Hydrophilic material surface super hydrophobic functional shift micro structure design method

A design method and technology for hydrophilic materials, which can be used in microstructure technology, microstructure devices, nanostructure manufacturing, etc., can solve the problems of difficult to achieve superhydrophobicity on the surface of hydrophilic materials, difficult to achieve superhydrophobicity, etc., and achieve surface performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

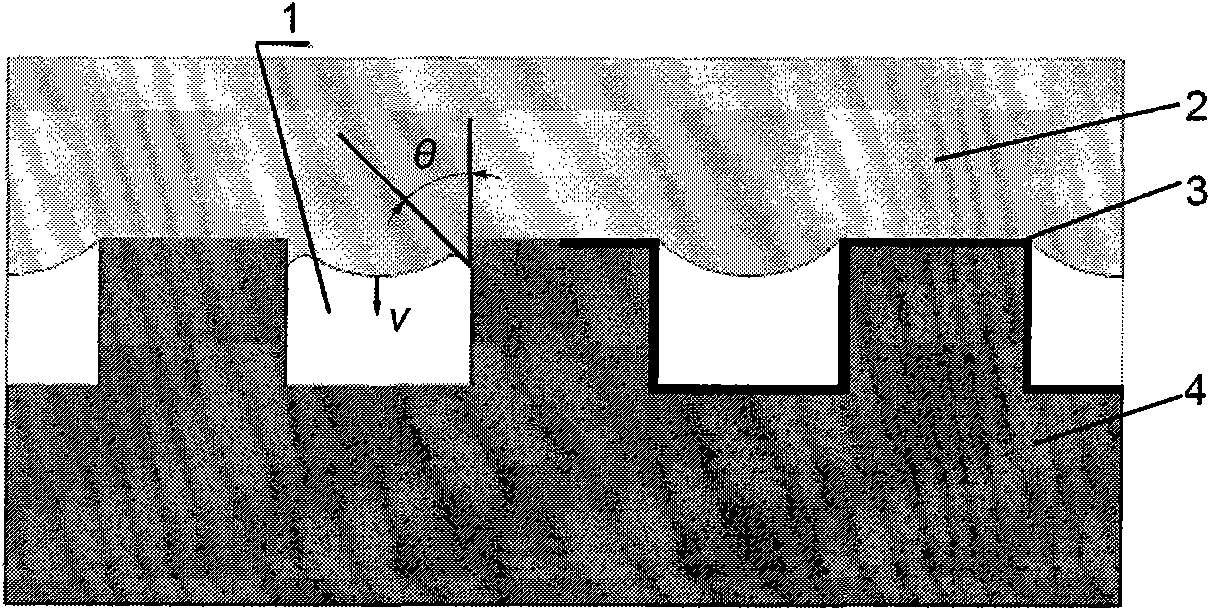

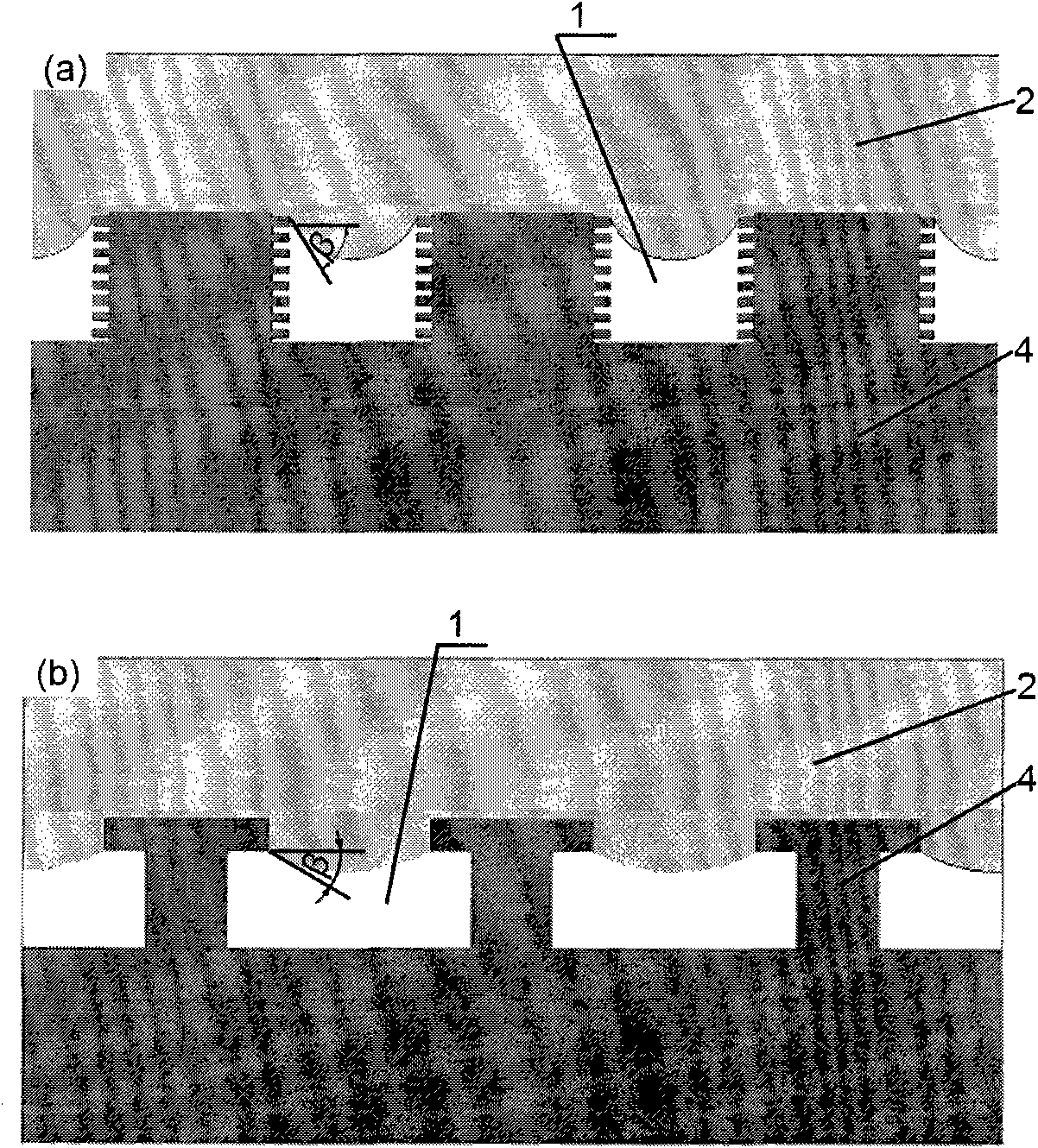

[0026] Embodiment 1 (square column form structure, section structure is figure 2 (a) The structural form, environmental conditions and parameters are: P-P 0 =1kPa, θ=50°, liquid 2 is water, γ=0.072N / m, θ C =150°):

[0027] Calculate the protrusion ratio of the surface 4 of the microstructure of the hydrophilic material according to the Cassie calculation formula. f=(cosθ C +1) / (cosθ+1)=0.08155;

[0028] Square column form, L 1 =L 2 =L,A=(Lf) 2 , S=4Lf, then there is L max 0 )(1-f 2 )]=23.6μm, where L max is the maximum period.

[0029] Select the hydrophilic material microstructure 4 whose structural period is L=1 μm, and calculate the angle β formed between the interface formed by the liquid 2 and air 1 in the microstructure and the microstructure wall, Much smaller than the intrinsic contact angle 50° of liquid water 2 on the surface of the smooth hydrophilic material, therefore, liquid water 2 is in the Cassie contact state on the surface 4 of the microstructur...

Embodiment 2

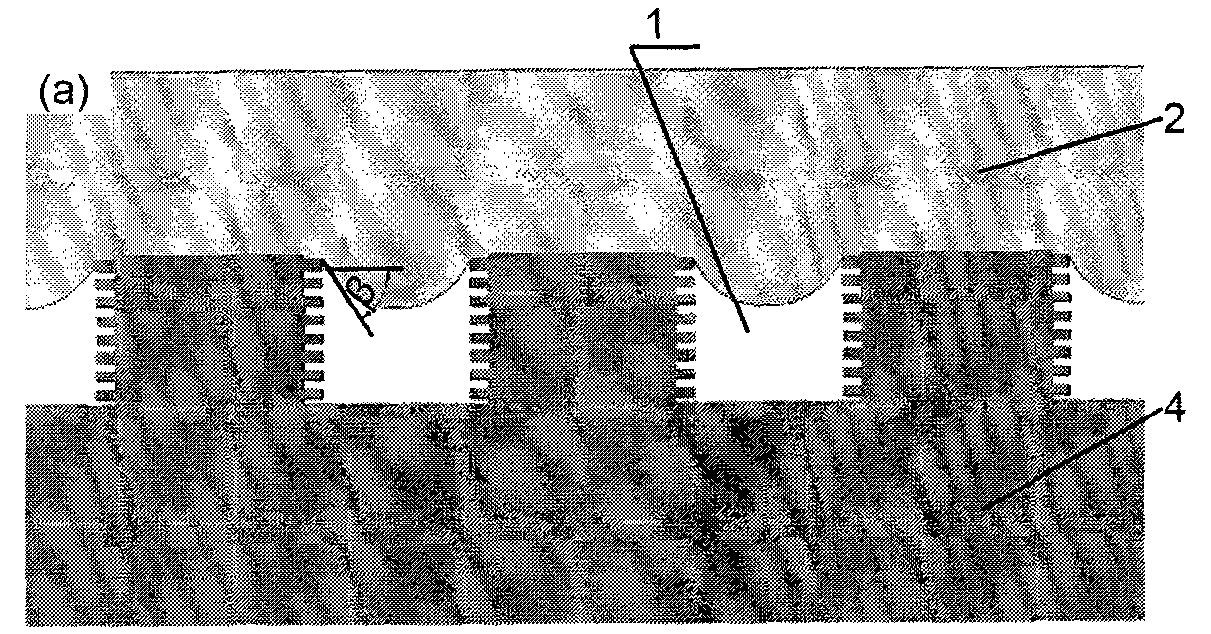

[0031] Embodiment 2 (square column form structure, section structure is figure 2 (b) The structural form, environmental conditions and parameters are: P-P 0 =10kPa, θ=50°, liquid 2 is water, γ=0.072N / m, θ C =150°):

[0032] Calculate the protrusion ratio of the surface 4 of the microstructure of the hydrophilic material according to the Cassie calculation formula. f=(cosθ C +1) / (cosθ+1)=0.08155;

[0033] Square column form, L 1 = L 2 =L,A=(Lf) 2 , S=4Lf, then there is L max 0 )(1-f 2 )]=23.6μm, where L max is the maximum period.

[0034] Select the hydrophilic material microstructure 4 whose structural period is L=1 μm, and calculate the angle β formed between the interface formed by the liquid 2 and air 1 inside the microstructure and the microstructure wall, Far smaller than the intrinsic contact angle 50° of liquid water 2 on a smooth hydrophilic surface, liquid water 2 is in the Cassie contact state on the surface 4 of the microstructure of the hydrophilic mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com