Foundation pile high-strain hammering system

A high-strain, hammering technology, applied in sheet pile walls, foundation structure engineering, foundation structure tests, etc., can solve problems such as low operating efficiency, difficult installation, and the inability of the hammering device to connect pile ends in real time, achieving The effect of reducing size and height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

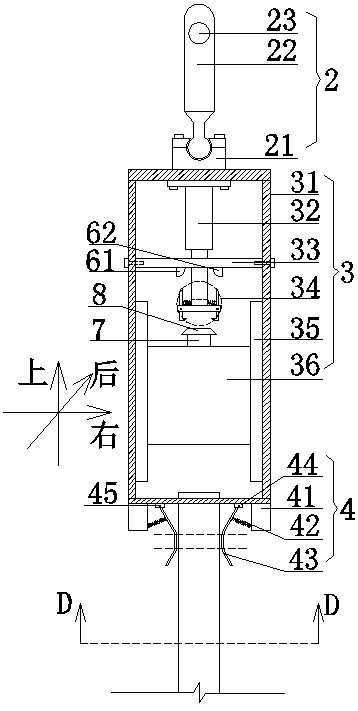

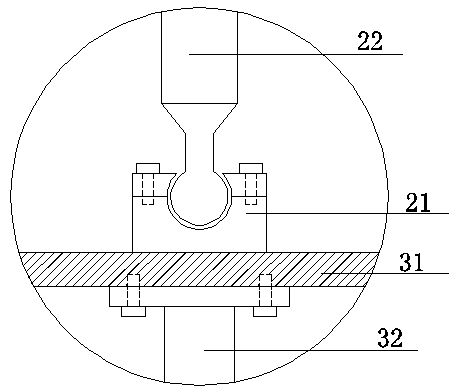

[0049] Embodiment 1: as Figure 1 to Figure 8 The high-strain hammering system for foundation piles shown includes an excavator 1 without a bucket at the end of the forearm, a connecting mechanism 2, a hammering device 3, and a limit mechanism 4. The top of the hammering device 3 passes through the connecting mechanism 2 Hinged to the end of the forearm of the excavator, the bottom is socketed with the pile body 5 through the limit mechanism 4; the connecting mechanism 2 is composed of a connecting seat 21, a connecting rod 22 and a pin shaft 23, and the connecting seat 21 is welded on the hammering device 3 On the top shell 31, one end of the connecting rod 22 is ball-hinged to the connecting seat 21, and the other end is vertically rotatably connected to the end of the forearm of the excavator 1 through the pin A23.

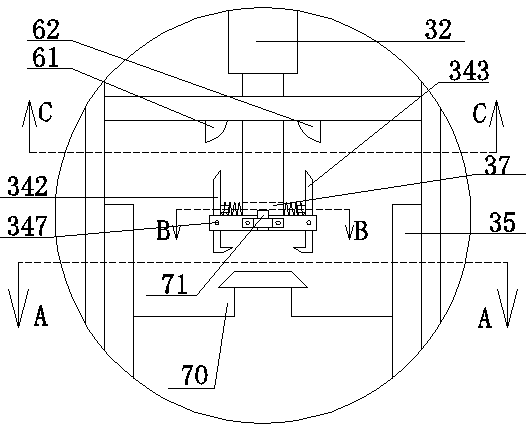

[0050] The hammering device 3 includes a casing 31, a hydraulic jack 32, a limit top plate 33, a decoupling device 34, an energized guide rail 35, and a weight...

Embodiment 2

[0059] Embodiment 2: as image 3 As shown, on the front side of the middle block 345, a proximity switch 71 is fixed by a locking bolt to determine whether the top surface of the card table 8 is close to the proximity switch 71 (the distance between the front and back of the top of the card table 8 is greater than the front and rear distance of the middle block 345). When the card platform 8 top surface is close to the proximity switch 71, the energized guide rail 35 is de-energized to prevent the energized guide rail 35 from being energized all the time, so that the weight is always in an accelerated state, and the impact force of the hammer is too fierce; when the card platform 8 leaves the proximity switch 71, that is When the weight 36 falls, the energized guide rail 35 is energized, so that a magnetic field is generated between the two energized guide rails 35, thereby generating a Lorentz force, and applying a downward accelerated Lorentz force to the weight 36 to increas...

Embodiment 3

[0060] Embodiment 3: as Figure 9 to ~ Figure 12 As shown, four support frames 81 are welded in a positive "cross shape" on the side walls around the lower part of the shell 31, and each support frame 81 is fixed with a hydraulic cylinder (82) by bolts. The hydraulic cylinder (82) is inverted and top The direction of the rod is inclined, and the earth shovel (83) is fixed on the ejector rod of the hydraulic cylinder (82). Form a circle, the radius of this circle is greater than or equal to the radius of the pile body 5, the soil around the pile body 5 buried in the ground can be dug out by the soil shovel (83), and then the upper end of the pile body 5 is leaked out, which is convenient for the hammering device The installation of 3 eliminates the need for manual excavation preparations before the test, which is conducive to rapid detection tests and improves work efficiency. At the same time, before digging, the hydraulic cylinder 82 can be used to extend the ejector rod, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com