Multichannel discharging, atomizing, ablating and grinding compound processing method

A compound processing and multi-channel technology, which is applied in the field of multi-channel discharge atomization ablation grinding compound processing, can solve the problems that ablation processing cannot be continued, does not have conductivity and flammability, and reduces the utilization rate of spark discharge, etc. To achieve a wide range of use, improve the quality of the processed surface, and the effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

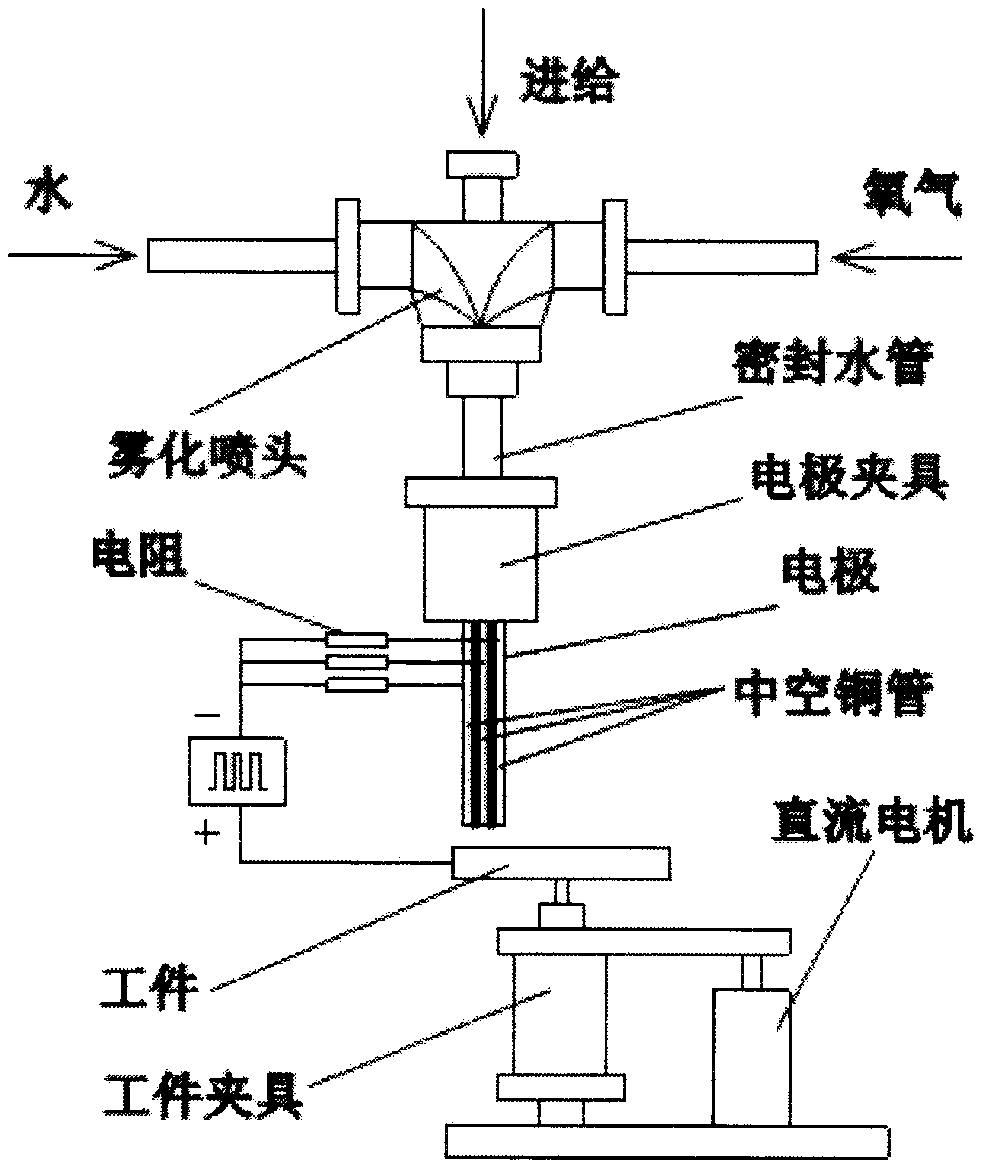

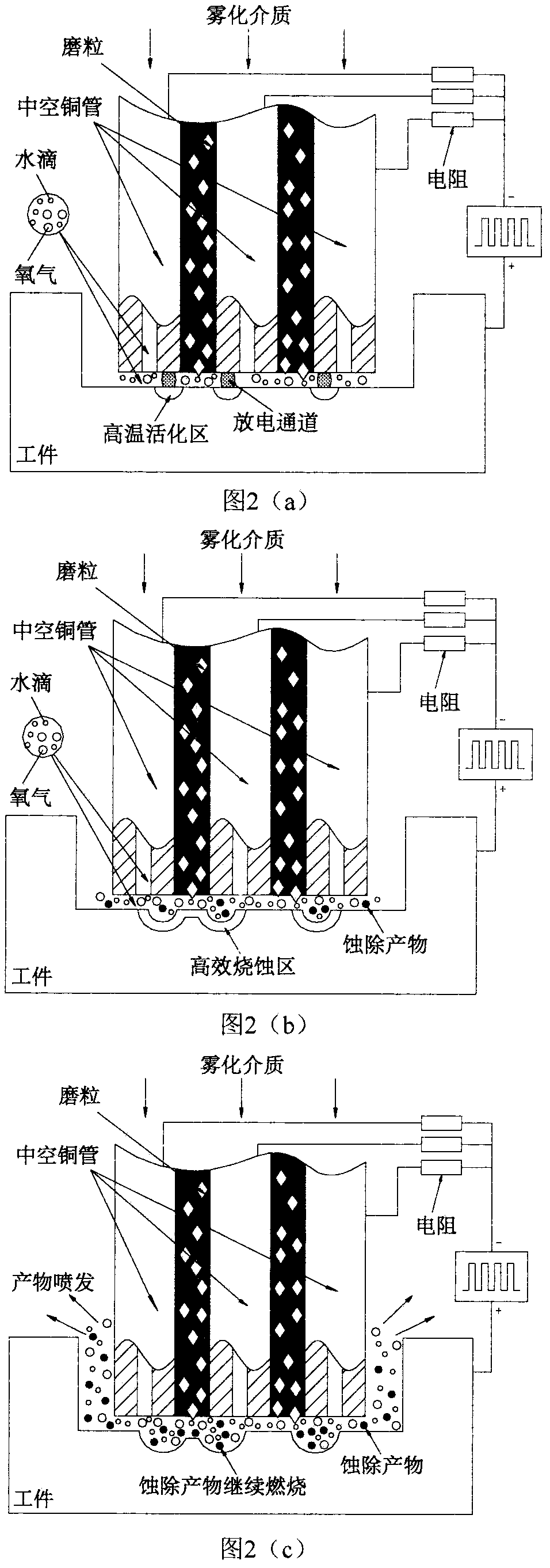

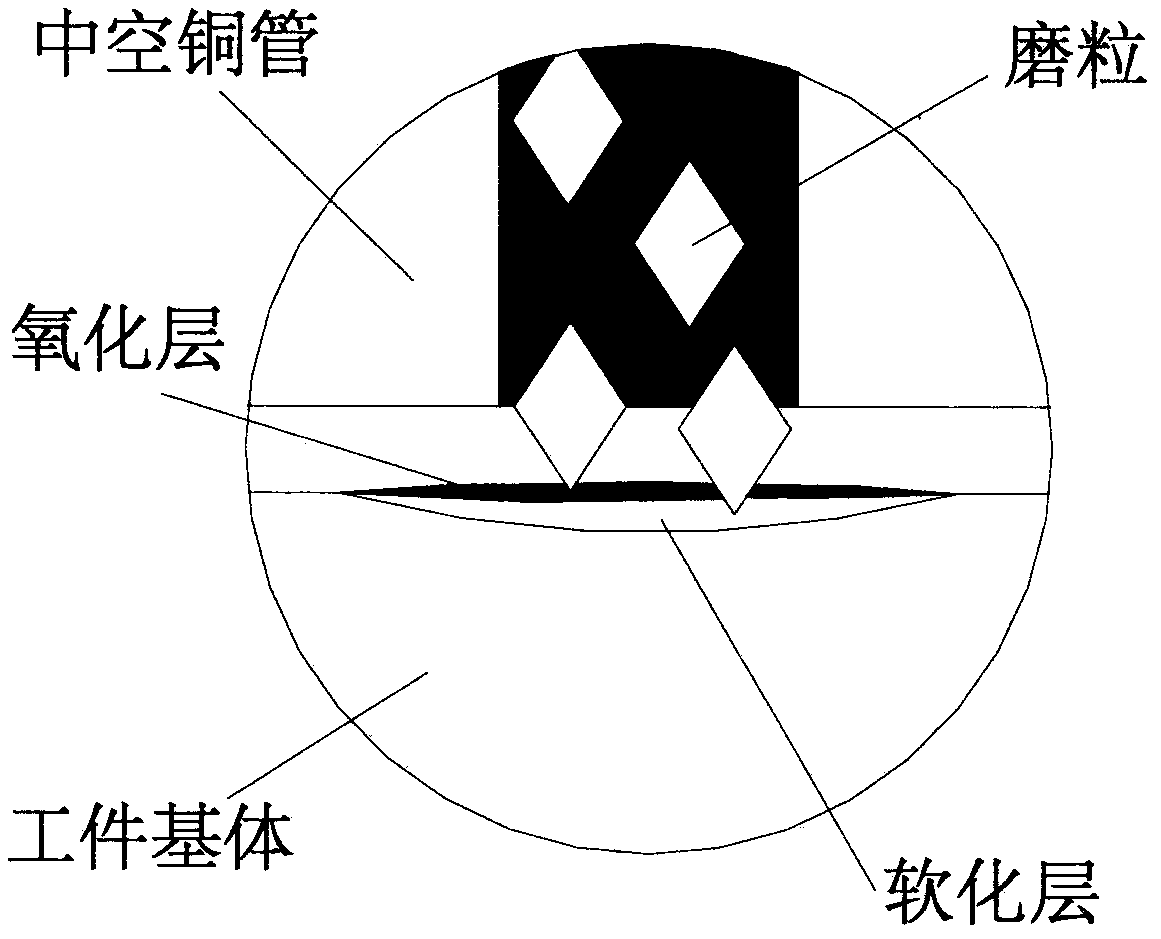

[0037] The multi-channel discharge atomization ablation grinding composite processing method specifically uses the induction effect of the multi-channel discharge of the electric spark to realize multiple discharge points at the same time in the processing area, so as to disperse the discharge energy and expand the metal burning during the processing. The range, fully utilizing the ablation effect produced by the multi-point activation of the material, is beneficial to improve the processing efficiency. The mechanical grinding effect of abrasive grains plays an online dressing effect on the ablated surface, removes the surface oxide layer and the metal material that has been ablated and softened, promotes the continuous ablation reaction, and improves the processing efficiency and surface quality. The atomization medium is introduced to disperse the oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com