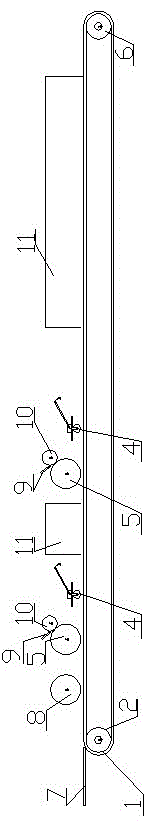

Production process and painting equipment of composite heat-insulation board

A technology of composite heat preservation and production process, which is applied in the direction of heat preservation, liquid coating device on the surface, coating, etc., which can solve the problems of uneven coating thickness, poor coating quality, large wet work load, etc., and achieve good uniformity , High coating efficiency, good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

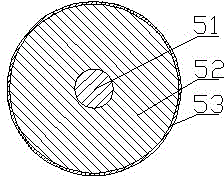

Embodiment 1

[0025] The production process of the composite insulation board includes the following steps: (a) Cutting the insulation layer so that the lower part of a pair of adjacent sides or a pair of opposite sides of the insulation layer protrudes outward to form a tenon, and the lower part of the other pair of adjacent sides or opposite sides shrinks inward Grooves are formed, and glue is applied on the upper surface of the insulation layer; (b) Protective layer slurry is configured. The raw materials of the protective layer slurry are cement, fly ash, sand and water, and the cementitious materials (including cement and fly ash ) to sand and gravel at a mass ratio of 1:1, the mass ratio of water and cementitious material at 0.4, and the cement content at 2%, after configuration, stirring, injection molding and pressure filtration; (c) compounding of insulation layer and protective layer (d) curing; (e) coating and drying the surface of the protective layer of the composite insulation ...

Embodiment 2

[0030] The production process of the composite insulation board includes the following steps: (a) Cutting the insulation layer so that the lower part of a pair of adjacent sides or a pair of opposite sides of the insulation layer protrudes outward to form a tenon, and the lower part of the other pair of adjacent sides or opposite sides shrinks inward Form grooves and apply glue on the upper surface of the insulation layer; (b) configure the protective layer slurry. The raw materials of the protective layer slurry are cement, fly ash, sand and water, and the sand and stone are made of particles with a particle size between 0.1-5mm. Artificial gravel, the cement is composite portland cement; the fly ash is low-calcium grade II fly ash; wherein, the mass ratio of the cementitious material (including cement and fly ash) to sand and gravel is 1:2 , the mass ratio of water and cementitious material is 0.5, and the cement content is 30%. The mass ratio of the insulation layer is 0.16...

Embodiment 3

[0038]The production process of the composite insulation board includes the following steps: (a) Cutting the insulation layer so that the lower part of a pair of adjacent sides or a pair of opposite sides of the insulation layer protrudes outward to form a tenon, and the lower part of the other pair of adjacent sides or opposite sides shrinks inward Grooves are formed, and glue is applied on the upper surface of the insulation layer; (b) Protective layer slurry is configured. The raw materials of the protective layer slurry are cement, fly ash, sand and water, and the cementitious materials (including cement and fly ash ) to sand and gravel at a mass ratio of 1:6, the mass ratio of water to cementitious material at 0.7, and the cement content at 50%, after configuration and stirring, injection molded and press-filtered; (c) insulation layer and protective layer composite (d) curing; (e) coating and drying the surface of the protective layer of the composite insulation board obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com