Hydraulic traction installation and construction method for double-rubber-ring socket and spigot type large-diameter pipelines

A technology for large-diameter pipelines and construction methods, which is applied in the field of hydraulic traction installation and construction of double-rubber ring socket-type large-diameter pipelines, and can solve problems such as difficult alignment of nozzles, easy deviation of pipelines, and affecting the installation efficiency of adjacent pipelines. , to achieve the effect of easy connection, reducing the possibility of large deformation and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

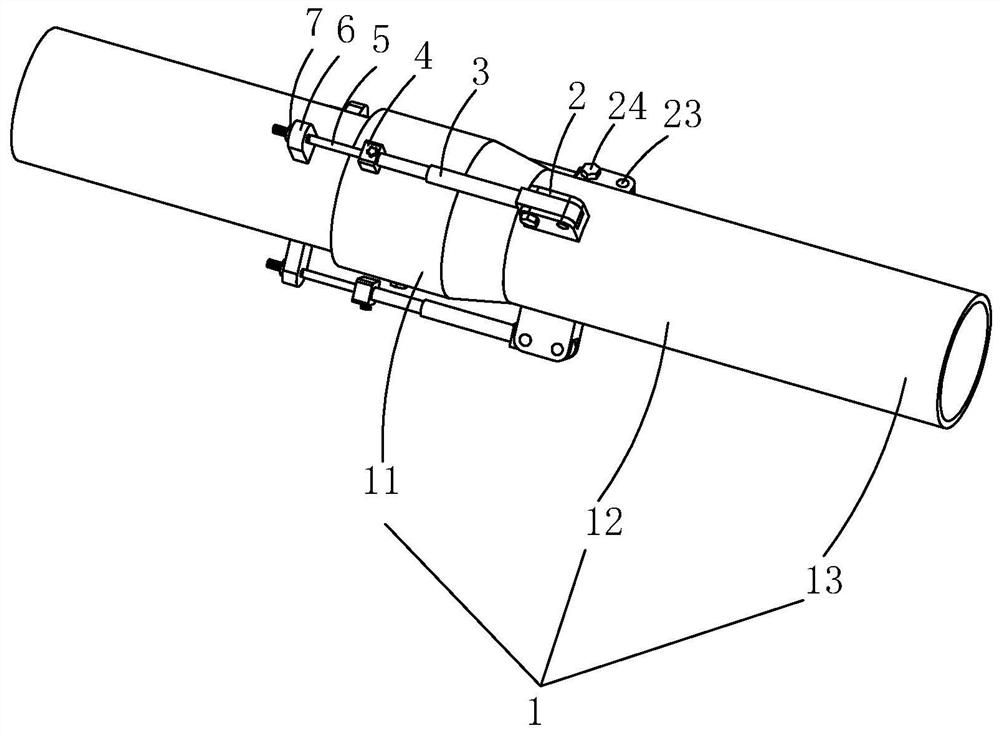

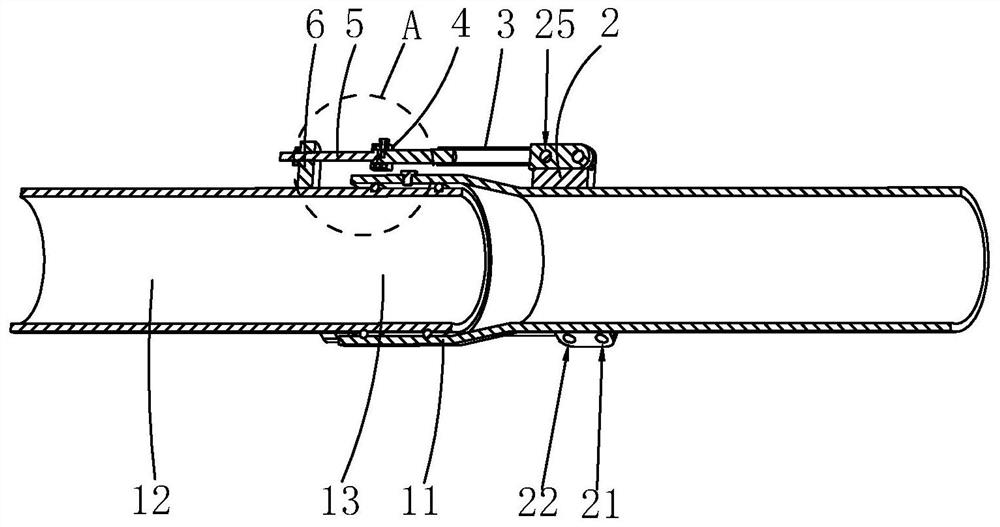

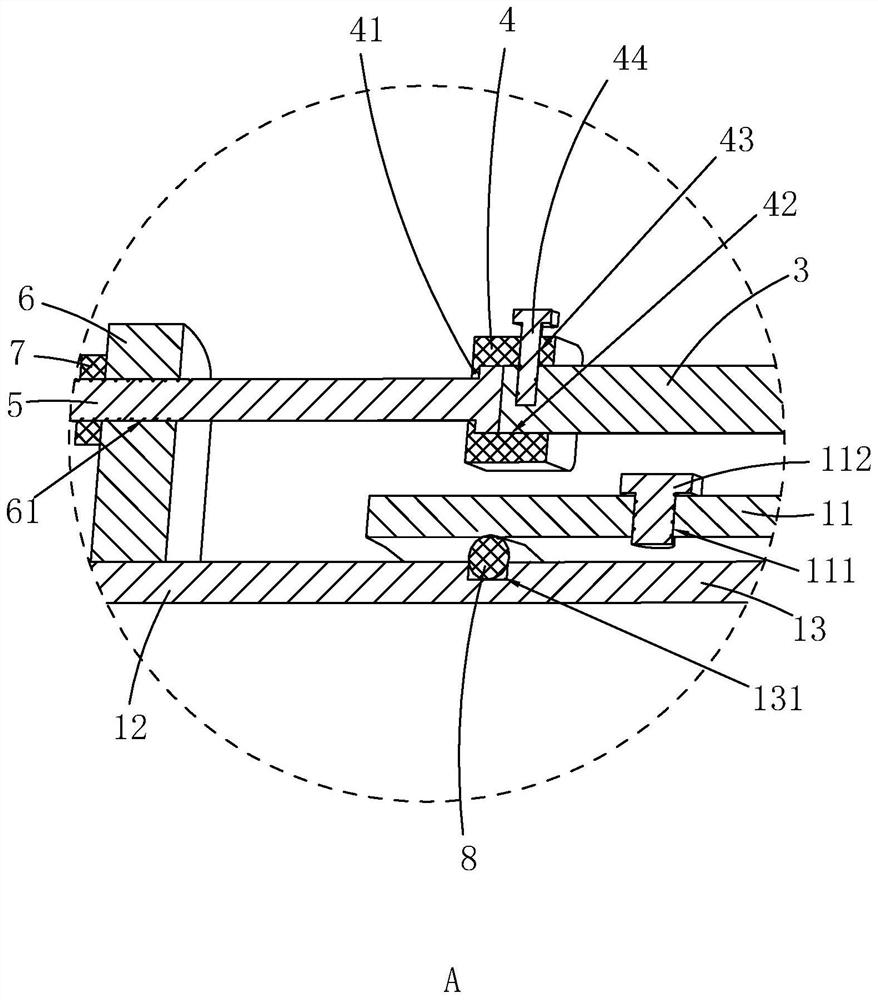

[0054] Attached to the following Figure 1-3 This application will be described in further detail.

[0055] The embodiment of the present application discloses a construction method for hydraulic traction installation of a double apron socket type large-diameter pipeline, and the installation and construction steps of the construction method for the hydraulic traction installation of a double rubber ring socket type large-diameter pipeline are as follows:

[0056] S1, construction preparation;

[0057] S11. Construction groove detection: check whether the bottom elevation of the construction groove, the width of the center line of the bottom wall of the construction groove, and the deviation of the slope of the construction groove are within the allowable deviation range;

[0058] S12. Inspection of pipeline 1: Check that the specifications, dimensional tolerances and performance of the pipe joint and pipeline 1 meet the relevant regulations and design requirements, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com