N and S dual-doped carbon nanotube-coated FexC catalyst and preparation method and application thereof

A technology of carbon nanotubes and double doping, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of further simplification of the preparation process, high requirements for calcination conditions, unfavorable large-scale preparation, etc., and achieve low raw material prices , cheap raw materials, conducive to the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

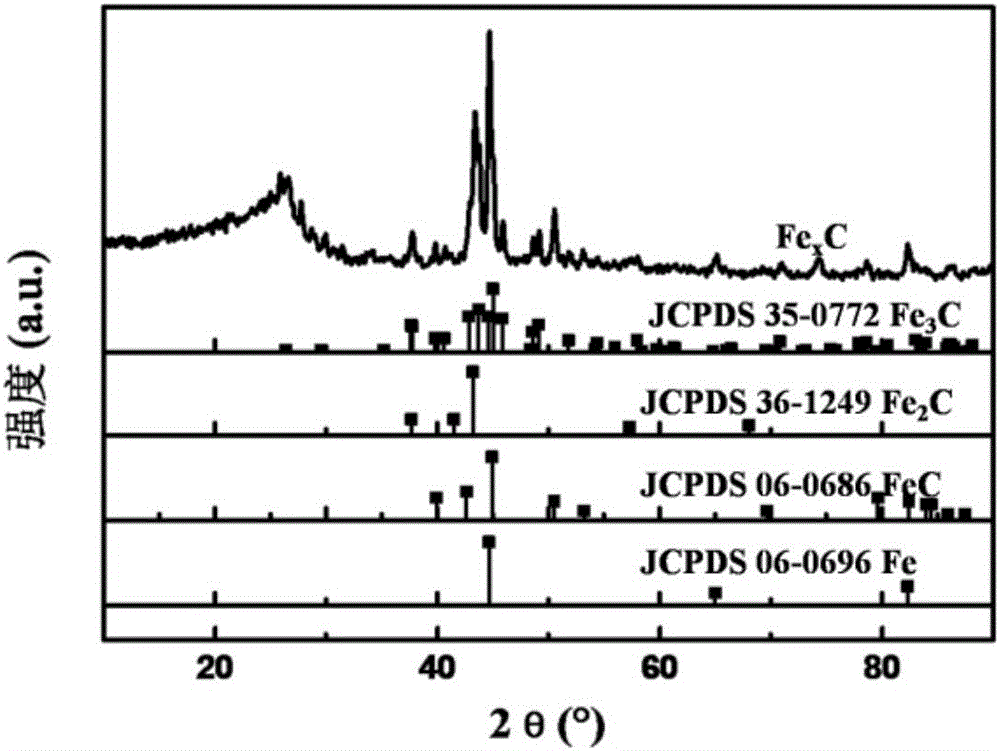

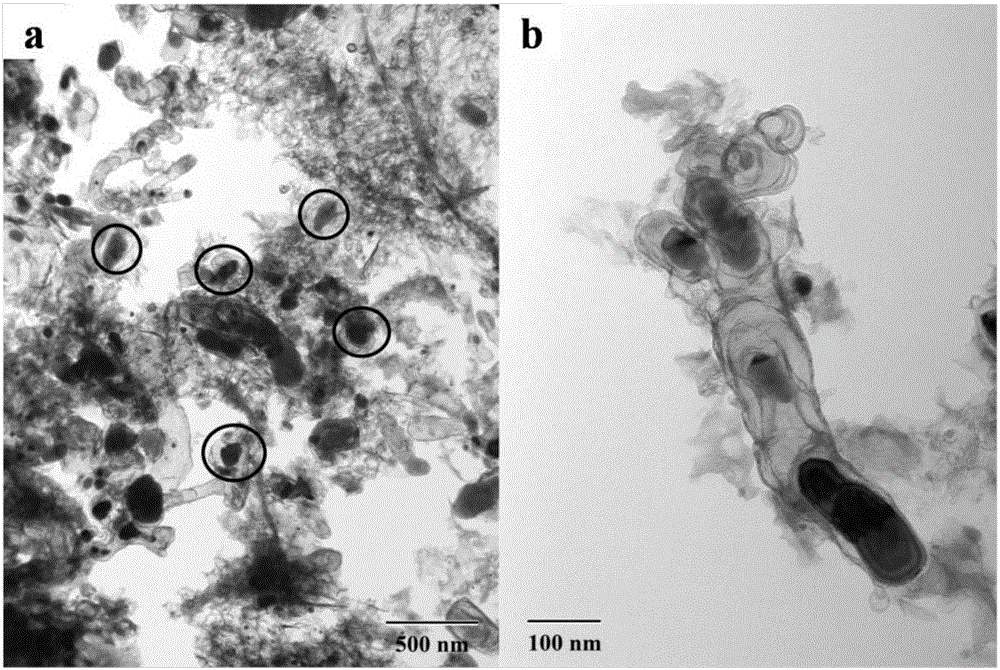

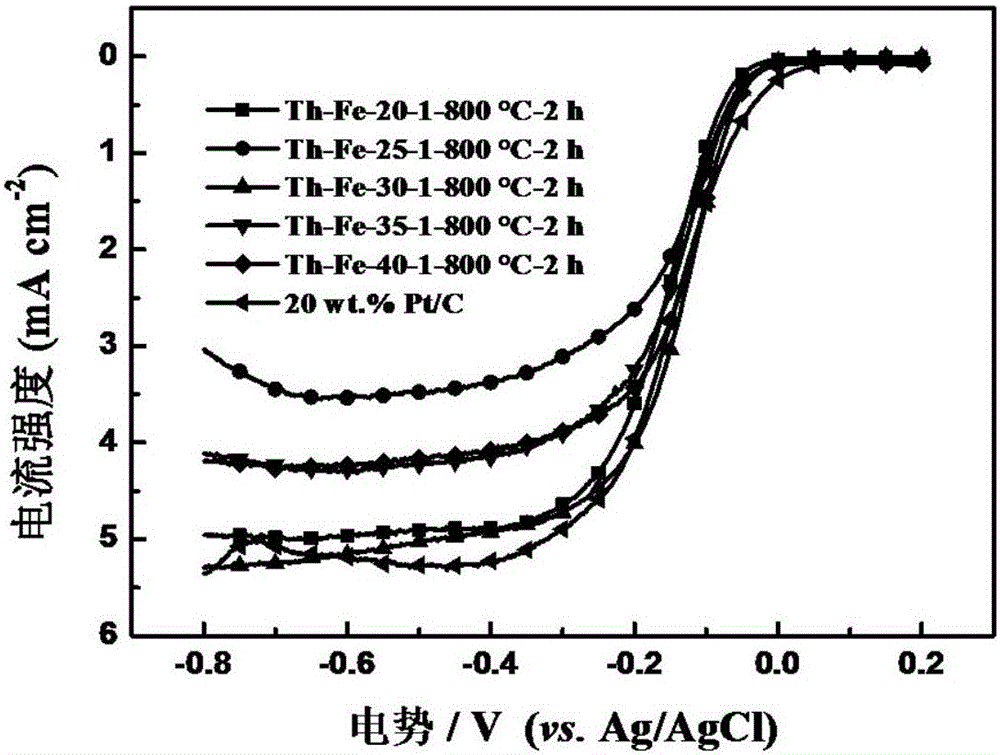

[0040] Example 1: Th-Fe-30-1-800°C-2h (Th: Thiourea, Fe: FeCl 3 ·6H 2 O, Th-Fe-30-1-800℃-2h refers to thiourea and FeCl in raw materials 3 ·6H 2 The molar ratio of O is 30:1, the calcination temperature is 800°C, and the calcination time is 2h)

[0041] 0.2367g of FeCl 3 ·6H 2 O was dissolved in 2mL deionized water to obtain solution A; then 2g of thiourea was weighed and dissolved in 80mL absolute ethanol to obtain solution B; solution A and solution B were mixed to obtain solution C and ultrasonically dispersed for 15min; the dispersed solution C was transferred to a petri dish, and dried in an air drying oven to obtain a catalyst precursor; the dried precursor was placed in a mortar, ground evenly, placed in a quartz boat, and calcined at 800°C for 2 hours under nitrogen protection; the calcined The resulting powder was transferred to a round bottom flask, 0.5molL -1 h 2 SO 4 Etching for 10 h; the sample obtained after etching was washed until the filtrate was neutr...

Embodiment 2

[0042] Example 2: Th-Fe-20-1-800°C-2h (Th: Thiourea, Fe: FeCl 3 ·6H 2 O, Th-Fe-20-1-800℃-2h refers to thiourea and FeCl in raw materials 3 ·6H 2 The molar ratio of O is 20:1, the calcination temperature is 800°C, and the calcination time is 2h)

[0043] 0.3551g of FeCl 3 ·6H 2 O was dissolved in 2mL deionized water to obtain solution A; then 2g of thiourea was weighed and dissolved in 80mL absolute ethanol to obtain solution B; solution A and solution B were mixed to obtain solution C and ultrasonically dispersed for 15min; the dispersed solution C was transferred to a petri dish, and dried in an air drying oven to obtain a catalyst precursor; the dried precursor was placed in a mortar, ground evenly, placed in a quartz boat, and calcined at 800°C for 2 hours under nitrogen protection; the calcined The resulting powder was transferred to a round bottom flask, 0.5molL -1 h 2 SO 4 Etching for 10 h; the sample obtained after etching was washed until the filtrate was neutr...

Embodiment 3

[0044] Example 3: Th-Fe-25-1-800°C-2h (Th: Thiourea, Fe: FeCl 3 ·6H 2 O, Th-Fe-25-1-800℃-2h refers to thiourea and FeCl in raw materials 3 ·6H 2 The molar ratio of O is 25:1, the calcination temperature is 800°C, and the calcination time is 2h)

[0045] 0.2841g of FeCl 3 ·6H 2 O was dissolved in 2mL deionized water to obtain solution A; then 2g of thiourea was weighed and dissolved in 80mL absolute ethanol to obtain solution B; solution A and solution B were mixed to obtain solution C and ultrasonically dispersed for 15min; the dispersed solution C was transferred to a petri dish, and dried in an air drying oven to obtain a catalyst precursor; the dried precursor was placed in a mortar, ground evenly, placed in a quartz boat, and calcined at 800°C for 2 hours under nitrogen protection; the calcined The resulting powder was transferred to a round bottom flask, 0.5molL -1 h 2 SO 4 Etching for 10 h; the sample obtained after etching was washed until the filtrate was neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com