Motor rotor lamination gluing machine and method

A technology for motor rotors and rotor laminations, which can be used in the manufacture of stator/rotor bodies, coatings, and devices for coating liquids on surfaces, etc. Uniform coating, high-efficiency automatic production, and the effect of improving coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

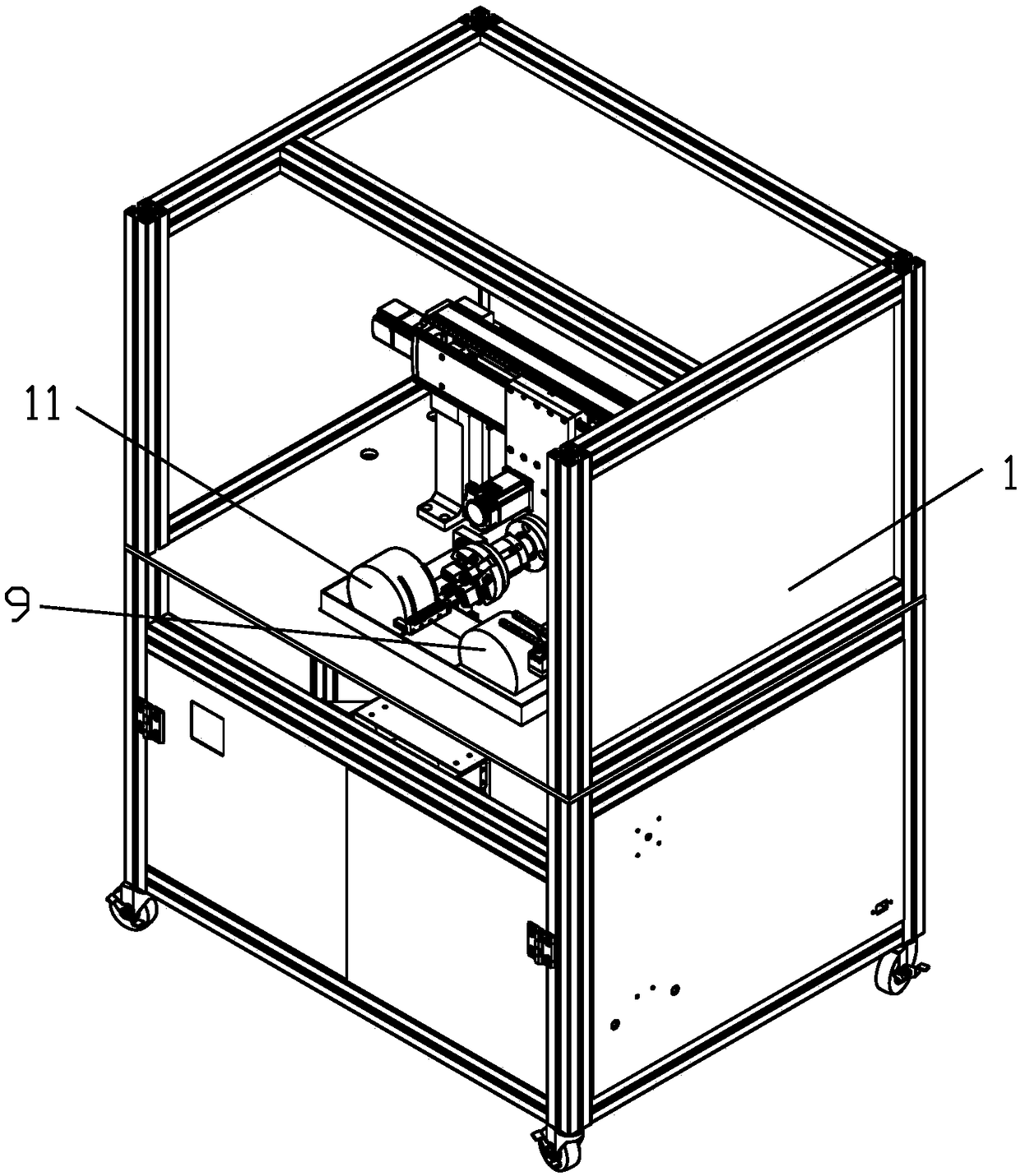

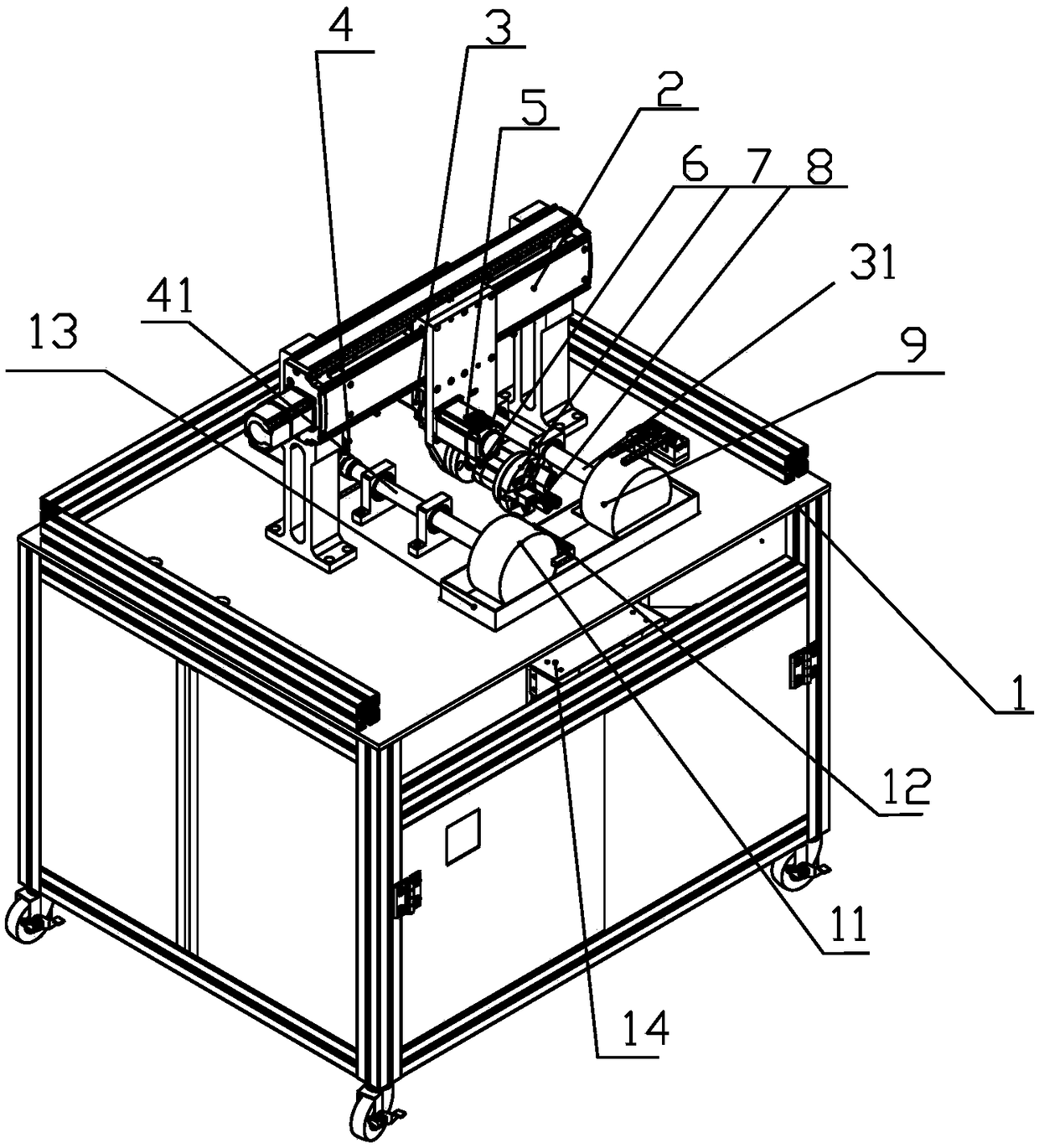

[0028] Such as figure 1 , 2 Shown, a motor rotor lamination glue coating machine, it includes:

[0029] Glue groove device, described glue groove device comprises glue groove 13, and described glue groove 13 is provided with the glue accommodating cavity that can be injected into glue, and described glue groove 13 has at least the squeegee glue station;

[0030] Rotor lamination clamping device, the rotor lamination clamping device is used for loading and unloading motor rotor laminations and can drive the motor rotor laminations installed thereon to rotate;

[0031] Gluing device, the gluing device comprises a gluing wheel 9 and is connected with the gluing wheel 9 so as to drive the gluing wheel rotation drive mechanism of the gluing wheel 9 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com