Systems and methods for implementing an advanced energy efficient boiler control scheme

a technology of advanced energy efficient boilers and control schemes, applied in the direction of air heaters, heating types, lighting and heating apparatus, etc., can solve the problems of not employing conventional thermostats, reducing the efficiency of boiler cycle cycle cycle, and significantly affecting the operation of the boiler. , to achieve the effect of increasing the comfort of building occupants, maximizing the combustion efficiency of the boiler, and significant cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

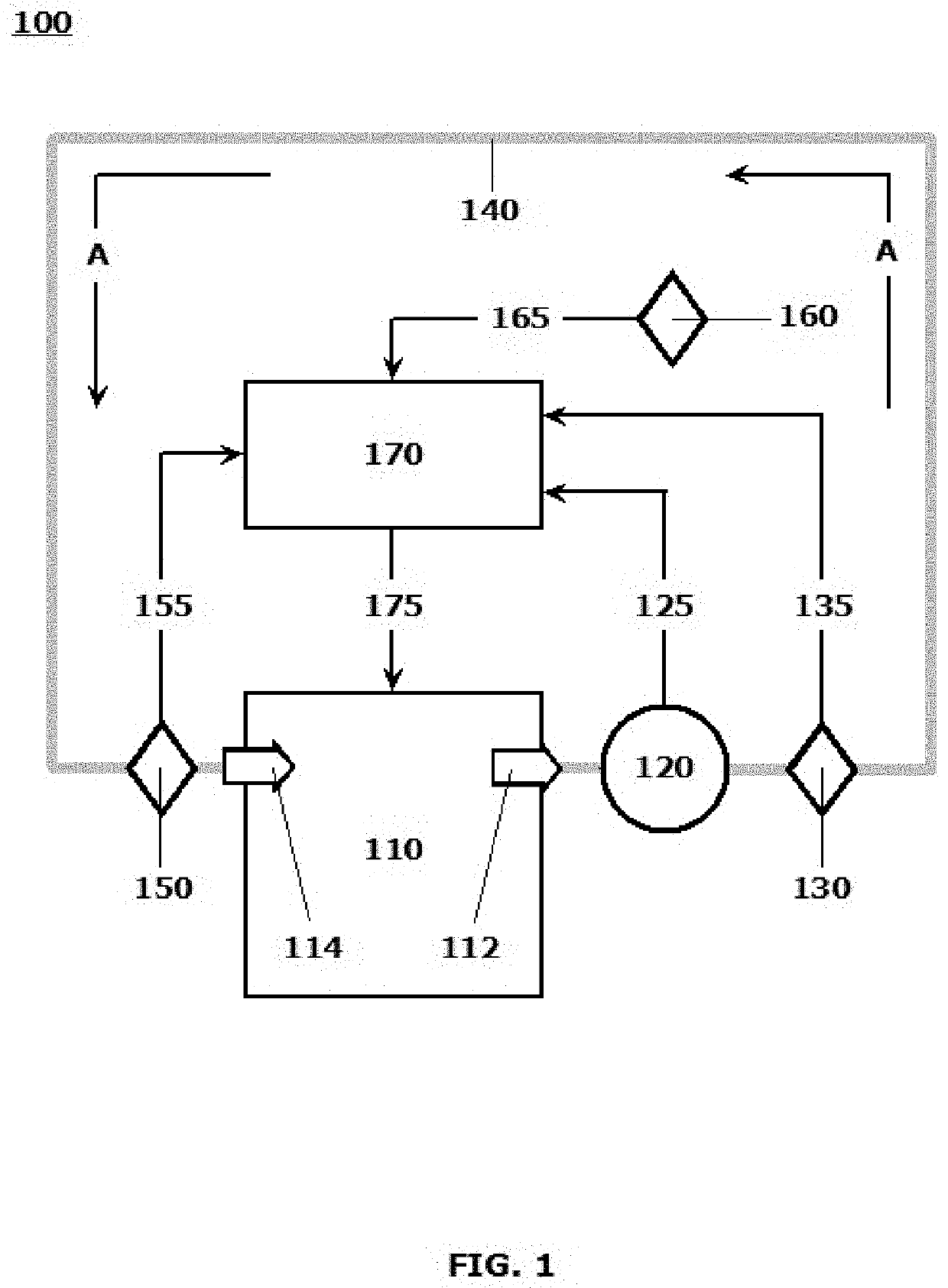

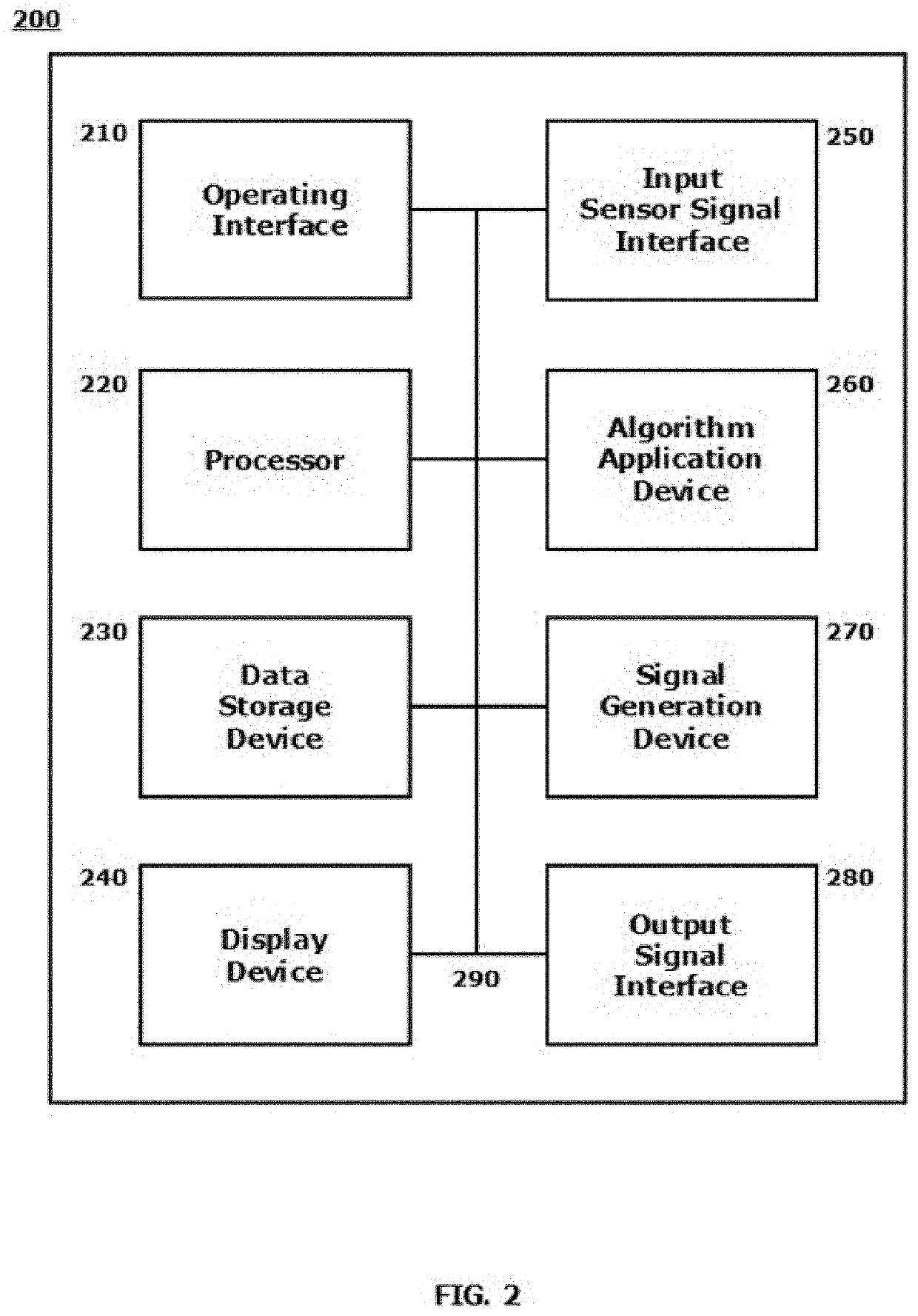

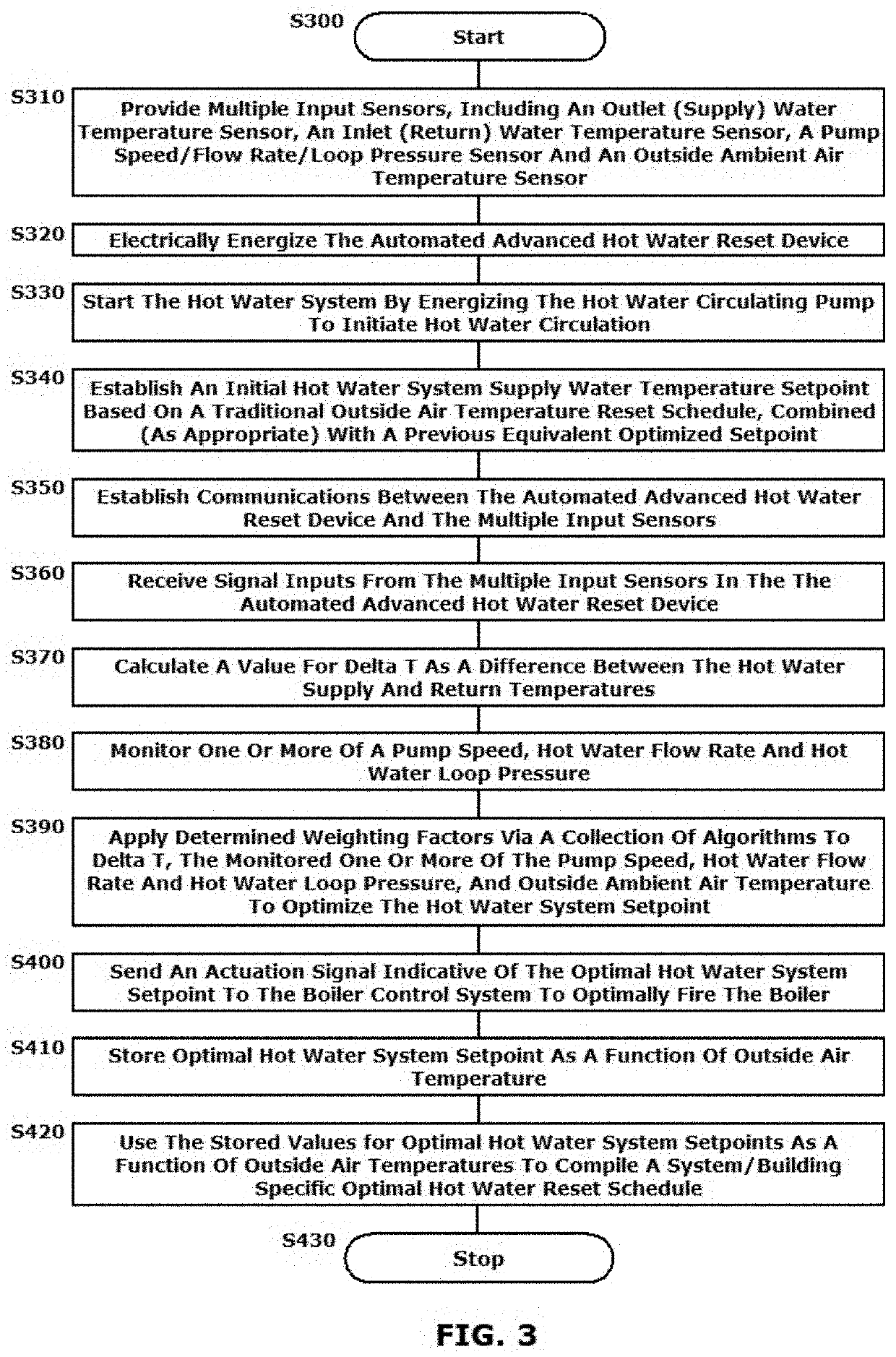

[0010]In view of any one or more of (1) advances in system sensors, system control components, including digital controls and intelligent equipment design, (2) a challenge to constantly increase efficiencies in environmental control systems, and (3) an understanding of limitations in further efficiencies that may be realized given the dated nature of the conventional linear reset techniques, it may be advantageous to introduce uniquely updated and contemporary boiler control systems, algorithms, and system control components, and to implement associated methods, for advanced non-linear hot water reset for boilers.

[0011]In exemplary embodiments of the systems and methods according to this disclosure, it may be advantageous to implement certain schemes that allow modern digital building control systems, and advanced control for boilers, whereby a supply water temperature needed to meet space environmental comfort requirements is determined in a manner that maximizes combustion efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com