Automatically vibrating glue-spraying machine

A glue spraying machine, automatic technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of low pass rate, affecting the bonding quality of rubber and steel parts, and low manual production efficiency. , to achieve good coating effect, high coating efficiency, and avoid toxic gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

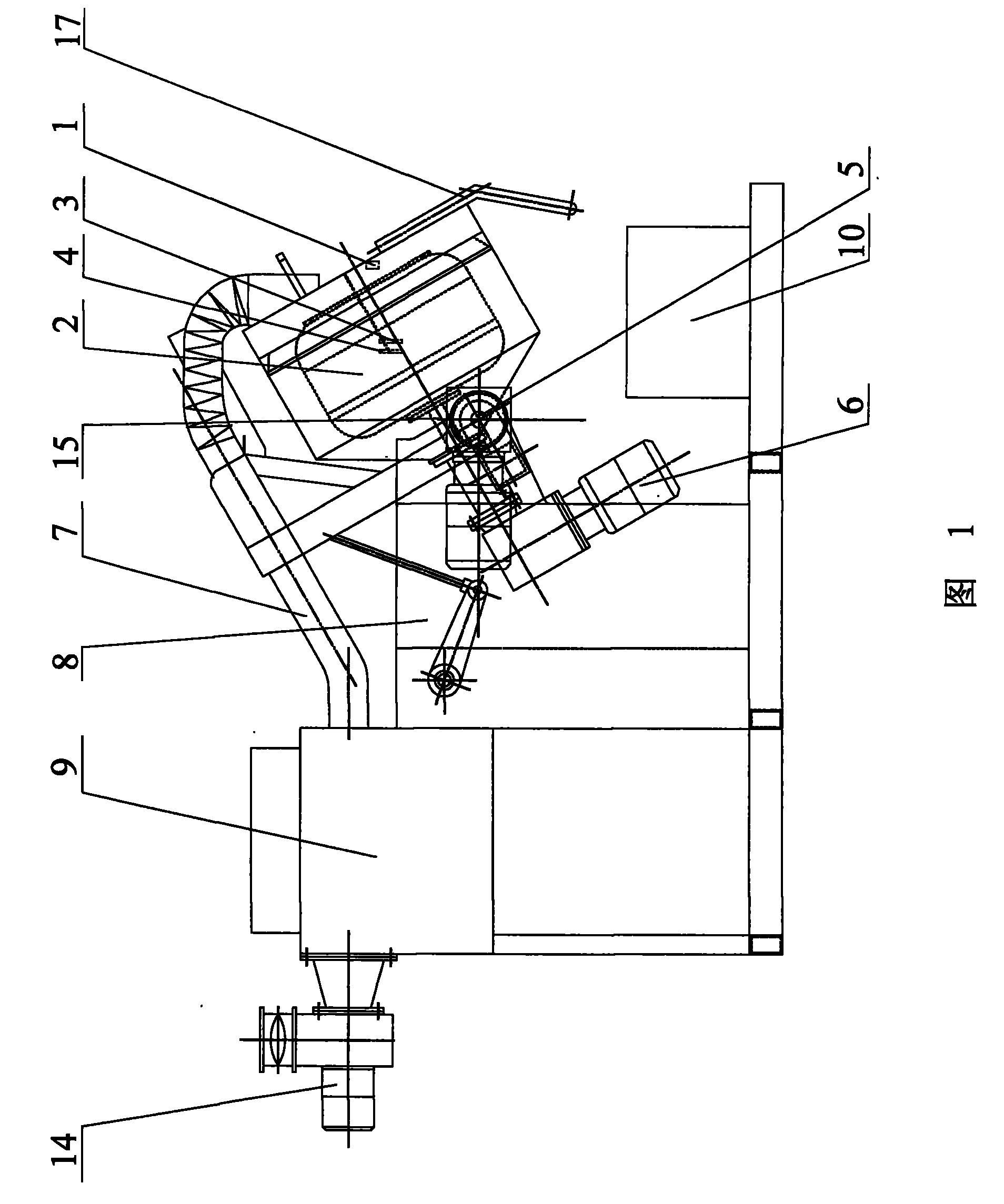

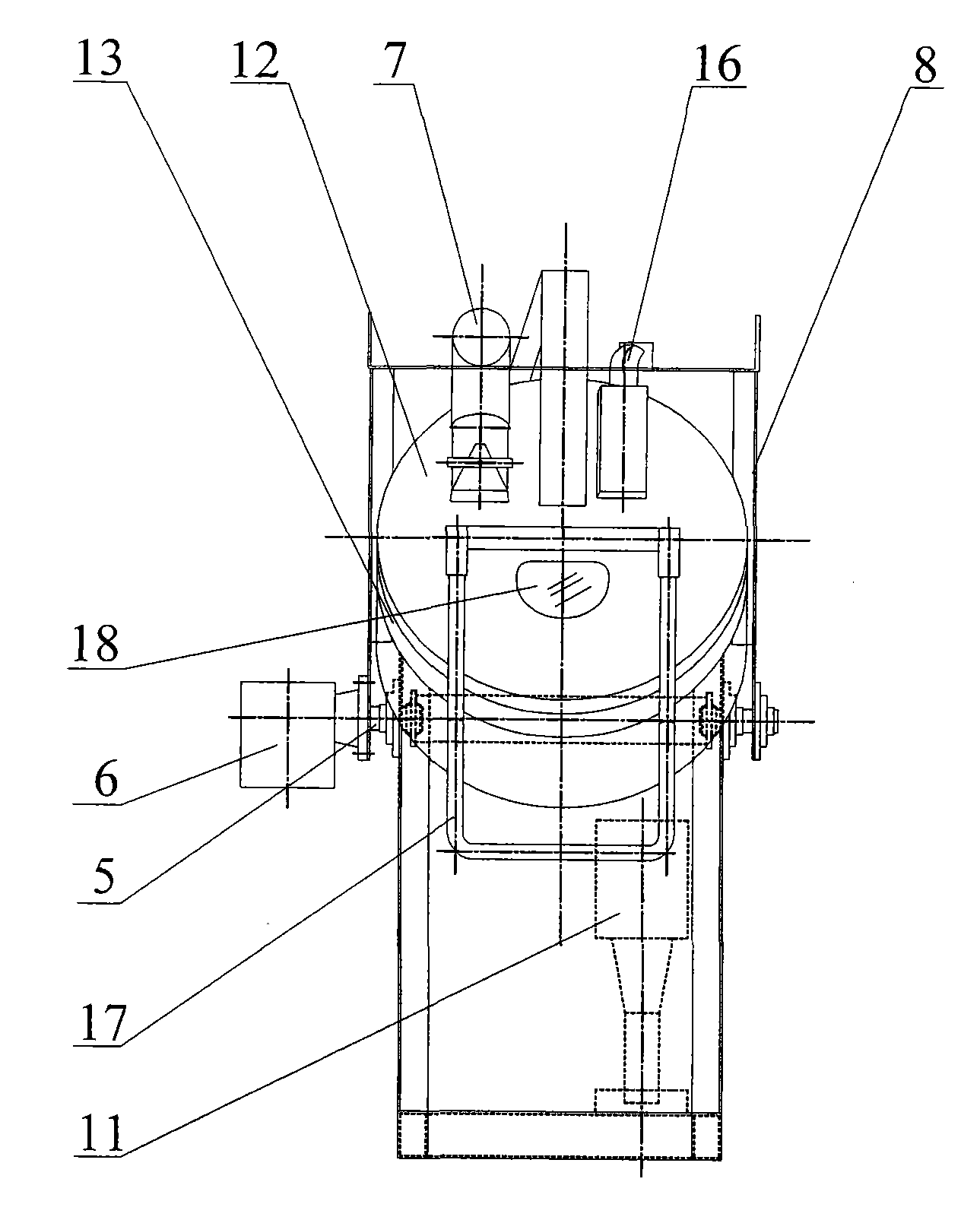

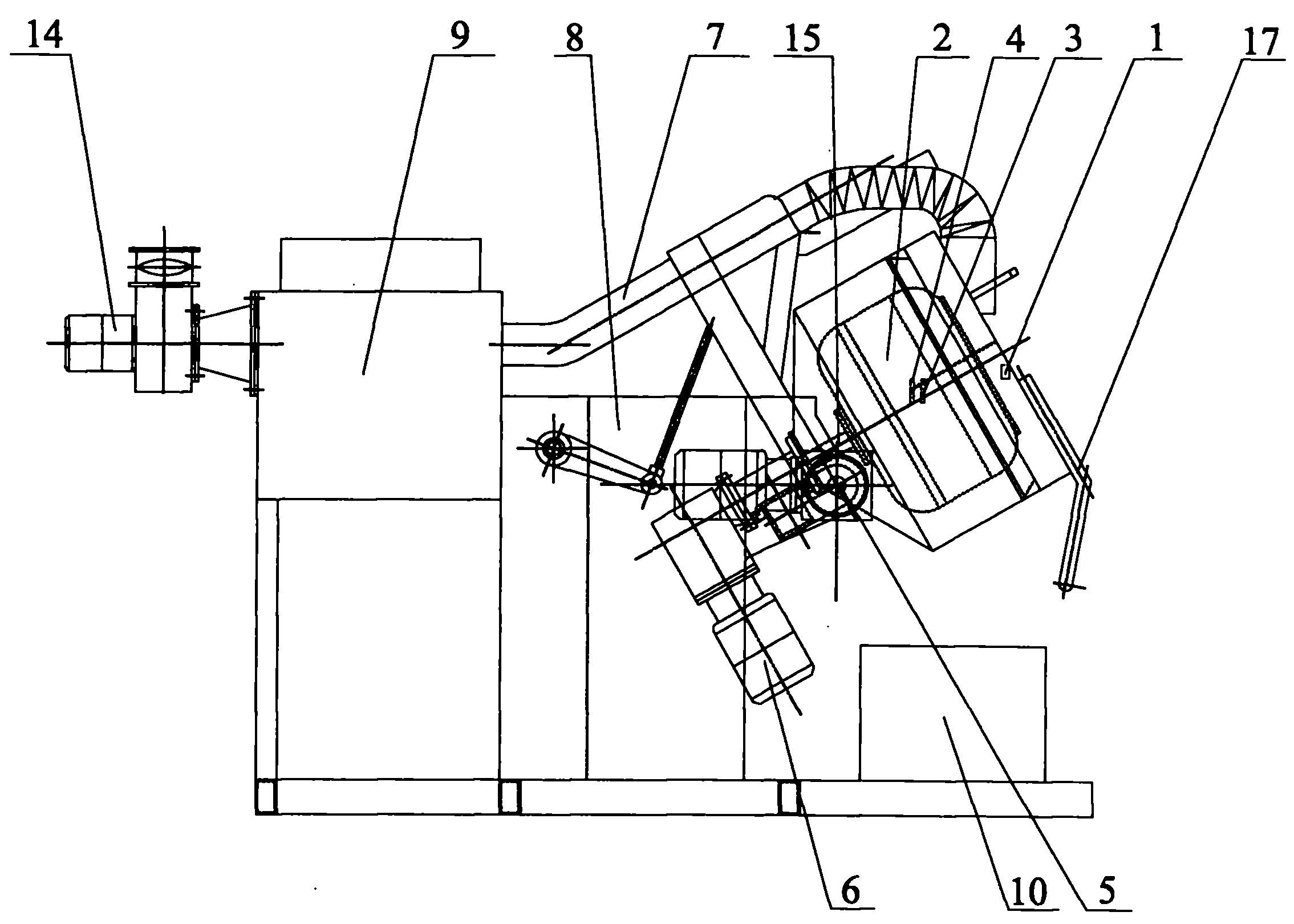

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0013] As shown in the figure: the heat exchanger 9 is fixedly installed on the frame 8, the air inlet end of the heat exchanger 9 is connected with the fan 14, and the air outlet end of the heat exchanger 9 is connected with a hot air heating pipe 7, which is used for swinging the workpiece The mounting seat of the drum 2 is hinged on the frame 8 through the pin shaft 5, and a rotating shaft 15 is rotatably connected in the mounting seat. The output shaft of the machine is connected, and the air outlet end of the hot air heating pipe 7 extends into the rocking drum 2. An automatic spray gun 4 is arranged on the rocking drum 2. A sealing cover 12 is hinged on the outlet of the rocking drum 2. The outlet of the rocking drum 2 A sealing strip 13 sealingly matched with the airtight cover 12 is fixedly arranged on the feed port, and a suction duct 16 for absorbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com