A method for superhydrophobicizing the surface of aluminum material

A kind of aluminum material and super-hydrophobic technology, applied in the direction of metal material coating process, etc., can solve the problems of unfavorable large-scale production, large oxidation current, and difficult quality control, etc., to achieve large-scale production, stable super-hydrophobic performance, high quality easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] After polishing the aluminum sheet with grade 1235 with metallographic sandpaper, wash it with water, acetone and ethanol for 5 minutes respectively; then roughen it with boiling water for 30 seconds, dry it and place it in 2% In the toluene solution of mercaptopropyltrimethoxysilane, react at 80°C for 5 hours and then wash the sample with toluene and ethanol; finally let the sample react with the toluene solution of carboxyl-terminated polyisoprene at 90°C for 4 hours, after washing with toluene, ethanol and water, and drying at room temperature to obtain a superhydrophobic aluminum sheet.

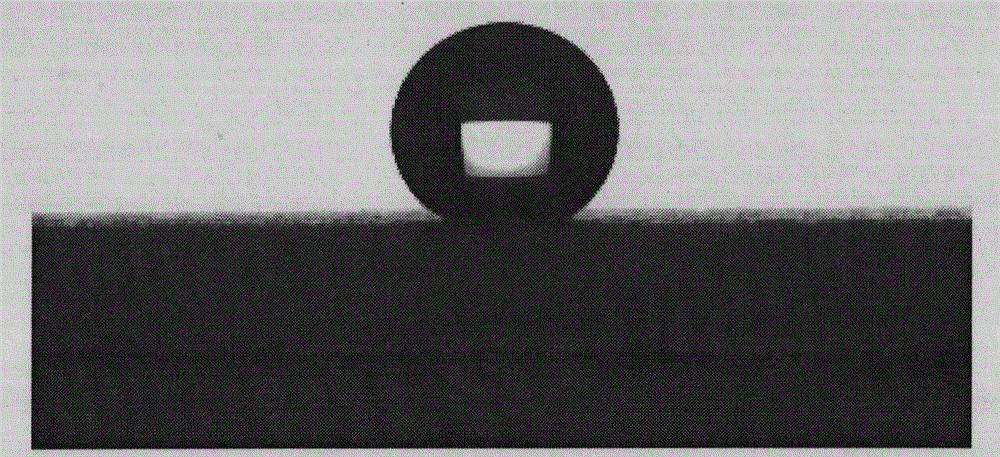

[0028] The distilled water contact angle performance test was carried out on the surface of the treated aluminum sheet. The test results show that the surface of the treated aluminum sheet has super-hydrophobic functional properties, and the contact angle of distilled water droplets on the surface of the aluminum sheet reaches 152±1°. figure 1 Photo of the static contact angle on ...

Embodiment 2

[0030] Flatten the 3005 aluminum strip and polish it with metallographic sandpaper, wash it with water, acetone and ethanol for 5 minutes respectively; then roughen it with boiling water for 1 minute, dry it and place it in 3% In the toluene solution of propoxy tris (dioctyl phosphate) titanate, react at 80°C for 8 hours and then wash the sample with toluene and ethanol; finally let the sample and the ethyl acetate solution of carboxyl-terminated polystyrene React at 120°C for 4 hours, wash with acetone, ethanol and water, and vacuum dry at 40°C for 6 hours to obtain superhydrophobic aluminum strips.

[0031] The distilled water contact angle performance test was carried out on the treated aluminum strip surface. The test results show that the surface of the treated aluminum strip has super-hydrophobic functional properties, and the contact angle of distilled water on the surface of the aluminum strip reaches 155±1°.

Embodiment 3

[0033] Polish the aluminum alloy foil with the brand name 3A21 with metallographic sandpaper, wash it with water, acetone and ethanol for 5 minutes respectively; In the toluene solution of 2,3-epoxypropyl)trimethoxysilane, react at 80°C for 6 hours and then wash the sample with toluene and ethanol; After reacting at low temperature for 4 hours, after washing with acetone, ethanol and water, vacuum drying at 40° C. for 6 hours to obtain a superhydrophobic aluminum alloy foil.

[0034] The distilled water contact angle performance test was carried out on the surface of the treated aluminum alloy foil. The test results show that the surface of the treated aluminum alloy foil has super-hydrophobic functional properties, and the contact angle of distilled water on the surface of the aluminum alloy foil reaches 153±1°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com