Spray preparation method of industrialized and anti-stripping largesuper-hydrophobic surface

A super-hydrophobic surface and super-hydrophobic coating technology, which is applied to the surface coating device, special surface, coating, etc., can solve the problems of poor anti-stripping performance and unstable anti-stripping performance of super-hydrophobic coatings. Achieve excellent anti-stripping performance, improve coating utilization, and stabilize superhydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

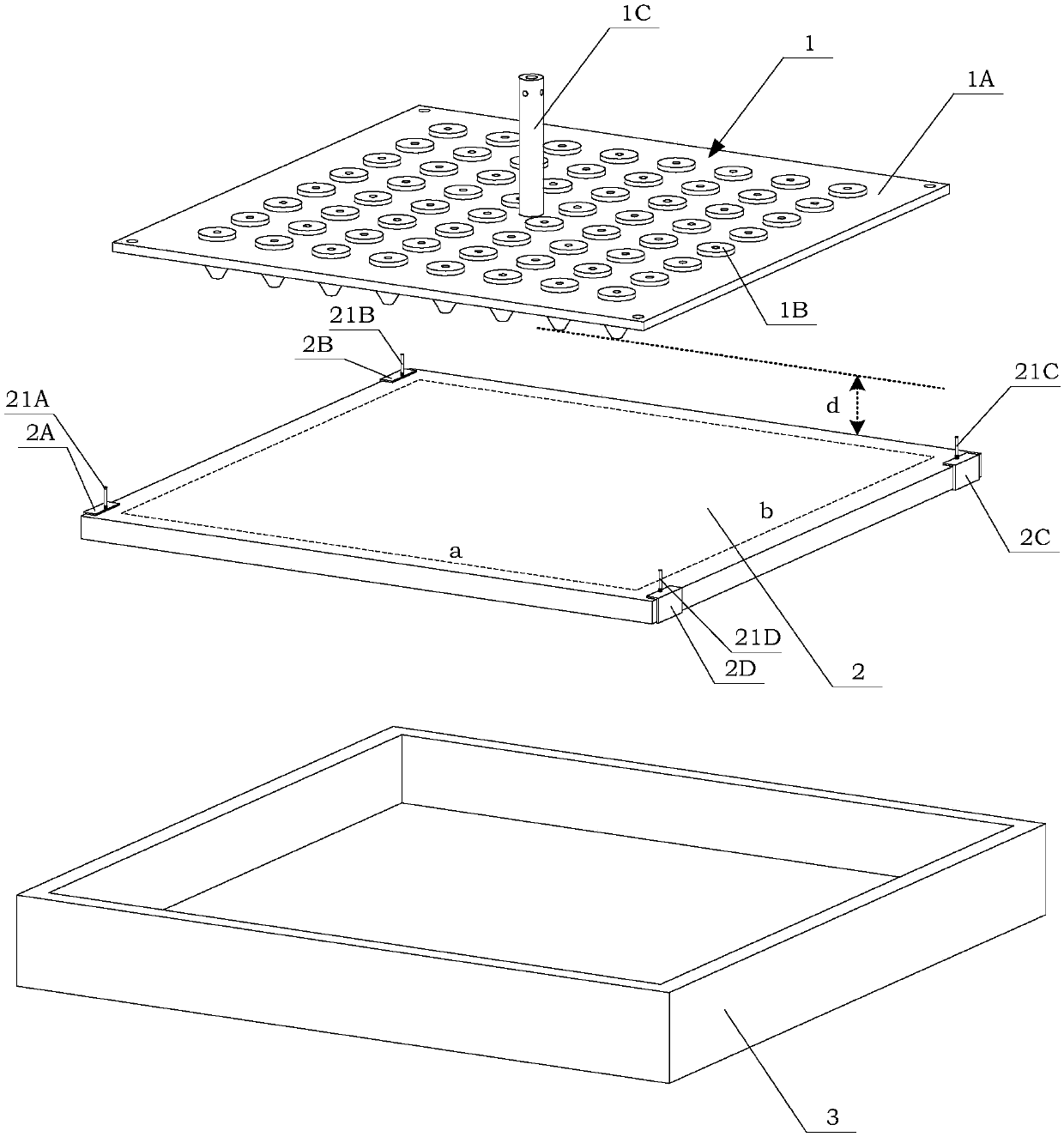

[0061] see Figure 4 Shown, the spray coating preparation method of a kind of industrialization anti-stripping large-area super-hydrophobic surface of the present invention, comprises the following steps:

[0062] Step 1, with epoxy resin solution

[0063] 8-80g of bisphenol A epoxy resin (E51), 2-20g of curing agent (T31) and the balance of acetone are required to prepare 1kg of epoxy resin solution, for use;

[0064] In the present invention, the curing agent is matched with the bisphenol A epoxy resin, that is, the traditional curing agent.

[0065] Step 2, mix hydrophobic coating solution

[0066] Prepare hydrophobic nano-silica particles of 1-50 nm and acetone into a hydrophobic coating solution with a concentration of 1-10 wt% (mass percentage), and set aside;

[0067] Step 3, epoxy resin coating preparation

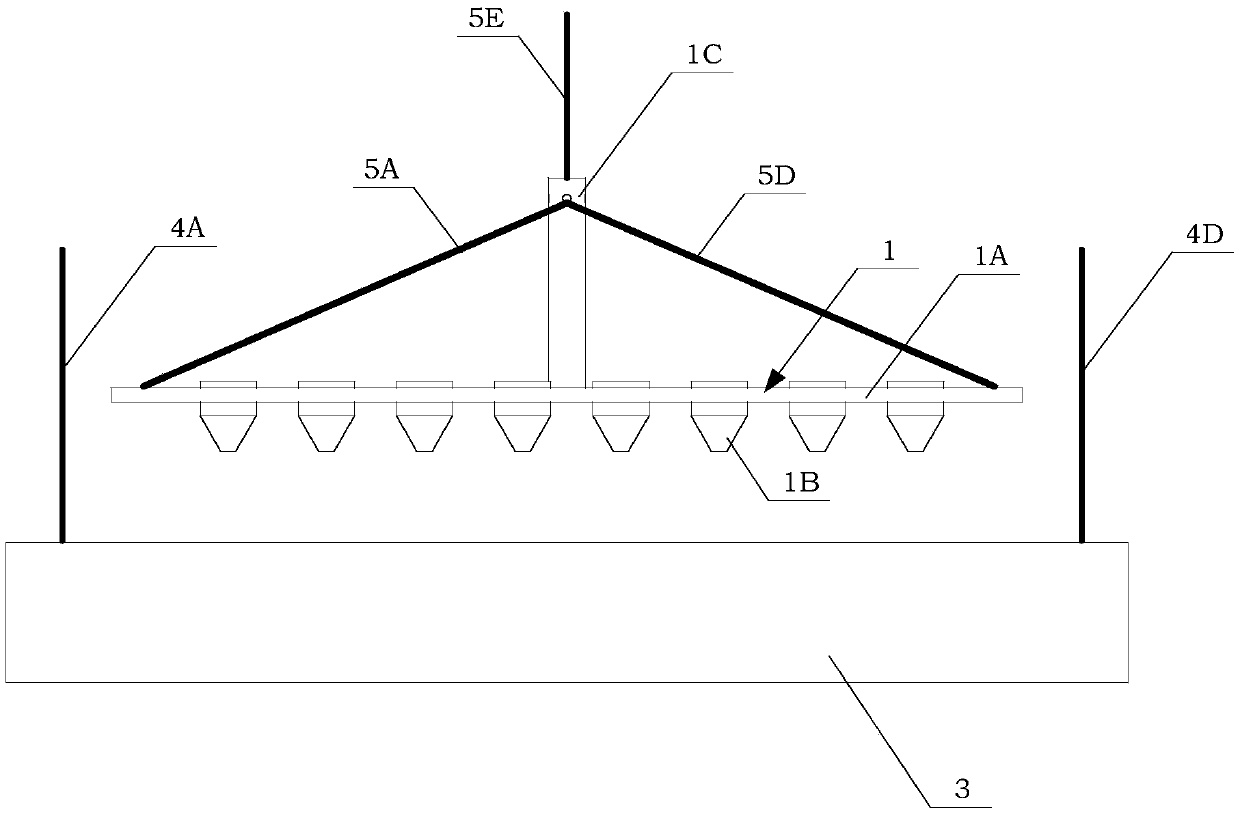

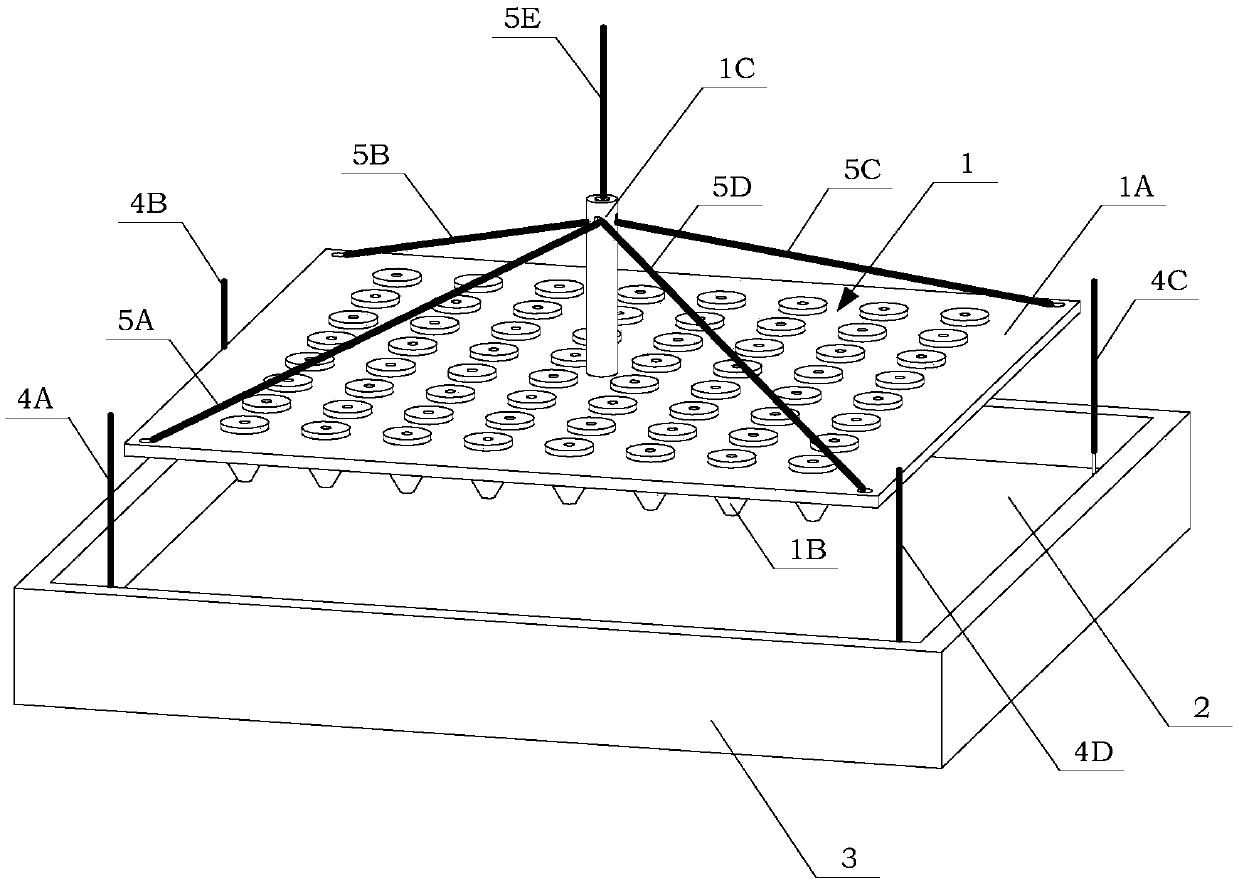

[0068] Step 31, assemble the base body 2 with the four fixtures (2A, 2B, 2C, 2D), and then assemble the jacking screws on the fixtures, and adjust the balance ...

Embodiment 1

[0079] Industrial production 0.8m×0.8m( Figure 1B The dotted line a×b above, a is the length of the sprayed area on the substrate, and b is the width of the sprayed area on the substrate) Large-area super-hydrophobic coating

[0080] Embodiment 1 selects the glass substrate (5mm thickness) of 0.8m * 0.8m to carry out sodium dodecylbenzene sulfonate aqueous solution (1wt%) cleaning, then rinses with pure water, obtains clean substrate;

[0081] Step 1, with epoxy resin solution

[0082] Prepare 60g of bisphenol A epoxy resin (E51), 12g of curing agent (T31) and the balance of acetone for 1kg of epoxy resin liquid, and set aside;

[0083] Step 2, mix hydrophobic coating solution

[0084] The hydrophobic nano-silica particles and acetone with the industrial grade of R974 are prepared as a hydrophobic coating solution with a concentration of 5wt% (mass percentage), for use;

[0085] Step 3, epoxy resin coating preparation

[0086] Step 31, assemble the clean substrate 2 with ...

Embodiment 2

[0100] Industrial production of 1.0m×0.8m large-area super-hydrophobic coating

[0101] The aluminum plate substrate (2mm thickness) of 1.0m * 0.8m selected in embodiment 1 is cleaned with sodium dodecylbenzenesulfonate aqueous solution (1wt%), and then rinsed with pure water to obtain a clean substrate;

[0102] Step 1, with epoxy resin solution

[0103] 20g of bisphenol A epoxy resin (E51), 5g of curing agent (T31) and the balance of acetone are required for 1kg of epoxy resin solution, for use;

[0104] Step 2, mix hydrophobic coating solution

[0105] The hydrophobic nano-silica particles and acetone with the industrial grade of R974 are prepared as a hydrophobic coating solution with a concentration of 3wt% (mass percentage), for use;

[0106] Step 3, epoxy resin coating preparation

[0107] Step 31, assemble the clean substrate 2 with four fixtures (2A, 2B, 2C, 2D), assemble the jacking screws on the fixtures, and adjust the balance with the A lifting mechanism and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com