Composite phosphorus removing agent and use method thereof

A compound dephosphorization agent and dephosphorization agent technology, which is applied in the field of water treatment, can solve the problems of reduced production capacity and achieve cost saving, ideal phosphorus removal effect and ideal precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

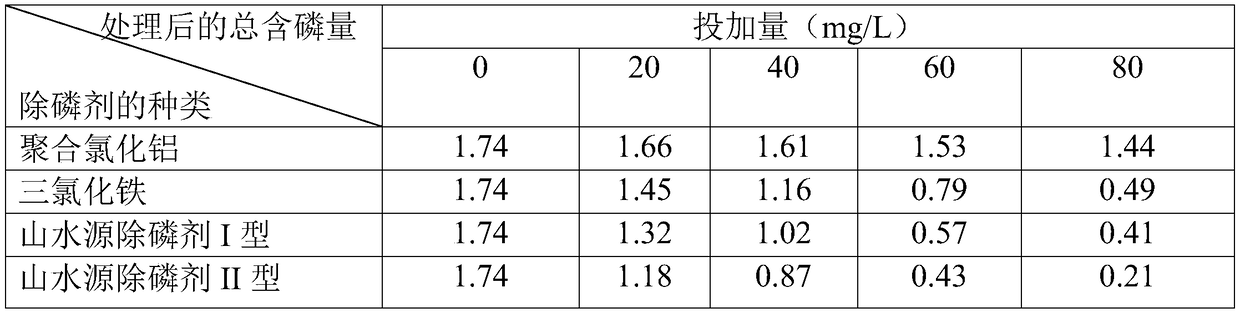

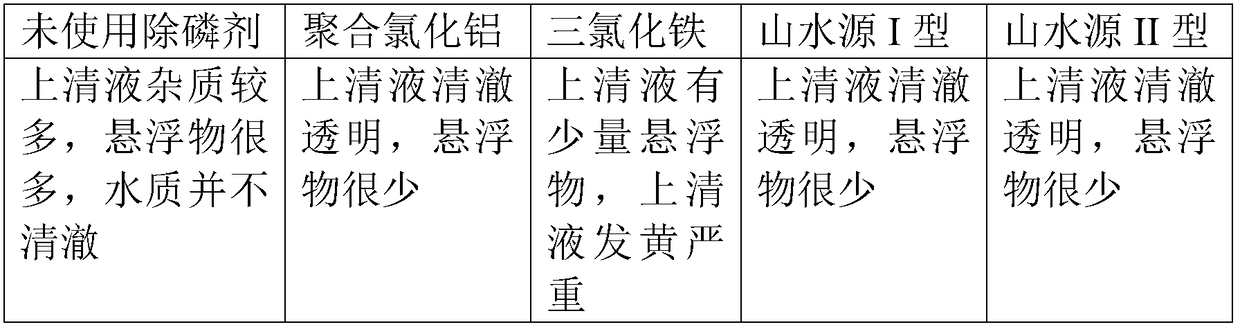

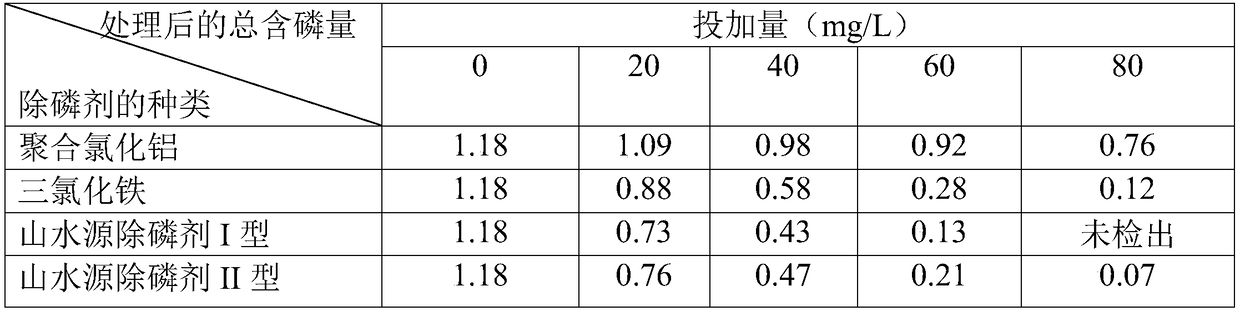

Embodiment 1

[0026] A compound dephosphorization agent for treating sewage with a total phosphorus concentration of 5-10 mg / L, such as municipal sewage or industrial sewage. The compound dephosphorization agent includes the following raw materials in proportions by weight: 15 parts of aluminum salt, 60 parts of ferrous salt, 2 parts of polyferric sulfate, 2 parts of sodium silicate, 0.2 parts of polyacrylamide, 3 parts of carbon source supplement.

[0027] The water solvent of the composite dephosphorization agent is that the aluminum salt, ferrous salt, polyferric sulfate, sodium silicate, polyacrylamide and carbon source supplement are mixed and added to 166.9 parts of pure water to form a composite solution with a concentration of 33%. The solvent of the dephosphorization agent can be used to obtain the liquid dephosphorization agent from Shanshui.

[0028] The aluminum salt is aluminum sulfate, the ferrous salt is ferrous sulfate, and the carbon source supplement is sodium acetate.

...

Embodiment 2

[0035] A compound dephosphorization agent for treating sewage with a total phosphorus concentration of 5-10 mg / L, such as municipal sewage or industrial sewage. The compound dephosphorization agent includes the following raw materials in proportions by weight: 15 parts of aluminum salt, 60 parts of ferrous salt, 2 parts of polyferric sulfate, 2 parts of sodium silicate, 0.2 parts of polyacrylamide, 3 parts of carbon source supplement.

[0036] The water solvent of the composite phosphorus removal agent is that the aluminum salt, ferrous salt, polyferric sulfate, sodium silicate, polyacrylamide and carbon source supplement are mixed and added to 123.3 parts of pure water to form a composite solution with a concentration of 40%. The solvent of the dephosphorization agent can be used to obtain the liquid dephosphorization agent from Shanshui.

[0037] The aluminum salt is aluminum sulfate, the ferrous salt is ferrous sulfate, and the carbon source supplement is sodium acetate.

...

Embodiment 3

[0044] A compound dephosphorization agent for treating sewage with a total phosphorus concentration of 5-10 mg / L, such as municipal sewage or industrial sewage. The compound dephosphorization agent includes the following raw materials in proportions by weight: 30 parts of aluminum salt, 70 parts of ferrous salt, 3 parts of polyferric sulfate, 3 parts of sodium silicate, 0.5 parts of polyacrylamide, 10 parts of carbon source supplement.

[0045] The water solvent of the composite phosphorus removal agent is that the aluminum salt, ferrous salt, polyferric sulfate, sodium silicate, polyacrylamide and carbon source supplement are mixed and added to 236.5 parts of pure water to form a composite solution with a concentration of 33%. The solvent of the dephosphorization agent can be used to obtain the liquid dephosphorization agent from Shanshui.

[0046] The aluminum salt is aluminum sulfate, the ferrous salt is ferrous sulfate, and the carbon source supplement is sodium acetate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com