Superhydrophobic wood fiber powder and preparation method thereof

A technology of lignocellulose and lignocellulose, which is applied in the directions of repelling fibers for liquids, fiber processing, plant fibers, etc., can solve the problems of unstable superhydrophobicity, complex preparation process, high cost, and achieve abundant yield and preparation method. Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

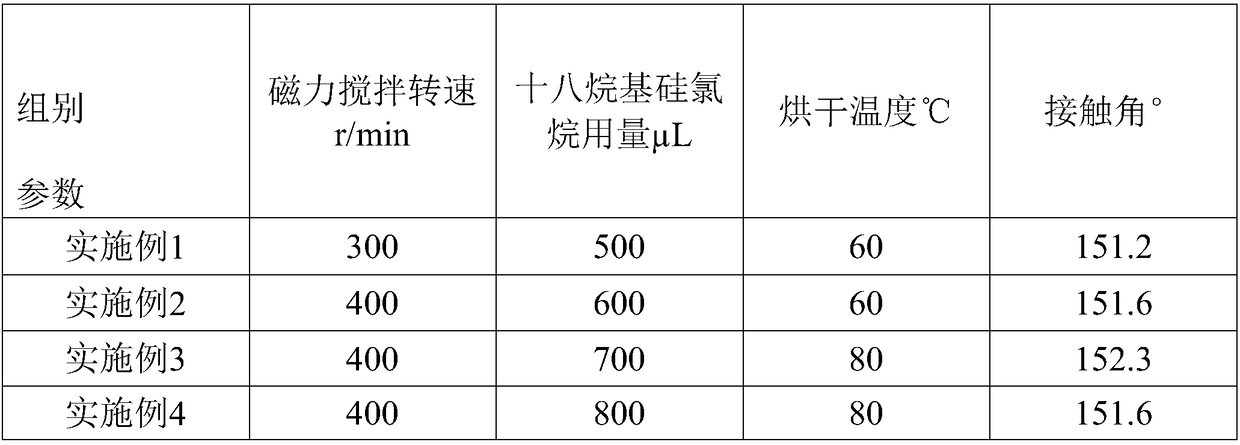

Embodiment 1

[0032] A kind of superhydrophobic coffee grounds material, prepare as follows:

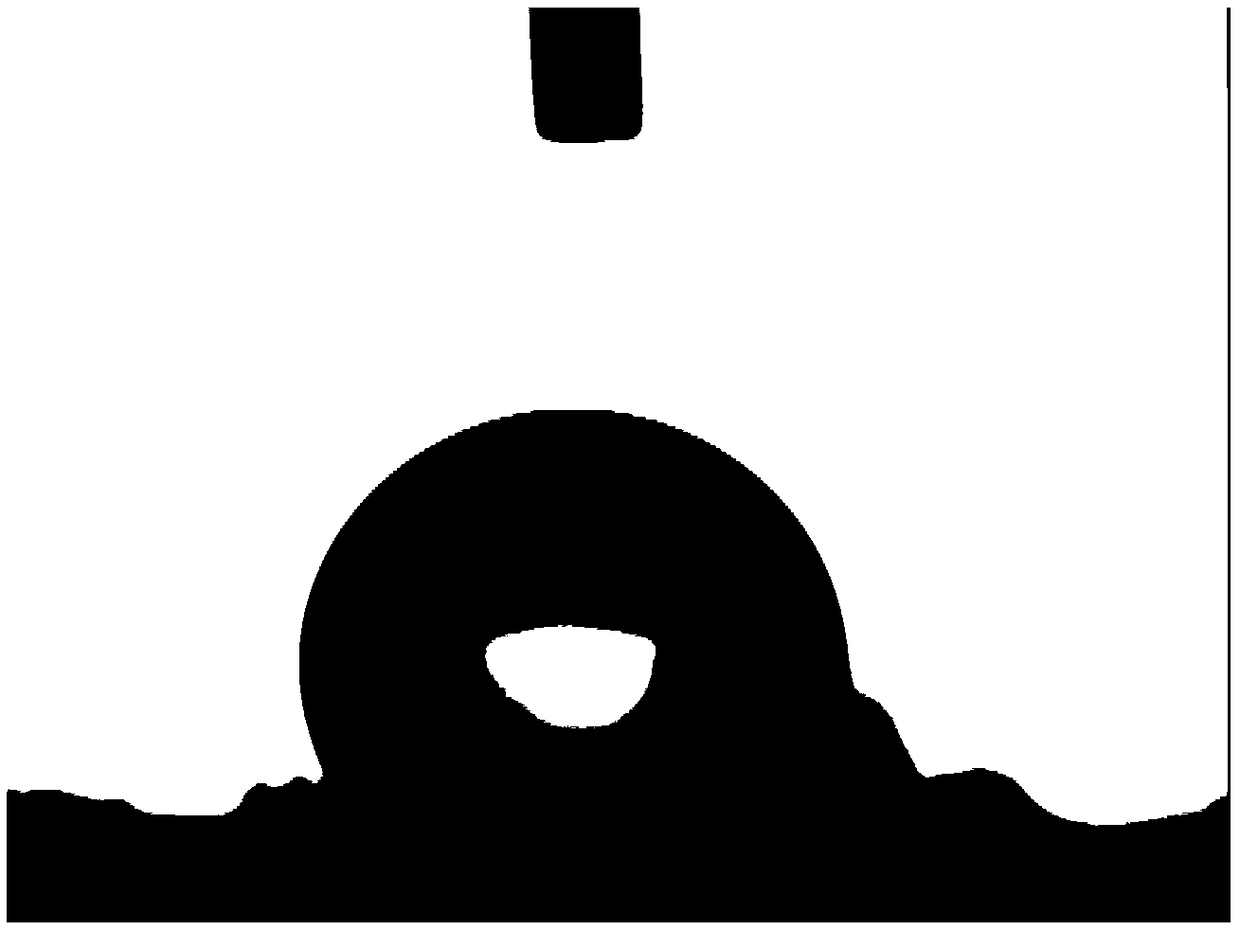

[0033] Coffee grounds grafted silica particles: first measure 5mL of ammonia water and 65mL of ethanol solution, mix them into the conical flask; take another 5mL of tetraethyl silicate dissolved in 25mL of ethanol, make it fully dispersed in the ethanol solution, Add the obtained tetraethyl silicate solution into the above-mentioned Erlenmeyer flask, collect coffee grounds of 40-200 meshes with a standard sieve, weigh 10g of coffee grounds, add them to the above-mentioned Erlenmeyer flask together, and keep magnetic stirring to make it fully React for 12 hours, and the magnetic stirring speed is 300r / min; after the reaction is completed, place the obtained mixture in an oven at 80°C until the water is completely evaporated to dryness, and obtain coffee grounds grafted with silica. see attached figure 1 (b), with figure 1 (a) is the electron microscopic image of untreated coffee grounds raw mate...

Embodiment 2

[0036] A kind of superhydrophobic coffee grounds material, prepare as follows:

[0037] Grafting silica particles with coffee grounds: first measure 5mL of ammonia water and 65mL of ethanol solution, mix them into the Erlenmeyer flask; take another 5mL of tetraethyl silicate and dissolve it in 25mL of ethanol to make it fully dispersed in the ethanol solution, Add the obtained tetraethyl silicate solution into the Erlenmeyer flask mentioned above, collect coffee grounds of 40-200 meshes with a standard sieve, weigh 10 g of coffee grounds, add them to the Erlenmeyer flask mentioned above, and keep magnetic stirring to make it fully React for 12 hours, and the magnetic stirring speed is 400r / min; after the reaction is completed, the obtained mixture is placed in an oven at 80°C until the water is completely evaporated to dryness, and coffee grounds grafted with silica are obtained. Example 1 is similar.

[0038] Superhydrophobic modification was carried out on the prepared coff...

Embodiment 3

[0040] A kind of superhydrophobic coffee grounds material, prepare as follows:

[0041] Grafting silica particles with coffee grounds: first measure 5mL of ammonia water and 65mL of ethanol solution, mix them into the Erlenmeyer flask; take another 5mL of tetraethyl silicate and dissolve it in 25mL of ethanol to make it fully dispersed in the ethanol solution, Add the obtained tetraethyl silicate solution into the Erlenmeyer flask mentioned above, collect coffee grounds of 40-200 meshes with a standard sieve, weigh 10 g of coffee grounds, add them to the Erlenmeyer flask mentioned above, and keep magnetic stirring to make it fully After 12 hours of reaction, the magnetic stirring speed was 400r / min; after the reaction was completed, the obtained mixture was placed in an oven at 80°C until the water was completely evaporated to obtain solid coffee grounds grafted with silica.

[0042] Superhydrophobic modification was carried out on the prepared coffee grounds grafted with sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com