Method for preparing polymer superhydrophobic surface by virtue of hydrophobic nanoparticle spontaneous deposition

A super-hydrophobic surface and nano-particle technology, applied in the field of preparation of polymer super-hydrophobic surface, can solve the problems of high investment threshold for precision coating equipment, increased film haze, complex coating process, etc., and achieves good repeatability/continuity. , good wear resistance, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

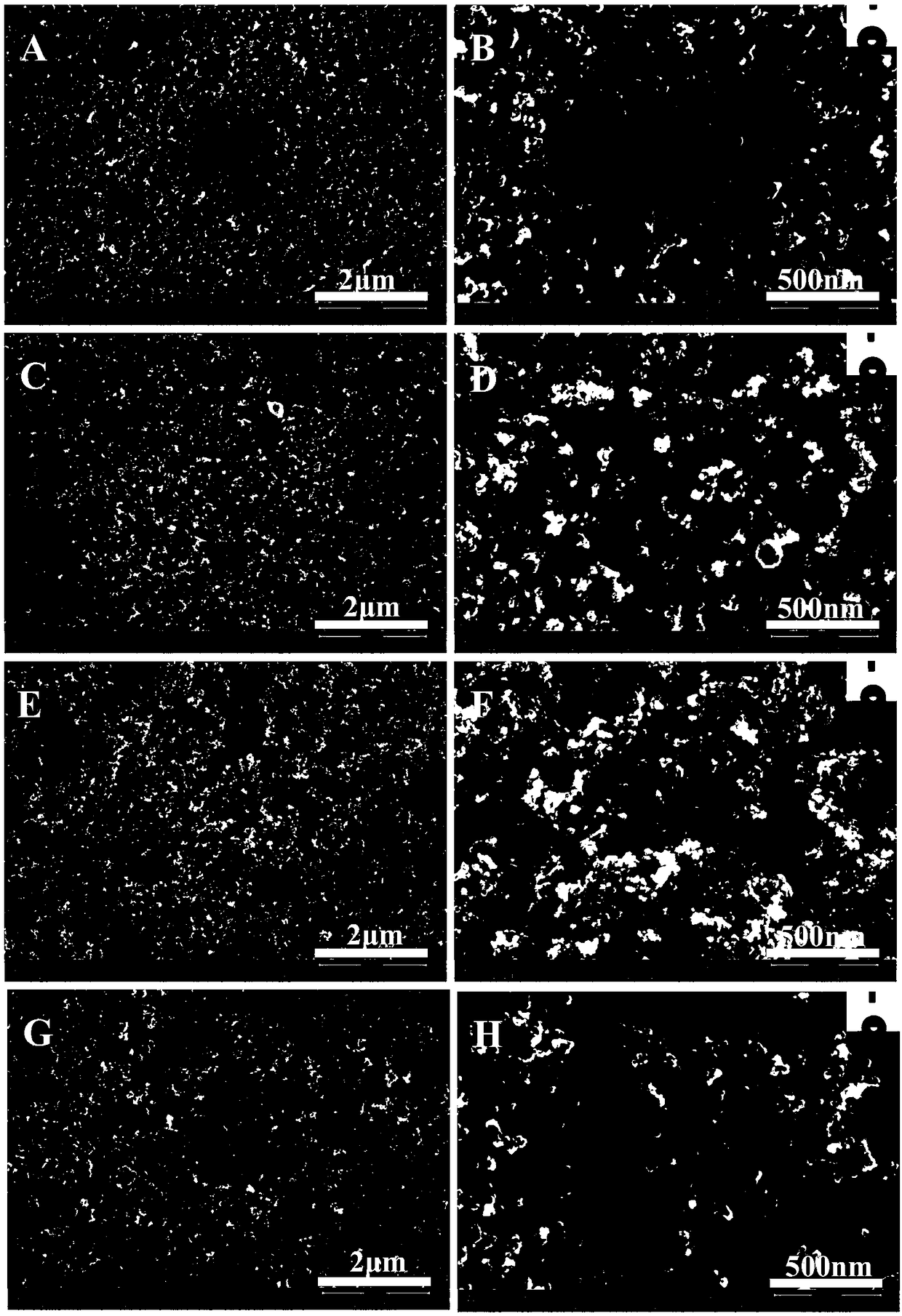

[0043] 0.5g of hydrophobic white carbon black (nano silica grafted with methyl group) (Evonik Industries AG, R812s, average particle size 20-30nm, the same below) was added to 37g of ethanol, magnetically stirred for 1h, and ultrasonicated for 30min to obtain hydrophobic white carbon black. Carbon black / ethanol suspension, spray it evenly on the surface of LDPE film (about 0.5mm thick, the same below), dry it at room temperature and then put it in an oven at 120°C for 20min, cool it to room temperature and rinse it thoroughly with ethanol, N 2 Blow dry to obtain LDPE-SiO 2 membrane.

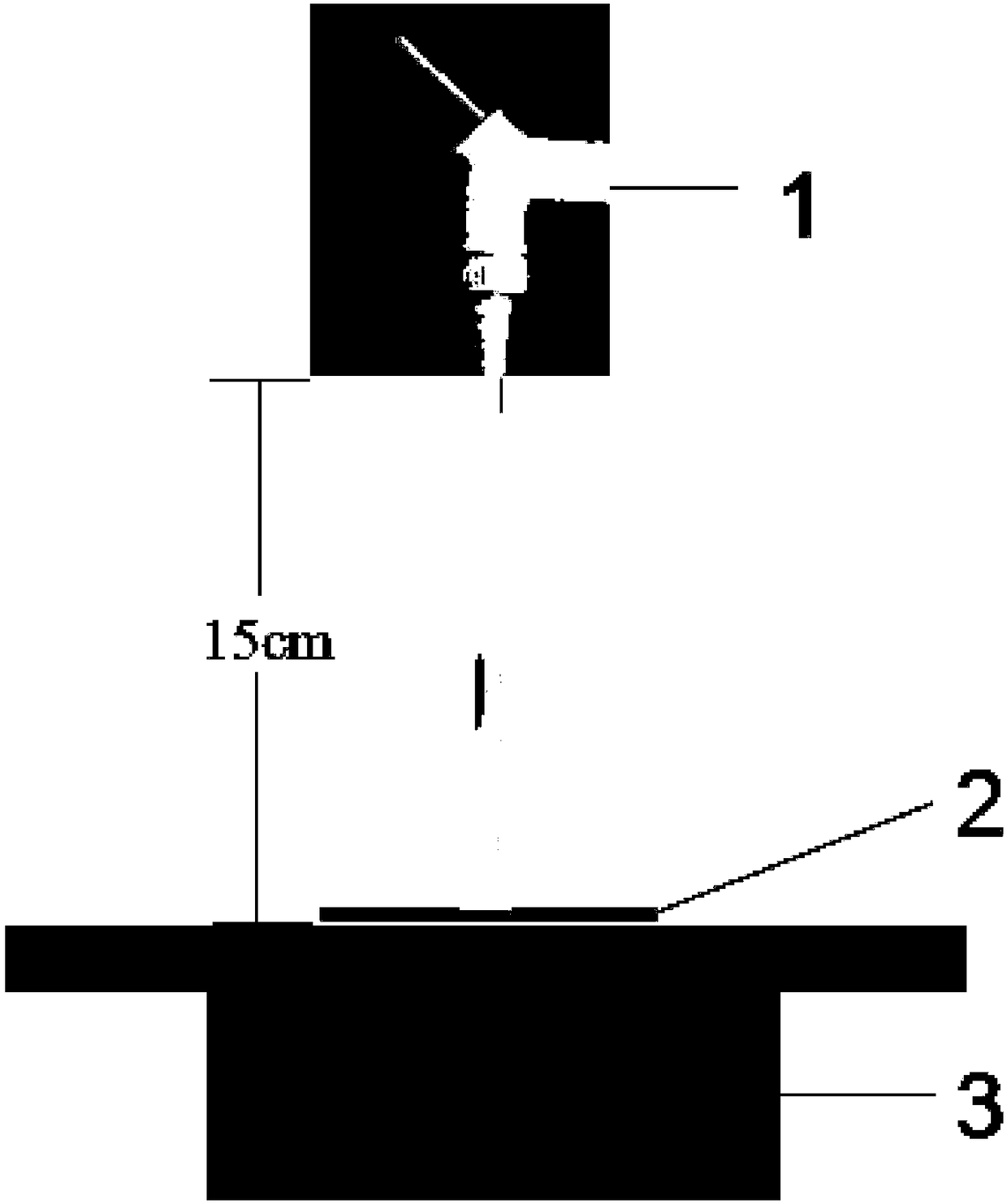

[0044] The film has good transparency, and the surface morphology is as follows: figure 1 As shown in A / B, the static contact angle and rolling angle of water droplets are 154.8° and 2.8°, respectively, showing typical superhydrophobic properties ( figure 1 B inset). The LDPE superhydrophobic membrane that makes utilizes self-made device (such as figure 2 ) to test their water resistance ( ...

Embodiment 2

[0048] Others are the same as in Example 1, changing the oven temperature to 130°C. The surface morphology of the resulting LDPE film is shown in figure 1 C / D. The LDPE film exhibits typical superhydrophobic properties (the static contact angle of water is 154.2°, and the rolling angle is 3.0°).

Embodiment 3

[0050] Others are the same as in Example 1, changing the oven temperature to 140°C. The surface morphology of the resulting LDPE film is shown in figure 1 E / F. The LDPE film exhibits typical superhydrophobic properties (the static contact angle of water is 153.8°, and the rolling angle is 3.2°).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com