A life-prolonging, energy-saving and shape-stable PBO 2 Preparation method of arc thermal spraying for anode intermediate layer

An intermediate layer, thermal spraying technology, applied in coating, fusion spraying, metal material coating process and other directions, can solve the problems of high energy consumption and poor durability, and achieve low operating costs, long service life and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

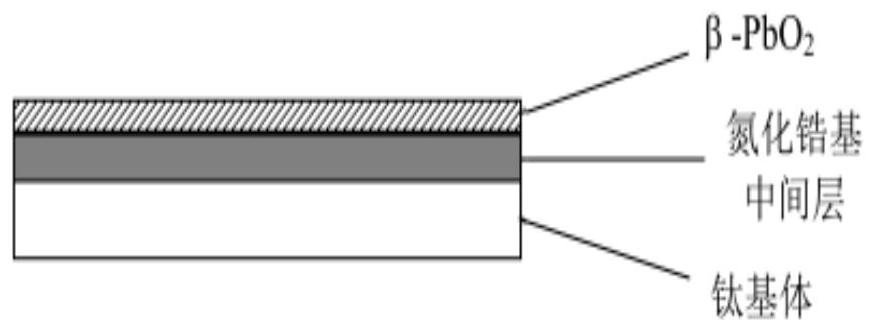

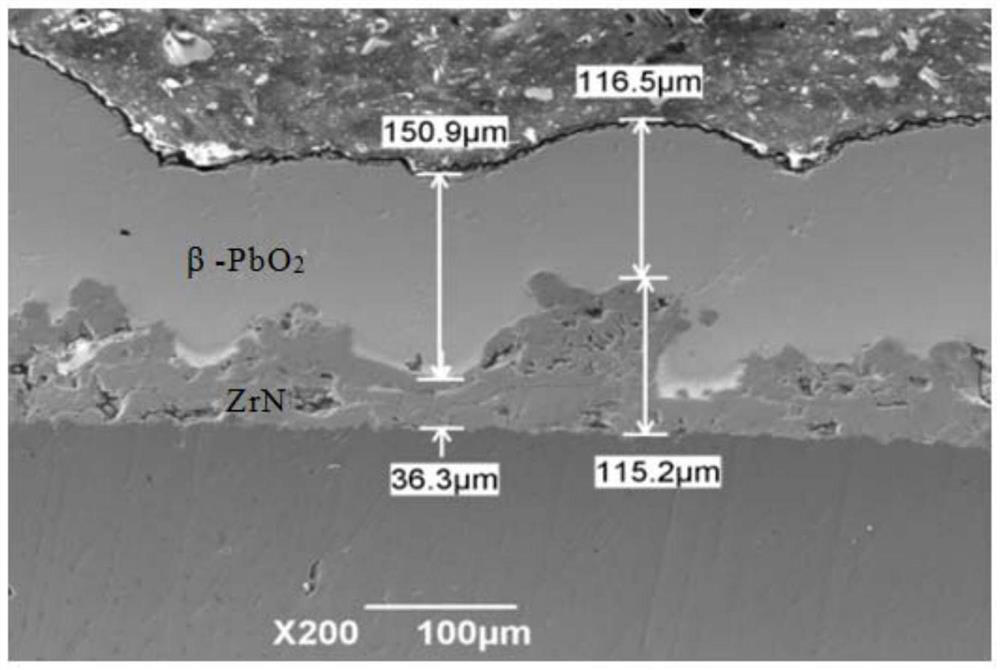

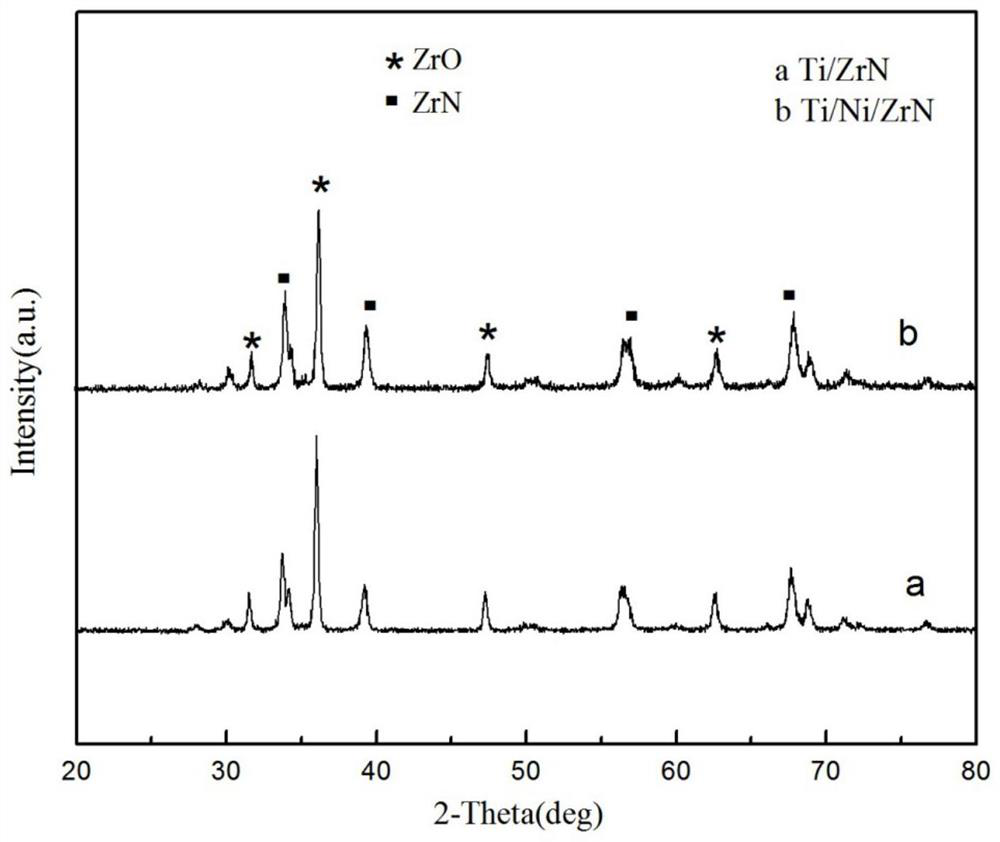

[0022] First, the titanium plate that has been polished, alkali-washed, and pickled is used as the substrate to prepare the zirconium nitride-based intermediate layer. The arc spraying technology uses nickel-cobalt alloy (Ni(Co)CrY) as the consumable, and the arc voltage is 5-35V. The power is 30-40kW, the spraying distance is 100-200mm, the compressed air pressure is 0.3-0.6MPa, and the spraying time is 5-10s. With the help of high-temperature and high-speed flame flow, the nickel-cobalt alloy wire is melted, and the molten nickel-cobalt particles hit the titanium substrate. , forming an uneven bonded primer layer; then the metal nitride intermediate layer is prepared by arc spraying technology, and finally the electrode material of the Ti / zirconium nitride-based intermediate layer is used as the anode, and stainless steel of equal area size is used as the cathode, and the anodic electrooxidation is prepared. β-PbO 2 active layer, resulting in a Ti / ZrN-based interlayer / β-PbO ...

Embodiment 2

[0023] Embodiment 2 phenol degradation experiment

[0024] The ground, alkali-washed and pickled titanium plate is used as the substrate, and the zirconium nitride-based intermediate layer is prepared by arc spraying technology, and then the electrode material of the Ti / zirconium nitride-based intermediate layer is used as the anode, and stainless steel of equal size is used as the cathode , prepared β-PbO by anodic electrooxidation 2 Active layer (electrodeposition temperature is 40±5°C, electrodeposition time is 60min, current density is 20mA / cm 2 ). Groove pressure records of the prepared surface ( Figure 5 ). Ti / ZrN-based interlayer / β-PbO 2 Electrodes and Ti / PbO 2 The comparison of the electricity consumed by the electrode for 100mg / L phenol simulated wastewater degradation for 3h to remove phenol showed a decrease of 0.007 degrees (tank pressure record, Figure 6 ), power consumption is only Ti / PbO 2 1 / 3 of the electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com