Method for preparing non-crystal molybdemum sulfide nano powder

A nano-powder, amorphous technology, applied in the field of preparation of amorphous molybdenum sulfide nano-powder, can solve the problems of difficult industrial production and low output, and achieve the effects of simple operation, short reaction time and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

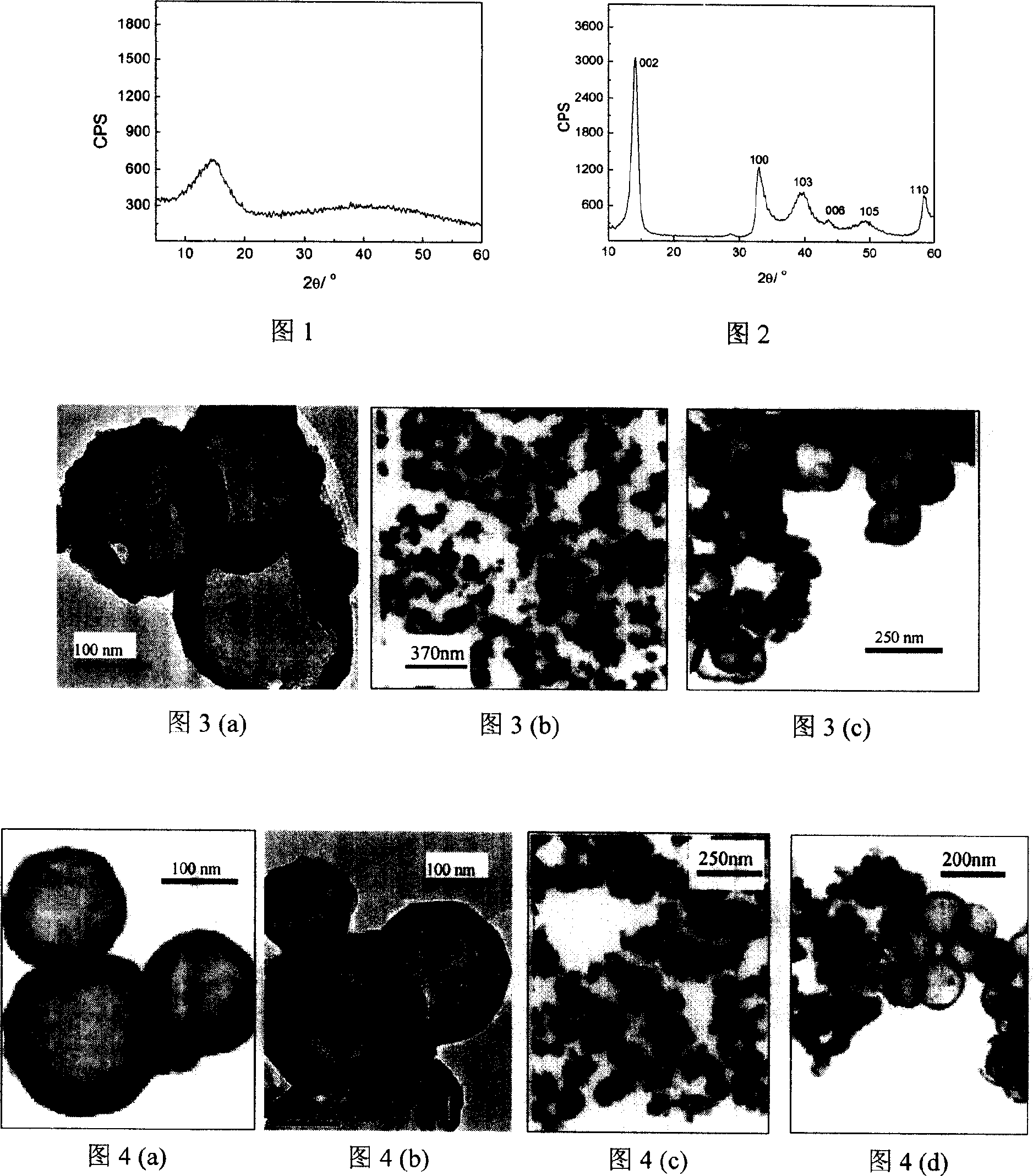

Embodiment 1

[0029] At 90°C, dissolve 4mmol sodium molybdate and 24mmol thioacetamide in 80mL distilled water, then add 5mL polyethylene glycol, 5mL propanol and 10mL ethanol, and finally add 15mL within 2 minutes. 12mol L -1 Hydrochloric acid and tail gas hydrogen sulfide are absorbed with sodium hydroxide solution. After constant temperature reaction at 82°C for 5 minutes, the precipitate was filtered, washed and dried at 120°C for 10 hours to obtain hollow spherical amorphous MoS x Nano powder.

[0030] Then, the hollow spherical amorphous MoS x The nano-powder is put into a porcelain burning boat, put into a tubular electric furnace, calcined under a hydrogen atmosphere at 780°C, reacted for 50 minutes, cooled, and the sample is taken out to obtain a hollow spherical molybdenum disulfide nano-powder.

Embodiment 2

[0032] At 85°C, dissolve 4mmol potassium molybdate and 32mmol thioacetamide in 100mL distilled water, then add 5mLOP emulsifier and 5mL methanol, and finally add 15mL 6mol L within 2 minutes -1 Hydrochloric acid and tail gas hydrogen sulfide are absorbed with sodium hydroxide solution. After constant temperature reaction at 85°C for 5 minutes, the precipitate was filtered, washed and dried at 100°C for 12 hours to obtain hollow spherical amorphous MoS x Nano powder.

[0033] Then, the hollow spherical amorphous MoS x The nano-powder is put into a porcelain burning boat, put into a tubular electric furnace, calcined for 40 minutes at 680° C. under a nitrogen atmosphere, and then cooled to obtain a hollow spherical molybdenum disulfide nano-powder.

Embodiment 3

[0035] At 78°C, dissolve 4 mmol of ammonium molybdate and 12 mmol of thioacetamide in 180 mL of distilled water, and then add 5 mL of 0.05 mol·L -1 Hexadecyltrimethylammonium bromide, 15mL 5mol L was added within 2 minutes at the end -1 Hydrochloric acid and tail gas hydrogen sulfide are absorbed with sodium hydroxide solution. After constant temperature reaction at 95°C for 10 minutes, the precipitate was filtered, washed and dried at 120°C for 10 hours to obtain hollow spherical amorphous MoS x Nano powder.

[0036] Then, the hollow spherical amorphous MoS x The nano-powder is put into a porcelain burning boat, put into a tubular electric furnace, calcined in an argon atmosphere at 960°C for 120 minutes, and then cooled to obtain a polyhedral molybdenum disulfide nano-powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com