A preparation method of tungsten carbide anti-corrosion and wear-resistant composite coating

An anti-corrosion and wear-resistant, composite coating technology, applied in the field of material processing, can solve the problems of poor coating density, manual operation, cumbersome production, affecting anti-corrosion and wear resistance, etc., to prevent agglomeration, facilitate mechanized operation, coating Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

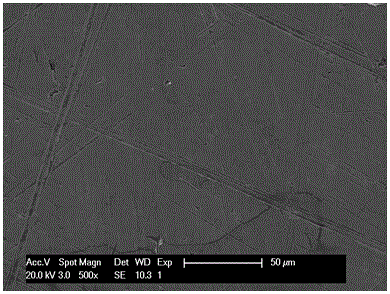

Image

Examples

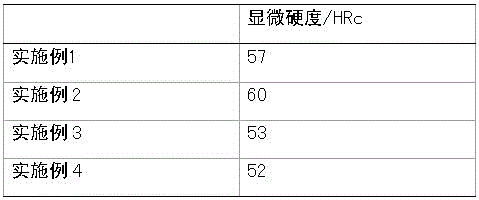

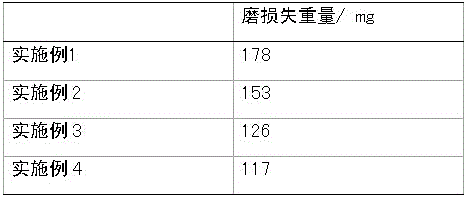

Embodiment 1

[0036] A preparation method of tungsten carbide anti-corrosion wear-resistant composite coating, specifically comprising the following steps:

[0037] (1) Mix tungsten carbide particles, anticoagulant, nickel-based solder and water-based epoxy adhesive evenly to form a slurry containing tungsten carbide particles, anti-coagulant, nickel-based solder and water-based epoxy adhesive material, and then sprayed on the metal substrate to be protected, and dried naturally to obtain a metal substrate with a coating material with a thickness of about 1mm;

[0038] The above-mentioned slurry containing tungsten carbide particles, anticoagulant, nickel-based solder and water-based epoxy adhesive, calculated by mass percentage, its raw material composition and content are as follows:

[0039] Tungsten carbide particles 48.6%

[0040] Anticoagulant 1%

[0041] Nickel-based solder 30.4%

[0042] Water-based epoxy adhesive 20%;

[0043] The diameter of the tungsten carbide particles is 1...

Embodiment 2

[0051] A preparation method of tungsten carbide anti-corrosion wear-resistant composite coating, specifically comprising the following steps:

[0052] (1) Mix cobalt-coated tungsten carbide particles, anticoagulant, nickel-based solder and water-based epoxy adhesive evenly to form a cobalt-coated tungsten carbide particle, anti-coagulant, nickel-based solder and water-based epoxy adhesive. The slurry of the adhesive is then sprayed on the metal substrate to be protected, and then dried naturally to obtain a metal substrate sprayed with a coating material with a thickness of about 1mm;

[0053] The above-mentioned slurry containing cobalt-coated tungsten carbide particles, anticoagulant, nickel-based solder and water-based epoxy adhesive, calculated by mass percentage, its raw material composition and content are as follows:

[0054] Cobalt coated tungsten carbide particles 60.5%

[0055] Anticoagulant 1%

[0056] Nickel-based solder 28.5%

[0057] 0.1% water-based epoxy adh...

Embodiment 3

[0066] A preparation method of tungsten carbide anti-corrosion wear-resistant composite coating, specifically comprising the following steps:

[0067] (1) Mix cobalt-coated tungsten carbide particles, anticoagulant, nickel-based solder and water-based epoxy adhesive evenly to form a cobalt-coated tungsten carbide particle, anti-coagulant, nickel-based solder and water-based epoxy adhesive. The slurry of the adhesive is then sprayed on the metal substrate to be protected, and then dried naturally to obtain a metal substrate sprayed with a coating material with a thickness of about 1mm;

[0068] The above-mentioned slurry containing cobalt-coated tungsten carbide particles, anticoagulant, nickel-based solder and water-based epoxy adhesive, calculated by mass percentage, its raw material composition and content are as follows:

[0069] Cobalt coated tungsten carbide particles 50.5%

[0070] Anticoagulant 1%

[0071] Nickel-based solder 28.5%

[0072] 0.1% water-based epoxy adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com