Washing machine motor fixing device and washing machine

A technology for fixing motors and washing machines, applied to washing devices, other washing machines, textiles and paper making, etc., can solve problems such as deformation of the outer cylinder, and achieve the effect of preventing the gap from being too large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

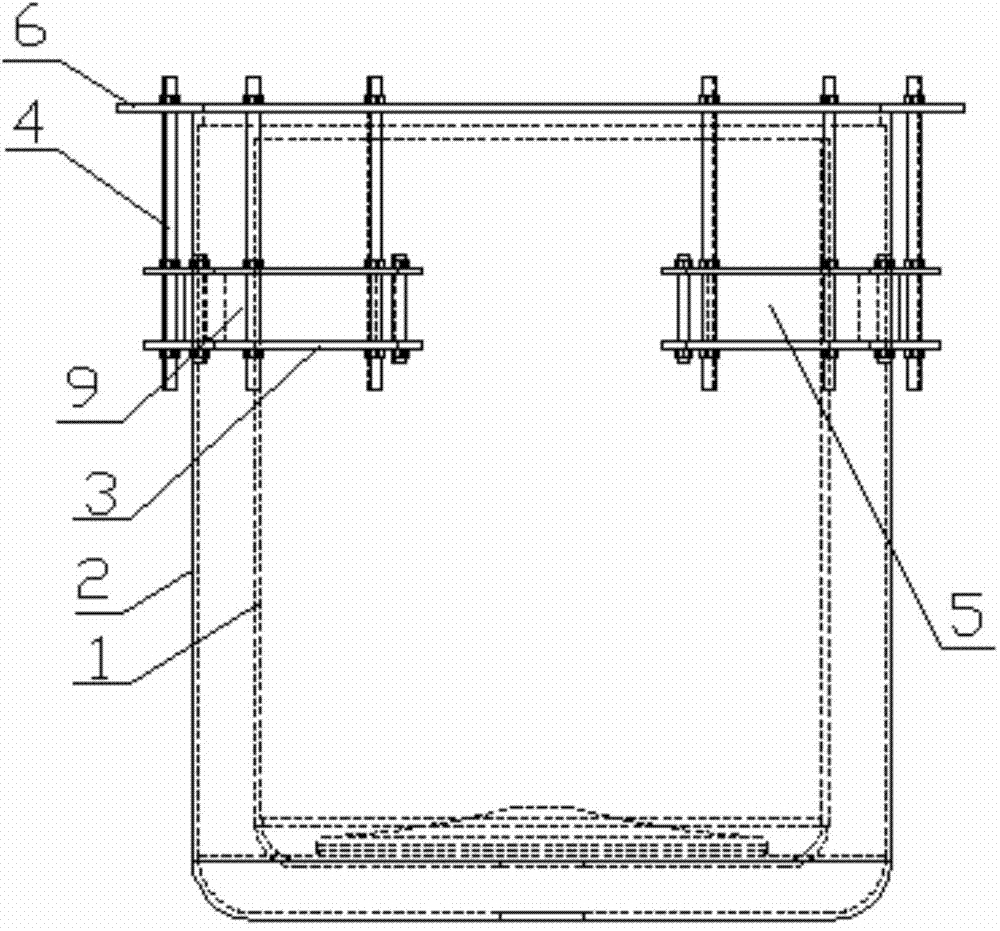

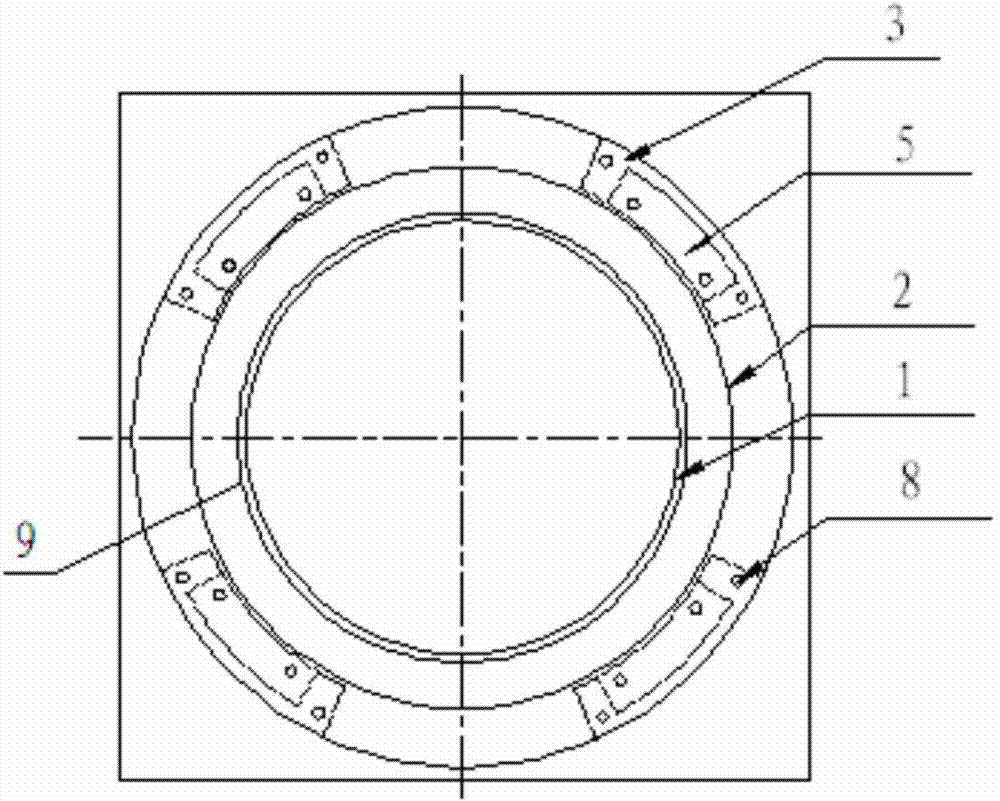

[0023] Such as figure 1 , 2 As shown in . The arc-shaped motor fixing bracket 3 is arc-shaped, and one side thereof matches the shape of the outer cylinder of the washing machine. The arc-shaped motor fixing bracket 3 is located outside the outer cylinder and fits with the outer cylinder 2 but is not fixed. The motor is fixed on the bracket 3 and attached to the outer cylinder 2 . One end of the connecting rod 4 is connected to the arc-shaped motor fixing bracket 3, and the other end is connected to the top of the outer cylinder 2. The connecting rod 4 hangs the arc-shaped motor fixing bracket 3 on the outside of the outer cylinder.

[0024] In order to facilitate the connection between the connecting rod and the outer cylinder, and to facilitate the coaxial installation of the arc-shaped motor fixing bracket 3 and the outer cylinder, in this embodiment, the motor fixing device of the washing machine also includes an upper fixing bracket 6 . The upper fixing bracket 6 is f...

Embodiment 2

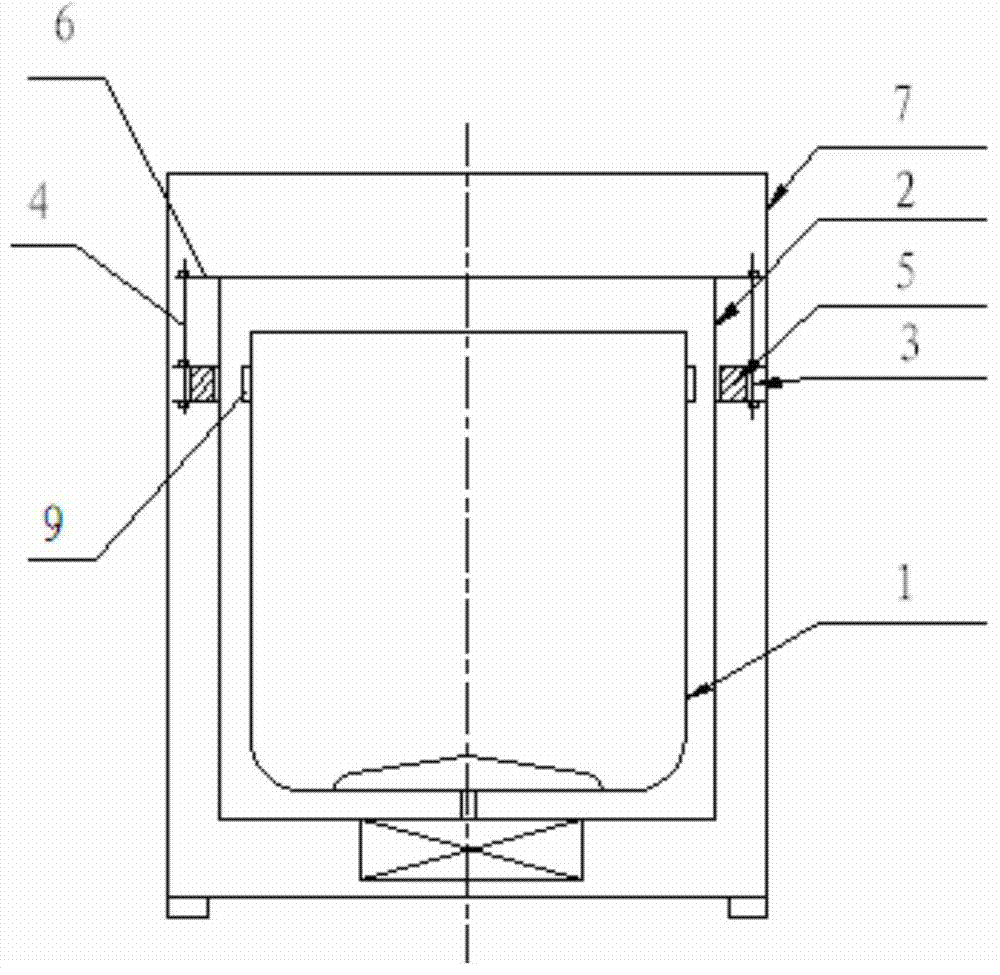

[0033] Such as figure 2 , 3 As shown, a washing machine includes the motor fixing device in the first embodiment. A motor fixing device is installed outside the outer cylinder of the washing machine, and an arc-shaped motor 5 is installed on the arc-shaped motor fixing bracket 3 of the motor fixing device and attached to the outer cylinder wall. The inner cylinder 1 is installed in the outer cylinder 2 and is coaxial with the outer cylinder 2 and can rotate relative to the outer cylinder 2. The outer cylinder 2 is installed on the washing machine frame 7 through the suspension rod. Since the technology installed through the suspension rod is the prior art, the suspension The rod is not shown in the figure. Utilizing the changing magnetic field generated by the arc motor 5 , an induced current is generated in the induction device installed on the inner cylinder 1 , and then a driving force is generated to drive the inner cylinder 1 to rotate. The sensing device may be an al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com