Super-hydrophobic radiation cooling porous film and preparation method thereof

A porous film and super-hydrophobic technology, applied in the field of super-hydrophobic radiation cooling porous film and its preparation, can solve the problems of affecting the cooling effect and service life of the material, and be easily polluted, achieve stable super-hydrophobicity and radiation cooling performance, simplify the Operation process and production cost, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

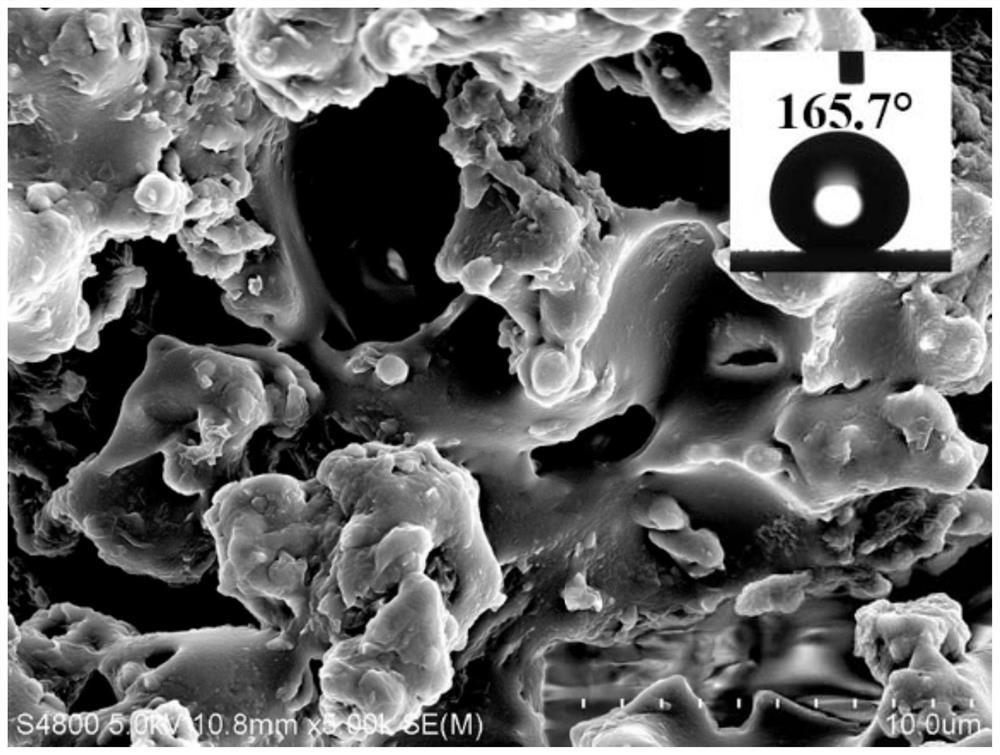

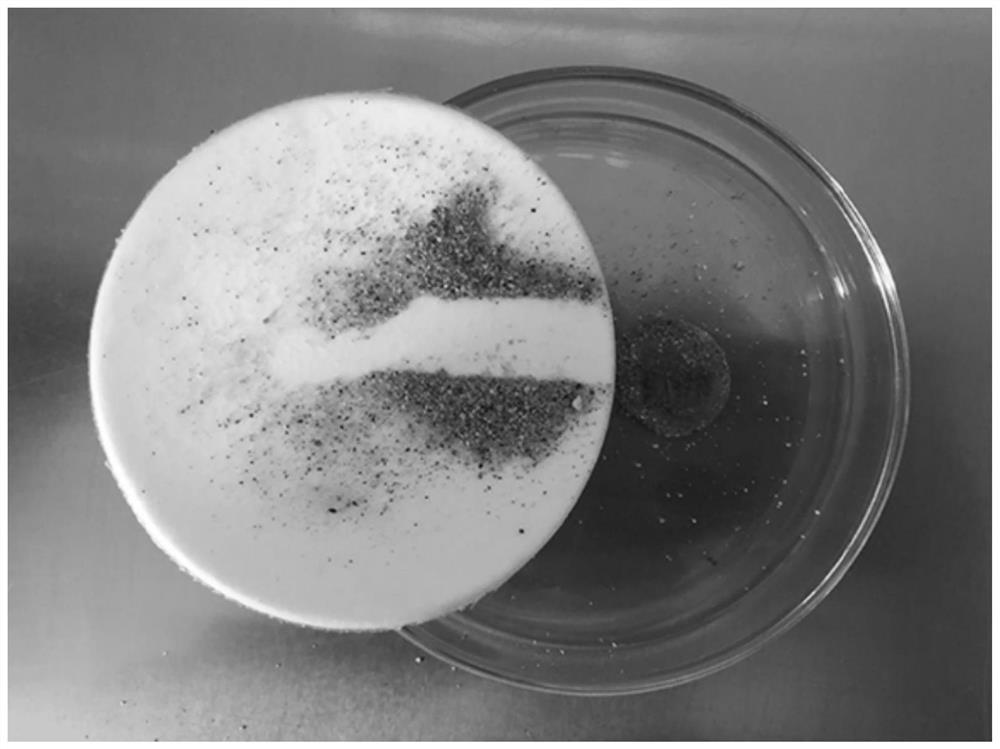

[0045] A method for preparing a superhydrophobic radiation-cooled porous film of the present invention, specifically comprising the following steps:

[0046] S1. Weigh a certain amount of PDMS prepolymer A and curing agent B components;

[0047] S2, take a certain amount of water;

[0048] S3. Add the water described in step S2 dropwise to the PDMS mixture described in step S1, keep the beaker sealed, and stir at room temperature for 2 hours to obtain a milky white emulsion, which is polydimethylsiloxane Alkane / water (PDMS / Water) emulsion;

[0049] S4. Pouring the milky white emulsion described in step S3 in a petri dish, and vacuum degassing for a certain period of time to remove internal micro-bubbles;

[0050] S5. After sealing the emulsion described in step S4, curing treatment at 45-70° C. for 4.5-6.0 hours to obtain a PDMS film containing water inside;

[0051] S6. Unseal the PDMS film containing water inside as described in step S5, and dry it at 120-200° C. for 120-...

Embodiment 1

[0060] The preparation process of the superhydrophobic radiation cooling porous film in this embodiment includes the following steps:

[0061] step 1

[0062] Weigh 9.0g of PDMS prepolymer A and 1.0g of curing agent B, add them to the beaker, keep the beaker sealed, and stir it with a constant speed stirrer at room temperature to obtain a uniform PDMS mixture; then weigh 9.0g Water, using a peristaltic pump to control the dropping rate to 3.5mL / min, add 9.0g of water dropwise to the PDMS mixture in step 1 to form a milky white emulsion, which is the PDMS / Water emulsion.

[0063] step 2

[0064] The emulsion obtained in step 1 was cast in a petri dish, and vacuum degassed at 20° C. for 45 minutes to remove air bubbles.

[0065] step 3

[0066] The emulsion obtained in step 2 was sealed and cured at 45° C. for 4.5 hours to obtain a PDMS film containing water inside.

[0067] step 4

[0068] The PDMS film obtained in step 3 was dried at 120° C. for 120 minutes to remove inte...

Embodiment 2

[0073] The preparation process of the superhydrophobic radiation cooling porous film in this embodiment includes the following steps:

[0074] step 1

[0075] Weigh 9.0g of PDMS prepolymer A and 1.0g of curing agent B, add them to the beaker, keep the beaker sealed, and stir it with a constant speed stirrer at room temperature to obtain a uniform PDMS mixture; then weigh 10.0g Water, using a peristaltic pump to control the dropping rate to 3.5mL / min, add 10.0g of water dropwise to the PDMS mixture in step 1 to form a milky white emulsion, which is the PDMS / Water emulsion.

[0076] step 2

[0077] The emulsion obtained in step 1 was cast in a petri dish, and vacuum degassed at 20° C. for 45 minutes to remove air bubbles.

[0078] step 3

[0079] The emulsion obtained in step 2 was sealed and cured at 45° C. for 4.5 hours to obtain a PDMS film containing water inside.

[0080] step 4

[0081] The PDMS film obtained in step 3 was dried at 120° C. for 120 minutes to remove in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com