Obstruction preventing material feeder

A feeder and anti-clogging technology, applied in the field of feeders, can solve the problems of long accumulation time, increase the labor intensity of staff, and bulk material, and achieve the effect of ensuring normal operation, saving manpower, and protecting from deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

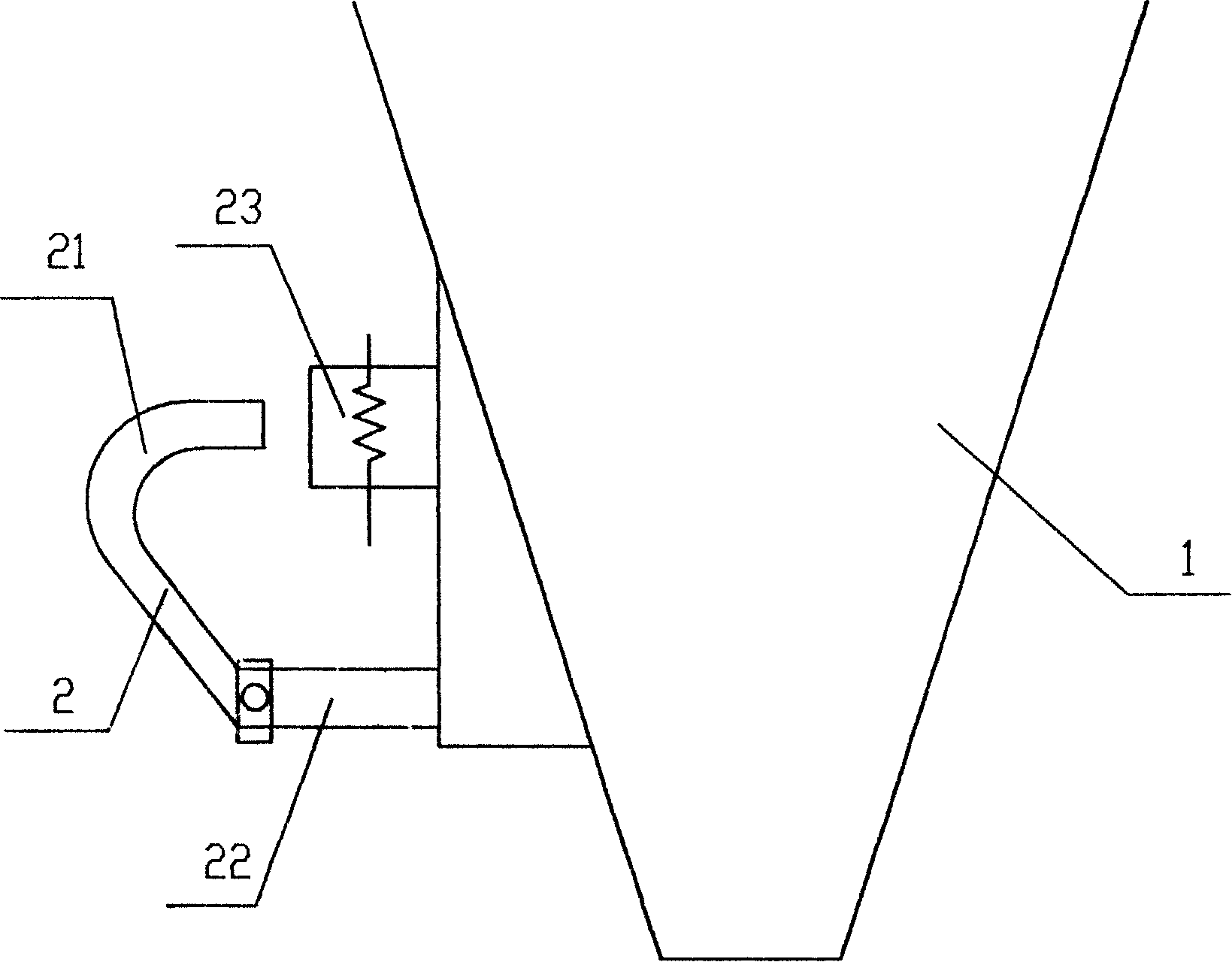

[0008] As shown in the accompanying drawings, the anti-clogging feeder includes a feeder discharge funnel 1, and a vibrator 2 is fixed on the outer wall of the feeder discharge funnel 1.

[0009] Described rapper 2 comprises the support frame 22 that is fixedly installed on the outer wall of described feeder feeding funnel 1, and described support frame 22 is hinged with vibration hammer 21, and the electromagnetic that controls described vibration hammer 21 vibrates. Iron 23.

[0010] The working principle of this embodiment is as follows:

[0011] The control switch of the vibrator is controlled by the operator. If it is found that the feeding hopper of the above-mentioned feeder is not feeding, the operator only needs to press the switch, and the above-mentioned rapping hammer will start to vibrate. The material in the feeding hopper of the above-mentioned feeder will Vibration will automatically fall, so as to achieve uninterrupted feeding. It can not only save manpower,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com