Super-hydrophobic transparent luminous latex coating for outer wall and preparation method thereof

A latex coating, super-hydrophobic technology, applied in luminescent coatings, antifouling/underwater coatings, latex paints, etc., can solve the problems of high cost of super-hydrophobic coating materials, unsuitable for large-scale applications, unstable super-hydrophobic performance, etc. , to achieve the effect of saving lighting energy consumption, improving lipophilicity and hydrophobicity, and good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preparation Example

[0026] According to the following method, prepare the superhydrophobic transparent luminous latex coating of exterior wall of the present invention:

[0027] Step 1, material preparation: carry out component material preparation according to the mass percentage shown in Table 1:

[0028] Step 2. Mixing: Mix all the components weighed in step 1 except the thickener, carry out the first high-speed stirring and dispersing for 50-60 minutes, add the thickener after the dispersion is uniform, and carry out the second stirring and dispersing for 10-20 minutes , evenly dispersed.

[0029]

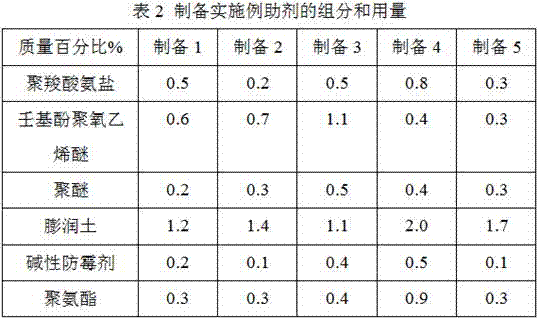

[0030] Wherein, the components contained in the auxiliary agent are shown in Table 2.

[0031]

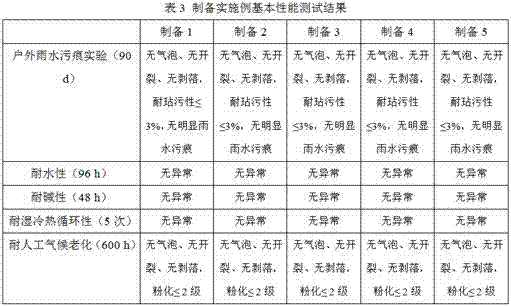

[0032] The superhydrophobic transparent luminous latex paint for exterior walls prepared in the above preparation examples was tested for basic performance, and the specific results measured are shown in Table 3.

[0033]

[0034] It can be seen from Table 3 tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com