Stable super hydrophobic self-cleaning surface and double-light-beam interference-method preparation method thereof

A double-beam interference and super-hydrophobic technology, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of preparation resolution limitation, inability to guarantee the stability of micro-nano composite structure, and inability to achieve higher precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

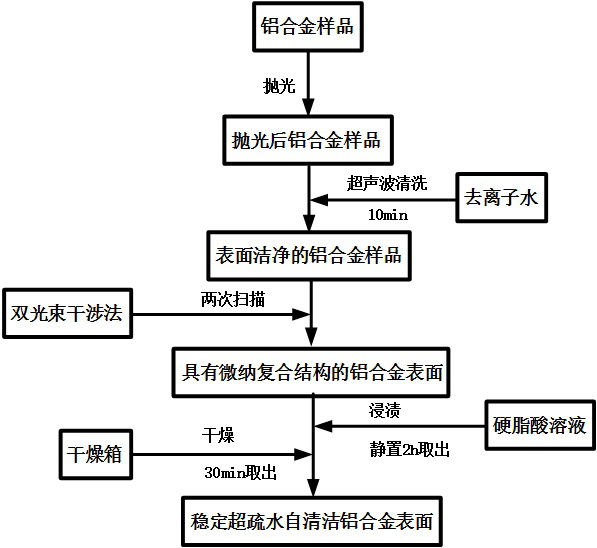

[0042] 1. Grind the aluminum alloy sheet with a size of 20*20*2mm with metallographic sandpaper, and perform polishing pretreatment; use a metallographic sample polishing machine to polish the surface of the polished workpiece to obtain surface-polished aluminum Alloy sample; surface roughness Rz is less than 1.0μm;

[0043] 2. Polish the aluminum alloy sample, and use deionized water as a solvent for ultrasonic cleaning. The temperature of ultrasonic cleaning is 25-40°C, the ultrasonic power is 160W, and the cleaning time is 10-13min. Then use cold air to dry to obtain a clean aluminum alloy sample;

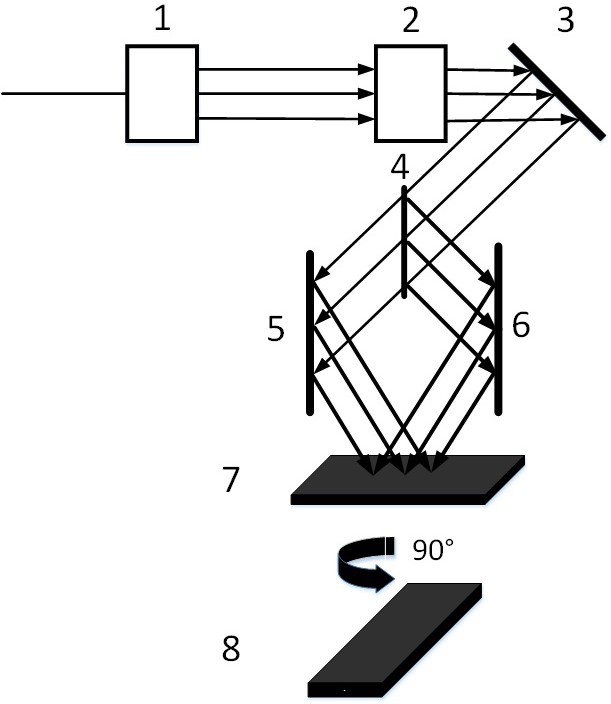

[0044] 3. Fix the clean aluminum alloy that has been cleaned on the surface on the preparation platform of the double-beam laser interferometry. The specimen is rotated 90°, scanned again, and the superposition of two scans is used to ablate the surface of the specimen to prepare a micro-nano composite structure; the laser processing parameters of the two-beam laser interferenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com