Evanescent mode coating spraying system

A spray system and lost foam technology, applied in tools, casting equipment, molds, etc., can solve the problems of difficult sand cleaning, low rigidity, structural blind spots, etc., to avoid structural blind spots, high coating efficiency, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

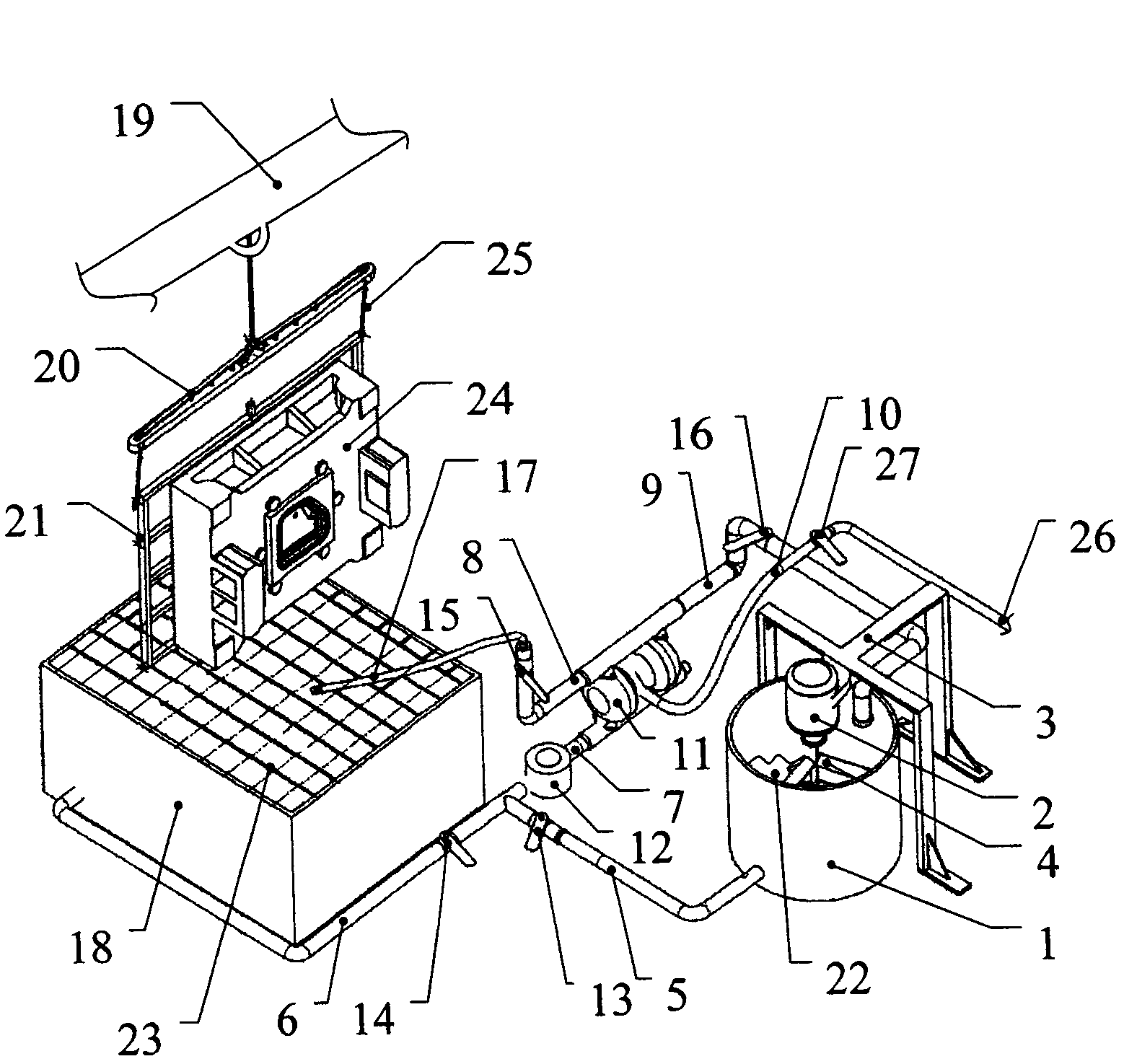

[0009] Such as figure 1 As shown, the spraying system for lost foam paint includes a storage tank 1, a motor 2, a motor bracket 3, a stirring wave wheel 4, a feeding pipe 5, a return pipe 6, a connecting pipe 7, an output pipe 8, a return pipe 9, Air pipe 10, pneumatic diaphragm pump 11, magnetic filter 12, first control valve 13, second control valve 14, third control valve 15, fourth control valve 16, nozzle 17, storage tank 18, crane 19, The lifting frame 20, the mounting frame 21, the lost foam coating 22, the net cover 23, and the fifth control valve 27 are characterized in that: the motor 2 is fixed on the motor bracket 3; the stirring pulsator 4 is fixed on the motor 2 on the rotor; the stirring pulsator is placed in the storage tank 1; the lost foam coating 22 is a special water-based coating for the lost foam and placed in the storage tank 1; the deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com