Buffering and filtering device for air exhaust port of vacuum pump

A filter device and air suction port technology, which is applied to parts of pumping devices for elastic fluids, pump elements, rotary piston type/oscillating piston type pump parts, etc., can solve the problem of reducing service life, damaging rotary vanes, loading Object movement and other issues to achieve the effect of reducing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

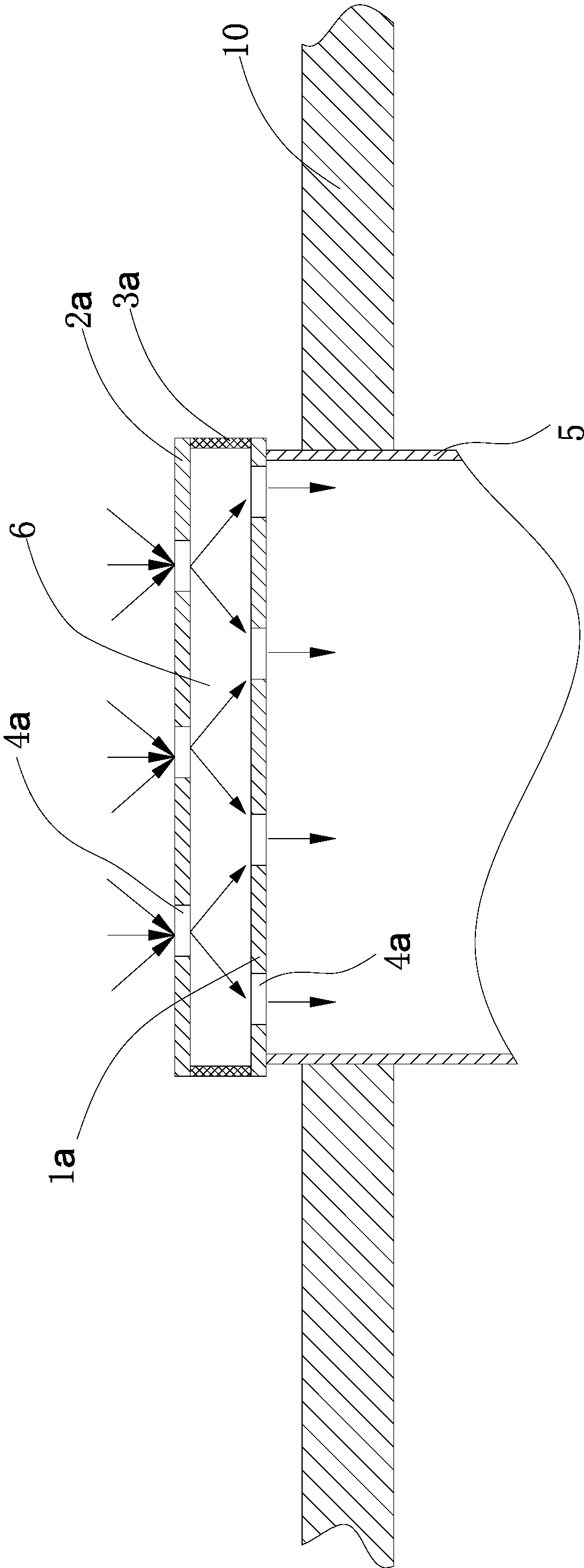

[0014] like figure 1 As shown, the buffer filter device for the suction port of the vacuum pump includes two baffles. A side wall 3a is welded between the edge of the first baffle 1a and the edge of the second baffle 2a. The area of the first baffle 1a is larger than the cross section of the air suction port. The area of a baffle plate 1a is equal to the area of the second baffle plate 2a, the first baffle plate 1a and the second baffle plate 2a are parallel, and the first baffle plate 1a, the second baffle plate 2a and the side wall 3a form an airtight cylindrical space cavity 6, the area of the first baffle plate 1a is greater than the radial cross-sectional area of the vacuum pump air outlet 5, and the bottom of the first baffle plate 1a is welded to the upper end of the air outlet 5; Air holes 4a, seven air extraction holes 4a communicating with the outside world are respectively arranged on the second baffle plate 2a, the air extraction holes 4a of the first baf...

Embodiment 2

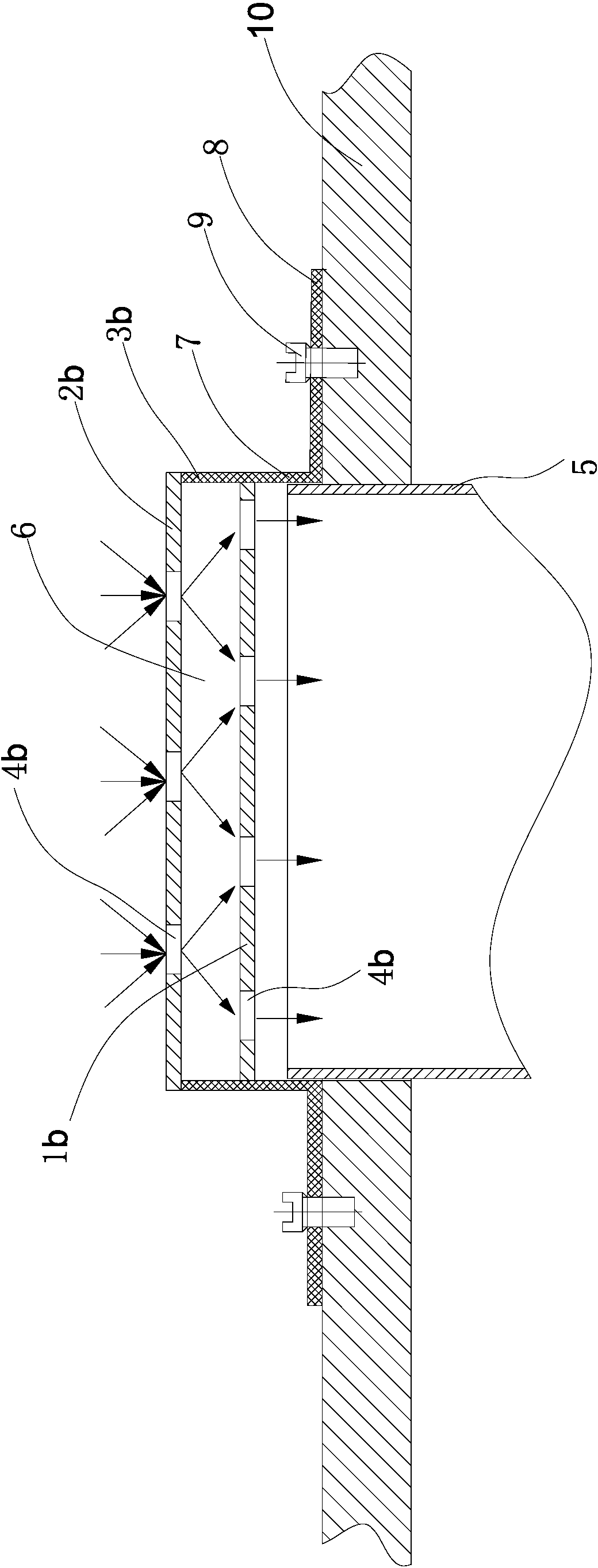

[0016] like figure 2 As shown, the buffer filter device at the suction port of the vacuum pump includes two baffles, a side wall 3b is welded between the edge of the first baffle 1b and the edge of the second baffle 2b, and the area of the first baffle 1b is equal to that of the second baffle 2b Area, the first baffle plate 1b and the second baffle plate 2b are parallel, the first baffle plate 1b, the second baffle plate 2b and the side wall 3b form a closed cylindrical cavity 6, and the area of the first baffle plate 1b is larger than the suction port of the vacuum pump 5 The radial cross-sectional area, the side wall 3b has an extension 7 in the axial direction of the air inlet 5 to the air outlet 5, so that the air outlet 5 is sleeved in the extension 7 of the side wall 3b, and the bottom of the extension 7 has a folded edge 8, through Bolts 9 make the flange 8 fixedly connected with the wall 10 of the vacuum chamber; the first baffle 1b has six air extraction holes 4b...

Embodiment 3

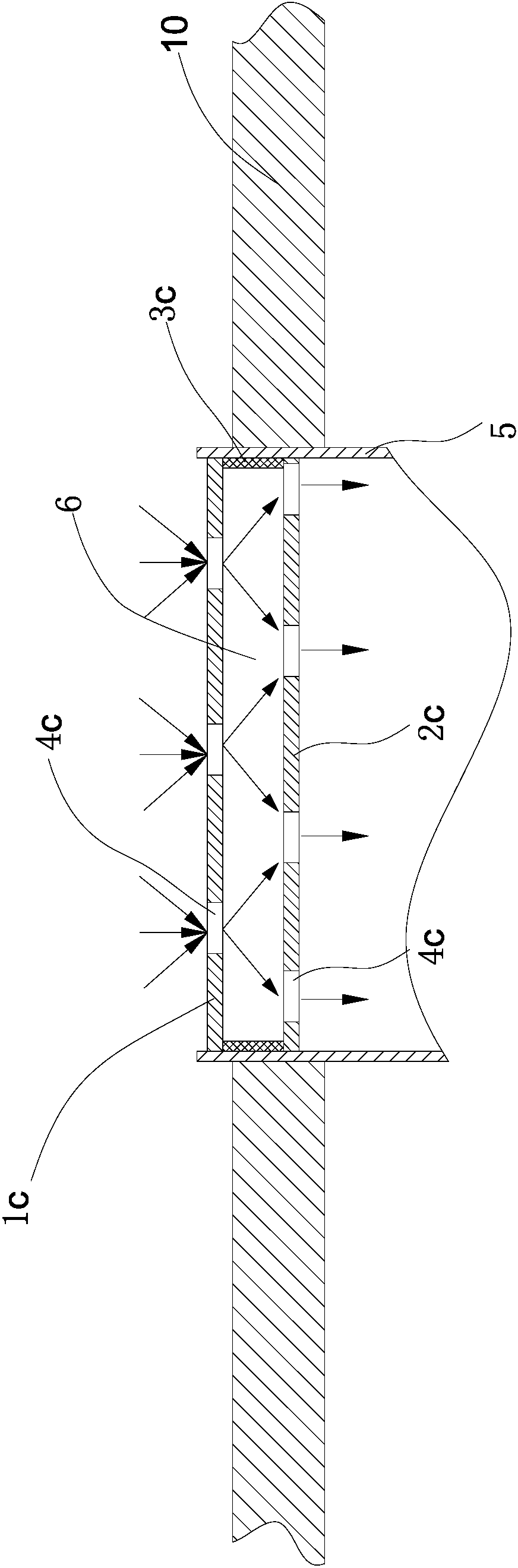

[0018] like image 3 As shown, the buffer filter device at the suction port of the vacuum pump includes two baffles. A side wall 3c is welded between the edge of the first baffle 1c and the edge of the second baffle 2c. The area of the first baffle 1c is equal to the section of the suction port 5. The area of the first baffle 1c is equal to the area of the second baffle 2c, the first baffle 1c and the second baffle 2c are parallel, and the first baffle 1c, the second baffle 2c and the side wall 3c form a closed cylindrical shape Cavity 6, the area of the first baffle plate 1c is equal to the radial cross-sectional area of the vacuum pump air outlet 5, and the side wall 3c is welded to the inner wall of the air outlet 5; the first baffle plate 1c has four air extraction holes 4c that make the cavity 6 communicate with the outside world , on the second baffle plate 2c, there are respectively three air extraction holes 4c communicating with the outside world, the air ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com