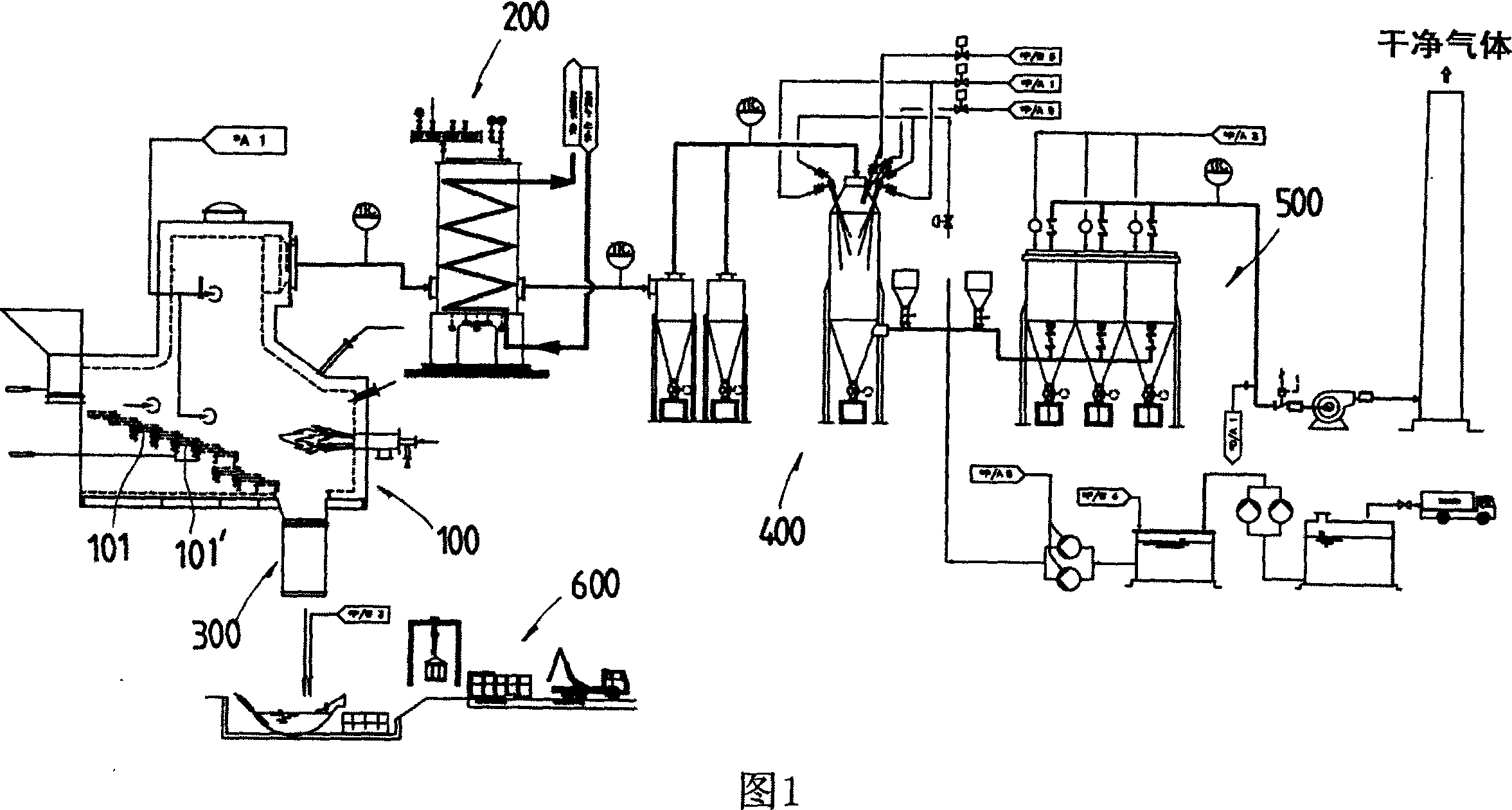

Combustion apparatus for r.p.f boiler

A solid fuel and combustion device technology, which is applied in the direction of solid fuel combustion, combustion chambers, combustion methods, etc., can solve the problems of uneven air, combustion air cannot be diffused in a wide range, and fuel waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

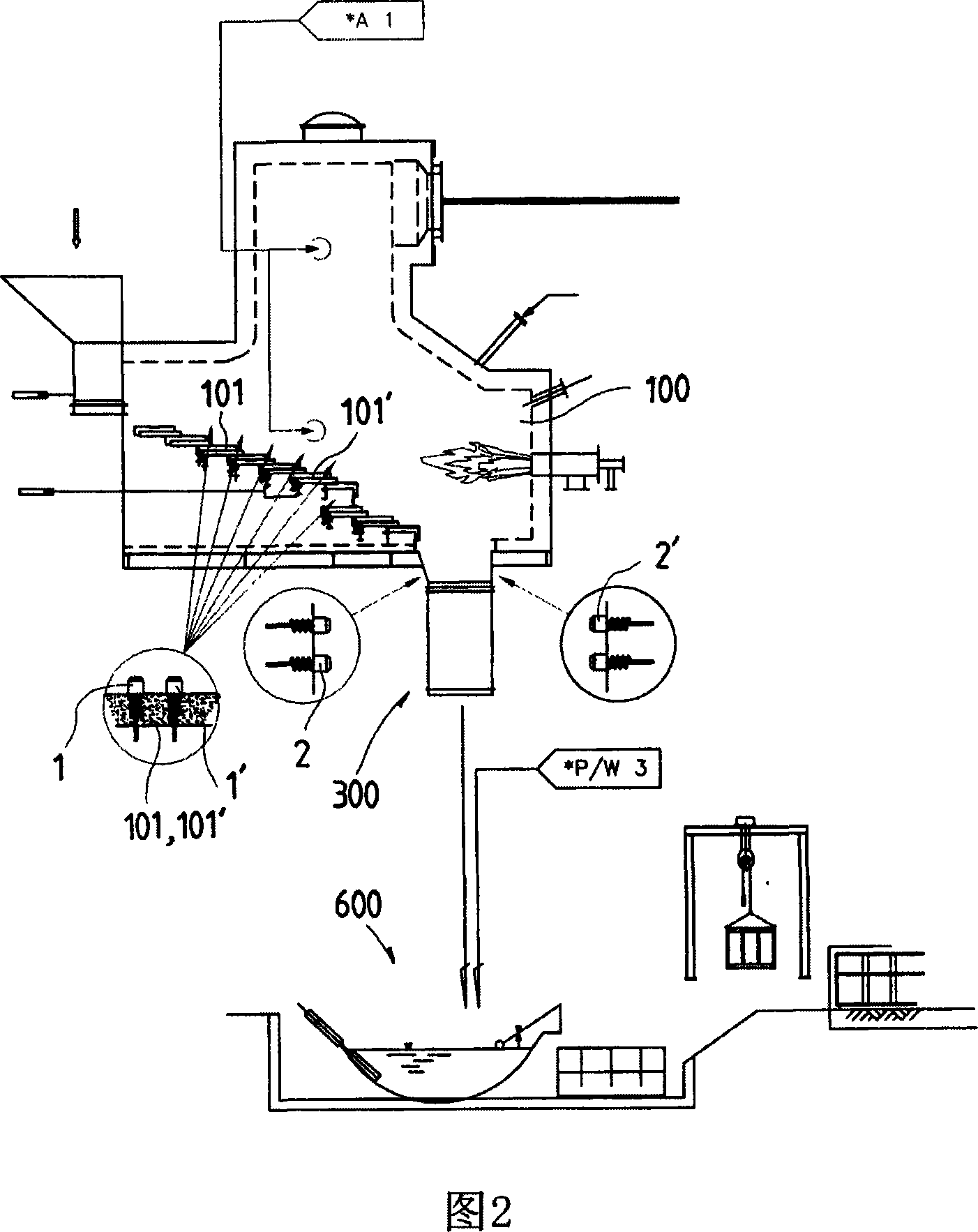

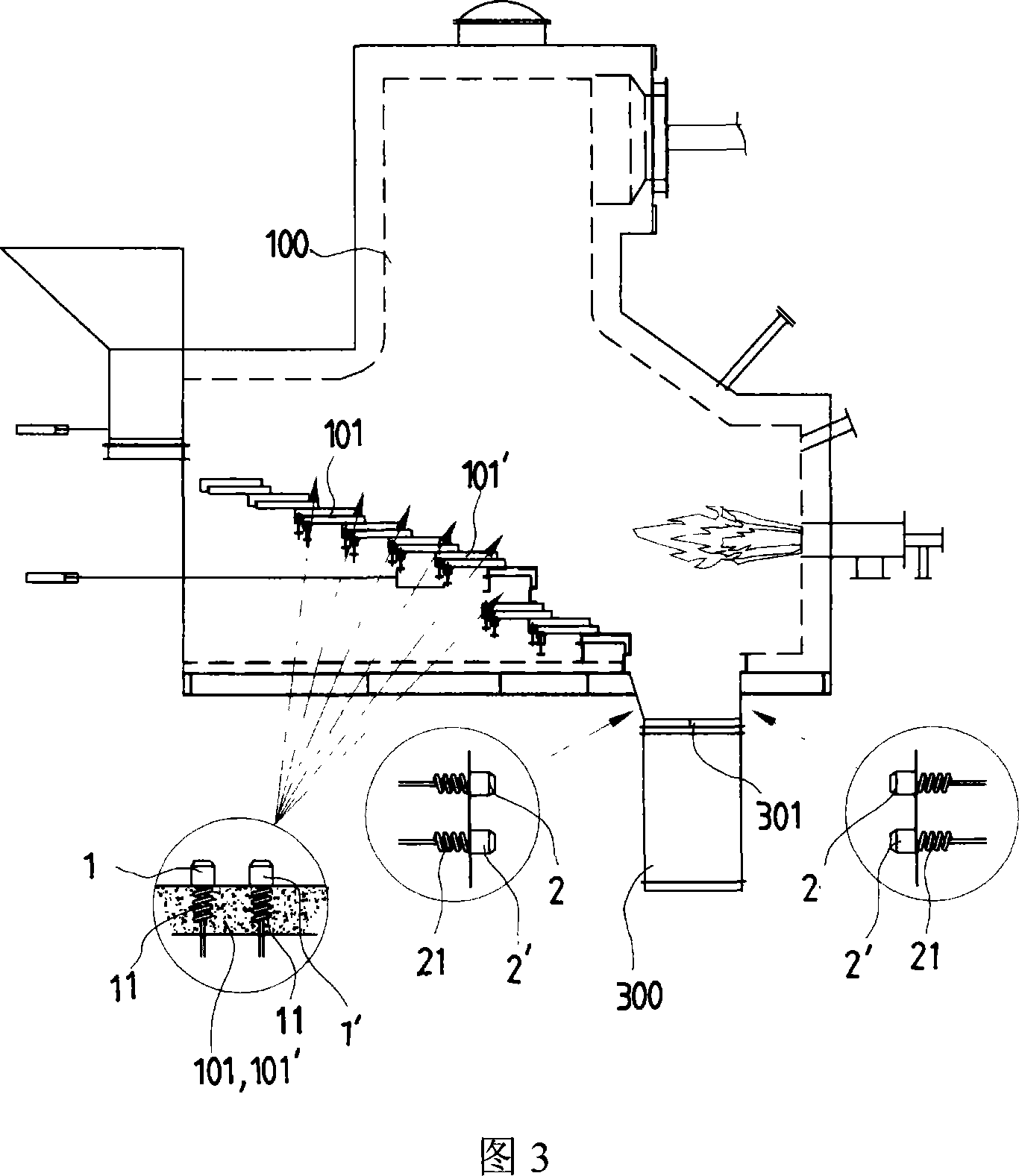

[0029] Spiral air nozzles (1, 1') are arranged on each fire grate (101, 101') arranged downwardly in a stepwise manner in the combustion furnace (100).

[0030] A part of the supply pipe (12) at the end of the spiral air nozzle (1, 1') provided on the grate (101, 101') is a coiled pipe part (12) of a spiral (Coil) type, and the air nozzle (1, 1') Make the combustion air supplied by the supply pipe (12) connected with the blower pass through the coiled pipe part (12) and be vortex dispersed, and generate a cyclone (Cyclone) in the combustion furnace (100) during supply, like this , the combustion air supplied into the combustion furnace (100) can be diffused and fully mixed with the solid fuel, thereby promoting the combustion of the fuel.

[0031] In order to utilize the spiral air nozzles (1, 1') to make the combustion air disperse and supply in a vortex flow in the combustion furnace (100) through the coiled pipe portion (12), the nozzle hole (13) should have a certain rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com