A kind of preparation method of side chain fluorine-containing degradable polyurethane resin

A polyurethane resin and side chain technology, which is applied in the field of preparation of side chain fluorine-containing degradable polyurethane resin for antifouling coatings, can solve the problems of destroying the marine ecological environment, etc., and achieve good antifouling effect, adhesion inhibition, and good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

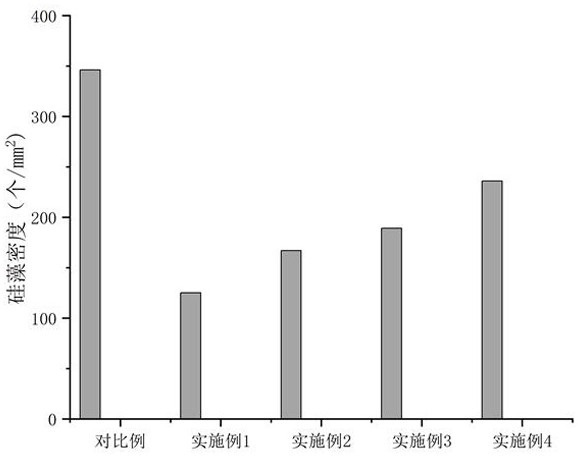

[0022] Example 1: Dissolve and disperse 10g of polymethacrylate-2-hydroxyethyl methacrylate in xylene and pour it into a three-necked flask, add 10.66g of isophorone diisocyanate under ice-water bath conditions, add 0.15g (0.5ωt% ) catalyst dibutyltin dilaurate, gradually heated up to 40°C for 2 hours at a speed of 250r / min to prepare a group-modified acrylic resin; 17.47g of 1H,1H,2H,2H-perfluoro-1-octanol Add 10.66g of isophorone diisocyanate in an ice-water bath, add 0.23g (0.5ωt%) catalyst dibutyltin dilaurate, and gradually raise the temperature to 40°C for 2 hours at 250r / min; weigh 38.4 gPEG 800 Slowly drop into a three-necked flask equipped with group-modified acrylic resin, heat to 50°C for 2 hours at a speed of 250r / min, and then drop into the modified 1H, 1H, 2H, 2H-perfluoro-1 - Octanol was heated to 60°C for 2 hours, and after the reaction was completed, it was purified and filtered.

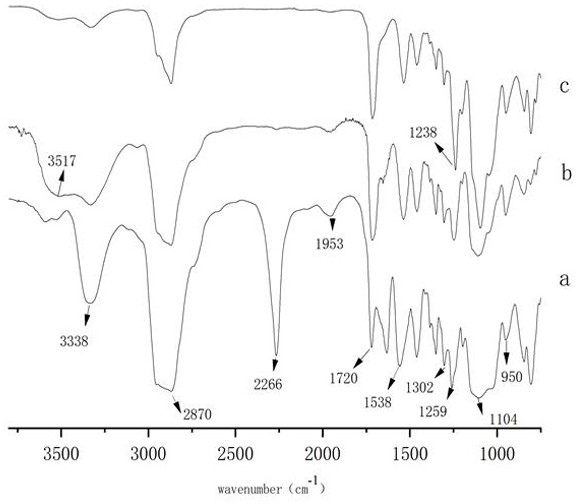

[0023] image 3 It is the infrared spectrogram of the side chain fluorine-co...

Embodiment 2

[0024] Example 2: Dissolve and disperse 10g poly-2-hydroxyethyl methacrylate in xylene and pour it into a three-necked flask, add 10.66g isophorone diisocyanate under ice-water bath conditions, add 0.08g (0.25ωt% ) catalyst dibutyltin dilaurate, gradually heated up to 40°C for 2 hours at a speed of 250r / min to prepare a group-modified acrylic resin; 13.98g of 1H,1H,2H,2H-perfluoro-1-octanol Disperse in tetrahydrofuran, add 8.53g isophorone diisocyanate under the condition of ice-water bath, add 0.09g (0.25ωt%) catalyst dibutyltin dilaurate, and gradually heat up to 40°C at 250r / min to react for 2h; weigh 23.04 gPEG 600 Slowly drop into a three-necked flask equipped with group-modified acrylic resin, heat to 50°C for 2 hours at a speed of 250r / min, and then drop into the modified 1H, 1H, 2H, 2H-perfluoro-1 - Octanol was heated to 60°C for 2 hours, and after the reaction was completed, it was purified and filtered.

Embodiment 3

[0025] Example 3: Dissolve and disperse 10g of polymethacrylate-2-hydroxyethyl methacrylate in xylene and pour it into a three-necked flask, add 10.66g of isophorone diisocyanate under ice-water bath conditions, add 0.15g (0.5ωt% ) Catalyst dibutyltin dilaurate, gradually heated up to 40°C at 250r / min and reacted for 2h to prepare a group-modified acrylic resin; 13.98g1H,1H,2H,2H-perfluoro-1-octanol Add 8.53g of isophorone diisocyanate in an ice-water bath, add 0.18g (0.5ωt%) catalyst dibutyltin dilaurate, and gradually heat up to 40°C for 2 hours at 250r / min; weigh 19.2 gPEG 400 Slowly drop into a three-necked flask equipped with group-modified acrylic resin, heat to 50°C for 2 hours at a speed of 250r / min, and then drop into the modified 1H, 1H, 2H, 2H-perfluoro-1 - Octanol was heated to 60°C for 2 hours, and after the reaction was completed, it was purified and filtered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com