Jumper feeding device

A technology of feeding device and jumper cap, which is applied to electrical components, electrical components, etc., can solve the problems of time and manpower waste, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

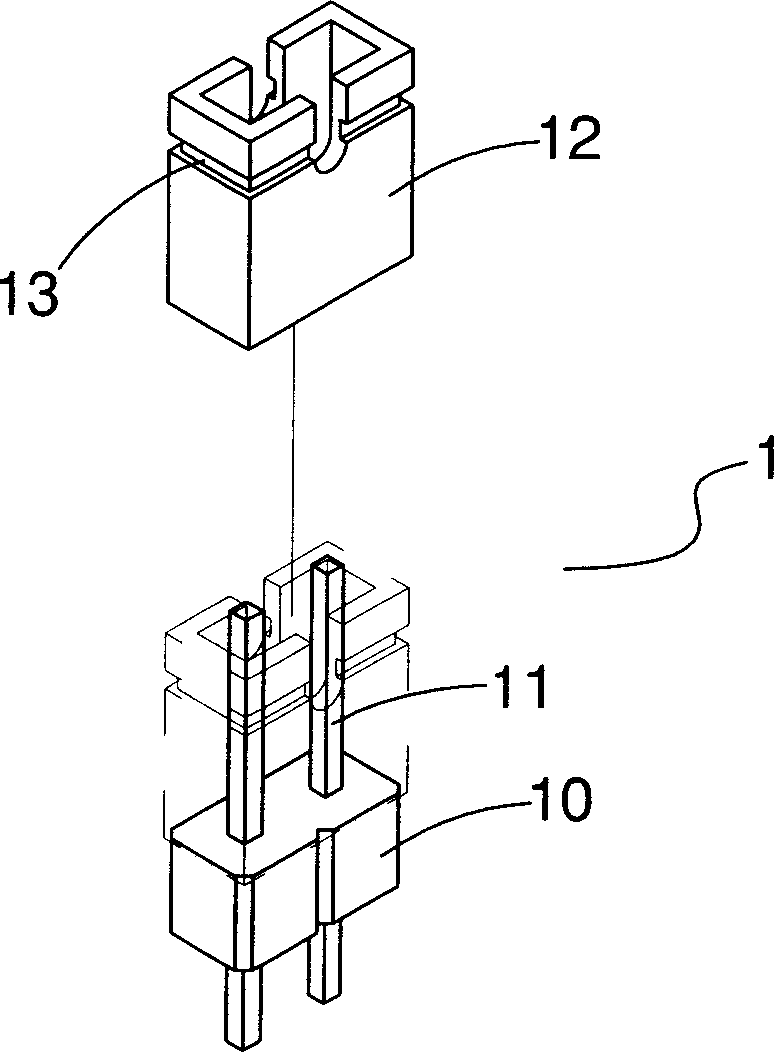

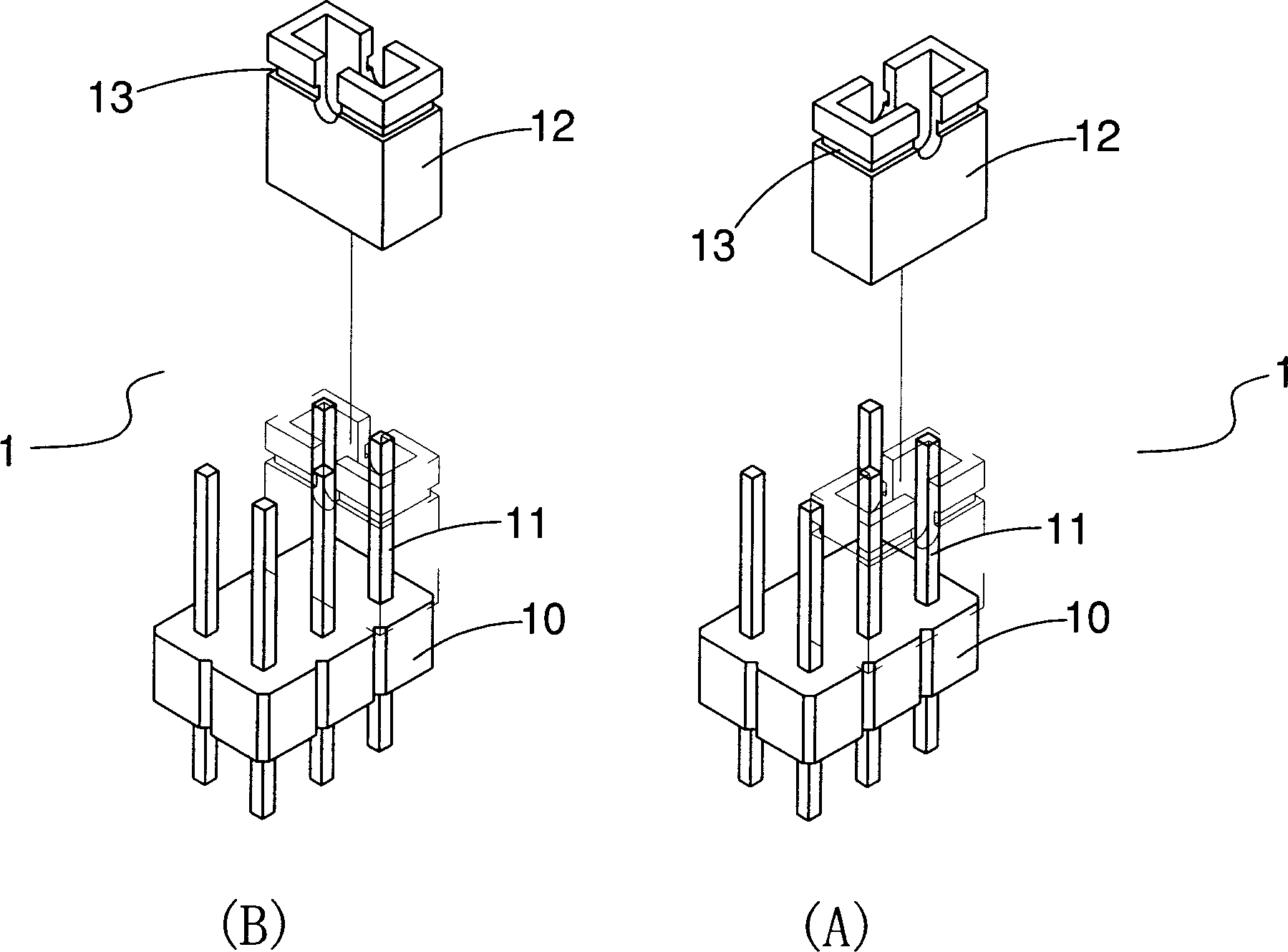

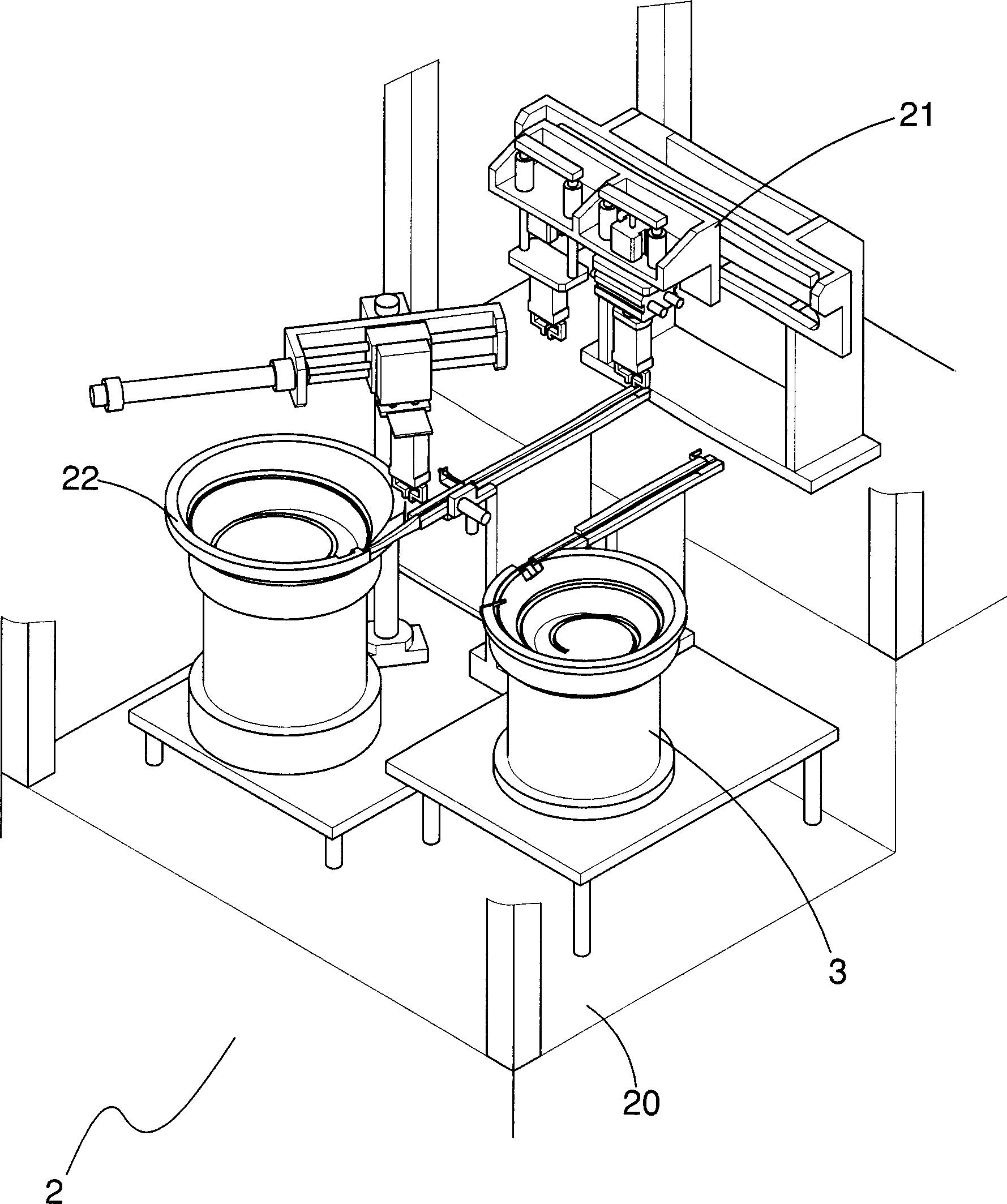

[0047] like image 3 As shown, an automatic assembly machine 2 for automatically inserting and combining the jumper cap 12 on the pin seat 10, the automatic assembly machine 2 is provided with an automatic plugging device 21, a pin seat feeding Device 22 and a jumper cap feeding device 3, wherein:

[0048] The automatic insertion device 21 is used to automatically insert a jumper cap 12 on two longer pins 11 of a pin seat 10, and transport the assembled jumper switch 1 to a collection place;

[0049] Pin seat feeding device 22, used to transport the pin seat 10 to the assembly position of the automatic plugging device 21;

[0050] The jumper cap feeding device 3 is used to turn the jumper cap 12 into a correct assembly direction and transport it to the assembly position of the automatic plugging device 21 .

[0051] like Figure 4 As shown, the jumper cap feeding device 3 includes:

[0052] A feeding tray 30 includes a material trough 300 for the jumper cap 12 to be accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com