Spinning micropore and processing method thereof

A technology of spinneret micropores and processing methods, which is applied in fiber processing, spinneret assemblies, and rayon manufacturing, can solve the problems of lack of necessary considerations in melt rheological resistance, and achieve low surface energy characteristics and guarantee Dimensional stability, effect of prolonged cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

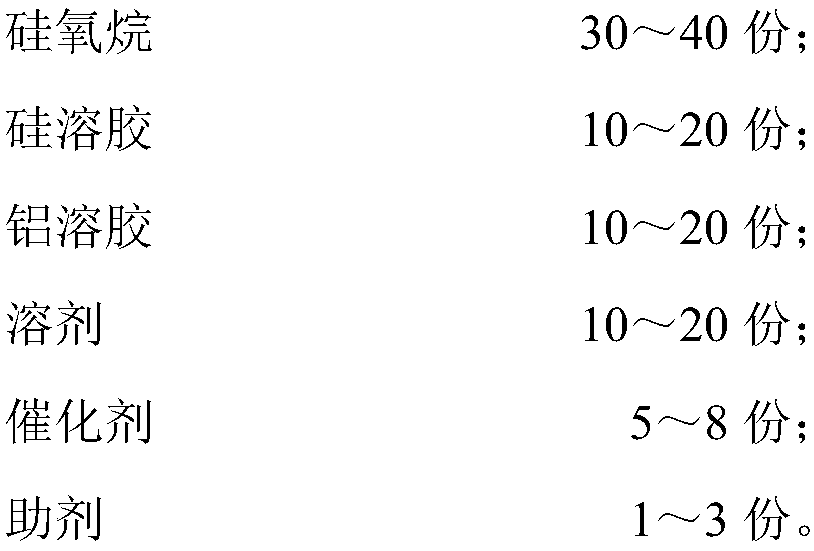

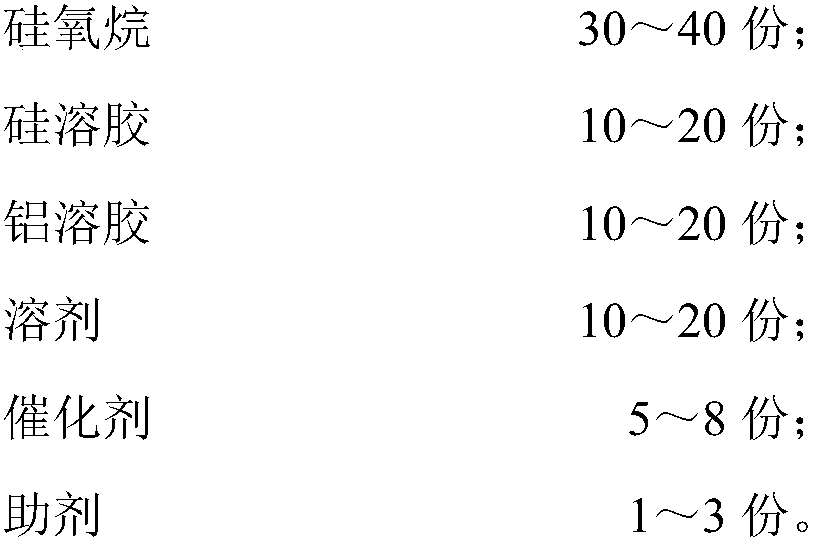

[0031] A treatment method for spinneret micropores. First, in parts by weight, 10 parts of alkaline silica sol with a pH value of 10.1, a solid content of 30 wt%, and an average particle diameter of 30 nm and 10 parts of alkaline silica sol with a pH value of 9.4 and a solid content of Alkaline aluminum sol with 20wt% and an average particle size of 45nm was mixed, then 5 parts of formic acid was added as a catalyst to adjust the pH value of the system, and the pH value was maintained at 2, and then 10 parts of mixed solvent of ethanol and water were added, and the mixture of ethanol and water The volume ratio is 1.25:1, then add 30 parts of methyltrimethoxysilane, then hydrolyze at room temperature for 15 minutes, then put the system at 45°C for high-temperature condensation, keep the reaction for 30 minutes, and then add 1 part after the reaction A mixture of leveling agent BYK 310, defoamer BYK 025, and surface hardening and wear-resistant agent T801 with a mass ratio of 1:1...

Embodiment 2

[0034] A treatment method for spinneret micropores. First, in parts by weight, 20 parts of alkaline silica sol with a pH value of 10.5, a solid content of 45 wt%, and an average particle diameter of 50 nm and 20 parts of alkaline silica sol with a pH value of 9.8 and a solid content of Alkaline aluminum sol with 35wt% and an average particle size of 65nm was mixed, then 8 parts of acetic acid was added as a catalyst to adjust the pH value of the system, and the pH value was maintained at 4.5, and then 20 parts of a mixed solvent of isopropanol and water were added, and isopropyl The volume ratio of alcohol to water is 1.42:1, then add 40 parts of methyltriethoxysilane, then hydrolyze at room temperature for 20 minutes, then put the system at 80°C for high temperature condensation, the reaction is maintained for 75 minutes, and the reaction is over Then add 3 parts of the mixture additives of leveling agent BYK 310, defoamer BYK 025 and surface hardening and wear-resistant agent...

Embodiment 3

[0037] A treatment method for spinneret micropores, first in parts by weight, 15 parts of alkaline silica sol with a pH value of 10.3, a solid content of 35wt%, and an average particle diameter of 40nm and 15 parts of alkaline silica sol with a pH value of 9.6 and a solid content of Alkaline aluminum sol with 30wt% and an average particle size of 50nm is mixed, then 6 parts of hydrochloric acid is added as a catalyst to adjust the pH value of the system, and the pH value is maintained at 3, and then 15 parts of butanol and water mixed solvent are added, butanol and The volume ratio of water is 1.60:1, then add 35 parts of ethyltriethoxysilane, then hydrolyze at room temperature for 18 minutes, then put the system at 50°C for high-temperature condensation, and keep the reaction for 40 minutes. Add 2 parts of a mixture of leveling agent BYK 310, defoamer BYK 025 and surface hardening and wear-resistant agent T801 with a mass ratio of 1:1:0.25. After stirring for 8 minutes, the sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com