Frac water heater and fuel oil heating system

a technology of frac water heater and fuel oil heating system, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, combustion types, etc., can solve the problems of poor cold tolerance, inconvenient heating, and inability to construct permanent heating facilities at well sites, so as to improve the viscosity and flow rate of fuel oil, the effect of improving the cold toleran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

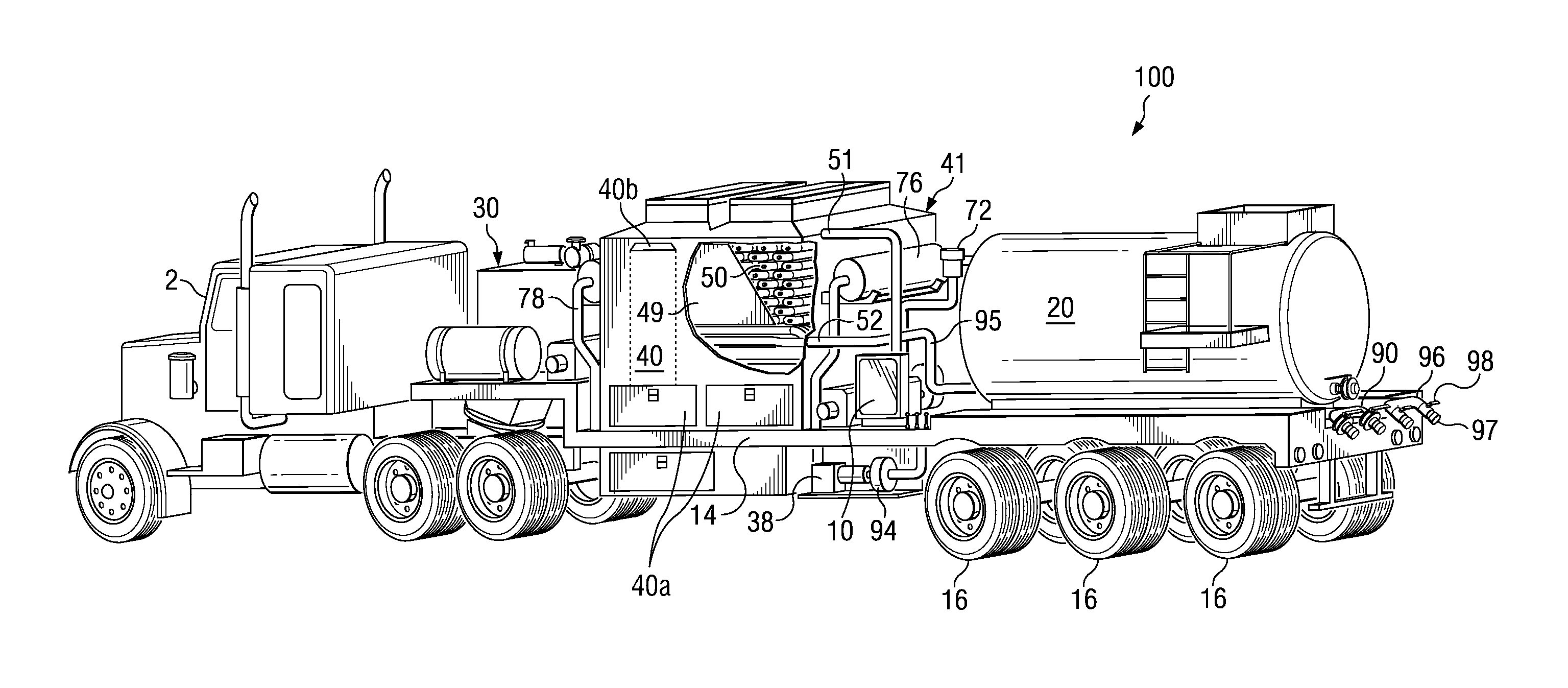

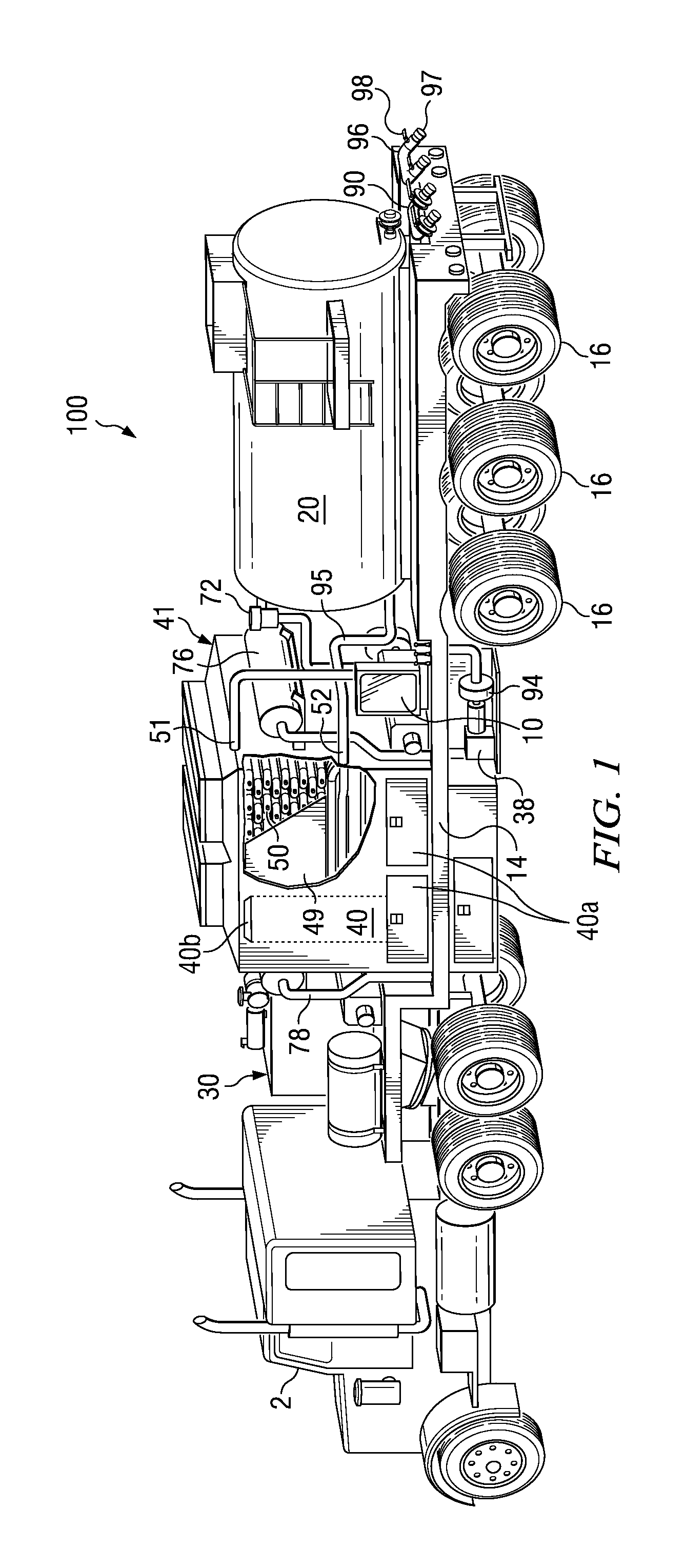

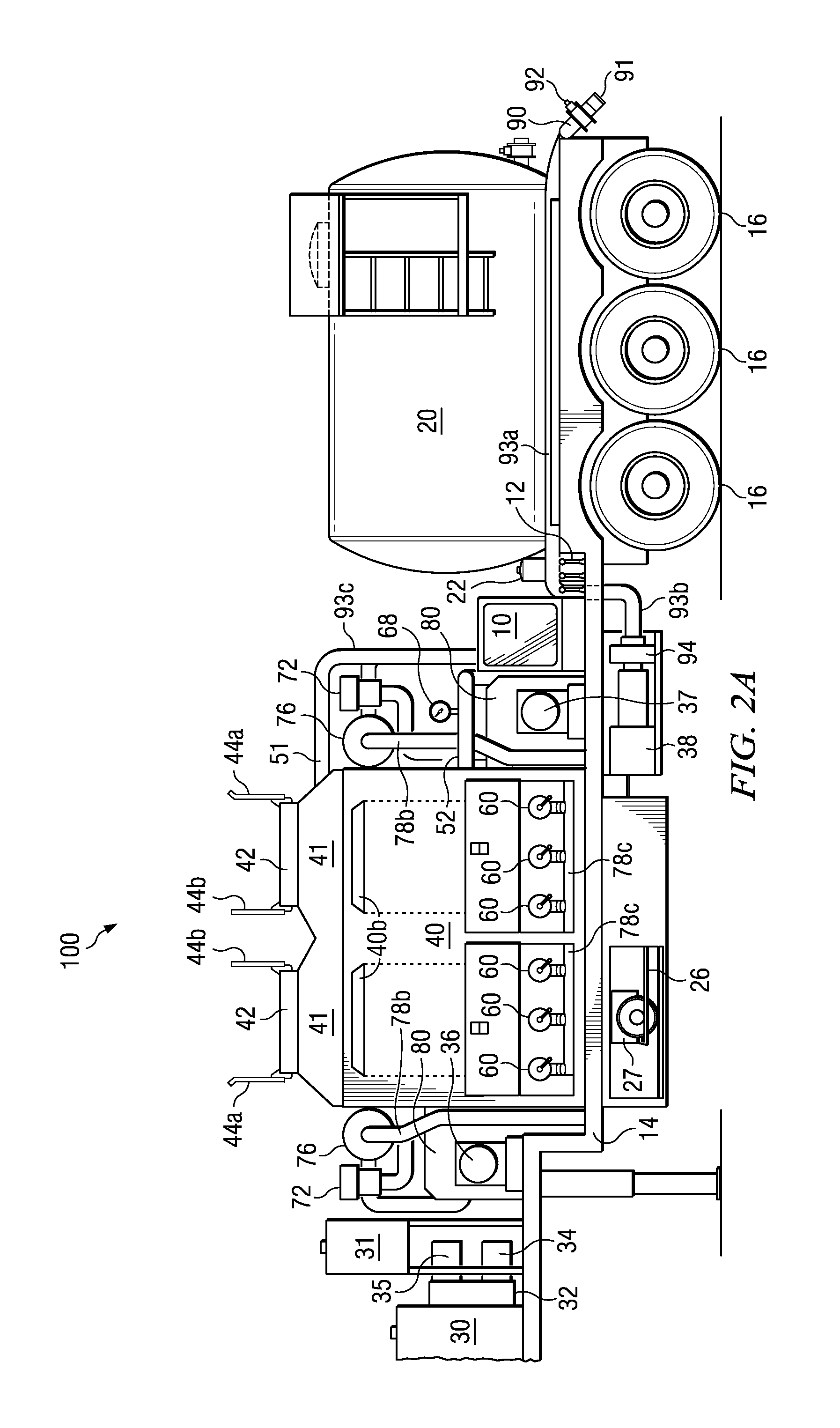

[0046]With reference to the Figures, and in particular to FIGS. 1 and 2A-C, an embodiment of the improved oil-fired heat exchanger system 100 of the present invention is shown. The embodiment 100 shown in the Figures is configured to be an oil-fired frac water heater system. As depicted, the embodiment of the frac water heater system 100 is configured on a drop deck trailer 14 and suitable for transport to remote oil field sites. The system 100 includes a fuel storage and supply system, a firebox 40 containing a single heat exchanger 50, primary 70 and secondary 80 air supply systems connected to the firebox 40, and an auxiliary power plant 30 for driving an accessory gearbox 32. The accessory gearbox 32, in turn, drives multiple hydraulic pumps, which power a main fluid pump 94 and the air supply systems. The main fluid pump 94 is used to draw fluid, such as water, from a fluid source and supply it to the intake 51 of the heat exchanger 50. The hydraulic pressure generated by the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com