Gas combustion arrangement using circular stream

A combustion device and gas technology, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of short time, large space, limited filtration capacity of purifiers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

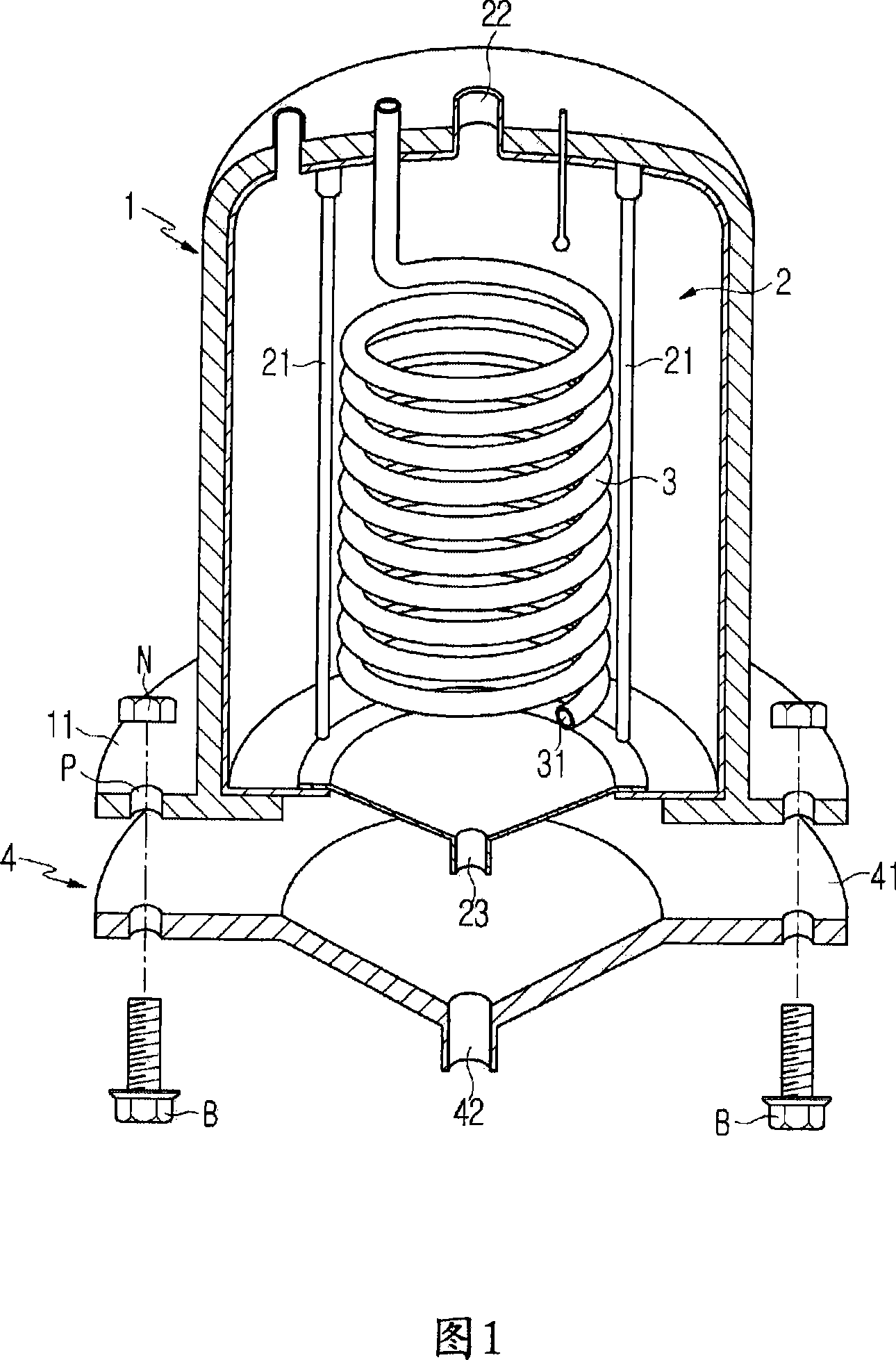

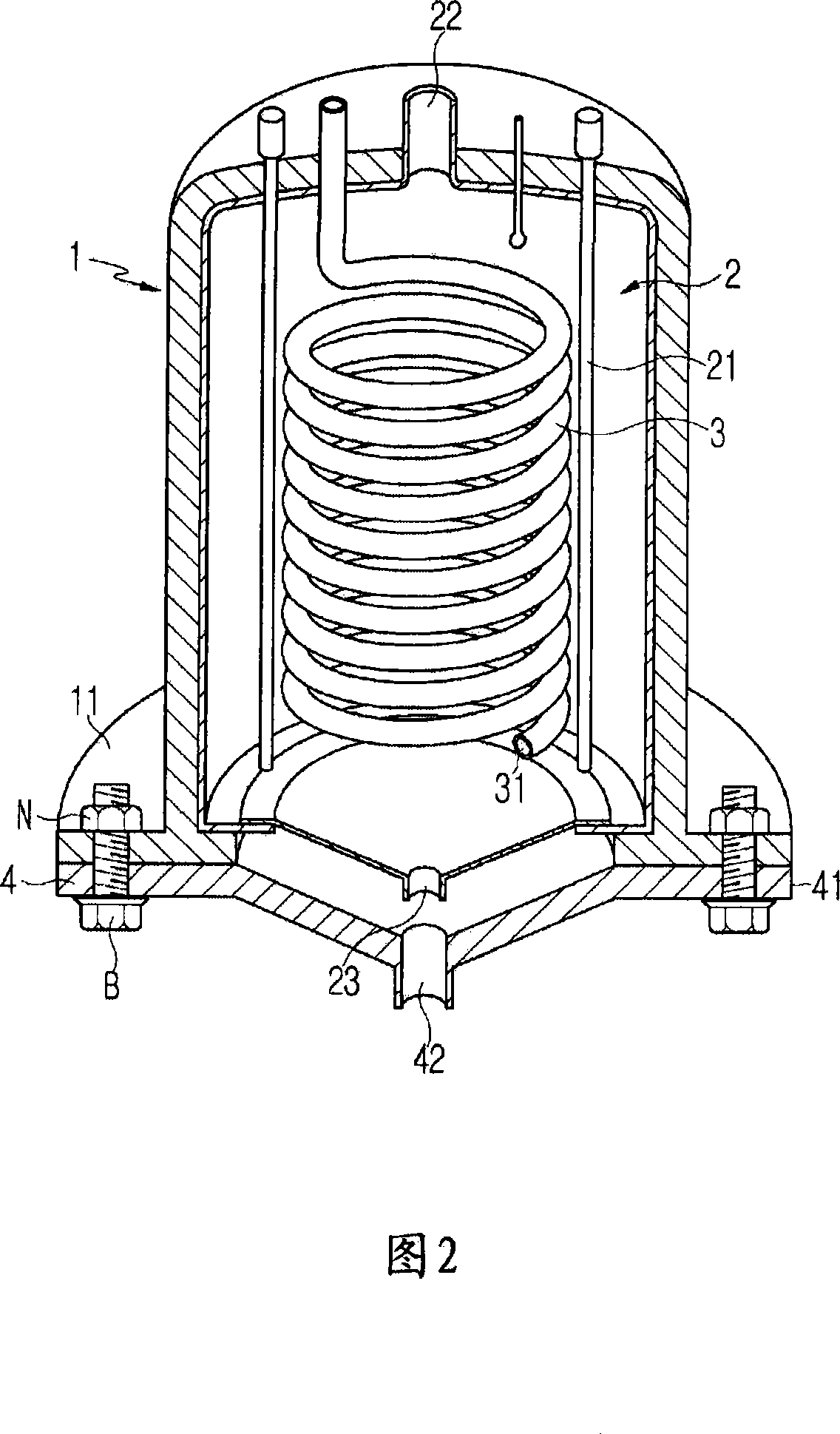

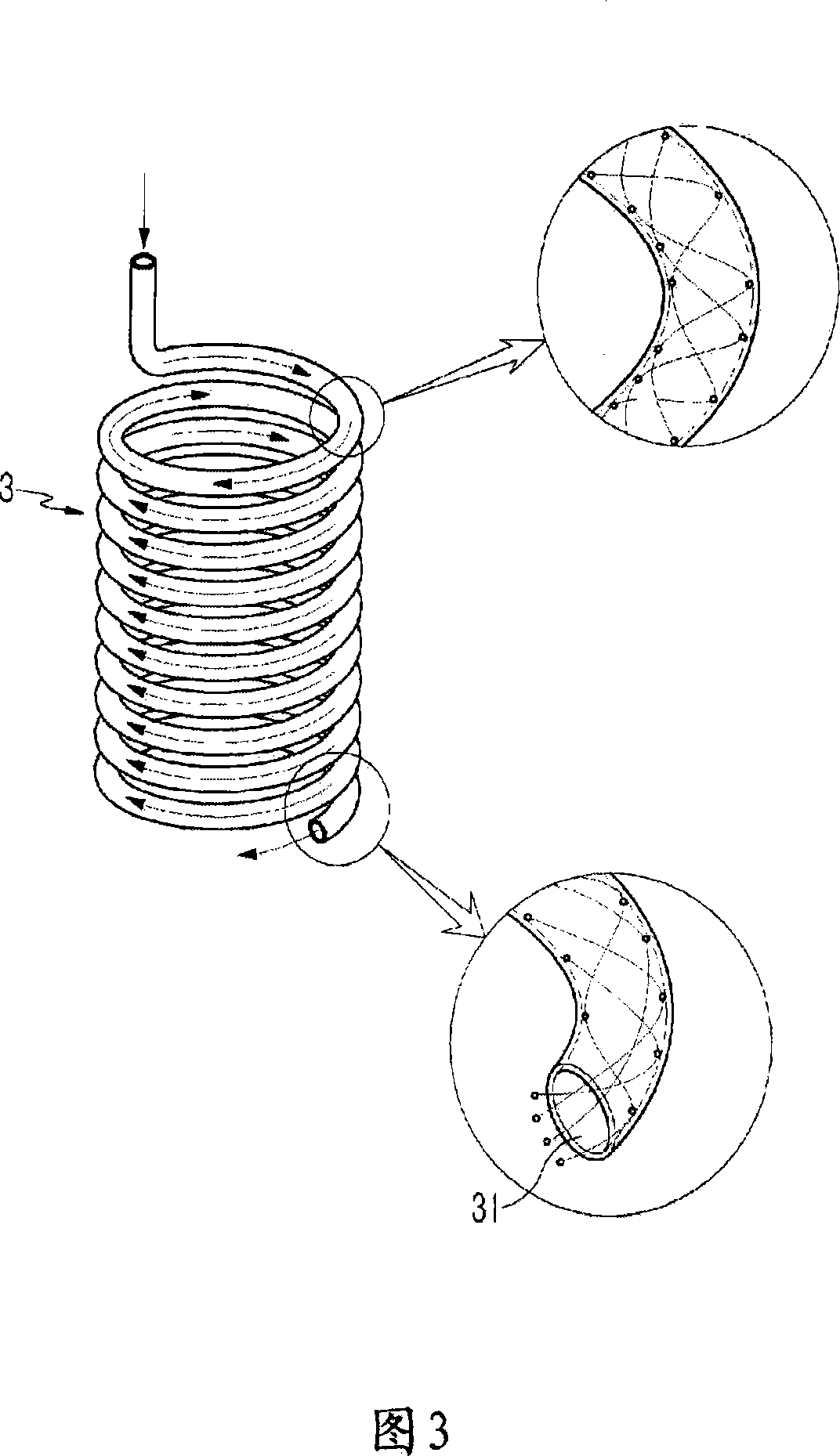

[0019] Hereinafter, the structure and operation of a gas combustion apparatus using circulating flow according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0020] Fig. 1 is the partial dissection view of the gas combustion device utilizing circulation according to the embodiment of the present invention; Fig. 2 is the sectional view showing the combined state of the gas combustion device utilizing circulation according to the embodiment of the present invention; Fig. 3 is according to the embodiment of the present invention and FIG. 4 is a view showing an operating state of the gas combustion device using circular flow according to an embodiment of the present invention.

[0021] Referring to FIGS. 1 to 4 , a gas combustion device using a circular flow according to an embodiment of the present invention includes a housing 1 , a heat generating part 2 , a combustion tube 3 and a supporting installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com