Special protection device for flange and union

A protection device and flange technology, used in flange connection, pipeline protection, pipeline damage/wear prevention, etc., can solve problems such as difficult handling, uneven force at the connection, and liquid piercing leakage, achieving economical, The effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

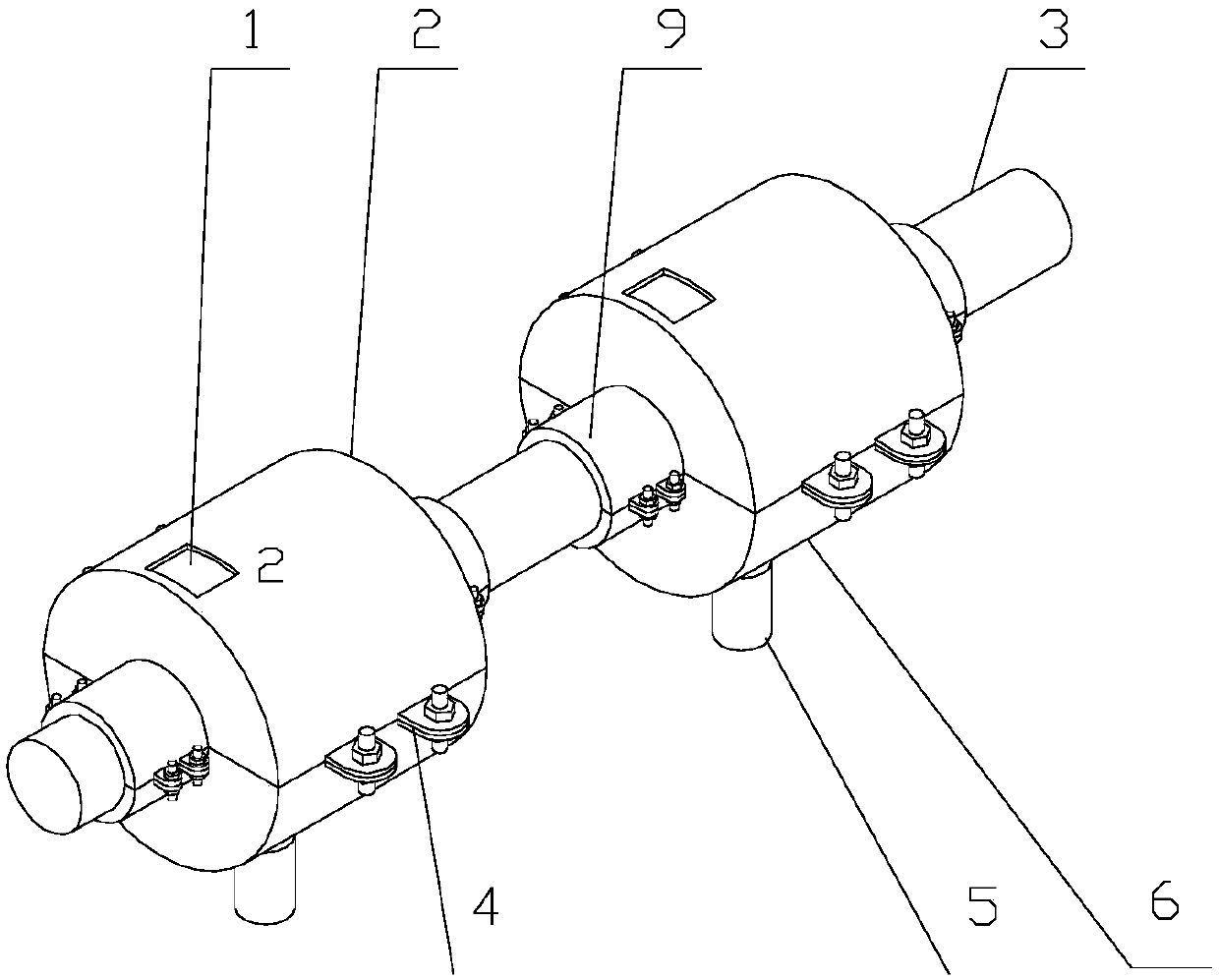

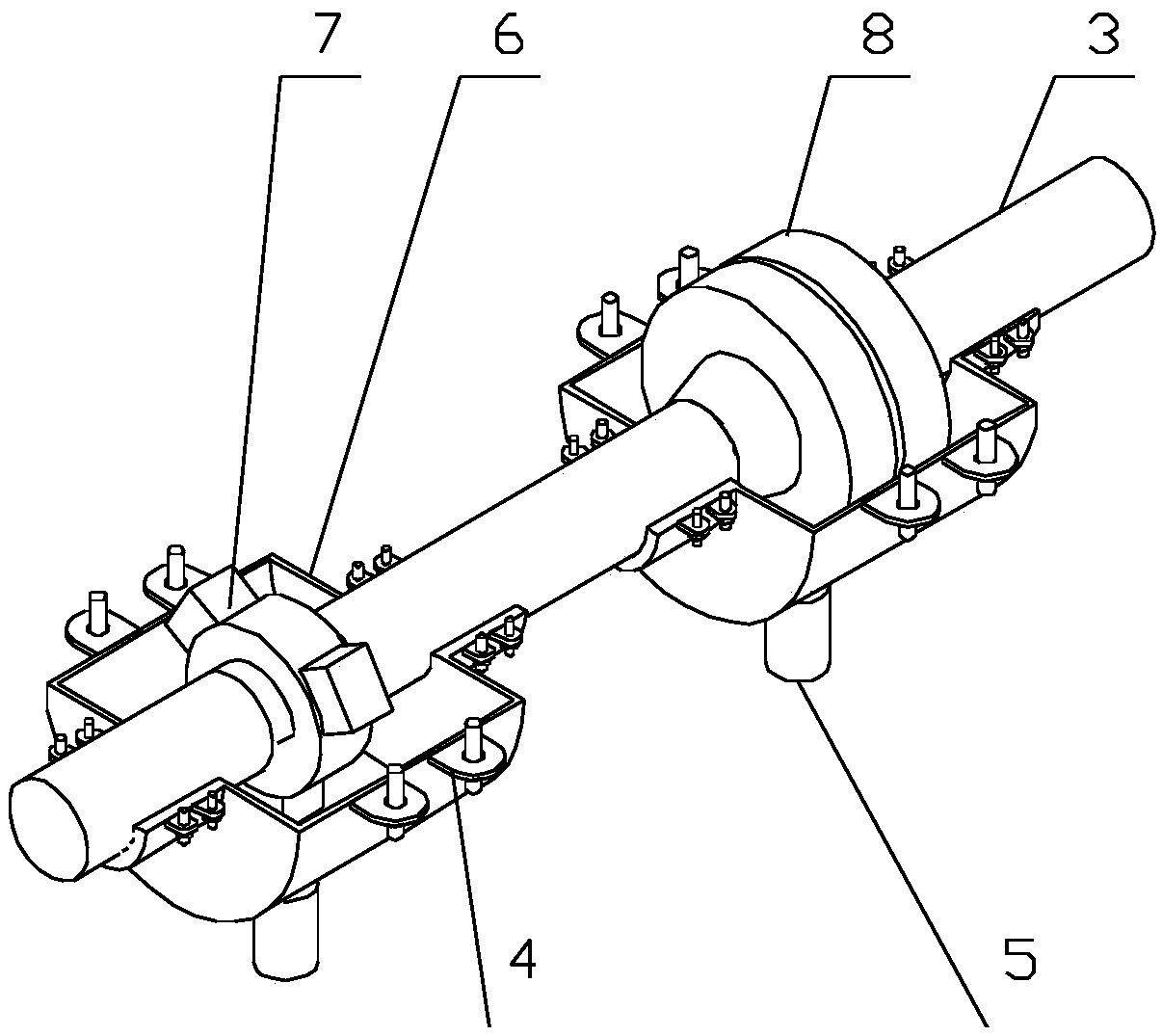

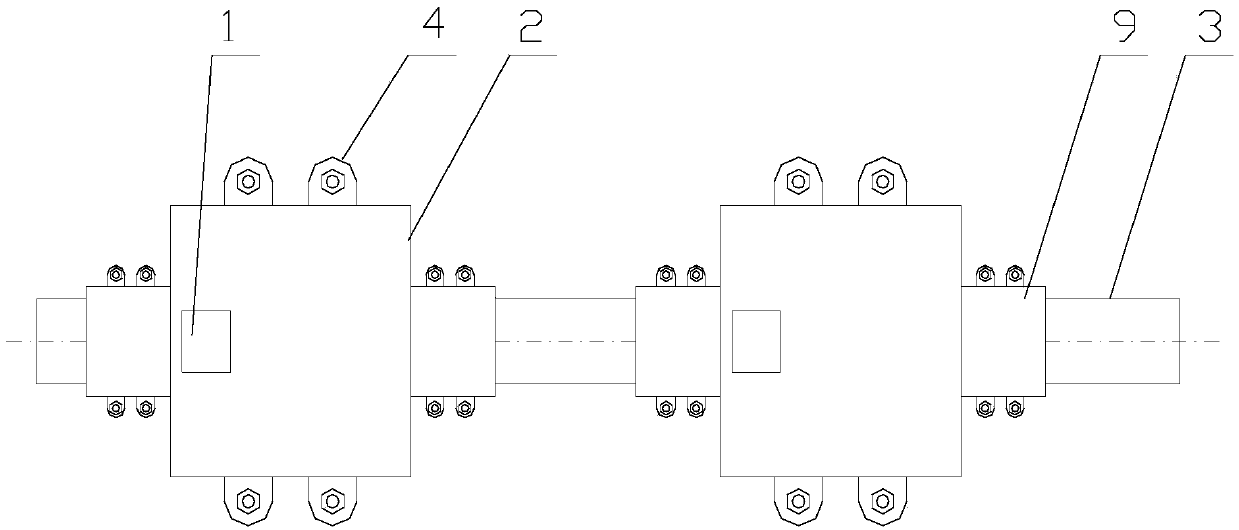

[0028] See Figure 1 to Figure 4 , a special protective device for flanges and unions, including a protective shell, the protective shell includes a shell 6 and a shell cover 2, the shell 6 and the shell cover 2 are detachably butted into a cylindrical body, The shell 6 and the shell cover 2 can be docked and fastened by various detachable methods such as bolts, and the cylindrical body is provided with a cavity for accommodating the flange 8 or the union 7, and the cylindrical body Both ends are provided with nozzles 9 that are socketed with the pipe 3, and the housing 6 and the shell cover 2 can be connected and fastened with bolts at the nozzles 9. The upper part of the shell 2 is provided with an overflow Flow port 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com