Combustion pursuing device

A combustion tube and fuel technology, which is used in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of inability to keep up with the working frequency, lack of competitiveness, and insufficient specific impulse, and achieves powerful functions, simple structure, The effect of reducing the exhaust time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

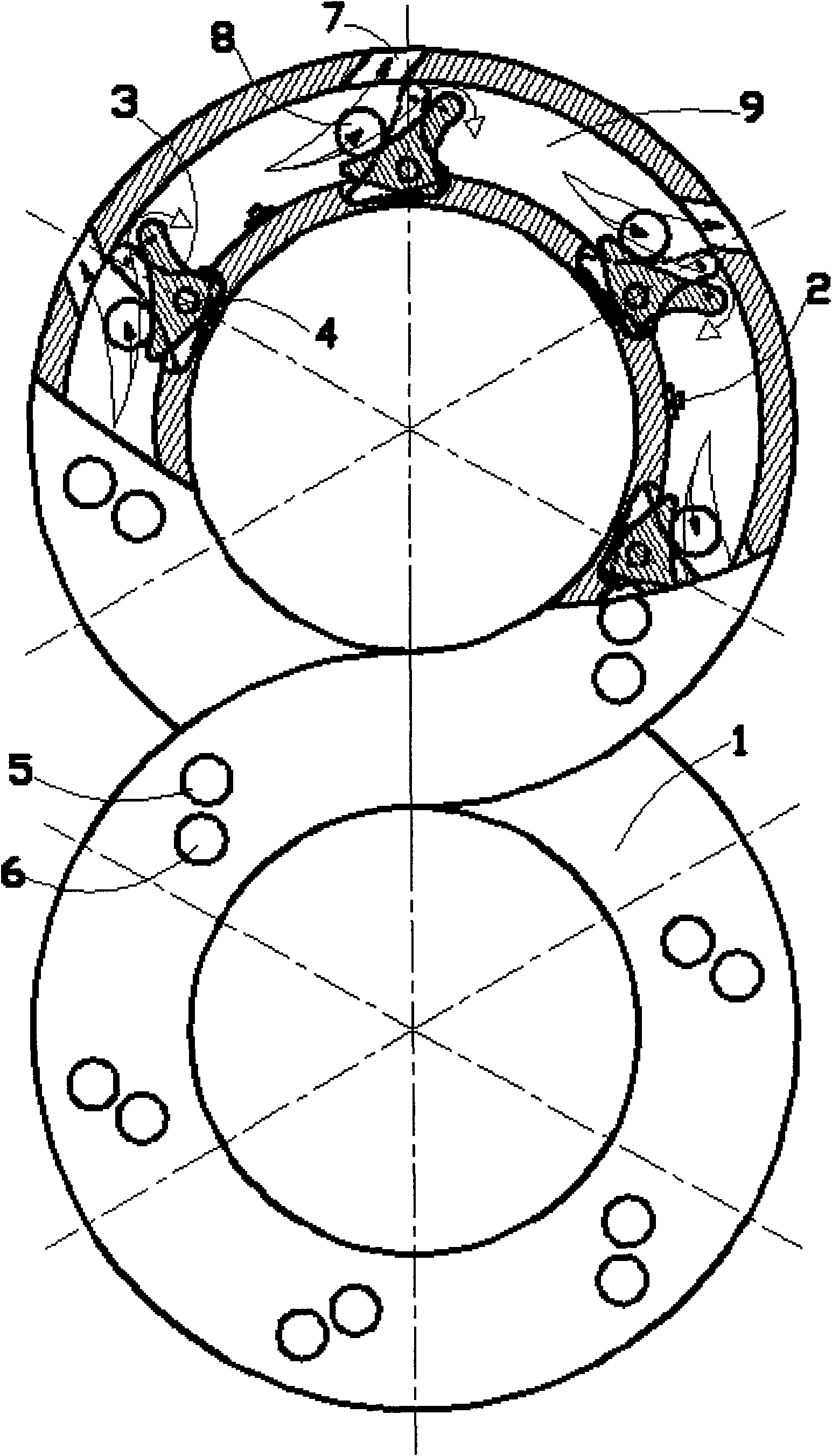

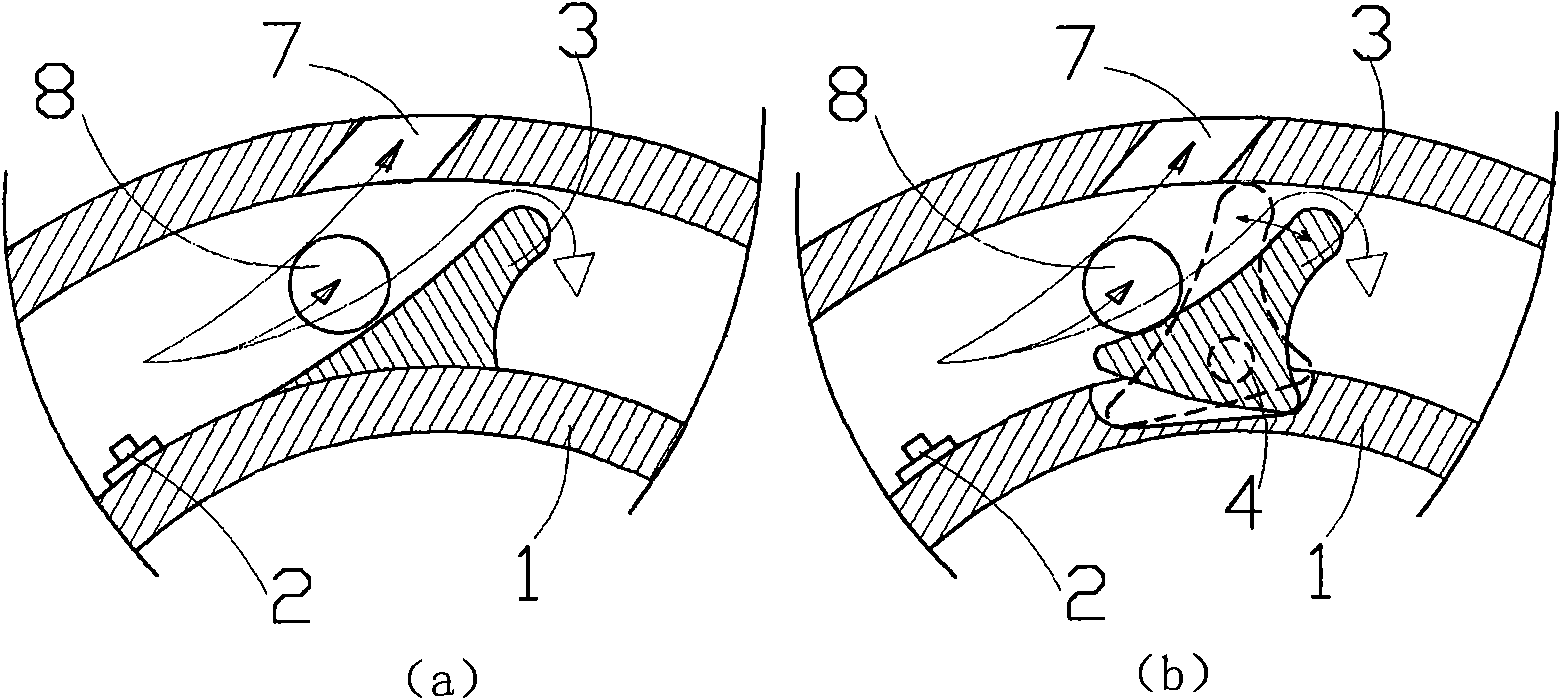

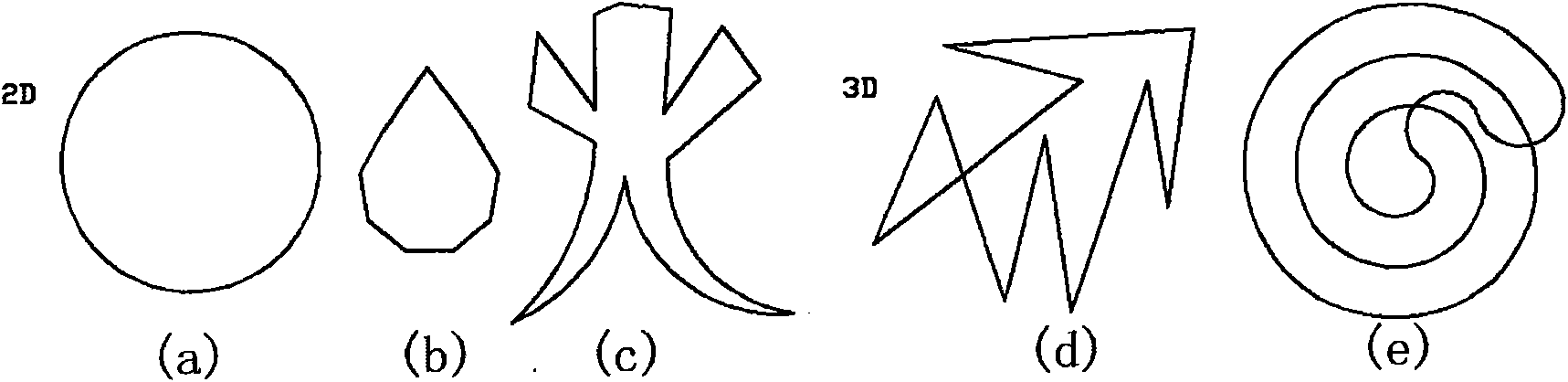

[0049] Embodiment two: see figure 1 , figure 2 and image 3 , the principle of this embodiment is the same as that of Embodiment 1, and the special feature is that: the pipe body (1) can have various configurations, including two-dimensional structures and three-dimensional structures, so as to meet the ignition requirements of complex geometry.

Embodiment 3

[0050] Embodiment three: see figure 1 , figure 2 and Figure 4 , this embodiment is the same as Embodiment 1, the special feature is: the ignition device in the pipeline can be multi-group ignition, depending on the actual demand.

Embodiment 4

[0051] Embodiment four: see figure 1 , figure 2 , Figure 4 and Figure 5 , this embodiment is the same as Embodiment 1, and the special feature is: the ignition device in the pipeline can be multi-group ignition can be synchronous ignition or asynchronous ignition, and the chasing of the flame surface can also be synchronous or asynchronous, depending on the actual need.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com