that the injected fuel forms a middle / high load cone angle large relative to a low load cone angle to inject a fuel for diffusive combustion. Accordingly, smoke and NOx are significantly reduced in a low load region while maintaining features of a middle / high load region with a single injector.

Owner:HYUNDAI MOTOR CO LTD

Full time regenerative type single radiant tube burner

ActiveUS20110056487A1Simple structureCompact designDomestic stoves or rangesAir supply regulationCombustorExhaust fumes

The present invention relates to a full time regenerative type single radiant tube burner. The full time regenerative type single radiant tube burner includes a radiant tube type burner; a regenerating unit that regenerates exhaust gas heat generated from the burner and is used for preheating the intake combustion air; and an intake and exhaust switching device that passes the intake air and the exhaust gas to the regenerating unit and heat-exchanges them and simultaneously progresses the intake and exhaust processes of the burner to perform the full time combustion.The present invention according to the above configuration operation can perform the full time combustion using the single radiant tube burner to maximize the combustion efficiency, thereby improve the energy efficiency, while the present invention makes the structure of the intake and exhaust switching device 300 simple, can compactly design the burner by mounting the regenerating unit 200, which is integrated with the intake and exhaust switching device, to surround the circumference of the burner body 110 and can manufacture the burner at a small size, such that it can be applied to various environments without limiting the installation space.

Owner:KOREA INST OF ENERGY RES

System and method for optimizing combustion of boiler

ActiveUS11232376B2Maximize combustion efficiencyMinimizationSimulator controlForecastingPower stationData modeling

A system for controlling a boiler apparatus in a power plant to combust under optimized conditions, and a method for optimizing combustion of the boiler apparatus using the same are provided. The boiler control system may include a task manager configured to collect information on a current operating state of a boiler and determine whether to perform a combustion optimization operation for the boiler, a pre-processor configured to preprocess data collected from the boiler and supply the pre-processed data, a modeler configured to create a boiler combustion model on the basis of the pre-processed data received from the pre-processor, an optimizer configured to receive the boiler combustion model from the modeler and perform the combustion optimization operation for the boiler using the boiler combustion model to calculate an optimum control value, wherein the pre-processed data is supplied to the modeler and the optimizer by the pre-processor, and an output controller configured to receive the optimum control value from the optimizer and control an operation of the boiler by reflecting the optimum control value to a boiler control logic.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Device for generating and transmitting heat capable of operating with fuel in any physical state and combustion flame

InactiveUS20110239916A1Emission reductionMaximize combustion efficiencyFuel feedersHollow bar grateCombustion chamberEngineering

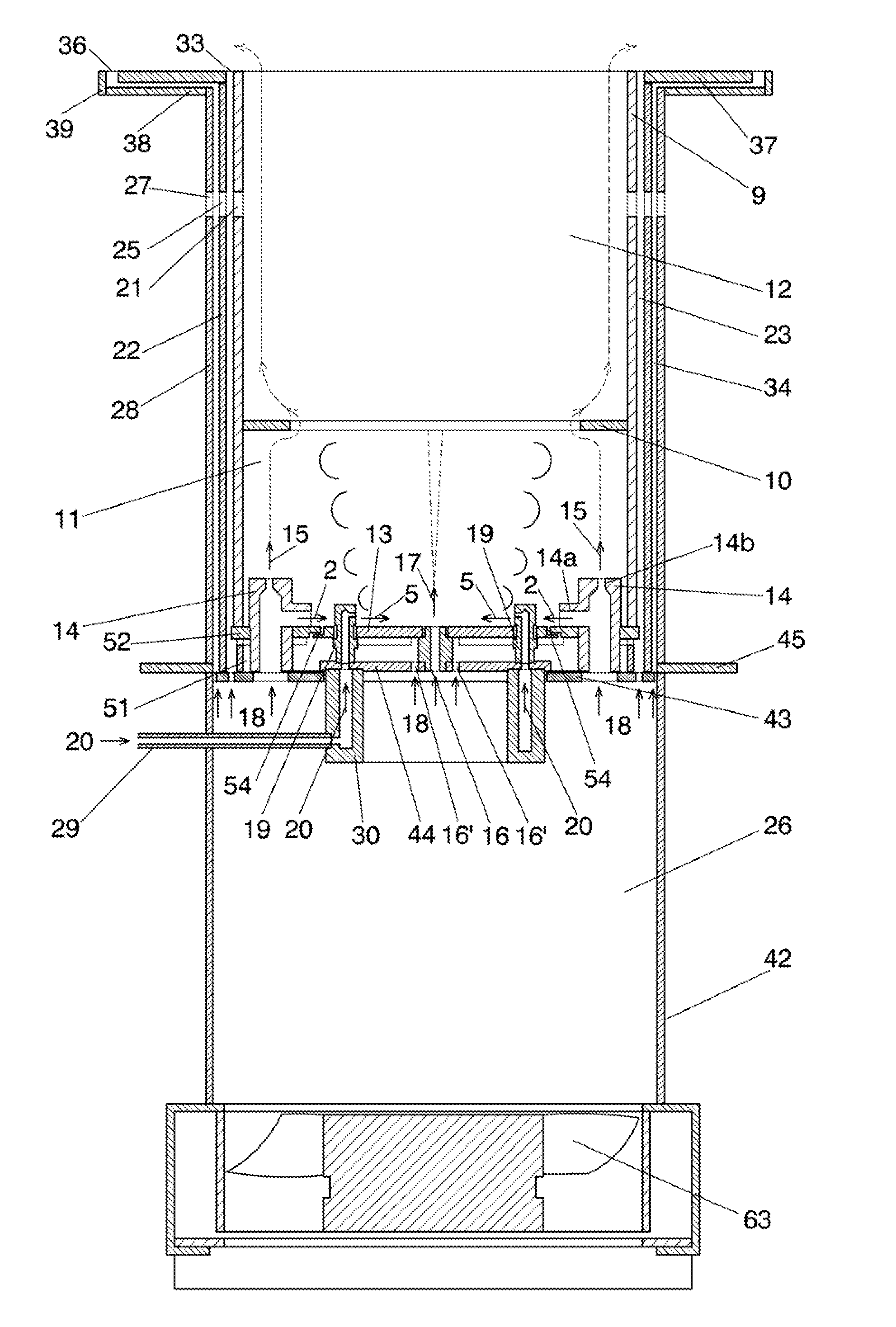

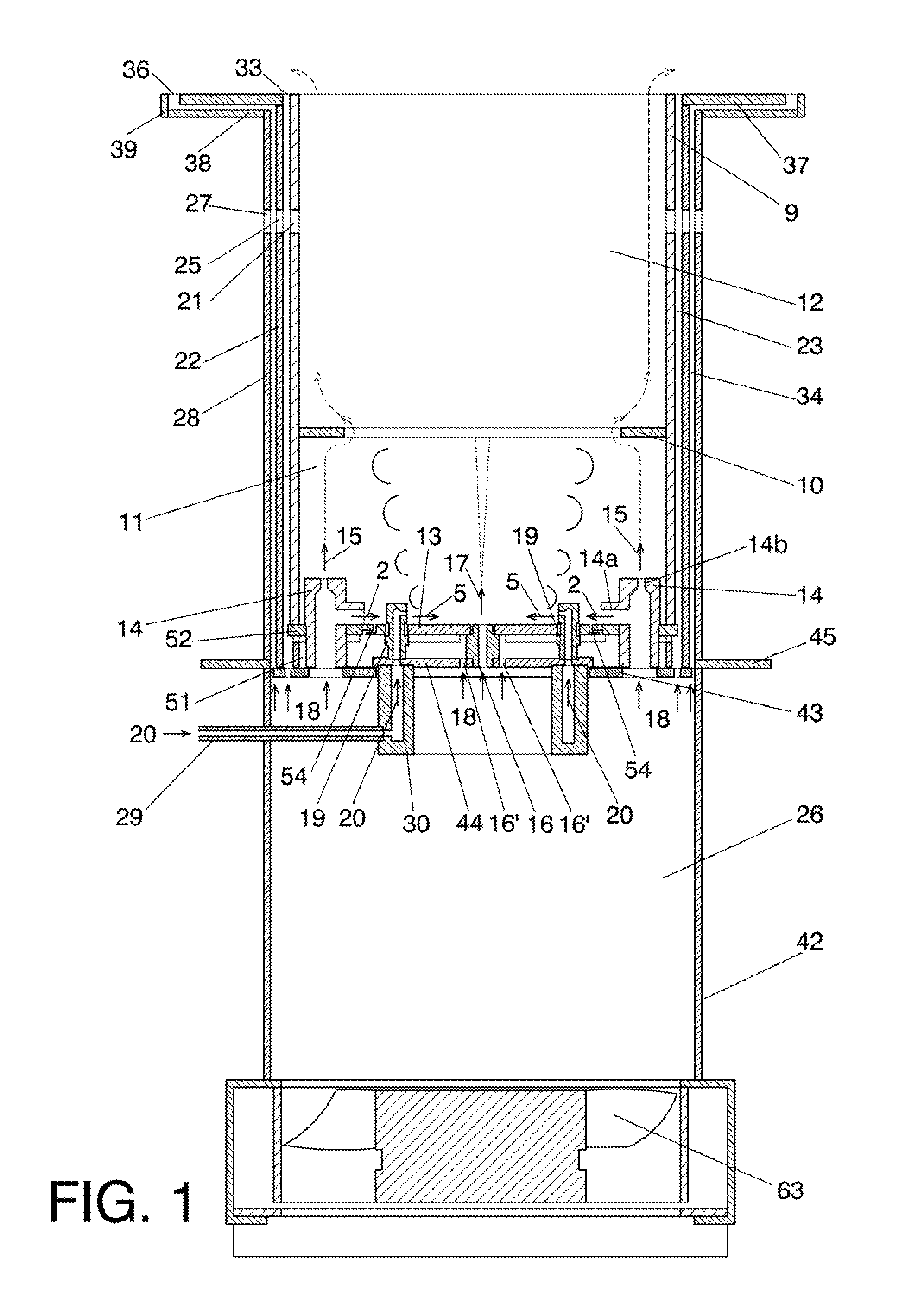

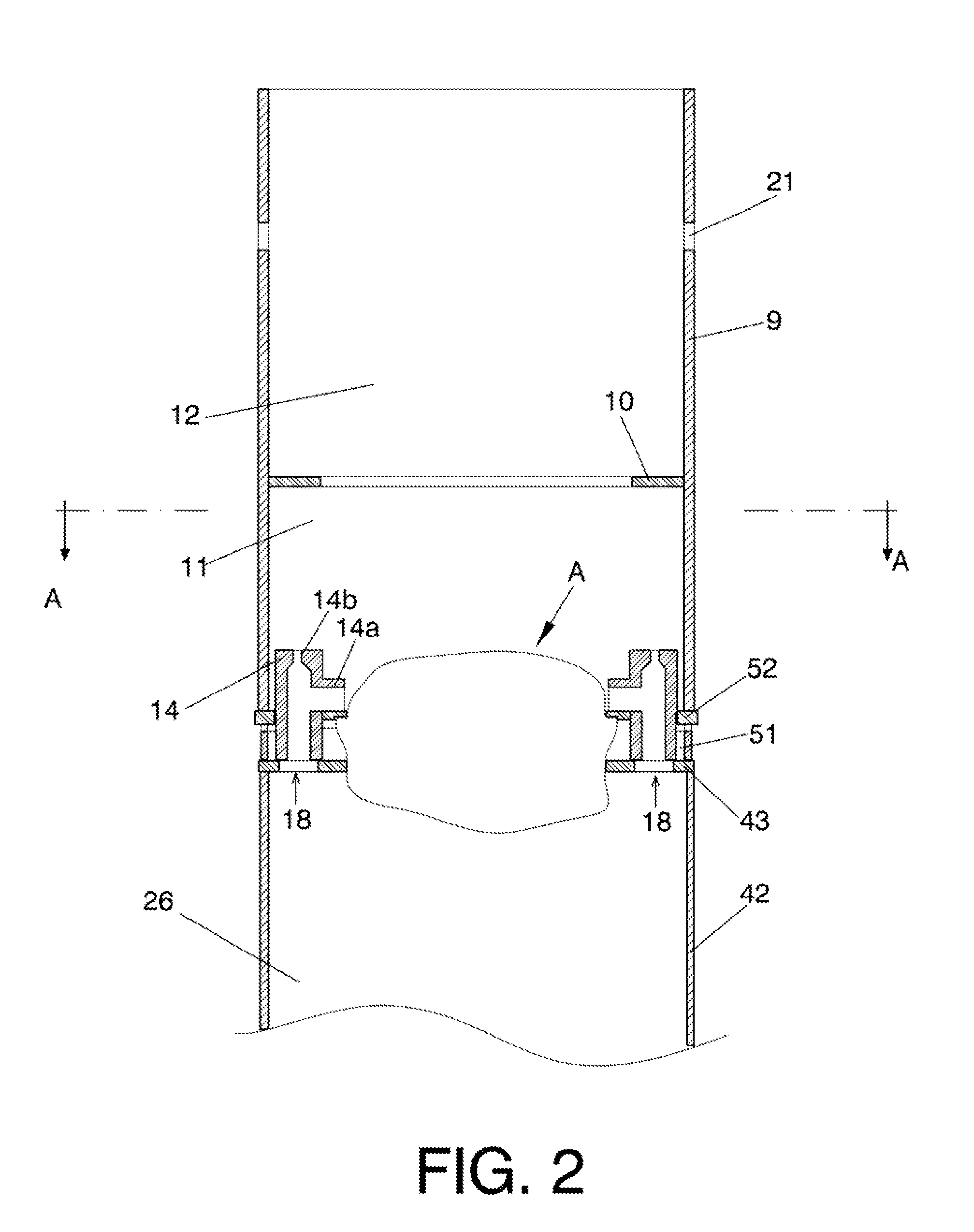

Device for generating and transmitting heat capable of operating with fuel in any physical state that includes at least one cylindrical combustion chamber (9) divided into a lower section (11) and an upper section (12) of variable height, a pressurized air chamber (26) arranged below the lower section (11) of the combustion chamber, and a plurality of air injectors (14). The device is characterized in that the air injectors (14) are supported on a flat ring (43) and set in a second flat ring (52) and in that it also includes a set of replaceable parts (A) arranged in the free centre of both flat rings (43 and 52) and whose specific configuration depends on the physical state of the fuel being used. Furthermore said set of replaceable parts (A) includes at least one central air injector (16) located in the geometric centre of the unit.

Owner:NUNEZ SUAREZ RENE MAURICIO

Boiler and method for controlling air and fuel ratio using air pressure sensor

InactiveUS7963236B2Easy dischargeEasy to controlDC motor speed/torque controlTemperatue controlFuel efficiencyVoltage reference

Disclosed is an air-fuel ratio control boiler using a air pressure sensor and method for controlling the air-fuel ratio thereof. The boiler is comprised of a fan, the air pressure sensor, a air pressure sensor voltage measurement unit, a air pressure sensor voltage compensation unit, and a controller, and previously compensates for noise factors caused by deviation (error) of a component property, a constituent, of the air pressure sensor so as to be matched to initial reference voltage prior to operating the fan, thereby maximizing the effectiveness of the air-fuel ratio. Further, the boiler makes it possible not only to exert an optimal fuel efficiency effect due to the maximization of combustion efficiency, but also to minimize discharge of harmful gases, thereby preventing environmental pollution in advance, and thus improving the reliability of products.

Owner:KYUNGDONG ONE CORP

Method for combustion control during replacement of hot-blast stove

InactiveCN105886687AQuick savingsMaximize combustion efficiencyBlast furnace detailsHeating stovesCombustionEngineering

The invention provides a method for combustion control during replacement of a hot-blast stove. The temperature of exhaust gas is increased by increasing the surplus coefficient. At the initial stage of replacement of the hot-blast stove, the gas amount is controlled to be 100000-110000 m<3> / h, the air proportion is 0.6-0.65, the surplus coefficient is 1.04-1.06, the hot-blast stove is heated until the roof temperature is 1320-1350 DEG C and the temperature of exhaust gas is 240-250 DEG C; and then the gas amount and the air proportion are increased, specifically, the gas amount is controlled to be 110000-120000 m<3> / h, the air proportion is 0.65-0.7, the surplus coefficient is 1.06-1.08, and air flow is driven by air so as to enable the temperature of exhaust gas to be increased to 390-400 DEG C. By means of the method, the extensive roof and exhaust gas control mode in an existing hot-blast stove combustion method is avoided, the stove replacement time can be shortened, fuel consumption is saved, the hot-blast stove can store energy rapidly, the combustion efficiency maximization of the hot-blast stove is achieved, the effect that heat is sufficient when the hot-blast stove feeds air is ensured, and accordingly higher air temperature is provided for a blast furnace.

Owner:ANGANG STEEL CO LTD

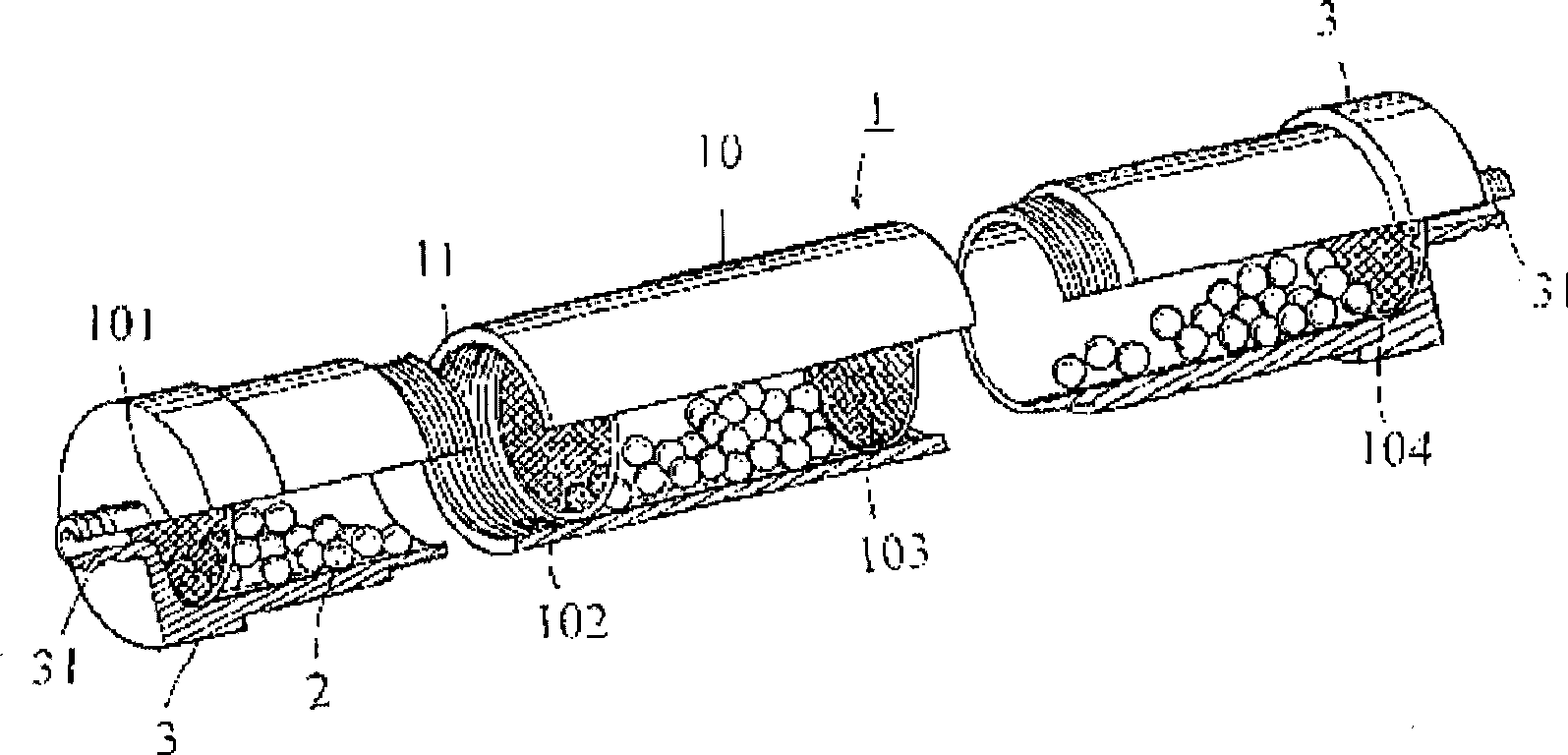

Device for accelerating combustion of liquid fuel and system for accelerating combustion of liquid fuel for internal combustion engine

InactiveCN101460731AReduce the amount of exhaust gasProtect the Earth's EnvironmentInternal combustion piston enginesCombustion-air/fuel-air treatmentPollutantCeramic

The present invention relates to a device for accelerating the combustion of liquid fuel for improving the combustion efficiency of liquid fuel used in an internal combustion engine and a system for accelerating the combustion of liquid fuel using the device. The device is characterized in that magnets are provided in a metal pipe, and pure tourmaline ceramics and mixed tourmaline ceramics are used as a catalyst, so that fuel molecules are atomized by the magnetic field, generated by the magnets, and by far infrared rays, radioactive rays, and the like generated from the catalyst, thereby accelerating the combustion of fuel. The internal combustion engine using the device and system of the present invention can realize fuel savings and can reduce the discharge of environmental pollutants.

Owner:TKL NEWTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com