Semiconductor device for correcting warpage of plastic packaging panel and correction method

A semiconductor and flat panel technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as unevenness and warping of plastic-encapsulated flat panels, and achieve the effect of protecting integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

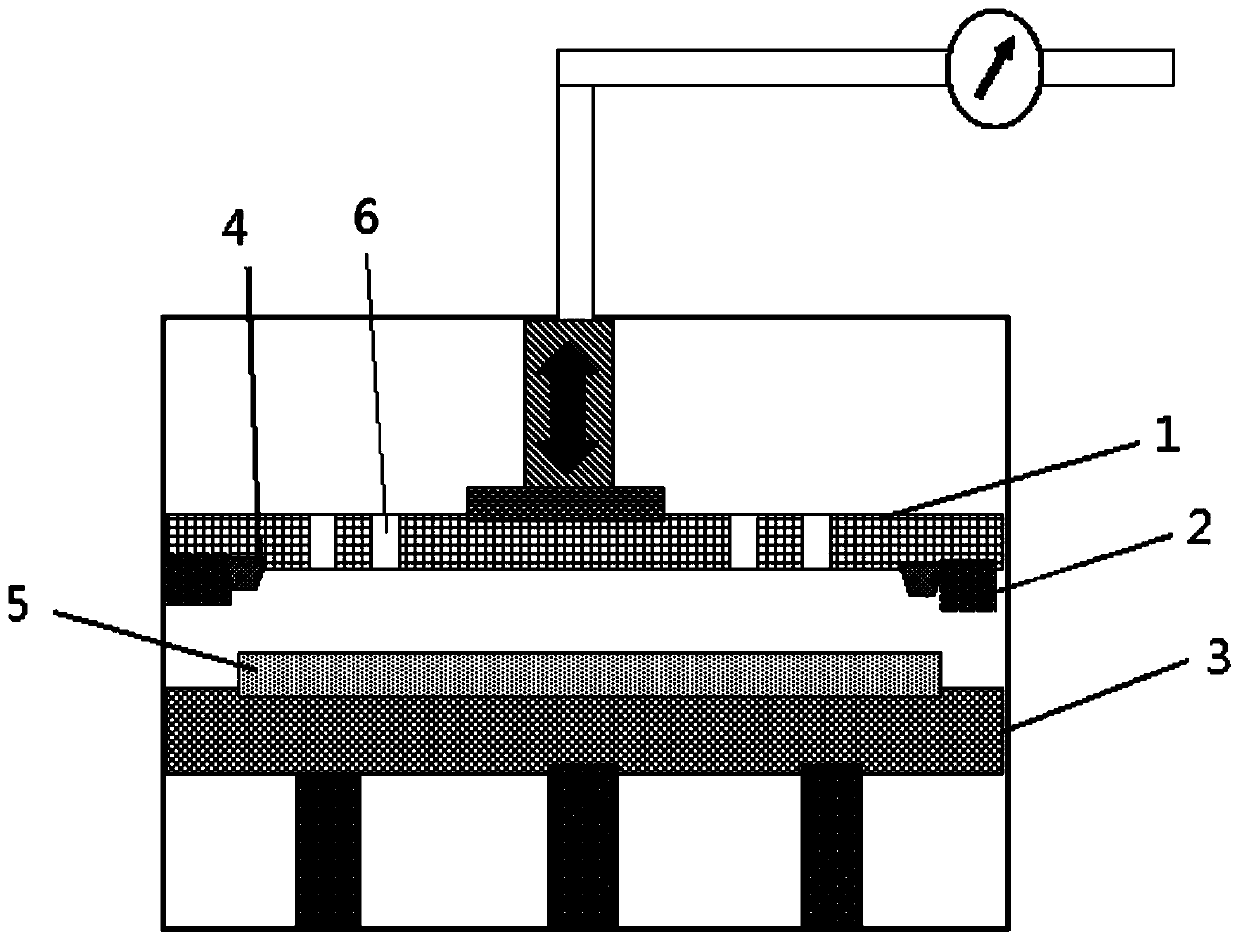

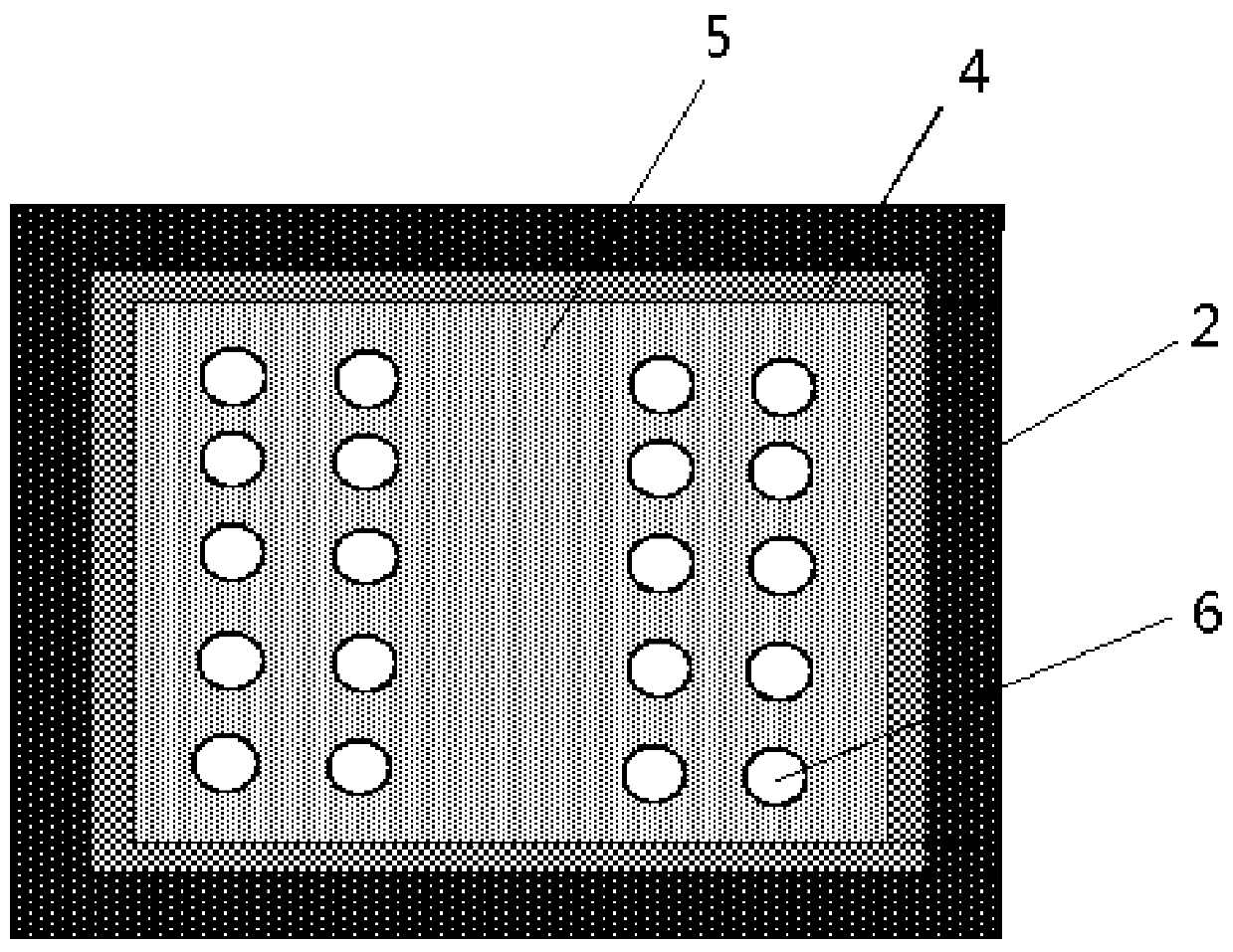

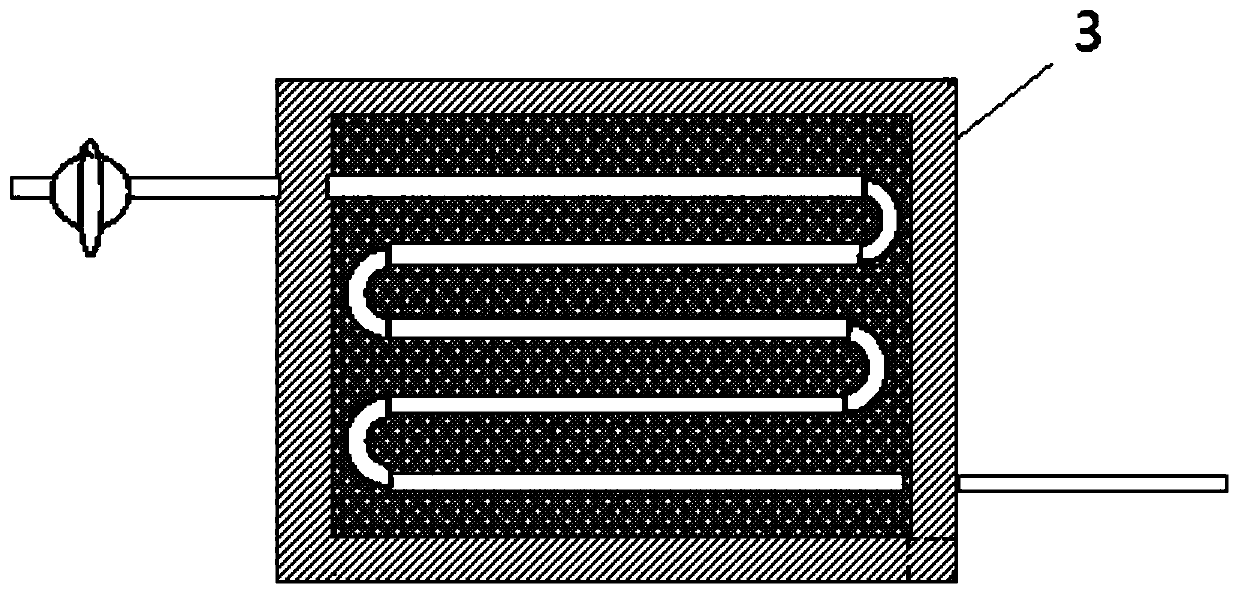

[0046] Such as figure 1 -3 shows a specific implementation of the semiconductor device used to correct the warpage of the plastic-encapsulated flat plate containing the integrated circuit chip involved in the present invention, which includes a carrying structure 3, a vacuum channel, a pressing structure, a protective ring 2 and a heating structure.

[0047] In this embodiment, the carrying structure 3 includes a carrying area for carrying the plastic-encapsulated flat panel 5 , and the carrying area is arranged on a plane. The surface of the bearing area needs to be polished to ensure that the back of the plastic-encapsulated flat panel will not be scratched when the warpage is corrected.

[0048] In this embodiment, a vacuum channel is provided on the carrying structure 3 and communicated with the carrying area to apply a vacuum to the gap between the plastic sealing plate 5 and the carrying area, thereby ensuring that the plastic sealing plate The back can be flatly attac...

Embodiment 2

[0069] The present invention provides a method for correcting a plastic-encapsulated flat panel using the semiconductor device described in Embodiment 1, which includes the following steps:

[0070] Place the plastic-encapsulated flat panel 5 on the bearing area and heat the plastic-encapsulated flat panel 5; the pressing structure moves toward the plastic-enclosed flat panel 5 and makes the pressing end 4 contact with the plastic-enclosed flat panel 5 to apply pressure , applying a vacuum to the gap between the plastic-encapsulated flat panel 5 and the bearing area, so that the plastic-enclosed flat panel 5 closely adheres to the surface of the loaded area; finally, cooling the flattened plastic-enclosed flat panel 5 .

[0071] The warped plastic flat plate of the fan-out package to be corrected is sent to the cavity of the semiconductor device and placed on the surface of the loading area accurately. The loading structure is preheated to the temperature required by the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com